Blind plug type receiving mechanism with platform

A technology of receiving mechanism and platform, applied in the field of test equipment interface transfer, can solve the problems of large occupation space, low safety and stability, and achieve the effect of low production cost, high safety and stability, and space saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

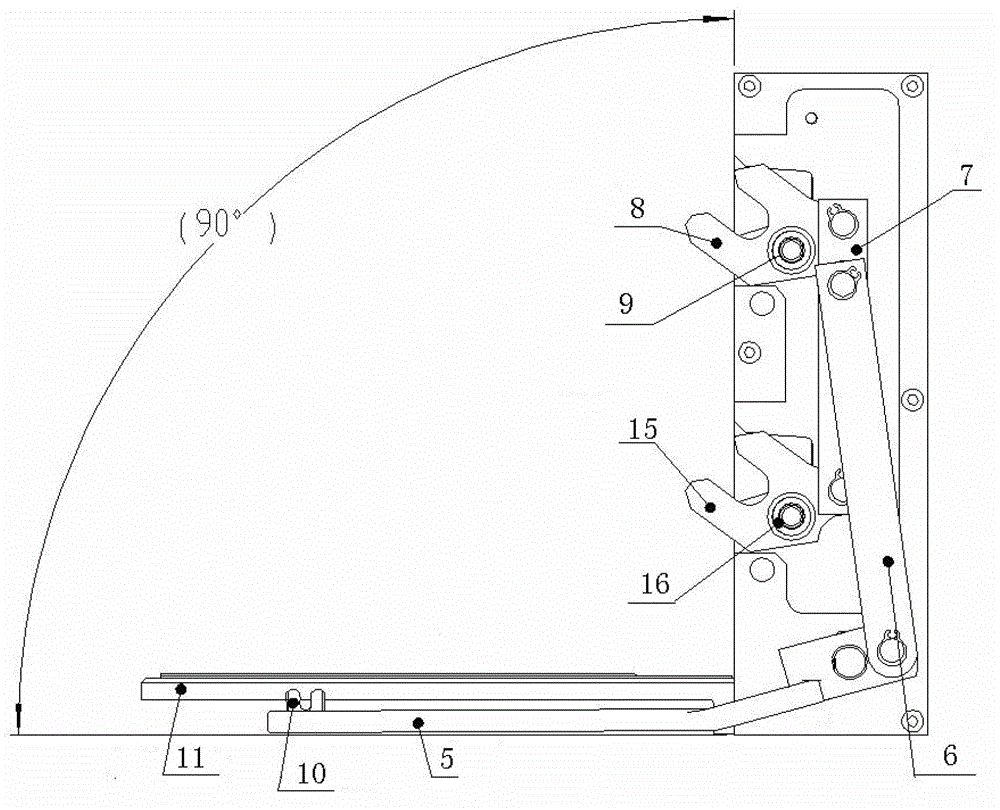

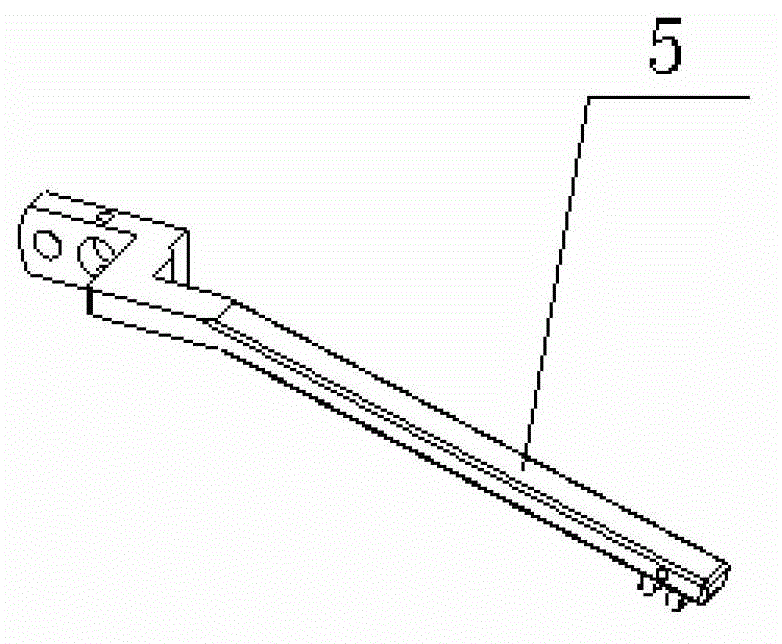

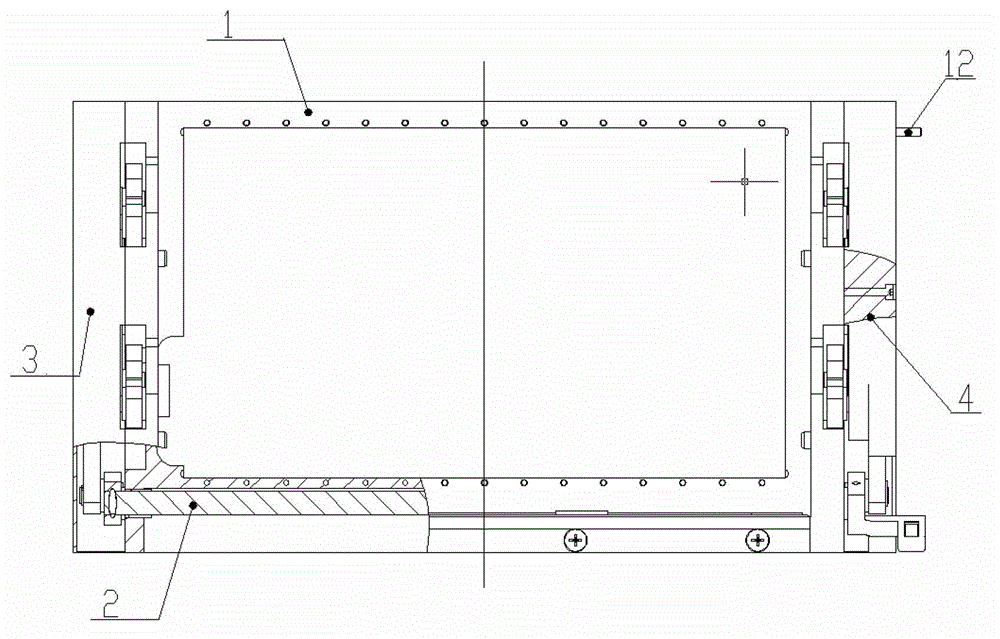

[0022] The blind plug-in platform receiving mechanism described in this embodiment includes a mechanism frame (1), a main shaft (2), a left bracket (3), a right bracket (4), a handle (5), and two main shaft connecting rods (6) , two connecting rods (7), four fork-shaped guide rails (8), four bearings (9), and lock hooks (10), among which, the left bracket (3) and the right bracket (4) are fixed by hexagon socket head screws Set on both sides of the mechanism frame (1), the mechanism frame (1) is connected to the main shaft (2) through the bearing a, and the two ends of the main shaft (2) are respectively fixedly connected to the two main shaft connecting rods (6) through two riveted cylindrical pins , the two spindle connecting rods (6) are respectively connected with the two connecting rods (7) through clearance fit, and the two connecting rods (7) are respectively connected with the corresponding fork-shaped guide rails (8) through the corresponding bearings (9) In the conne...

Embodiment 2

[0027] The receiving mechanism of the blind insertion type with platform in this embodiment, the receiving mechanism includes a mechanism frame (1), a main shaft (2), a left bracket (3), a right bracket (4), a handle (5), two main shafts connected Rod (6), two connecting