Power capacitor with improved internal fuse structure

A technology of power capacitors and internal fuses, applied in the direction of capacitors, electrical components, etc., can solve problems such as affecting the electrical performance of capacitors, and achieve the effect of avoiding electrical performance and avoiding diffusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

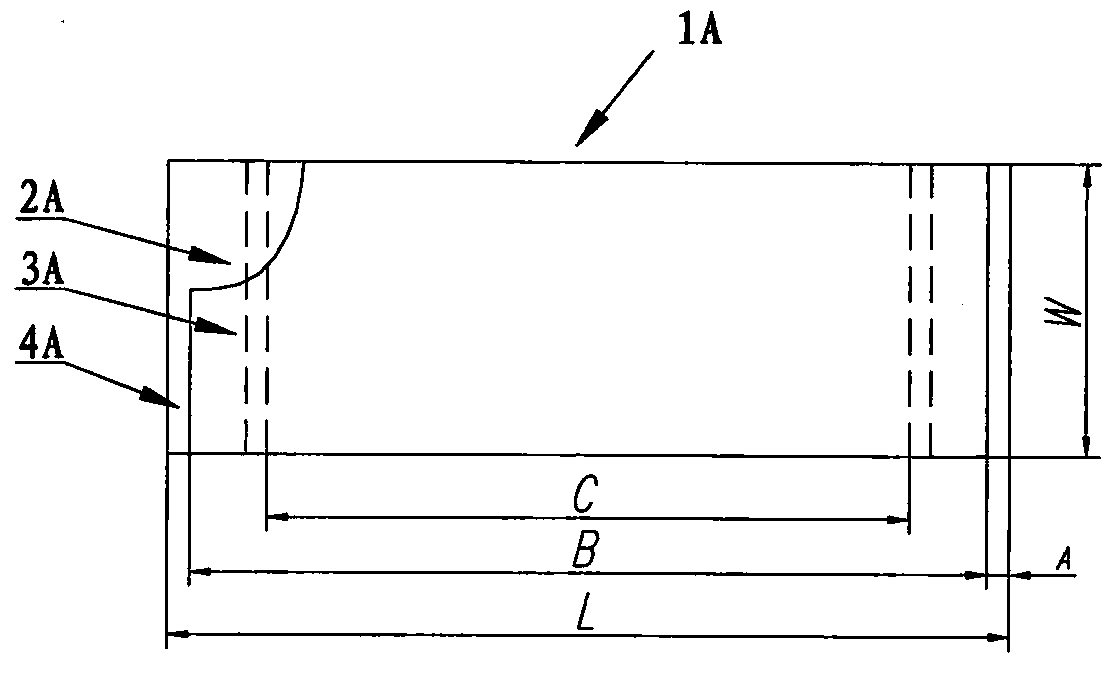

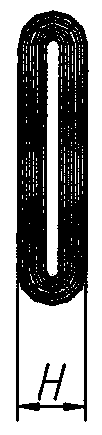

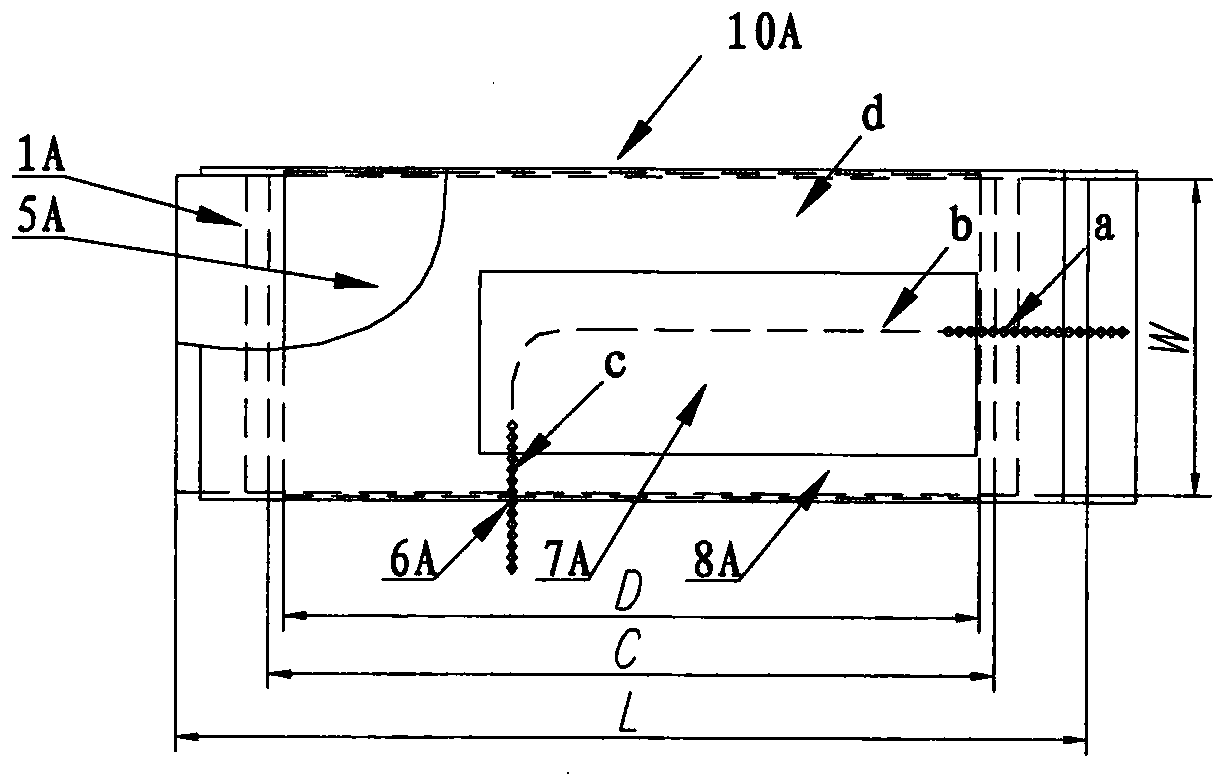

[0044] Such as Figure 14 and 15 As shown, the power capacitor with an improved internal fuse structure of the present invention includes a core 20 disposed in the capacitor casing, and the core 20 includes a plurality of welded assemblies 23, 24, 25. Each welding assembly 23, 24, 25 includes a plurality of capacitive element assemblies 10, such as Figure 11 As shown, each capacitive element assembly 10 includes a capacitive element 1, an element inner liner 5A, an element outer liner 8A, a fuse 6A and an adhesive tape 7, wherein the structure of the capacitive element 1 is as follows Figure 13 shown. The element inner liner 5A is arranged on the outside of the capacitor element 1, and the element outer liner 8A is arranged on the outside of the element inner liner 5A. The fuse 6A includes a melt part and terminals arranged at both ends of the melt part. The melt part of the fuse 6A is fixed on the non-stacked side of the element inner liner 5A by adhesive tape 7 and is l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com