Patents

Literature

68results about How to "With vibration reduction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

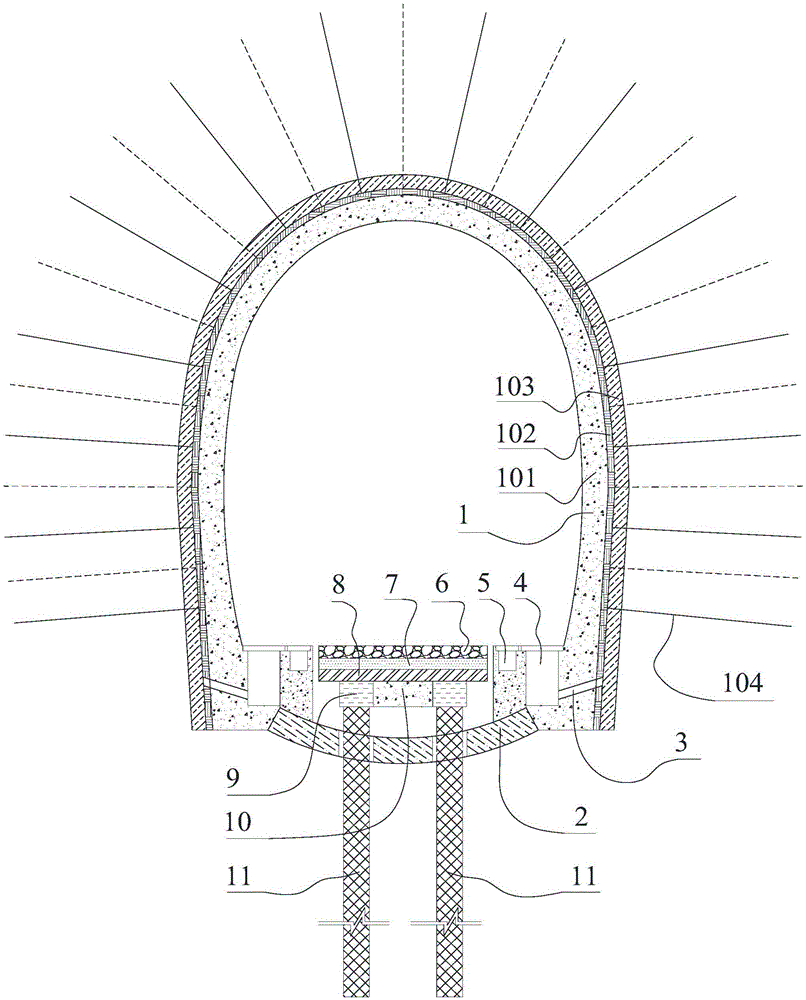

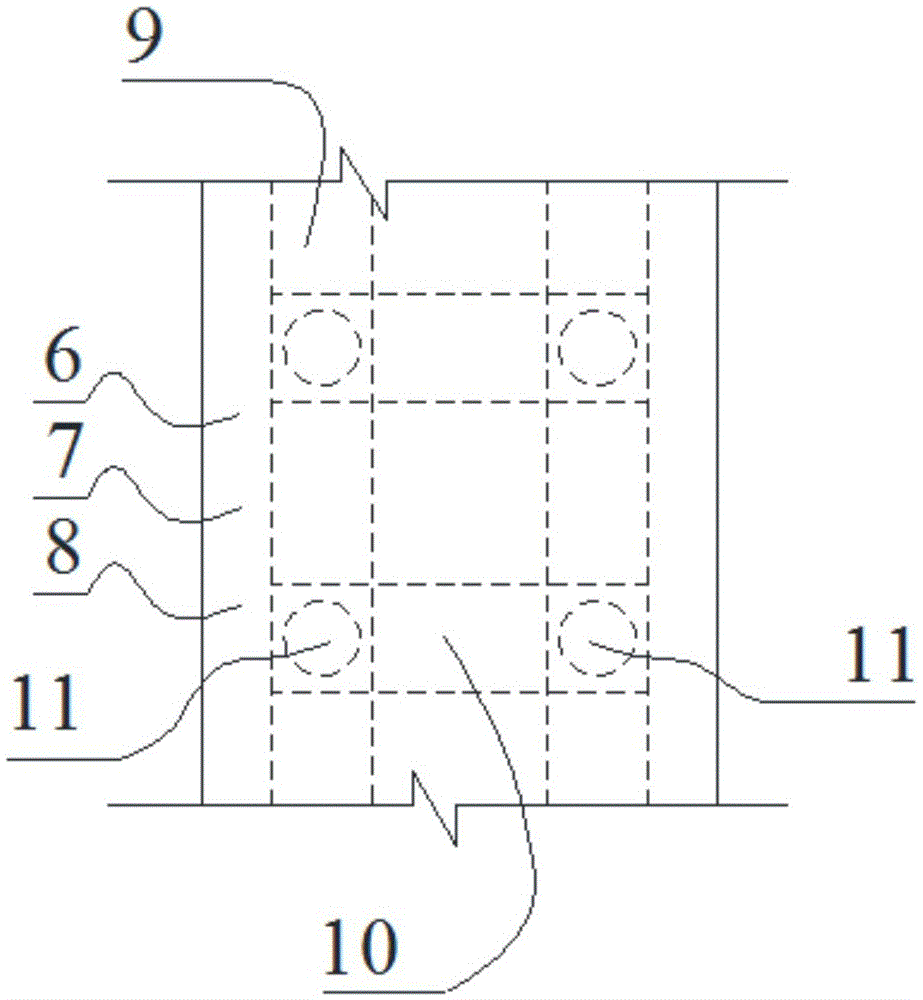

Tunnel structure for weak and broken high-temperature water-bearing stratum

InactiveCN105569674AReduce fatigue damageReduce vibrationUnderground chambersDrainageThermal insulationStructural engineering

The invention provides a tunnel structure for a weak and broken high-temperature water-bearing stratum. The tunnel structure comprises a tunnel lining and an inverted arch which form a closed annular structure, the footing of the tunnel lining is connected with the left end and the right end of the inverted arch, drain holes are formed in the footing, and drainage ditches and cable troughs are formed in the connecting portions of the lining and the inverted arch; a traffic lane in a tunnel is arranged on a vibration reduction layer, a bearing platform plate is arranged on the lower portion of the vibration reduction layer and supported by longitudinal beams and cross beams jointly, the longitudinal beams and the cross beams are supported by pile foundations which vertically penetrate through the inverted arch and are inserted into the stratum, the ends of the two sides of the traffic lane, the ends of the two sides of the vibration reduction layer and the ends of the two sides of the bearing platform plate are all disengaged from the positions where the drainage ditches and the cable troughs are located, and the longitudinal beams, the cross beams and the pile foundations are disengaged from the inverted arch. The tunnel structure has the effects of water resistance, thermal insulation and vibration reduction and is compact in structure, high in bearing performance, convenient to construct, lower in construction and maintenance cost and wide in application range.

