Shallow-water small micro-buoyancy photoelectric composite cable transmission assembly

A technology for optoelectronic composite cables and transmission components, applied in power cables, power cables including optical transmission components, electrical components, etc., can solve problems such as high cost, growth, and large cable resistance, and achieve increased tensile strength and resistance The effect of bending strength, extended service life, and simple assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

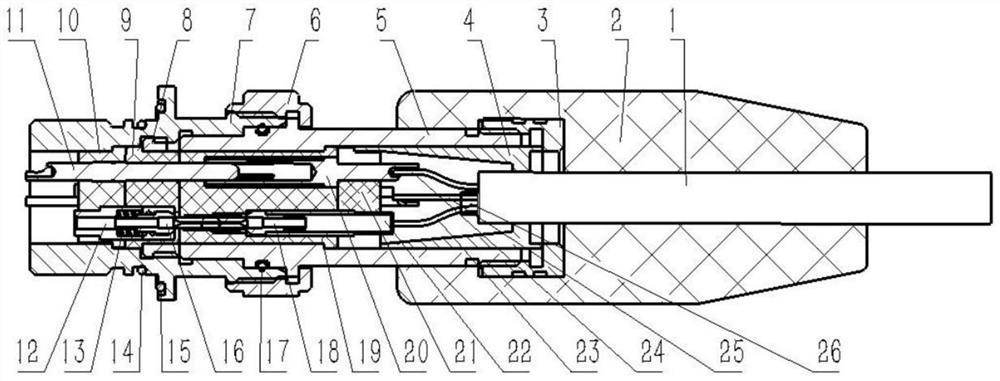

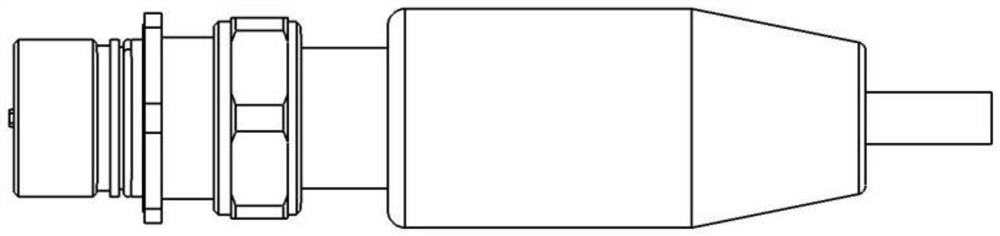

[0022] see Figure 1-2 , the present invention provides a technical solution:

[0023] A small micro-buoyancy photoelectric composite cable transmission assembly in shallow water, comprising a plug housing 5 and a socket housing 7, the outer left end of the plug housing 5 is provided with a connecting screw sleeve 6, and the outer left end of the plug housing 5 is provided with a first sealing ring 17. The inner right end of the plug housing 5 is provided with a plug front insulator 19 and a plug rear insulator 21, the outer right end of the plug housing 5 is provided with an injection molded elastomer 2, and the inner right end of the injection molded elastomer 2 is provided with a micro buoyancy The outer sheath 1 of the photoelectric composite cable, the inner side of the outer sheath 1 of the micro-buoyancy photoelectric composite cable is provided with a reinforced cladding 26, and the inner side of the reinforced cladding 26 is provided with a first optical fiber 23 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com