Hub nut for a planetary transmission and planetary transmission

A planetary transmission and nut technology, applied in the direction of nuts, transmissions, gear transmissions, etc., can solve the problem of wasting time, and achieve the effects of stable assembly process, firm assembly, and low tool cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

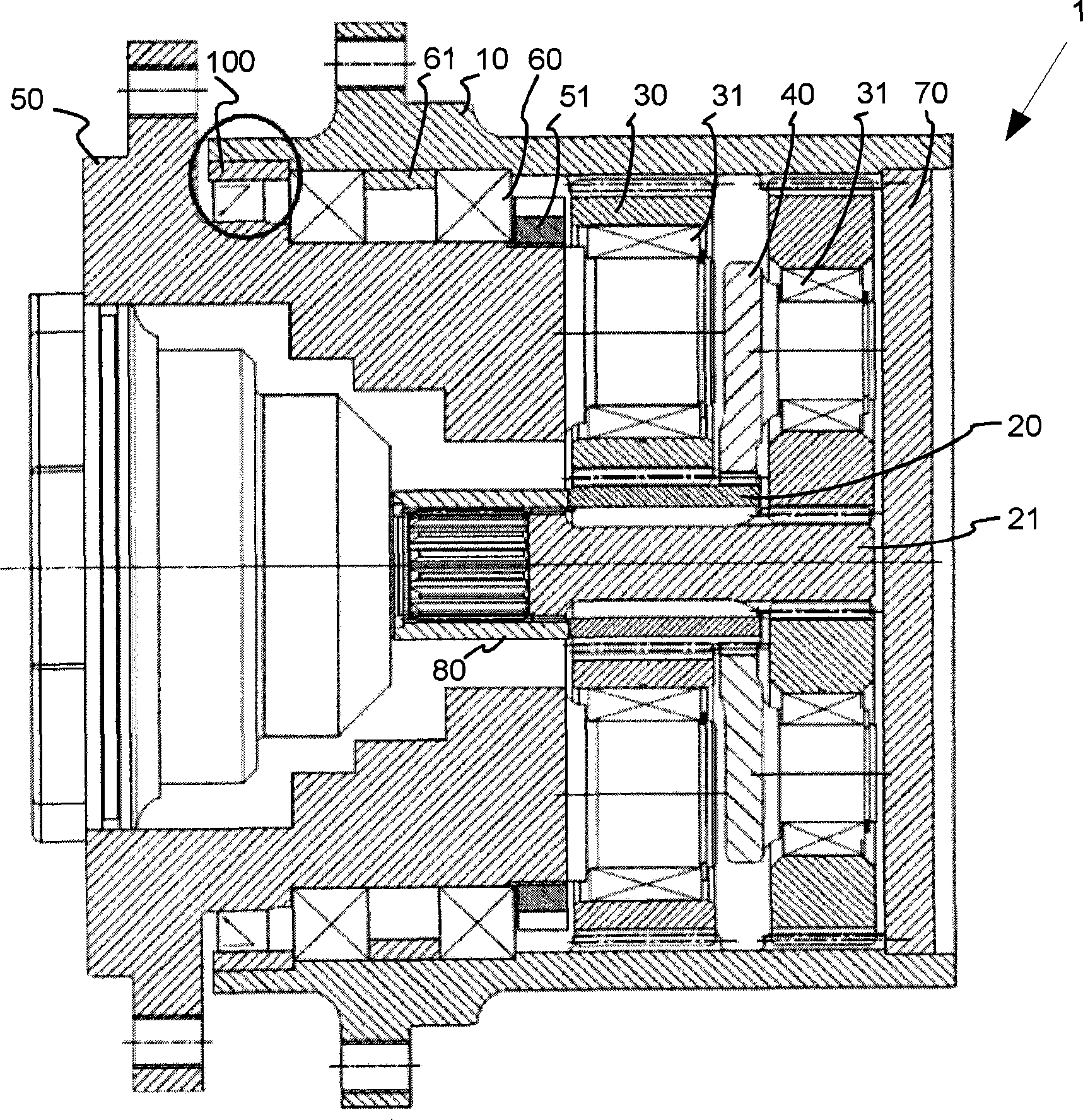

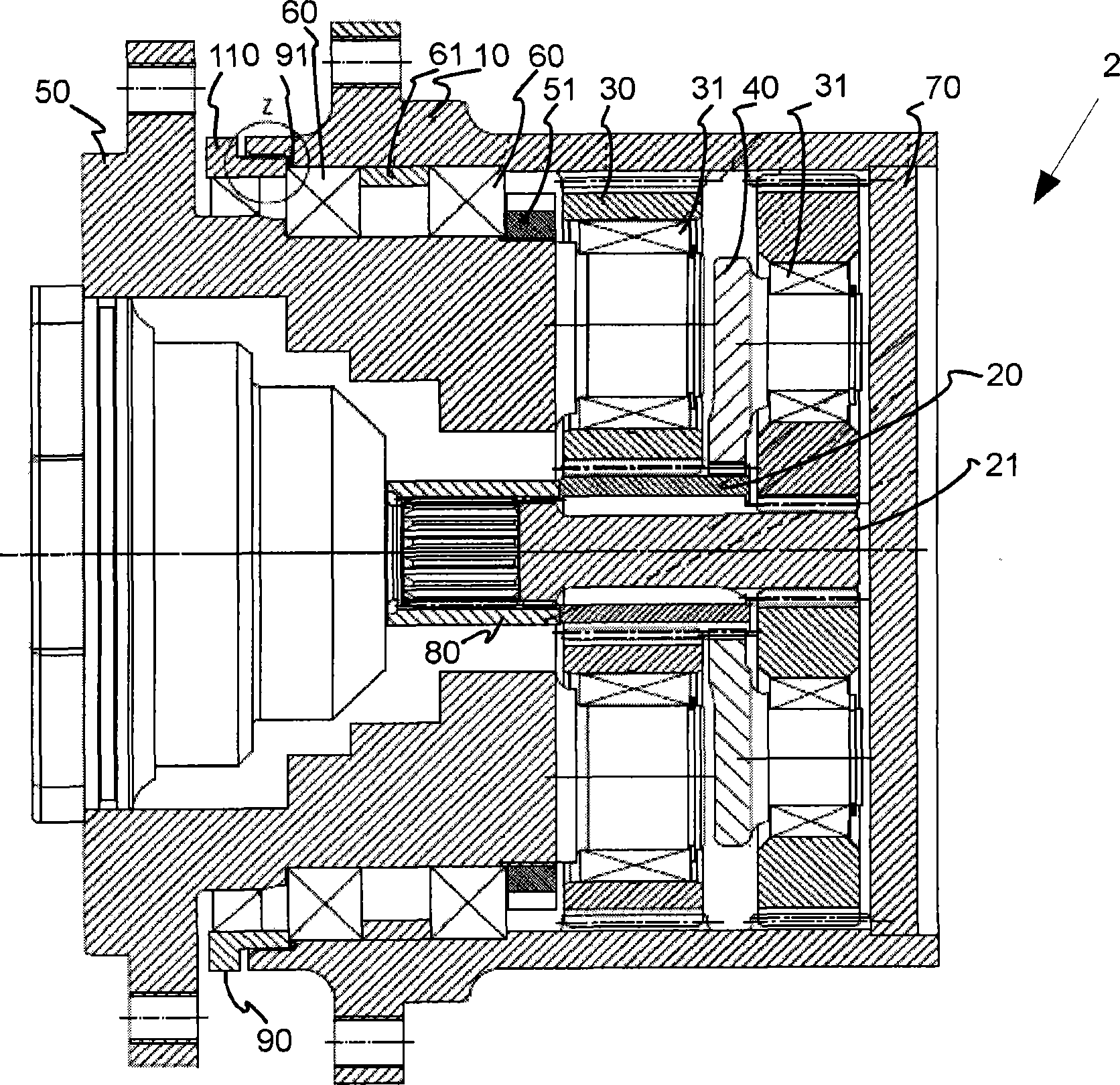

[0028] figure 1 shows a planetary gear 1 with a ring gear 10, a sun gear 20, a sun gear shaft 21, a planet gear 30, a planet bearing 31, a planet carrier or planet carrier 40, a bearing shaft 50, a shaft nut 51, a main bearing unit 60, eg Intermediate element 61 which is a washer, cover 70 , driver 80 , anti-rotation