Owner:SOUTHWEST JIAOTONG UNIV

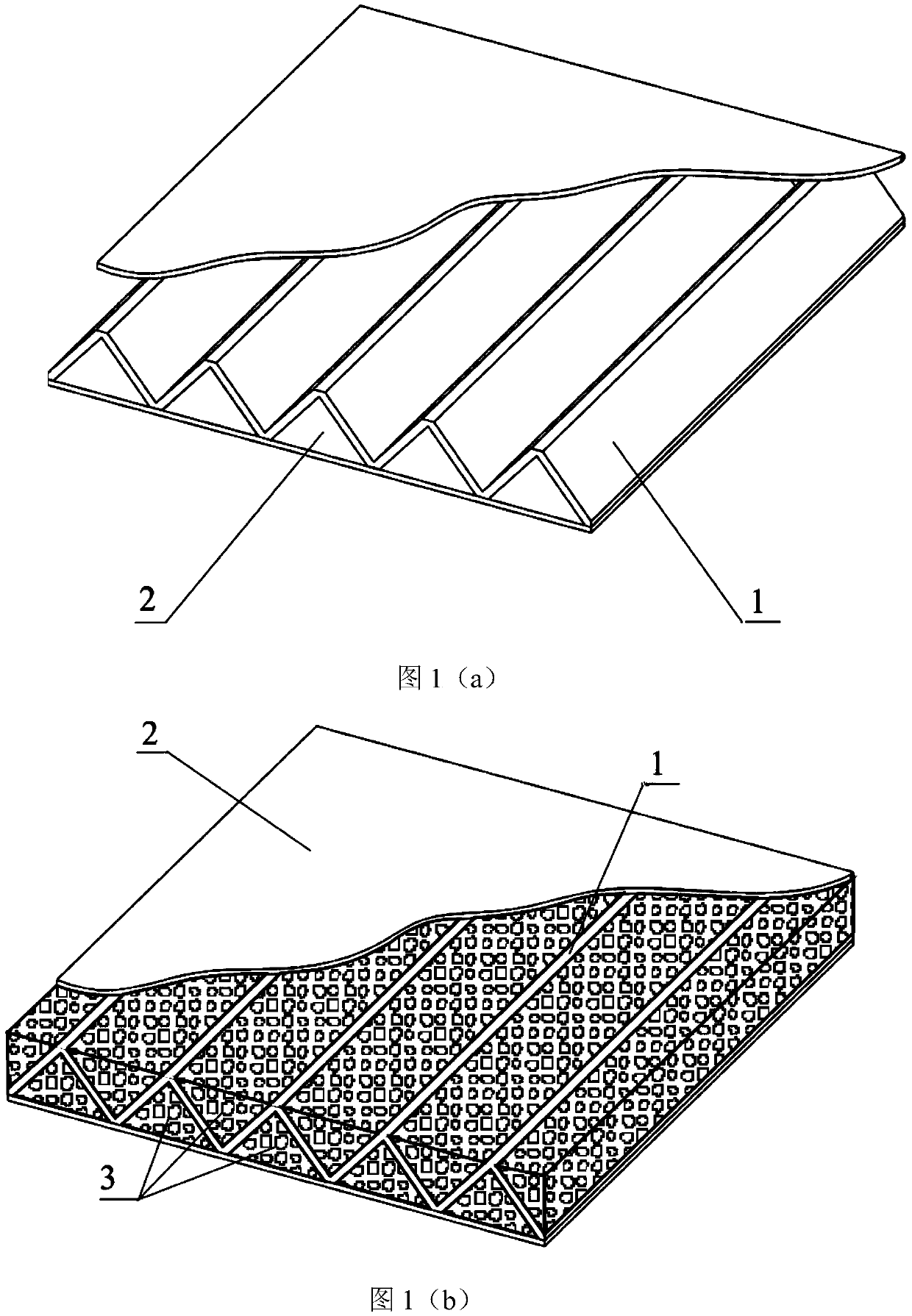

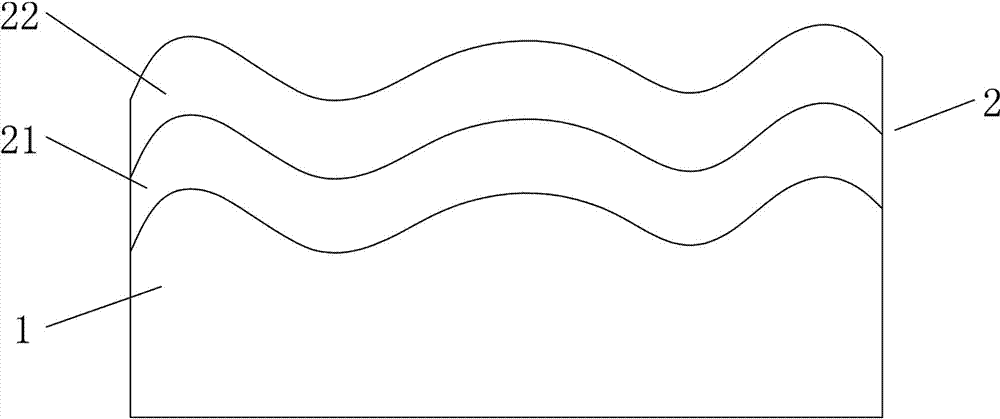

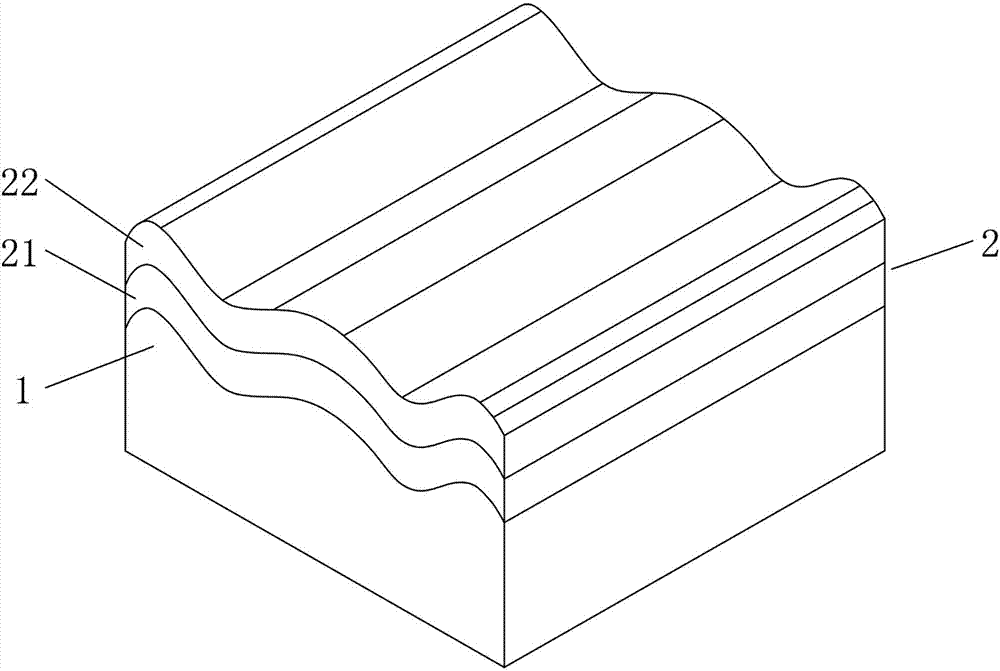

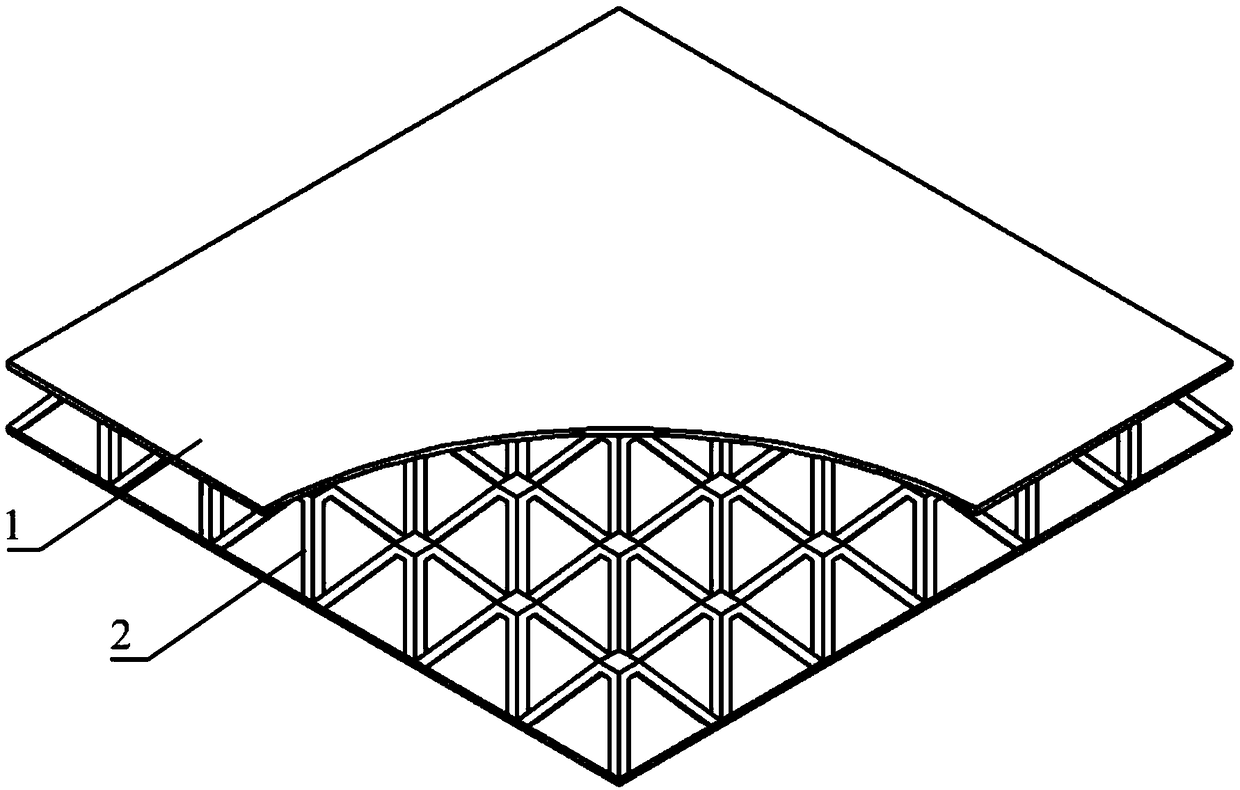

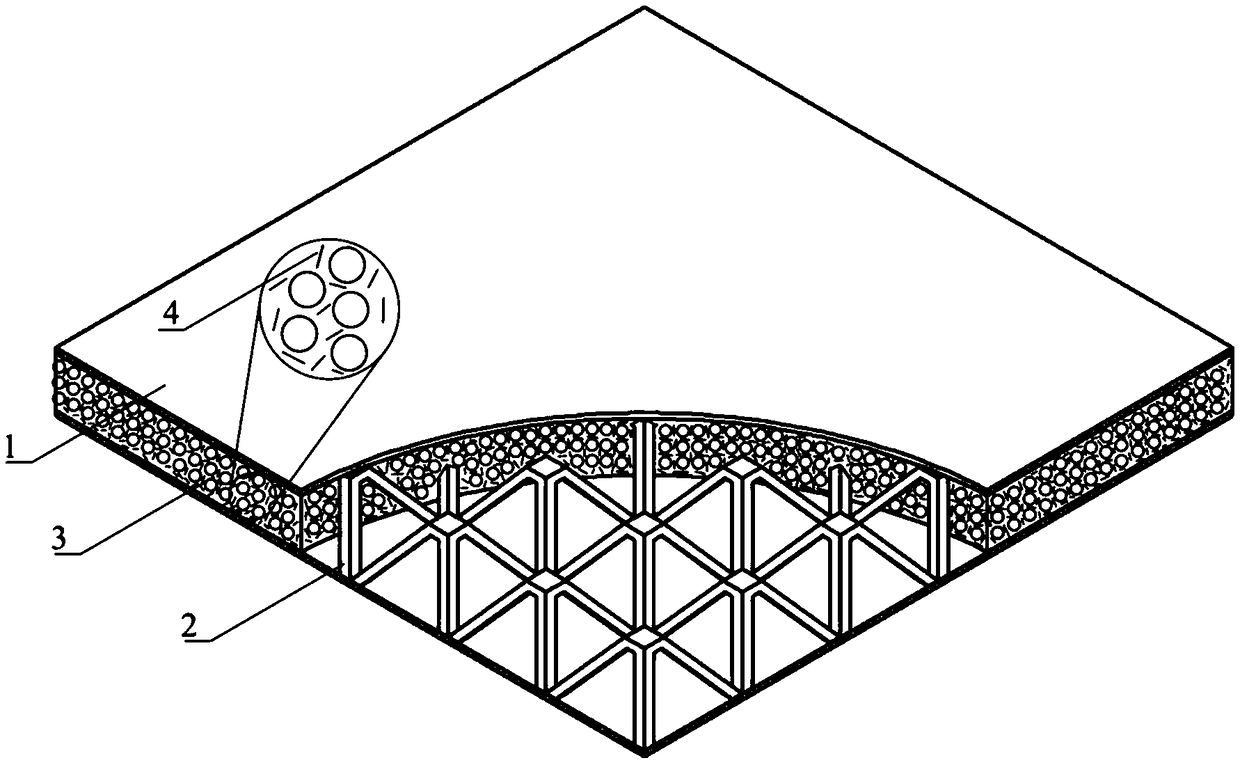

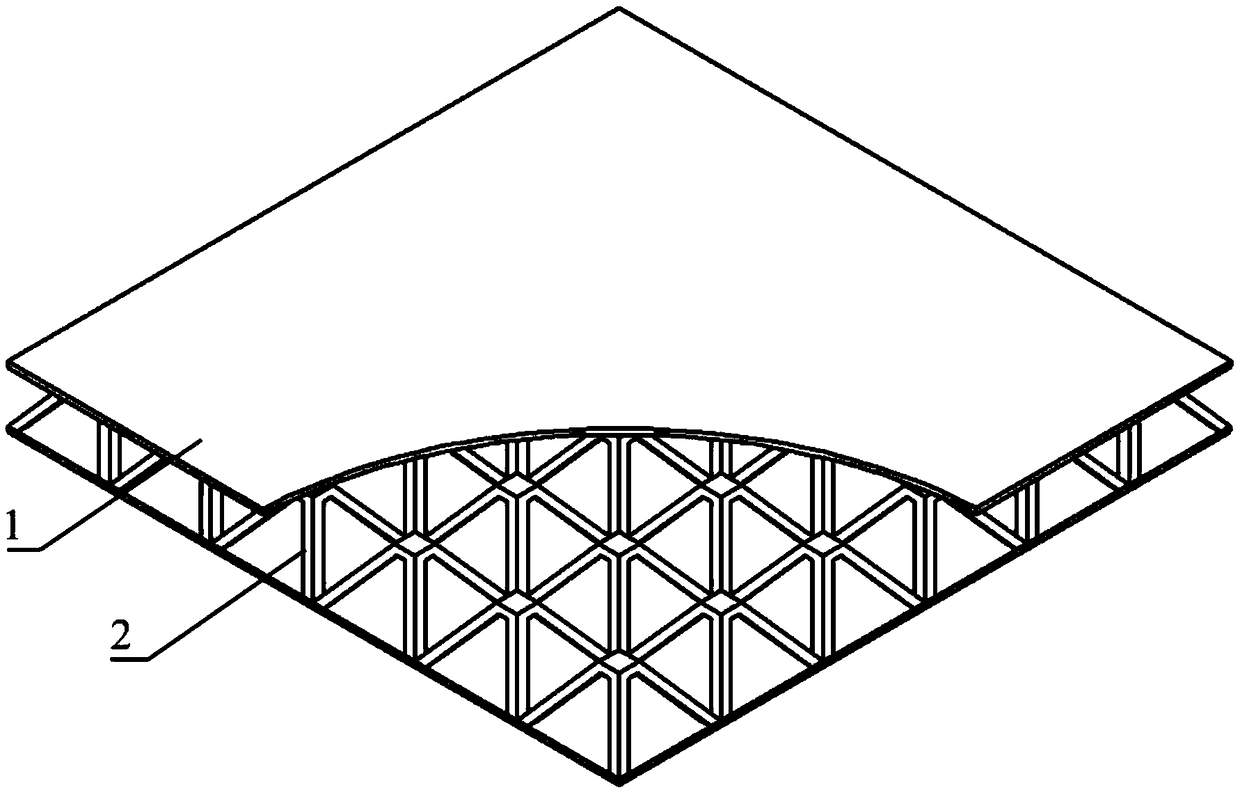

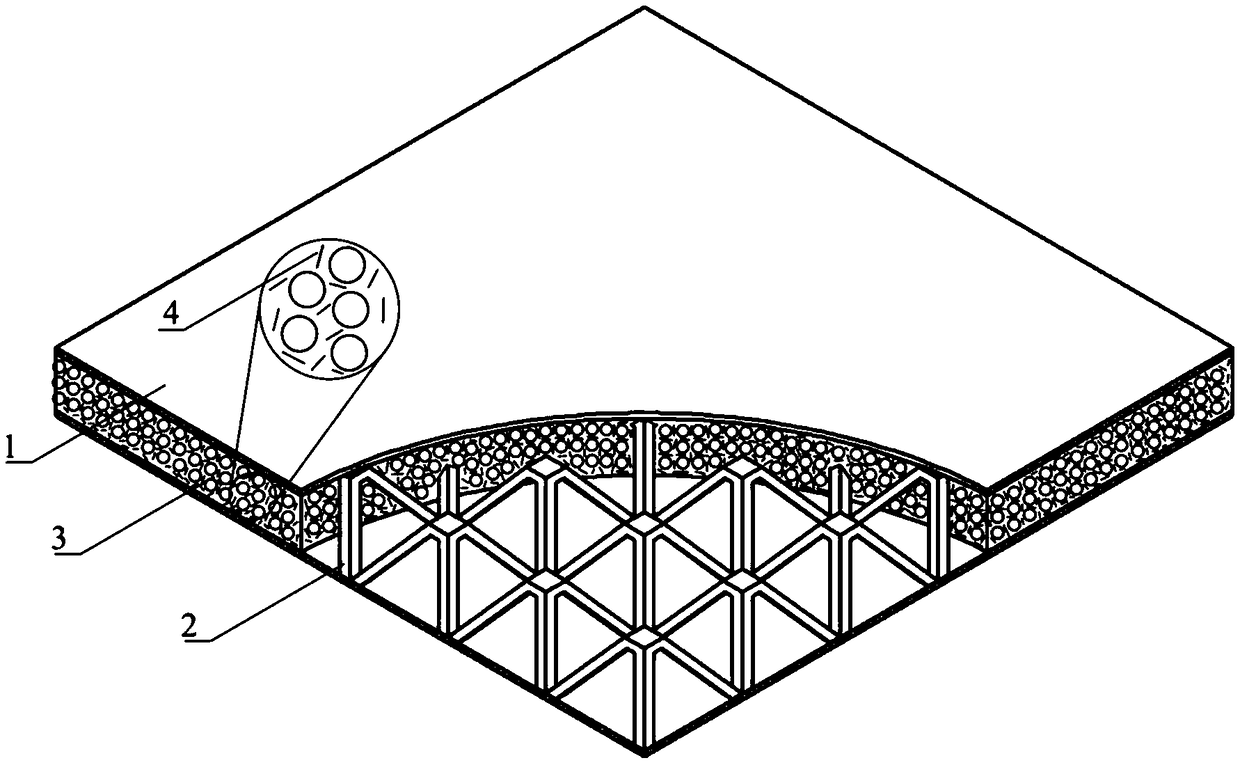

Foamed aluminum-corrugated plate composite sandwich plate and preparation method thereof

InactiveCN104175623AHigh shear mechanical propertiesWith heat insulationLamination ancillary operationsLaminationFoaming agentEnergy absorption

The invention relates to a foamed aluminum-corrugated plate composite sandwich plate and a preparation method thereof. The method comprises the following steps: firstly, manufacturing a corrugated core body; welding the corrugated core body to a panel to form a corrugated plate; putting basal powder and a foaming agent in a mixing machine for uniform mixing, and then extruding the mixed powder into a primary blank; putting the blank in a mould for pressing, filling the inside of the corrugated plate with a pressed foaming prefabricated body, and putting the corrugated plate in an atmosphere furnace for foaming; and heating and keeping warm until the prefabricated body is expanded to form foamed aluminum with which pores of the corrugated plate are completely filled, and then cooling. By using a powder metallurgy method, the inside of lattice metal is foamed in situ to form the metallurgical-bonding foamed aluminum-corrugated plate composite sandwich plate. The excellent mechanical property of the lattice metal and the advantages of energy absorption, sound insulation, shock absorption and thermal insulation of the foamed aluminum are utilized, so that the multifunctional coupling is realized, and the structure and function integration material with the relatively excellent comprehensive performance is obtained. The bonding strength is effectively improved by virtue of metallurgical bonding, and the performance of the composite material is further improved.

