an o-ring seal

An O-ring and modified technology, applied in the field of sealing rings, can solve problems such as failure to effectively ensure the sealing, damage and hardening of the oil circuit and gas circuit of the machine, and achieve the effect of enhancing bending elasticity, prolonging service life and improving mechanical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

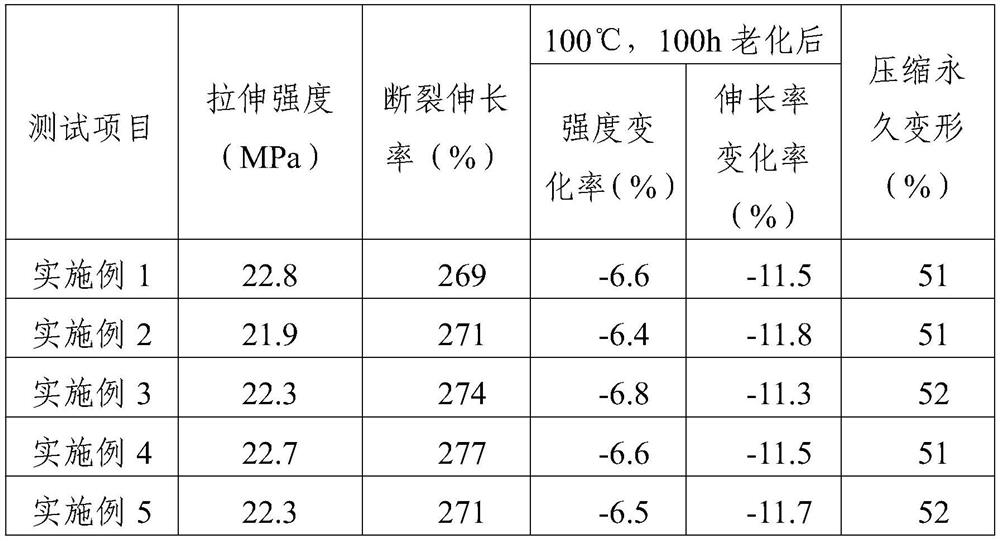

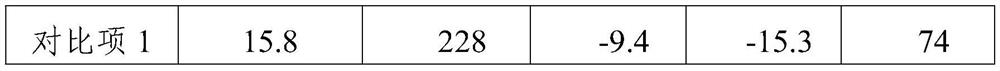

Examples

Embodiment 1

[0028] Polypropylene, mica, and magnesium sulfate whiskers were mixed and stirred at 80°C for 15 minutes in a high-speed mixer, with the mass ratio of mica and magnesium sulfate whiskers being 2:1, to obtain modified polypropylene.

[0029] Put butyl rubber and trichloroacetic acid on an open mill and knead for 15 minutes to obtain modified butyl rubber.

[0030] An O-shaped sealing ring, comprising the following raw materials in parts by weight: modified polypropylene: 18 parts, modified butyl rubber: 20 parts, natural rubber 15 parts, zinc oxide 5 parts, calcium stearate 9 parts, 5 parts of morpholine disulfide, 7 parts of antioxidant, 5 parts of oxidized polyethylene, and 5 parts of talcum powder.

[0031] The preparation method of above-mentioned O type sealing ring, comprises the following steps:

[0032] (1) According to the proportion by weight, the modified butyl rubber, modified polypropylene and natural rubber were heated and dissolved, stirred and mixed, and intern...

Embodiment 2

[0037] Polypropylene, mica, and magnesium sulfate whiskers were mixed and stirred at 90°C for 8 minutes in a high-speed mixer, with the mass ratio of mica and magnesium sulfate whiskers being 2:1, to obtain modified polypropylene.

[0038] Put butyl rubber and trichloroacetic acid on an open mill and knead for 8 minutes to obtain modified butyl rubber.

[0039] An O-shaped sealing ring, comprising the following raw materials in parts by weight: modified polypropylene: 25 parts, modified butyl rubber: 27 parts, natural rubber 10 parts, zinc oxide 8 parts, calcium stearate 6 parts, 7 parts of morpholine disulfide, 4 parts of antioxidant, 10 parts of oxidized polyethylene, 10 parts of talcum powder.

[0040] The preparation method of above-mentioned O type sealing ring, comprises the following steps:

[0041] (1) According to the weight ratio, the modified butyl rubber, modified polypropylene, and natural rubber were heated and dissolved, stirred and mixed, and banburyed at 80° ...

Embodiment 3

[0046] Mix polypropylene, mica, and magnesium sulfate whiskers in a high-speed mixer with a mass ratio of mica and magnesium sulfate whiskers of 2:1, and mix and stir at 85°C for 10 minutes to obtain modified polypropylene.

[0047] Put butyl rubber and trichloroacetic acid on an open mill and knead for 9 minutes to obtain modified butyl rubber.

[0048] An O-shaped sealing ring, comprising the following raw materials in parts by weight: 20 parts of modified polypropylene, 25 parts of modified butyl rubber, 12 parts of natural rubber, 7 parts of zinc oxide, 8 parts of stearic acid, disulfide 7 parts of morpholine, 5 parts of antioxidant, 7 parts of oxidized polyethylene, 7 parts of talcum powder.

[0049] The preparation method of above-mentioned O type sealing ring, comprises the following steps:

[0050] (1) According to the proportion by weight, the modified butyl rubber, modified polypropylene, and natural rubber were heated and dissolved, stirred and mixed, and banburyed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com