A kind of manufacturing method of pcb board with built-in active device

An active device and PCB board technology, applied in the field of built-in active device PCB board production, can solve the problems of increasing the production risk of enterprises, unable to fill the flow of glue, and contamination of the surface of the board, so as to facilitate the processing, production, application and product High reliability and good quality stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to enable those skilled in the art to better understand the technical solution of the present invention, the product of the present invention will be further described in detail below in conjunction with the embodiments and accompanying drawings.

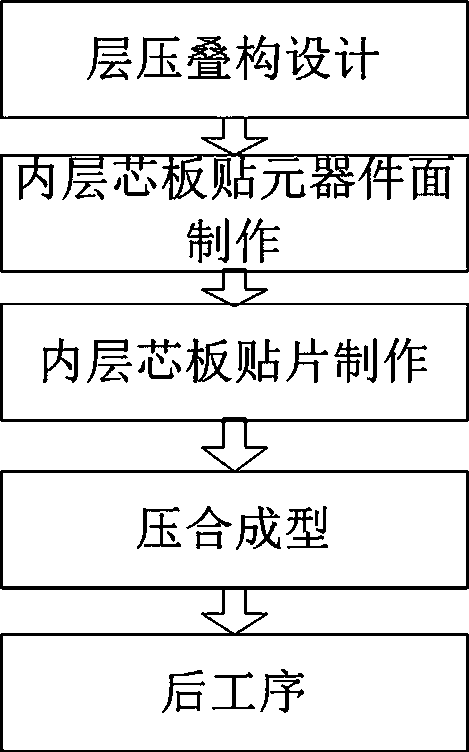

[0037] Such as figure 1 As shown, the invention discloses a method for manufacturing a built-in active device PCB board, comprising the following steps:

[0038] The first step, lamination stack design, adopts a symmetrical design, avoids damage to the active device during the lamination process by controlling the thickness of the prepreg, and prevents the active device from being separated from the other by placing a prepreg without milling grooves on the top of the active device. One side is in contact with the circuit pattern, and the expansion and shrinkage compensation of the fixture is used to ensure that the expansion and contraction of each layer returns to the ratio of 1:1 after the total pressure of the inn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com