Owner:XI AN JIAOTONG UNIV +1

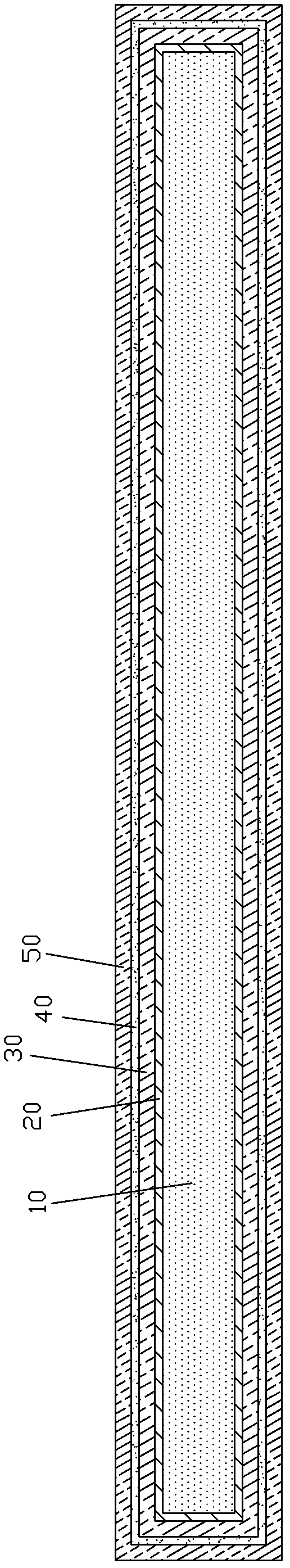

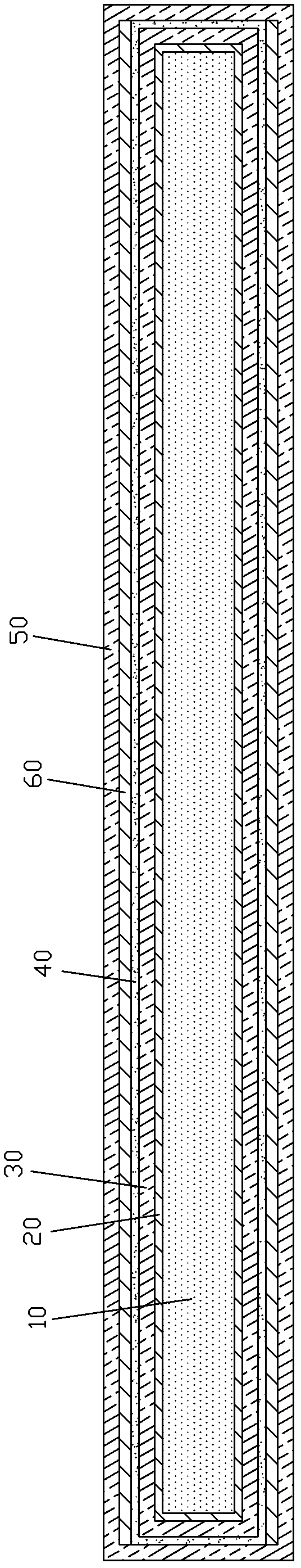

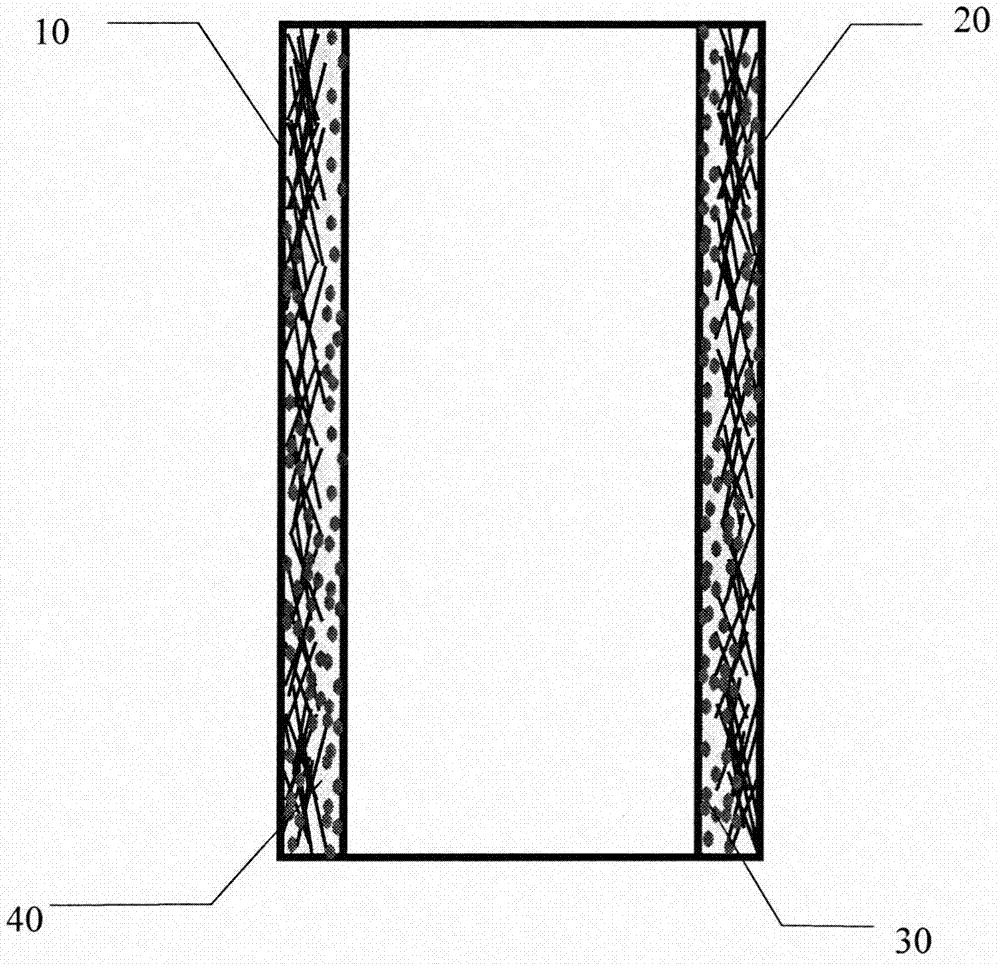

Wall body vacuum insulation plate and preparation method thereof

ActiveCN103104044AImprove wear resistanceImprove fire performanceClimate change adaptationInsulation improvementBuilding energyEngineering

The invention relates to the field of building energy-saving insulation, in particular to a wall body vacuum insulation plate and a preparation method thereof. The wall body vacuum insulation plate comprises a vacuum heat isolation plate formed by a high isolation package bag and an insulation core material arranged in the high isolation package bag through vacuum sealing, and a fiber reinforced composite isolation bag is arranged outside the vacuum heat isolation plate in a seal and vacuum mode. Compared with the prior art, due to the fact that the fiber reinforced composite isolation bag is arranged outside the vacuum heat isolation plate in the seal and vacuum mode, abrasion resistance, fire-proof performance and bonding performance with other materials of the wall body vacuum insulation plate are reinforced. The wall body vacuum insulation plate is particularly suitable for being used in the field of building energy-saving insulation, not only can be applied to external wall insulation, internal wall insulation and sandwich insulation, but also can be applied to thin-plastered and various decorating dry-hanging systems, and is particularly suitable for energy-saving buildings which have high requirements for heat insulation in cold areas.

Owner:FUJIAN SUPERTECH ADVANCED MATERIAL

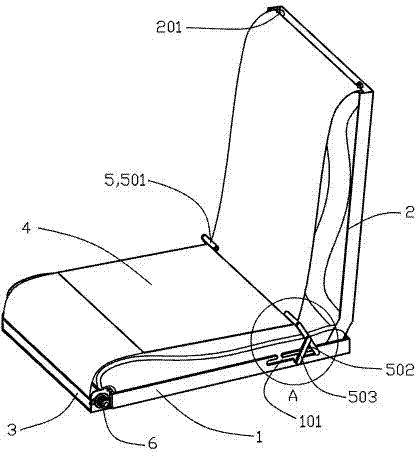

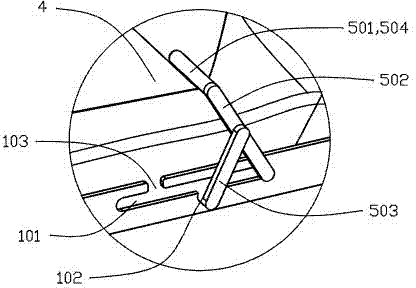

Automobile seat

ActiveCN102874150AEasy to replaceImprove ride comfortSeat coveringsEngineeringMechanical engineering

The invention discloses an automobile seat. The automobile seat comprises a furling drum for accommodating a cover film, a hanging structure and a tensioning mechanism, wherein the furling drum is arranged at the front end of a seat frame; the hanging structure is arranged on the top of a back frame; the tensioning mechanism is symmetrically arranged on two sides of the seat frame; a hook for hanging is arranged at the head end of the cover frame; the tensioning mechanism comprises a sliding chute formed on the two sides of the seat frame, a first support rod of which one end is slidingly connected in the sliding chute, a second support rod of which one end is pivoted on the two sides of the seat frame and a tensioning rod which is pivoted on the other end of the second support rod and extends into the cover film; the other end of the first support rod is hinged at the middle section of the second support rod, and a positioning slot is formed in the middle section of the sliding chute. When the cover film is required to be changed, the cover film is pulled out of the furling drum and is hung on the hanging structure of a back, and the cover film between the seat and the back is tensioned and compressed through the tensioning structure, so that a ventilation and vibration reduction space is formed between the seat and the back and problems of disassembly and assembly and exchange in the prior art are solved.

Owner:HANGZHOU BRANCH ZHEJIANG GEELY AUTOMOBILE RES INST +2

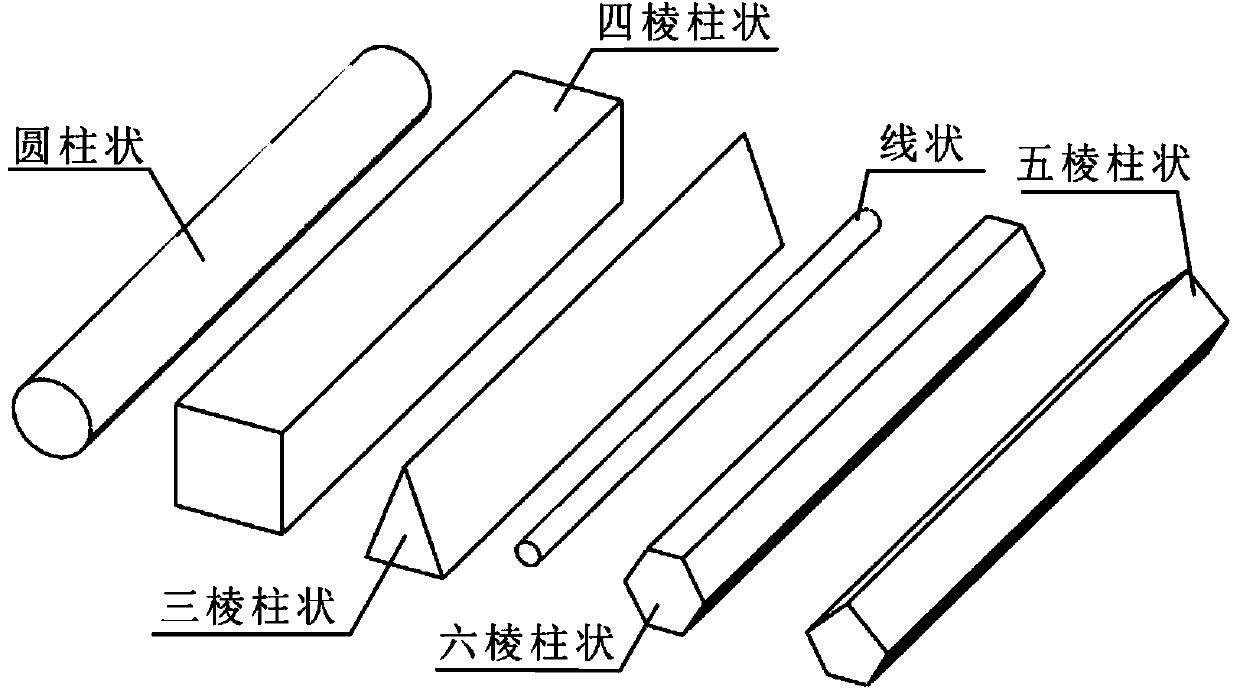

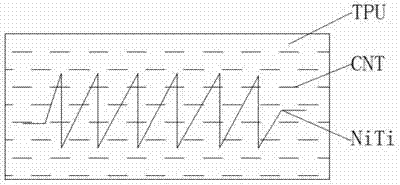

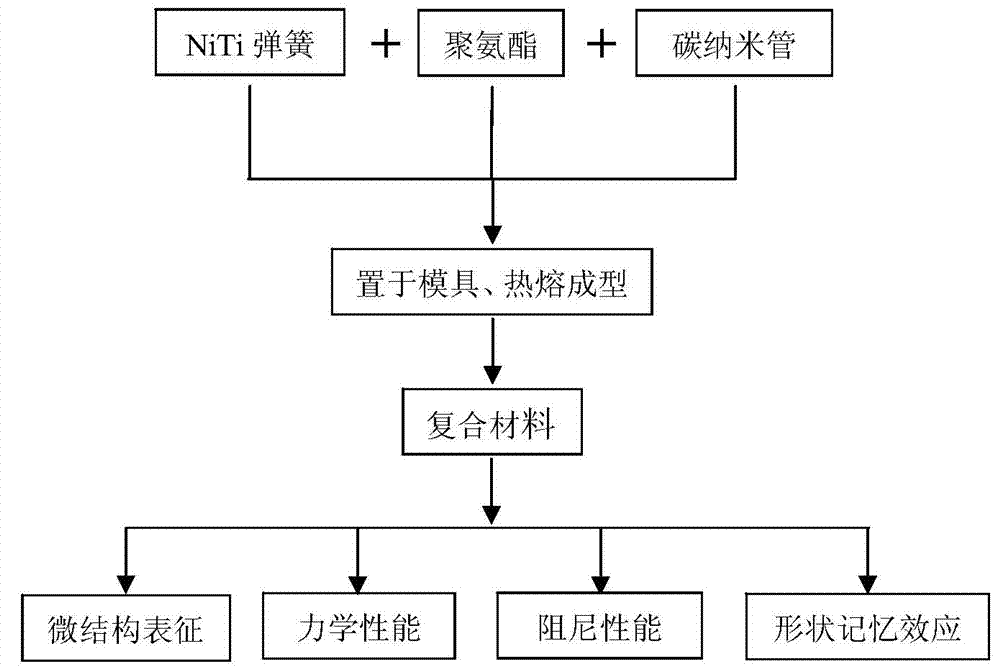

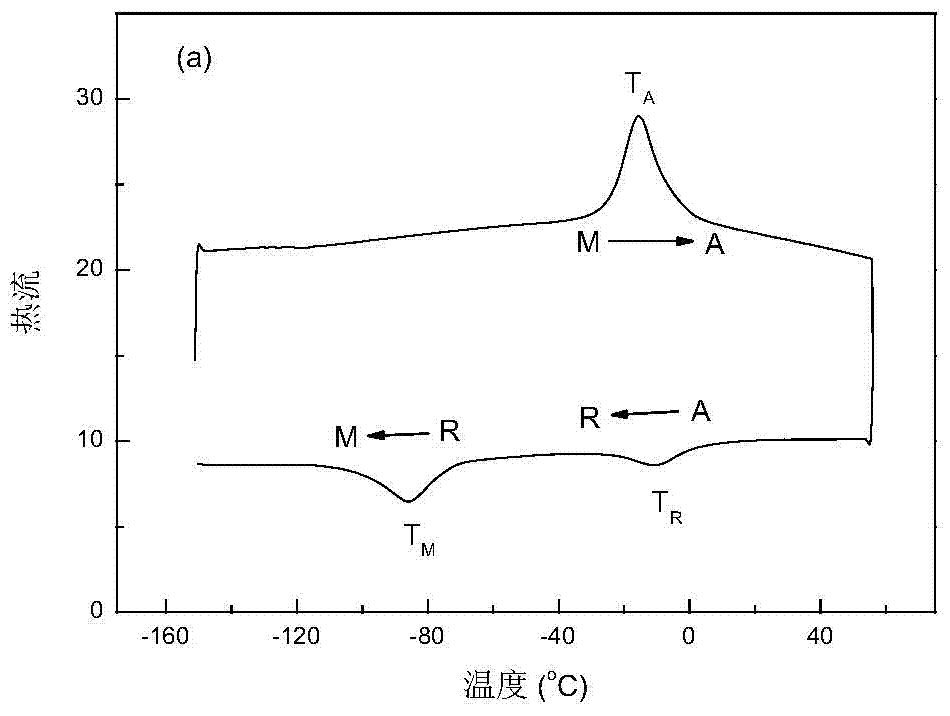

Polyurethane composite material doped by nickel-titanium memory alloy and carbon nanotube and preparation method thereof

