Engine packaging box with sealing function

A packaging box and engine technology, applied in packaging, food packaging, transportation and packaging, etc., can solve the problem that the engine packaging box cannot meet the protection requirements of the engine, and achieve the effect of humanized structure design, improved protection level, and guaranteed sealing function.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

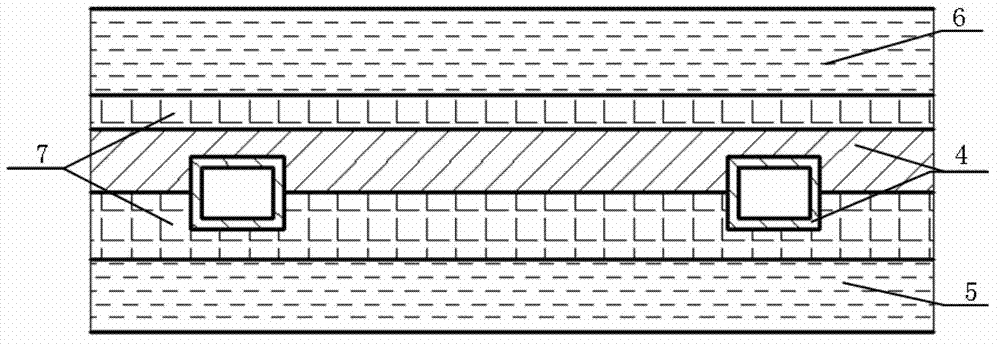

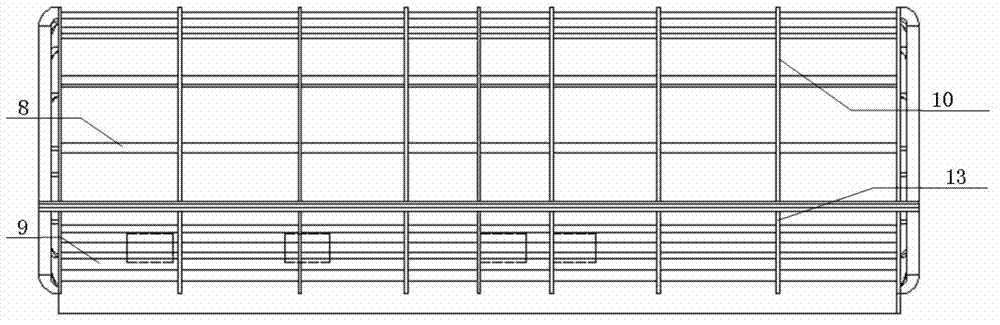

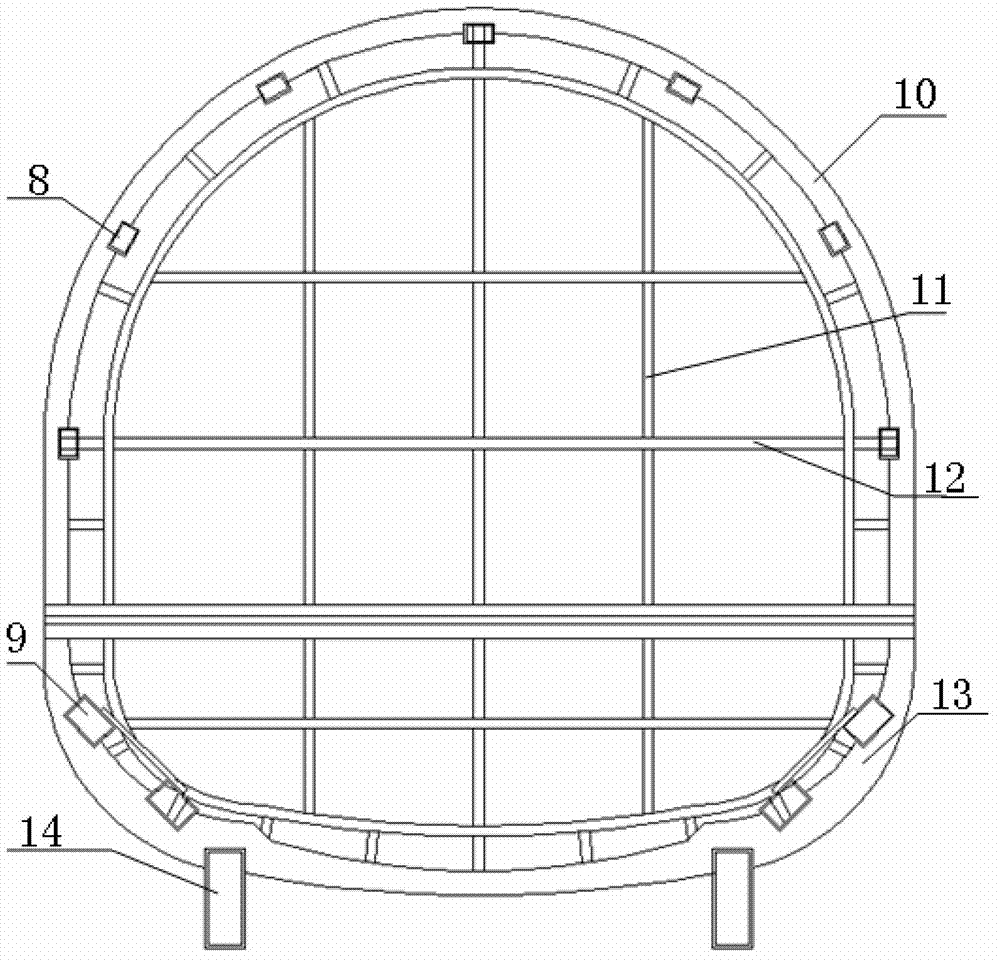

[0020] The engine packaging box with sealing function described in this embodiment, such as figure 1 , 2 , 3, and 4, including the box body (1), the box body (1) is composed of a box bottom (9) and a box cover (8) connected by buckles, and the packing box also includes a fixing bracket (2), a A shock device (3), wherein the fixed bracket (2) is placed in the box (1), and the shock absorber (3) is placed between the fixed bracket (2) and the box (1); the box (1) ) includes a metal frame (4), an inner layer of FRP (5), an outer layer of FRP (6), and a heat insulation layer (7), wherein the inner layer of FRP (5) is placed inside the metal frame (4), and the metal frame ( 4) The outer layer is provided with a heat insulation layer (7) and an outer layer of glass fiber reinforced plastic (6) according to the direction from the entrance to the distance.

[0021] The engine packaging box with a sealing function described in this embodiment, wherein nitrogen gas is provided in the ...

Embodiment 2

[0028] The engine packaging box with sealing function described in this embodiment, such as figure 1 , 2 , 3, and 4, including the box body (1), the box body (1) is composed of a box bottom (9) and a box cover (8) connected by buckles, and the packing box also includes a fixing bracket (2), a A shock device (3), wherein the fixed bracket (2) is placed in the box (1), and the shock absorber (3) is placed between the fixed bracket (2) and the box (1); the box (1) ) includes a metal frame (4), an inner layer of FRP (5), an outer layer of FRP (6), and a heat insulation layer (7), wherein the inner layer of FRP (5) is placed inside the metal frame (4), and the metal frame ( 4) The outer layer is provided with a heat insulation layer (7) and an outer layer of glass fiber reinforced plastic (6) according to the direction from the entrance to the distance.

[0029] The engine packaging box with sealing function described in this embodiment, wherein nitrogen gas is arranged in the en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com