rods (7), four fork-shaped guide rails (8), four bearings (9), lock hooks (10), wherein, the left bracket (3) and the right bracket (4) pass through the inner The hexagonal cylindrical screws are fixed on both sides of the mechanism frame (1), the mechanism frame (1) is connected to the main shaft (2) through the bearing a, and the two ends of the main shaft (2) are respectively connected to the two main shaft connecting rods through two riveted cylindrical pins ( 6) Fixed connection, the two spindle connecting rods (6) are respectively connected with the two connecting rods (7) through clearance fit, and the two connecting rods (7) are respectively connected with the corresponding fork-shaped guide rails (8) t...

Embodiment 3

[0031] The blind plug-in platform receiving mechanism described in this embodiment includes a mechanism frame (1), a main shaft (2), a left bracket (3), a right bracket (4), a handle (5), and two main shaft connecting rods (6) , two connecting rods (7), four fork-shaped guide rails (8), four bearings (9), and lock hooks (10), among which, the left bracket (3) and the right bracket (4) are fixed by hexagon socket head screws Set on both sides of the mechanism frame (1), the mechanism frame (1) is connected to the main shaft (2) through the bearing a, and the two ends of the main shaft (2) are respectively fixedly connected to the two main shaft connecting rods (6) through two riveted cylindrical pins , the two spindle connecting rods (6) are respectively connected with the two connecting rods (7) through clearance fit, and the two connecting rods (7) are respectively connected with the corresponding fork-shaped guide rails (8) through the corresponding bearings (9) In the conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com