The invention provides a polyurethane composite material doped by a nickel-titanium memory alloy and carbon nanotube, and a preparation method thereof. The preparation method comprises the following steps: (1) winding NiTi alloy wires around a spring winding machine to form a spring structure; (2) subjecting the obtained spring to a thermal treatment with a temperature of 400 to 500 DEG C; (3) mechanically stirring and mixing carbon nanotubes and polyurethane elastomer particles; (4) painting a demoulding agent on the inner surface of a mould; (5) placing the mixture obtained in the step (3) into the mould, melting the mixture at a temperature of 190 to 220 DEG C, and moulding; (6) evenly placing the NiTi alloy springs on the layer prepared in the step (5), then dispersing the mixture of carbon nanotubes and polyurethane elastomer around the NiTi springs until the springs are totally covered; (7) finally carrying out composite material melting and moulding in an air blast constant temperature oven. The prepared material is a damping intelligent composite material having a shape memory effect, is capable of adapting to the environmental and temperature changes, and can be applied to the vibration damping field.

Owner:黑龙江恒河沙科技开发有限公司

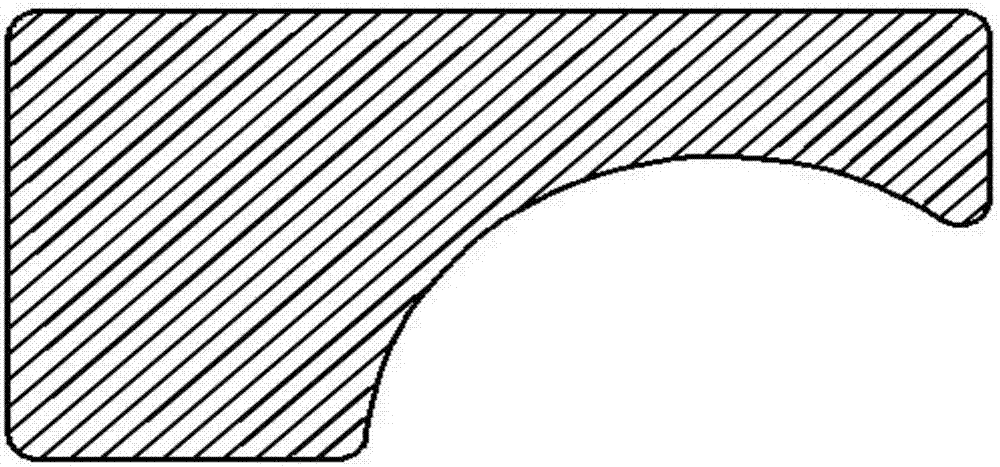

Brown fused alumina smoke composite base material for grinding wheel, manufacturing method and grinding wheel

ActiveCN104440599AHigh bonding strengthDrop off rateOther chemical processesAbrasion apparatusResin bondingGrinding wheel

The invention discloses a brown fused alumina smoke composite base material for a grinding wheel, a manufacturing method and the grinding wheel. The brown fused alumina smoke composite base material comprises, by weight, 30% to 60% of brown fused alumina smoke, 25% to 55% of phenolic resin, 5% to 20% of metal powder and 0.2% to 2% of silane coupling agents. According to the brown fused alumina smoke composite base material, components of the base material comprise phenolic resin the same as or similar to a grinding material layer in component and smoke recycling objects generated in the brown fused alumina production process, the interfacial compatibility between the base material and the grinding material layer is good, interface bonding strength is high, and the grinding material layer is not prone to decyclizaiton or off-falling; the brown fused alumina smoke composite base material has the self-consumption function and can fall off like the grinding material layer under the grinding force action when making contact with a workpiece without damaging the workpiece, the utilization rate of the grinding wheel can be increased, and the grinding quality of the grinding wheel can be improved; the grinding wheel using phenolic resin bonding agents has the function of compression resistance, vibration reduction and improving the machining quality of the grinding wheel.

Owner:ZHENGZHOU RES INST FOR ABRASIVES & GRINDING CO LTD

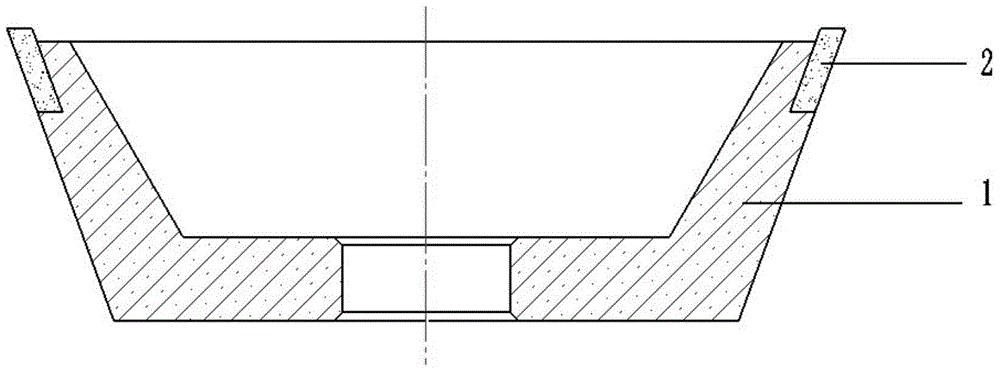

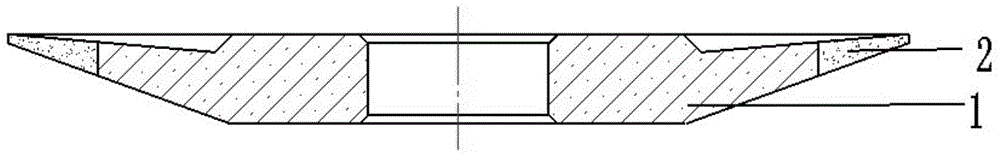

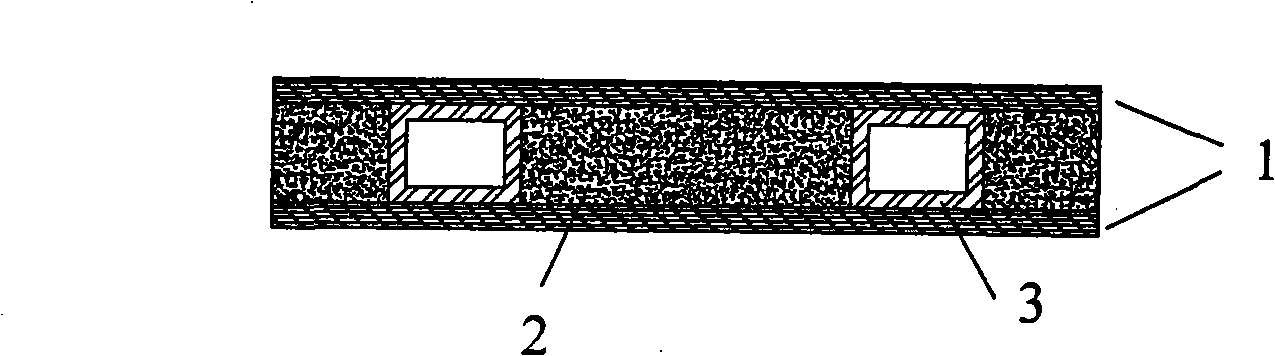

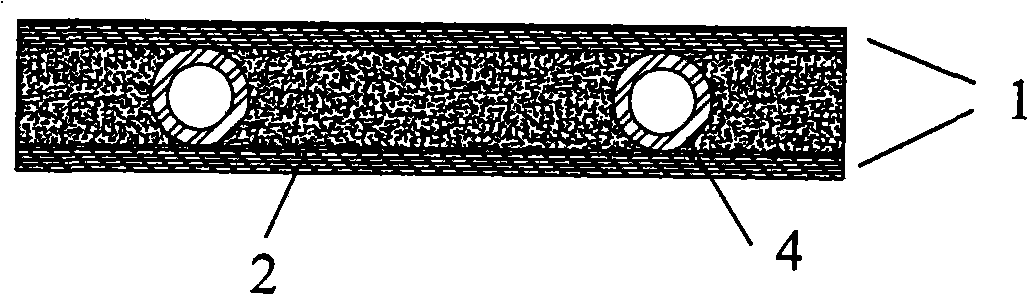

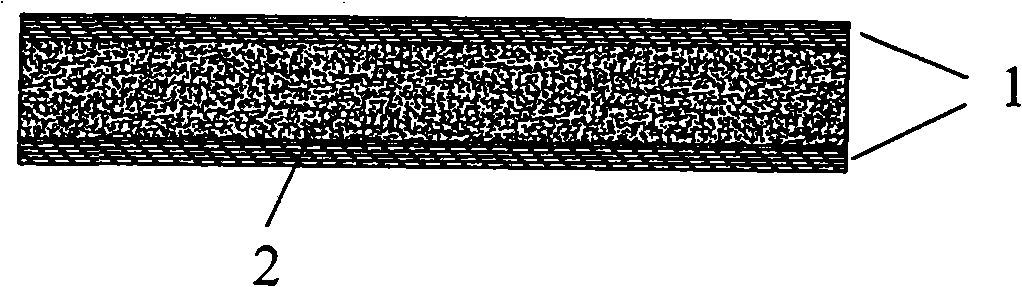

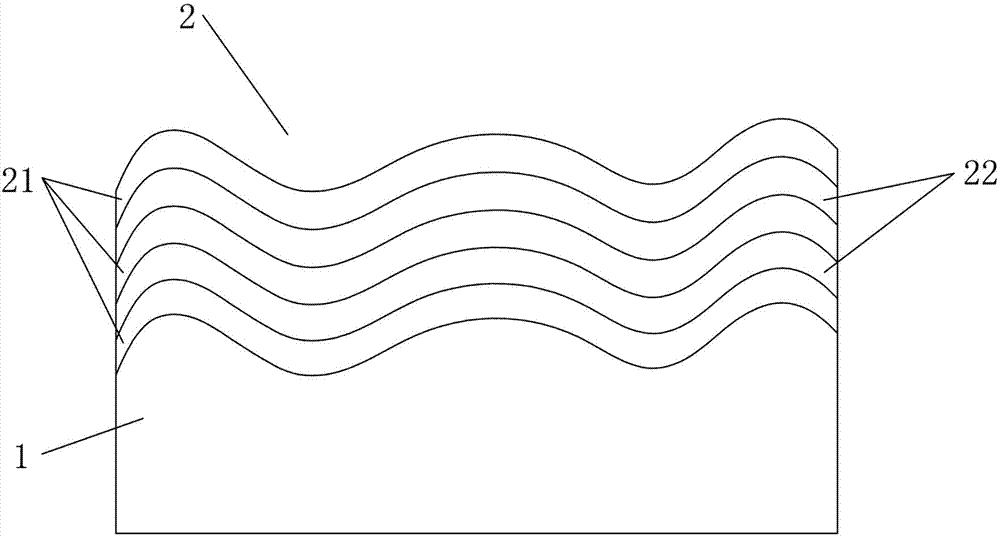

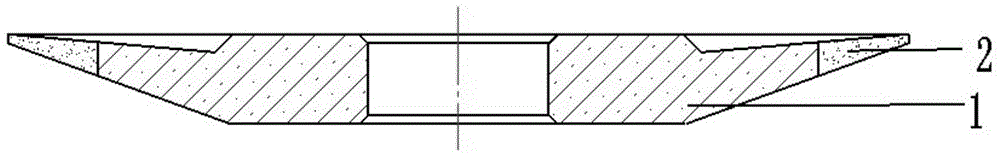

Vehicle bottom board of composite material

The invention discloses a novel composite material vehicle soleplate, which comprises surface plates (1) and a core material (2). The vehicle soleplate is characterized in that: the surface plate (1) is made of a fiber material, while the core material (2) is made of a light material; the surface plates (1) are arranged on the upper surface and the lower surface of the core material (2); and the surface plate (1) is glued with the core material (2) through the curing of resin. Moreover, the middle of the core material (2) can also be provided with a glass reinforced plastic pipe which can be a rectangular pipe (3) or a round pipe (4), thereby increasing the bearing capacity of the composite material vehicle soleplate. The composite material vehicle soleplate has light weight and can reduce the weight of a vehicle; meanwhile, the soleplate has excellent heat-preservation and heat-insulation performances, energy conservation and environmental protection; moreover, the soleplate also has better vibration-isolation and sound-insulation performances and can improve the riding comfort of a passenger. The novel composite material vehicle soleplate can be widely used as soleplates of various sedans, coaches and freight wagons.

