Hoop installation auxiliary support and hoop installation auxiliary device

A technology of installation assistance and clamps, which is applied in the direction of drilling equipment, earthwork drilling, drill pipes, etc., can solve the problems of high labor cost for clamp installation, easy damage of instruments on pipelines, and easy damage of instruments, so as to save labor costs, The effect of flexible use and avoiding pipeline oscillation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

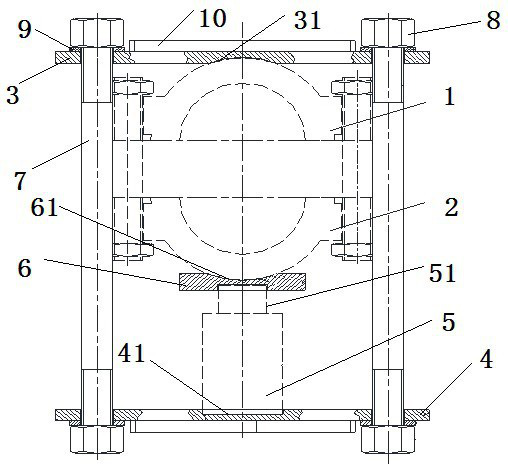

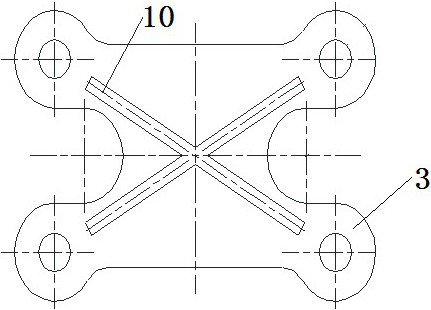

[0061] The clamp installation aid of the present invention, such as figure 1 As shown, it includes the clamp installation auxiliary bracket and the hydraulic jack 5 placed inside the clamp installation auxiliary bracket. The hoop installation auxiliary bracket includes an upper pressing part 3 and a lower pressing part 4 arranged at intervals up and down, and the two are connected by a connecting piece, which is a double-ended connecting stud 7 . Both the upper pressing piece 3 and the lower pressing piece 4 are of plate structure, and the upper pressing piece 3 and the lower pressing piece 4 are provided with through holes, and the two ends of the double-ended connecting stud 7 pass through the upper pressing piece 3 and the lower pressing piece 4 respectively. The through hole of the connecting nut 8 is threadedly installed on the external thread section at the upper and lower ends of the double-ended connecting stud 7 and is located on the outside of the upper pressing piec...

specific Embodiment 2

[0069] The difference from Example 1 is that the hydraulic jack is installed upside down and fixed on the upper pressure piece, the top of the hydraulic jack is provided with a flange, and the upper pressure piece is provided with a connection hole, and the bolt passes through the flange and the connection hole, and the hydraulic jack is fixedly installed On the upper pressing piece, the connecting holes constitute the mounting structure.

specific Embodiment 3

[0071] The difference from Embodiment 1 is that the horizontal positioning structure is a ring protrusion provided on the pressing member, and the inner structure of the ring protrusion is adapted to the bottom of the hydraulic jack.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com