mechanism 90 and hub nut 100 . The sun gear shaft 21 and / or the planet carrier 40 with the planet carrier journal 41 can move relative to the cover 70 . Furthermore, the sun gear 20 and the sun gear shaft 21 can move relative to each other.

[0029] hub nut 100 in figure 1 is installed between the anti-rotation mechanism 90 and the ring gear 10 . The hub nut 100 is arranged here in such a way that it fixes the main bearing unit 60 in the axial direction. The main bearing unit 60 serves to support the ring gear 10 on the support shaft 50 .

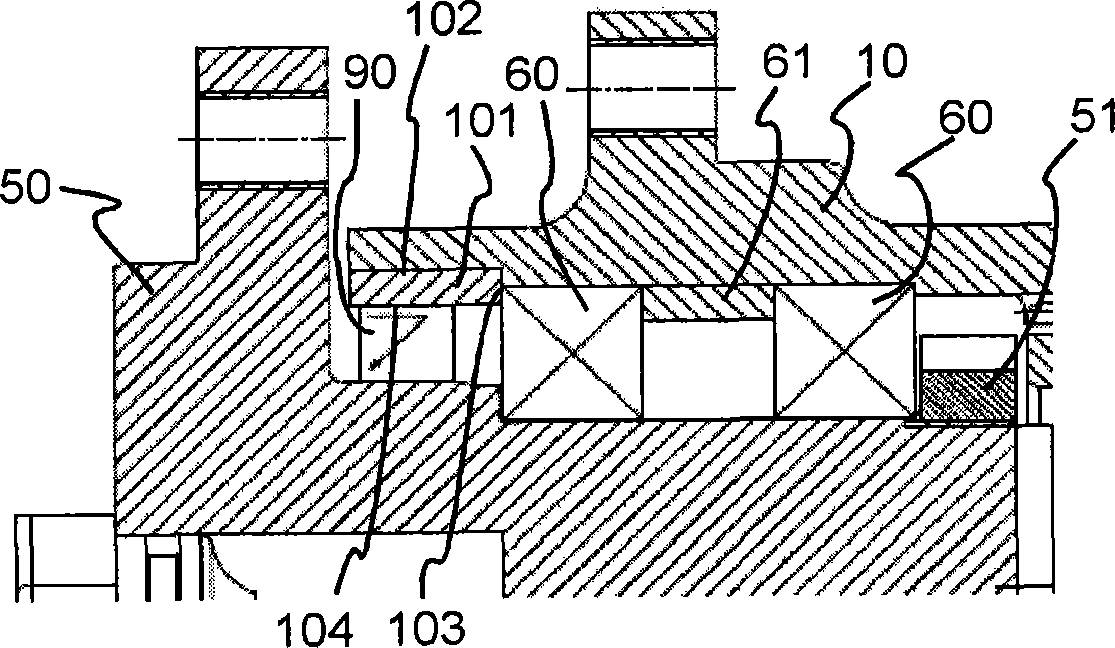

[0030] as from figure 2 As can be seen, the hub nut 100 has a body 101 . For fixing the main bearing unit 60 , the hu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com