Owner:NANJING UNIV OF TECH

Composite heat dissipation layer of power component, technology of composite heat dissipation layer of power component and power component with composite heat dissipation layer

ActiveCN103594434AUniform weightReduce temperature riseSemiconductor/solid-state device detailsSolid-state devicesPower componentMaterials science

The invention relates to a composite heat dissipation layer of a power component, a technology of the composite heat dissipation layer of the power component and the power component with the composite heat dissipation layer. The composite heat dissipation layer is formed by compositing at least one thin insulating layer and at least one thin solid metal heat dissipation layer. The bottom layer of the thin composite heat dissipation layer is the thin insulating layer, and the insulating layer located at the bottom layer is used for being closely attached to the outer surface of the power component. After the composite heat dissipation layer is combined with the power component, the thin composite heat dissipation layer formed by compositing at least one thin insulating layer and at least one thin solid metal heat dissipation layer can be formed quickly on the surface of the power component; the thin composite heat dissipation layer can form a cambered heat dissipation layer on the surface of the power component, wherein the heat dissipation layer is of an arbitrary shape and is attached to the component. In this way, the weight of a product is uniform; traditional single sided heat conduction is transformed to multiple sided composite heat conduction by utilizing high heat conductivity of metal ( traditionally, single sided heat conduction is mainly adopted, and the heat conduction is not uniform in different directions); therefore, the heat produced by the power component can be conducted quickly and effectively, the temperature rise of the protected power component is reduced, and the service life of the power component is prolonged.

Owner:GUANGDONG MENLO ELECTRIC POWER

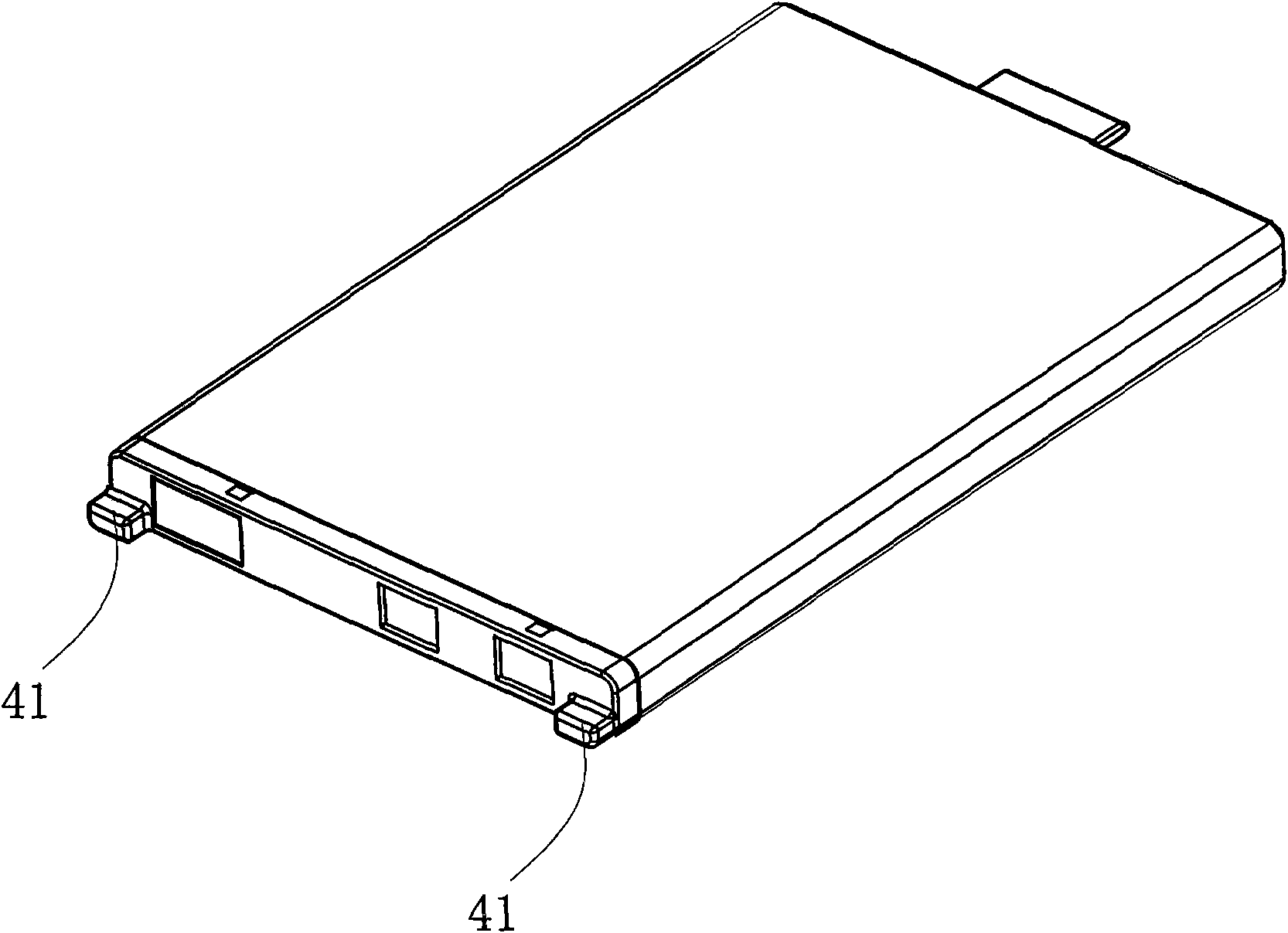

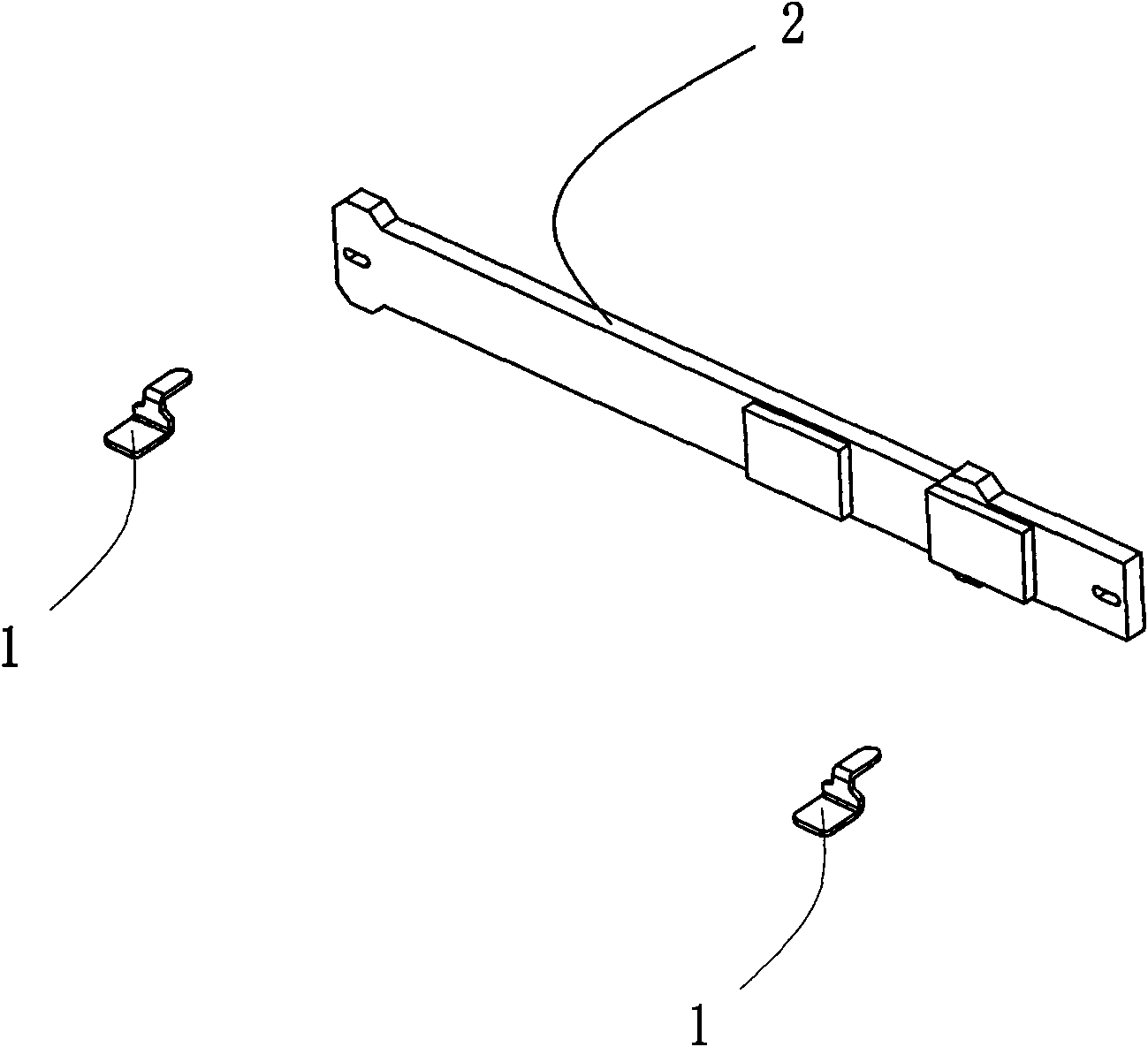

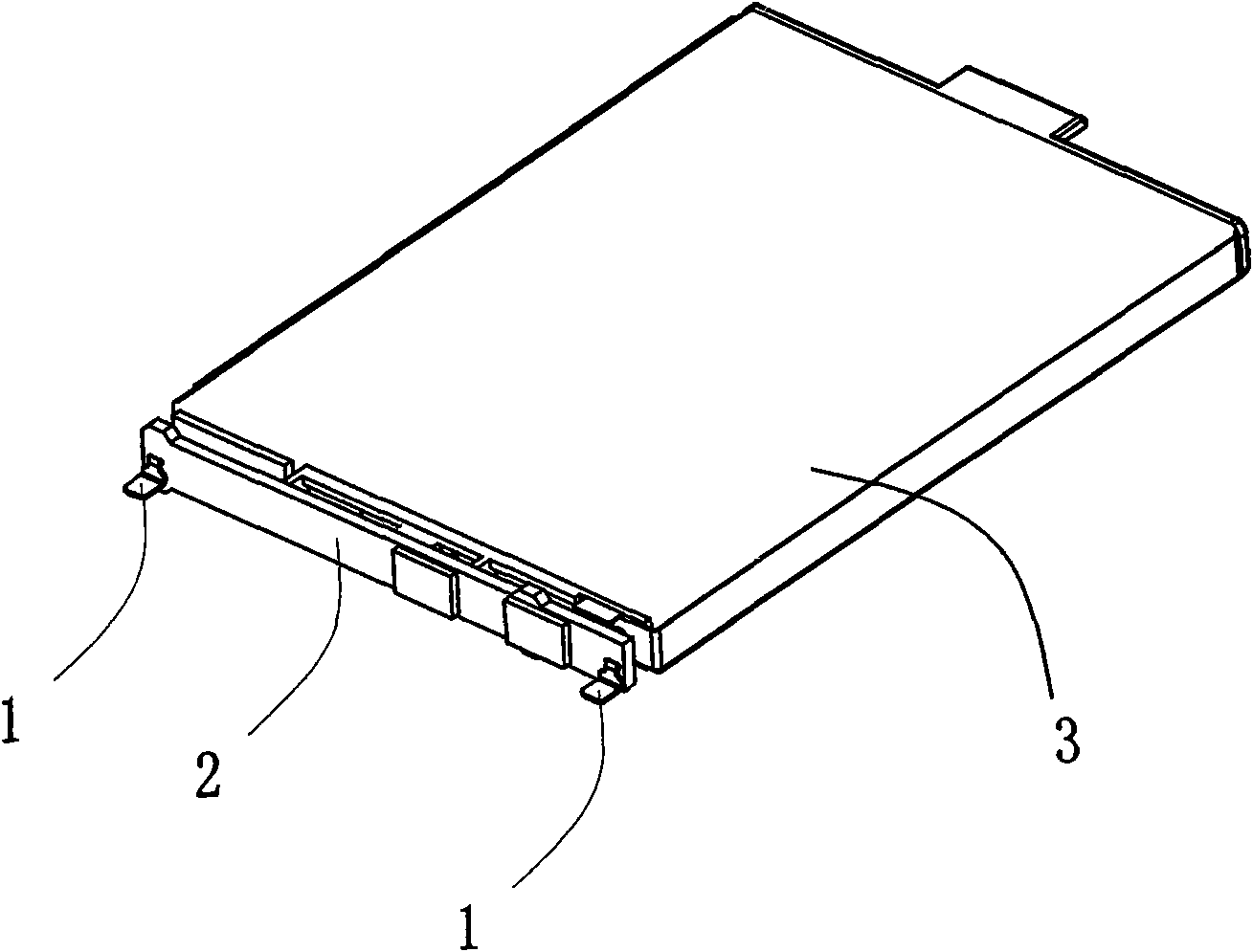

Low pressure injection molding method for battery buckle embedded copper sheet

InactiveCN101615690AHigh strengthWith insulationFinal product manufacturePrimary cellsMoistureCopper

The invention discloses a low pressure injection molding method for a battery buckle embedded copper sheet, which comprises the following steps: molding a metal sheet into a preset buckle shape; welding the molded metal sheet on a PCB of a battery; and spot-welding the PCB and a battery cell together, placing into an injection mold, and molding by adopting a low pressure injection molding process to obtain a semi-finished product of the battery. The method has the advantages of greatly increasing the strength of the battery buckle, guaranteeing sufficient strength of the battery buckle and meeting the requirement of test, such as falling off of the battery by embedding the copper sheet into the battery buckle and then performing low pressure injection molding; and the battery manufactured by the method has the advantages of insulation, temperature resistance, shock resistance, vibration reduction, moisture prevention, water prevention, dust prevention, chemical corrosion resistance, and the like.

Owner:SUNWODA ELECTRONICS

Carbon fiber reinforced PMI (Polymethacrylimide) foam-pyramid sandwich plate composite structure and preparation method thereof

InactiveCN108749160ABroaden the application backgroundImprove mechanical propertiesMetal layered productsFiberCarbon fibers

The invention discloses a carbon fiber reinforced PMI (Polymethacrylimide) foam-pyramid sandwich plate composite structure and a preparation method thereof. The structure comprises surface plates anda pyramid dot matrix core, wherein the pyramid dot matrix core is arranged between two surface plates to form a pyramid dot matrix sandwich plate; gaps of the pyramid dot matrix core are filled with carbon fiber reinforced PMI foams at intervals; the carbon fiber reinforced PMI foams are filled with a reinforced phase carbon fiber. The structure is relatively low in manufacturing process cost, easy in on-scale production and wide in application prospect in fields such as security protection, traffic transportation, machinery manufacturing and aerospace.

Owner:XI AN JIAOTONG UNIV

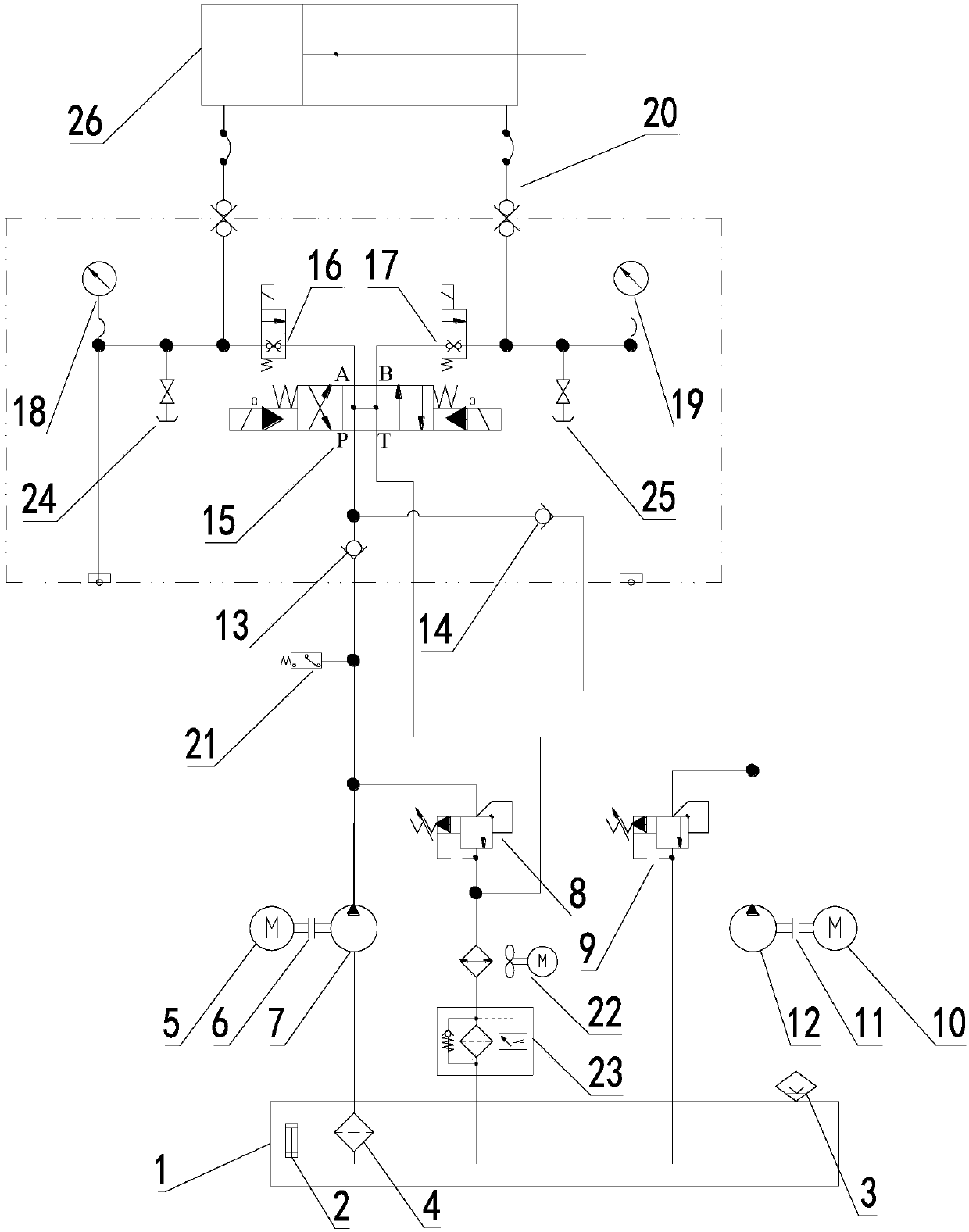

Hydraulic oil cylinder loading test hydraulic system

InactiveCN107725536AReduce installed powerReduce manufacturing costFluid-pressure actuator testingEngineeringHigh pressure

The invention discloses a hydraulic oil cylinder loading test hydraulic system which includes an oil tank body, a test system, a power system and a tested oil cylinder. The test system includes an H-type functional electromagnetic reversing valve, a plug-in mounting type left electromagnetic ball valve connected with a port A, a plug-in mounting type right electromagnetic ball valve connected witha port B, two manual ball valves and two pressure gauges. The power system includes a liquid filling unit and a loading unit. The upper part of the liquid filling unit is provided with a pressure switch and a one-way valve in turn, is connected to a port P of the electromagnetic reversing valve, and is in parallel connection with a low pressure overflow valve. The loading unit is connected to theport P of the electromagnetic reversing valve through the check valve, converges with the liquid filling unit, and is in parallel connection with a high pressure overflow valve. The installed power of the system is reduced by double-pump converging configuration, the pressure switch is adopted to detect loading pressure, the operation is convenient and reliable, and no energy waste is caused.

Owner:四川坤成润科技有限公司

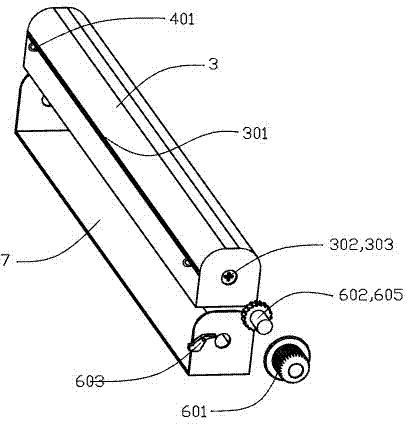

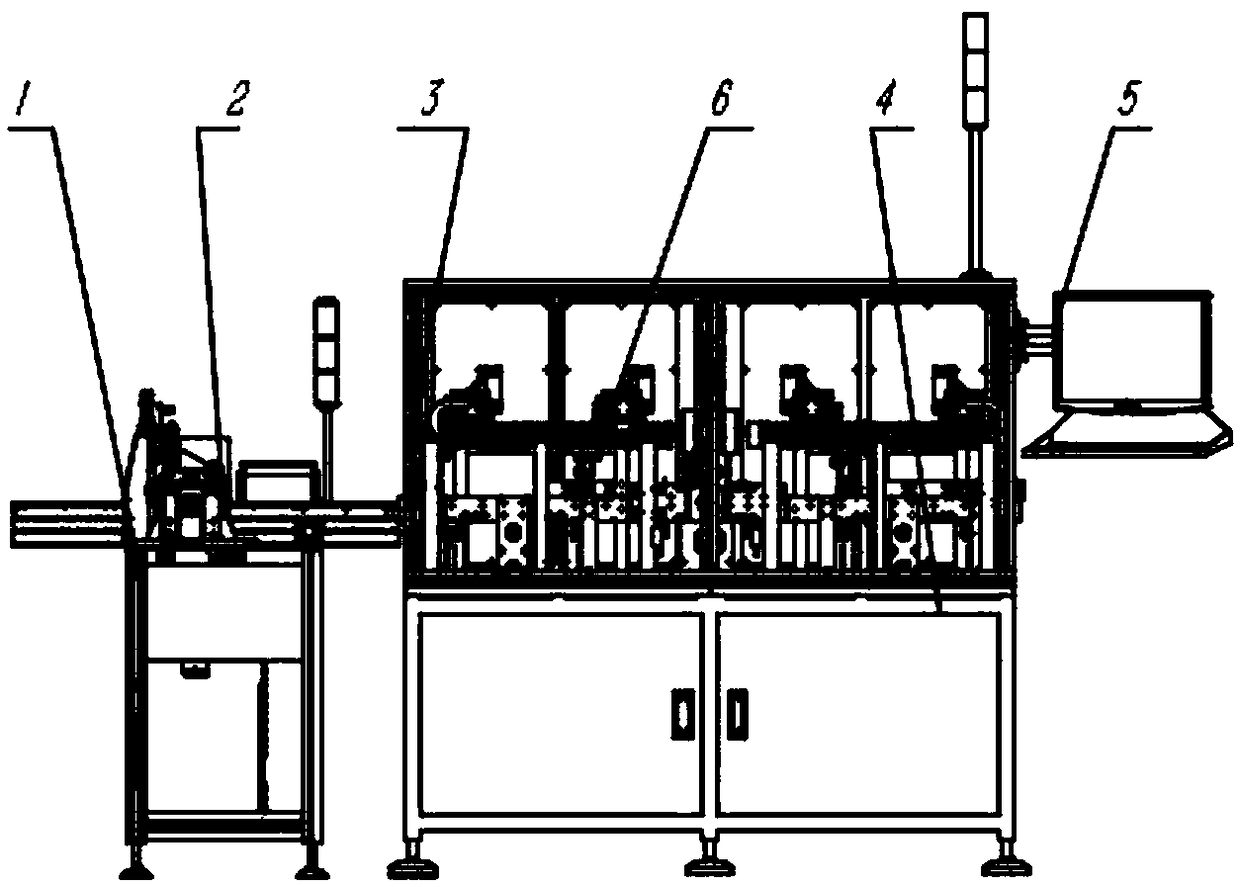

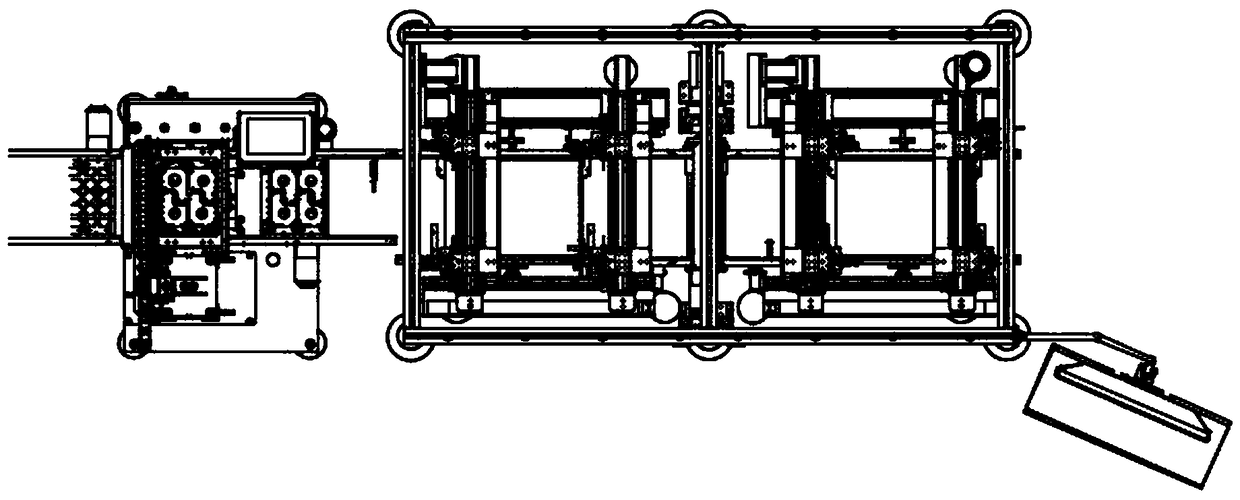

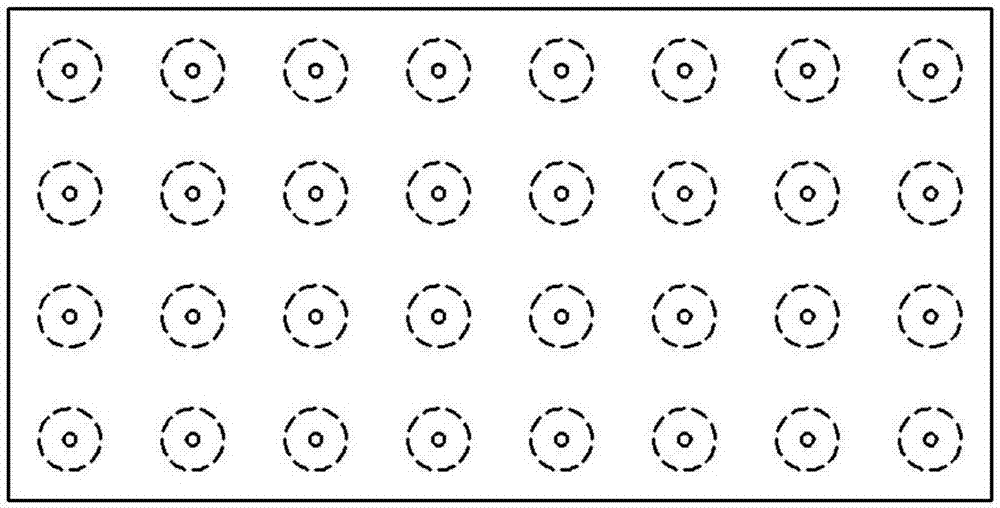

PCB patch adhesive dispensing device

InactiveCN108770231AImprove human-computer interactionAvoid lostPrinted circuit assemblingElectrical componentsSynchronous motorBall screw

The invention discloses a PCB patch adhesive dispensing device, which mainly solves a problem that an interval of PCB conveying lines is fixed and cannot be adjusted, only the PCB of a certain fixed size can be treated with adhesive dispensing and application range is small in the existing technology. The PCB patch adhesive dispensing device comprises a first frame, a STM patch feature mechanism,a second frame, an electric control cabinet, an operating panel and a PCB adhesive dispensing mechanism; the PCB adhesive dispensing mechanism comprises a conveying line adjusting mechanism and an adhesive dispensing mechanism. The conveying line is designed to be an interval-adjustable adjusted conveying line mechanism, and by a mode of driving ball screws by a synchronous motor, the interval ofthe conveying lines can be adjusted according to size of the PCB, thus, the PCBs of different size can be treated with adhesive dispensing, and the application range is wide.

Owner:张家港市欧微自动化研发有限公司

Composite matrix material for grinding wheel, preparation method and grinding wheel

ActiveCN104440600AHigh bonding strengthImprove interface compatibilityOther chemical processesAbrasion apparatusSelf consumptionGrinding wheel

The invention discloses a composite matrix material for a grinding wheel, a preparation method and a grinding wheel. The composite matrix material comprises, by mass, 30% to 60% of brown corundum ash, 25% to 55% of polyimide resin, 10% to 20% of metal additives and 0.2% to 2% of silane coupling agents. According to the composite matrix material for the grinding wheel, the matrix material comprises recovered materials which are the same as or are similar to a grinding material layer in composition and are obtained in production of polyimide resin and brown fused alumina, the interface between a matrix and the grinding material layer is good in compatibility and high in bonding strength, and decyclization or chip off-falling is not likely to be caused on the grinding material layer; the self-consumption effect is achieved, the composite matrix material can be disengaged like the grinding material layer under the effect of grinding force when making contact with a workpiece, the workpiece will not be damaged, and the grinding quality of the grinding wheel can be improved; the composite matrix material is used for the polyimide resin binder grinding wheel, and has the effects of being resistant to pressure, reducing vibration and improving the machining quality of the grinding wheel.

Owner:ZHENGZHOU RES INST FOR ABRASIVES & GRINDING CO LTD

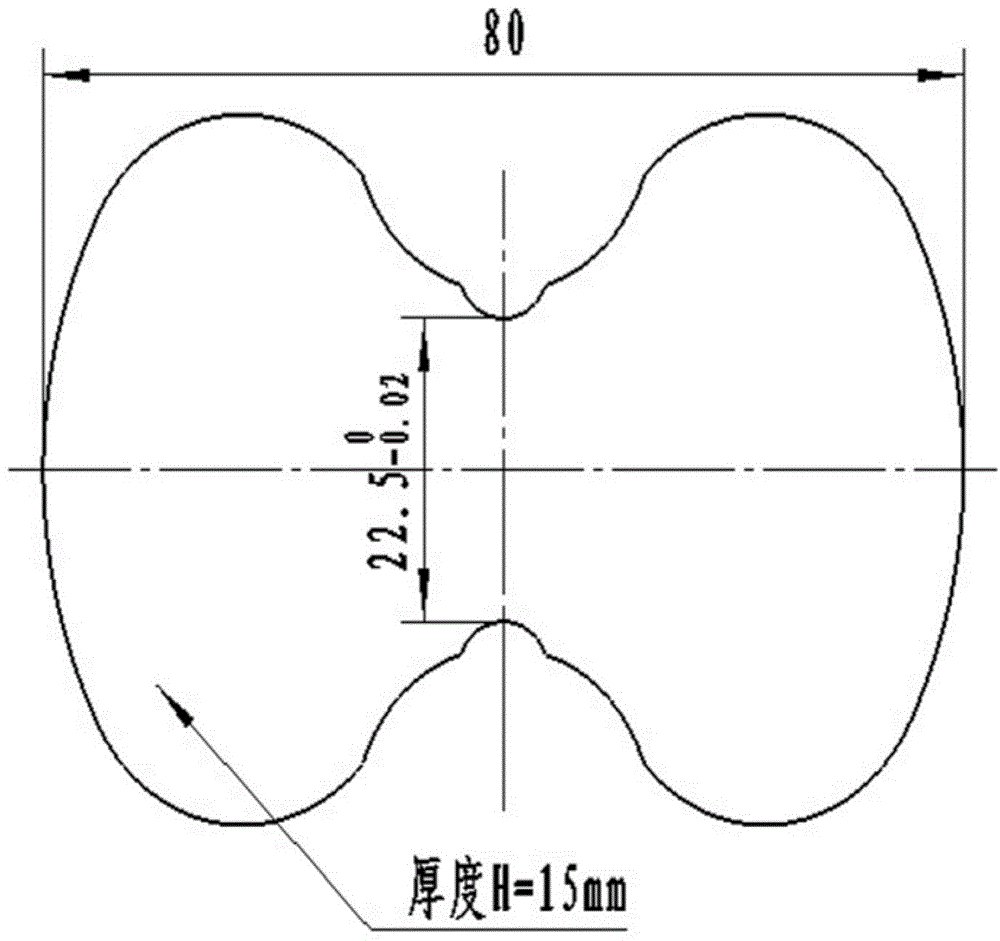

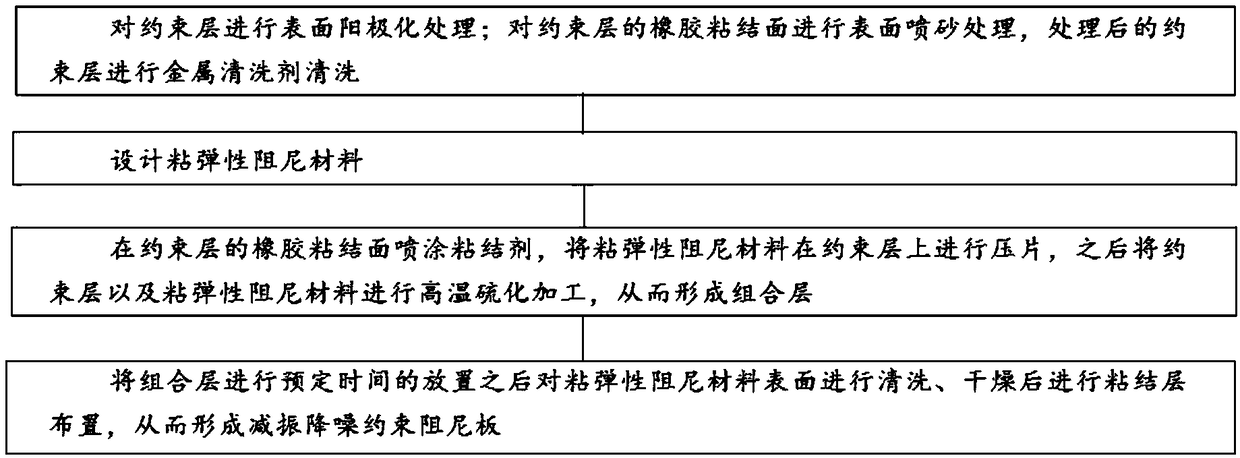

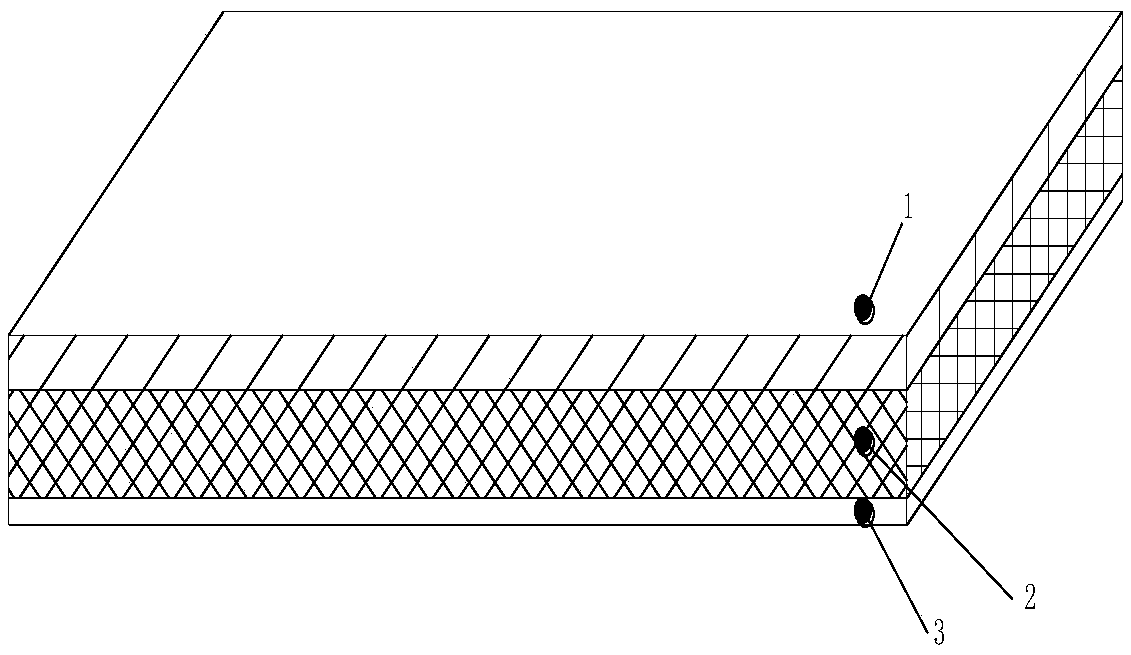

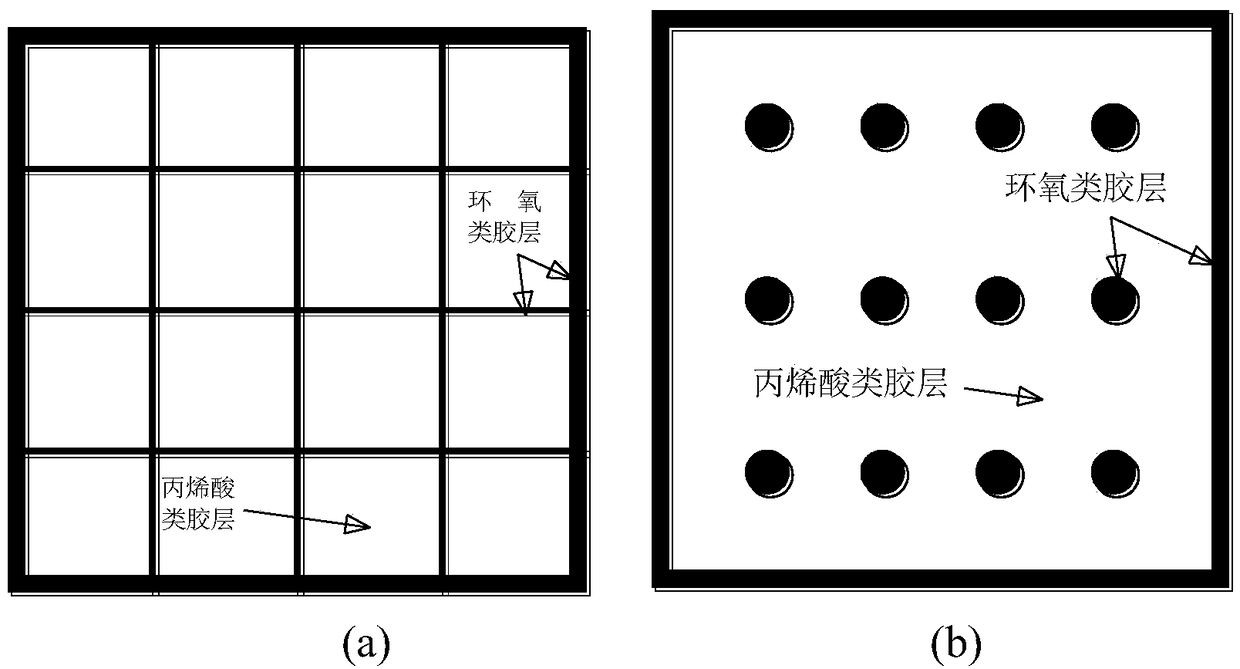

Vibration-attenuation and noise-reduction restrained damping plate manufacturing method and vibration-attenuation and noise-reduction restrained damping plate

InactiveCN109294470AMeet sound insulationWith sound insulationFilm/foil adhesivesVibration attenuationAbrasive blasting

The invention discloses a vibration-attenuation and noise-reduction restrained damping plate manufacturing method and the vibration-attenuation and noise-reduction restrained damping plate. The vibration-attenuation and noise-reduction restrained damping plate manufacturing method includes the following steps: carrying out surface anodization treatment of a restraint layer; carrying out surface sandblasting treatment of a rubber bonding surface of the restraint layer, and cleaning the treated restraint layer with a metal cleaning agent; designing a viscoelastic damping material; spraying the rubber bonding surface of the restraint layer with a binder, tabletting the viscoelastic damping material on the restraint layer, and then carrying out vulcanization processing of the restraint layer and the viscoelastic damping material at high temperature to form a composite layer; after placing the composite layer for a predetermined time, cleaning and drying the surface of the viscoelastic damping material, and then arranging a bonding layer, so as to form the vibration-attenuation and noise-reduction restrained damping plate.

Owner:CHINA AIRPLANT STRENGTH RES INST

Carbon fiber-enhanced high-temperature-resistance high-strength light hybrid ceramic-resin composite material pipe

ActiveCN107143704AGood heat protectionImprove temperature resistanceRigid pipesCarbon fibersResin-Based Composite

The invention discloses a carbon fiber-enhanced high-temperature-resistance high-strength light hybrid ceramic-resin composite material pipe. A ceramic-based composite material is used as a shell, a resin-based composite material is used as an inner shell, the outer shell and the inner shell are mutually nested to form a composite structure, the surfaces of inner and outer walls are smooth, the ceramic component in the composite material is distributed in a graded mode in the pipe wall thickness direction and is gradually reduced from the outer surface to the interior of the pipe, the high temperature resistance is good, and long-time application can be achieved at 600 DEG C; and compared with traditional aluminum alloy shells, the heat conductivity coefficient is lower, and high-temperature-resistance anti-heating performance is better. The resin component is also distributed in a graded mode in the pipe wall thickness direction and is gradually reduced from the inner surface to exterior of the pipe and filled with a certain amount of filler, the high temperature resistance and impact resistance of the resin-based material are improved, and therefore the resin-based material has the vibration reduction characteristics. The ceramic-based component and the resin-based component are integrally formed, and the light hybrid ceramic-resin composite material pipe integrating heat temperature resistance, heat prevention, heat insulation, bearing and vibration reduction is prepared.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

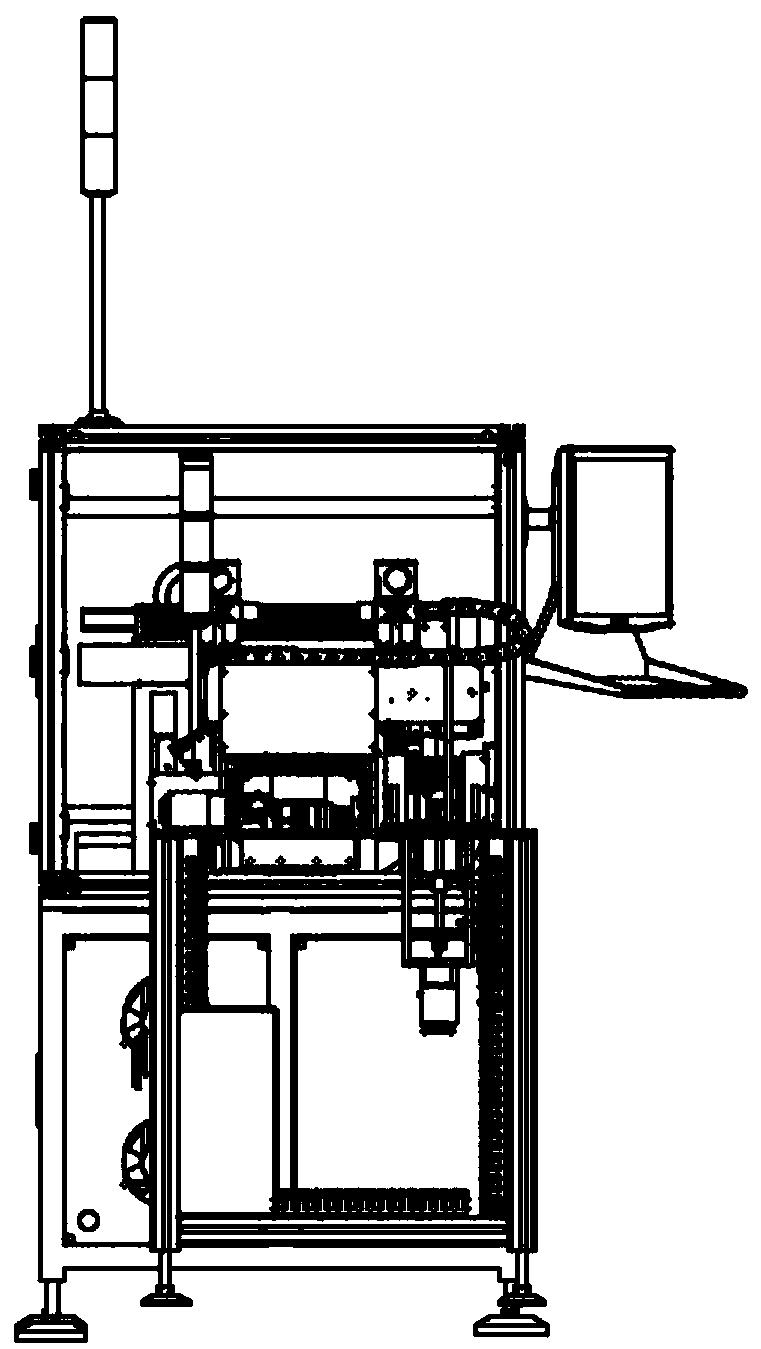

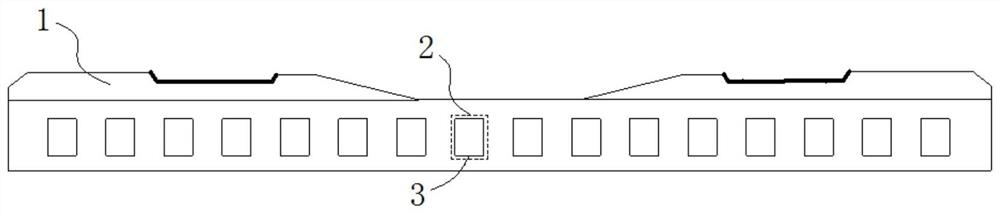

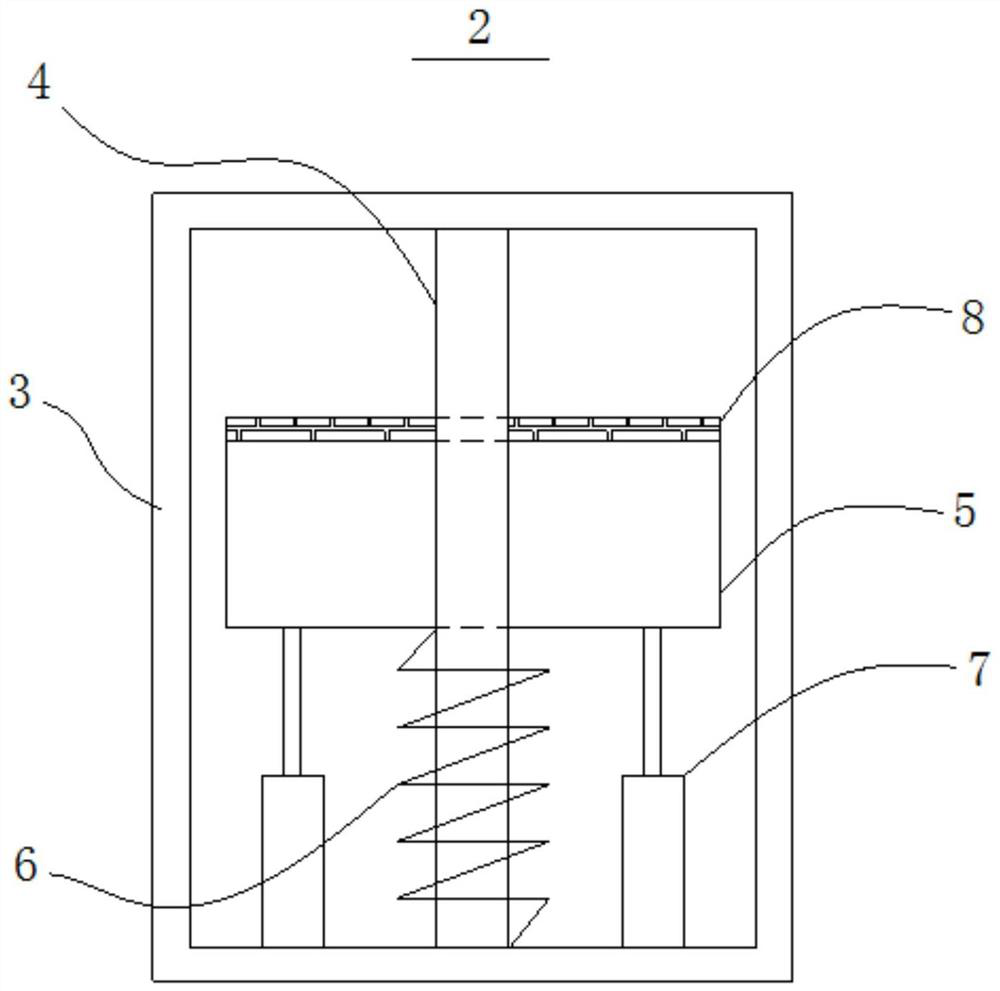

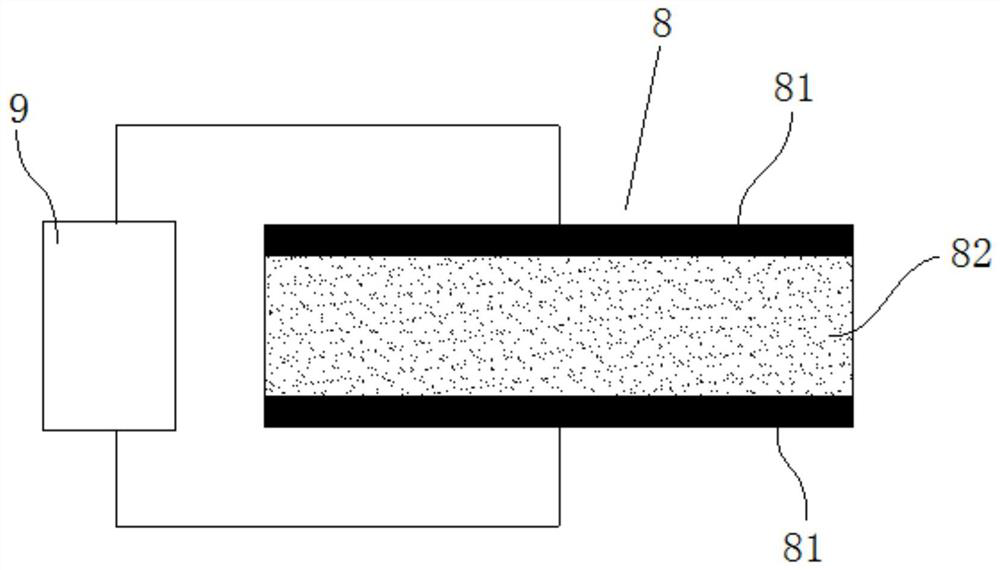

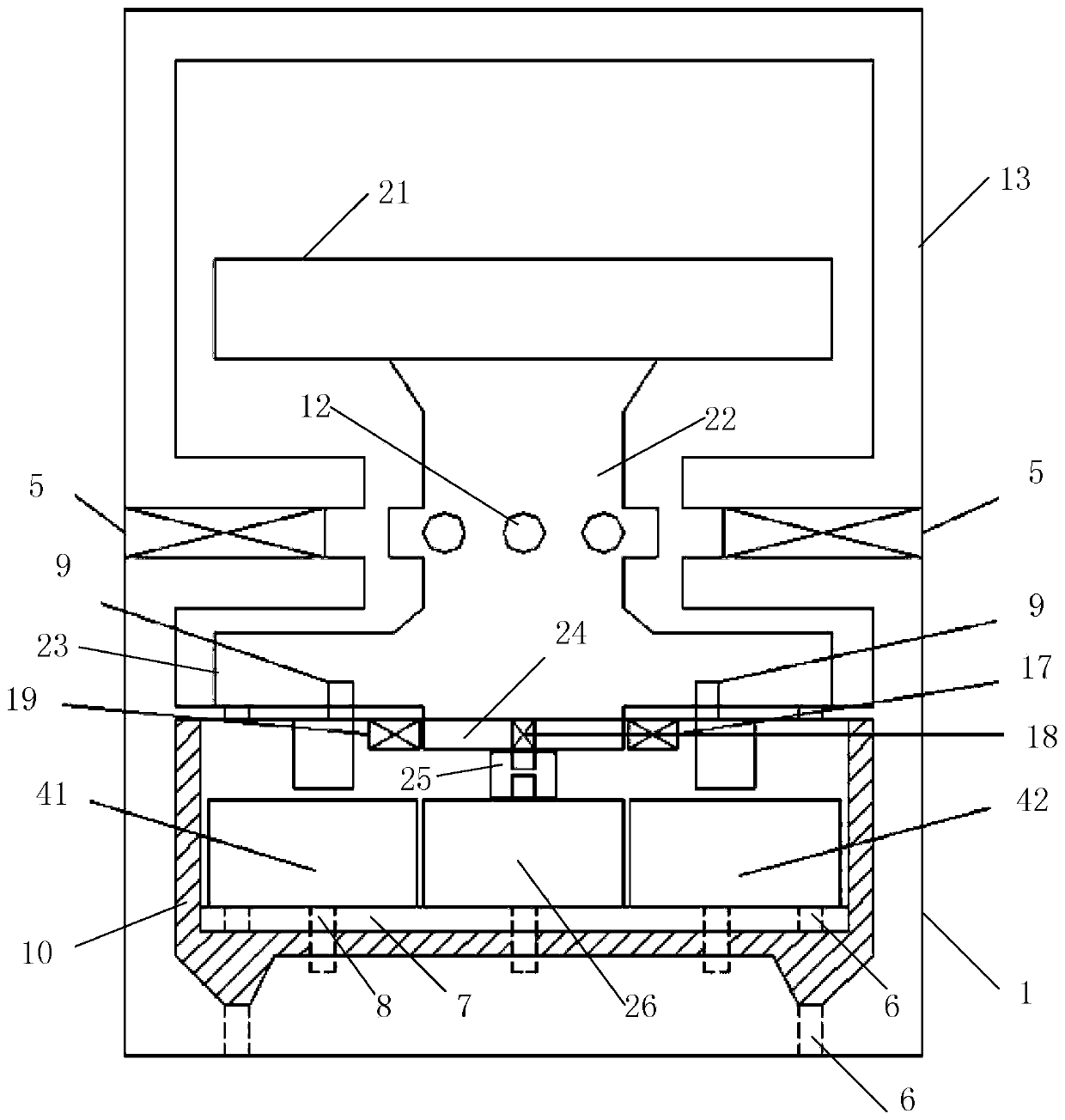

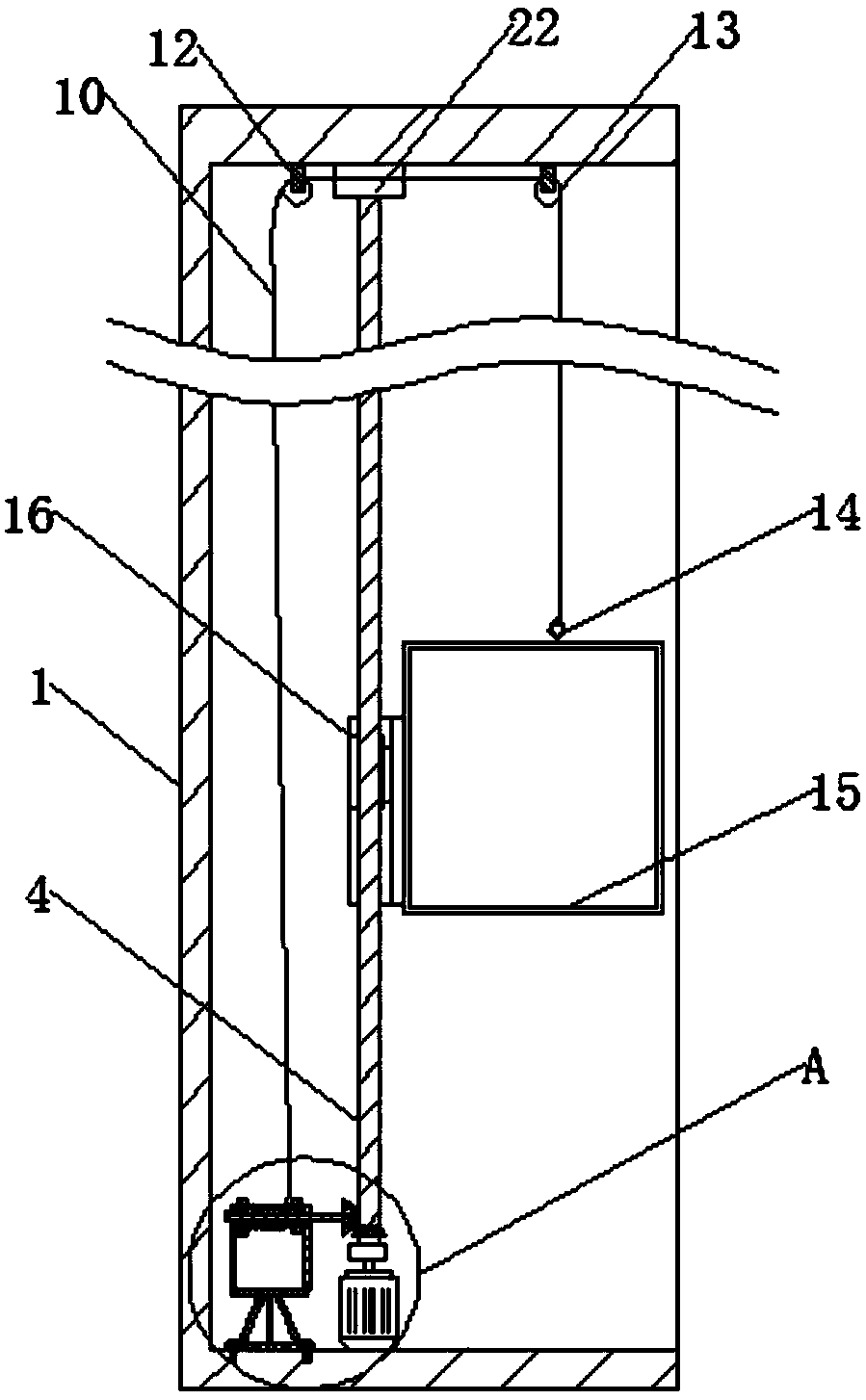

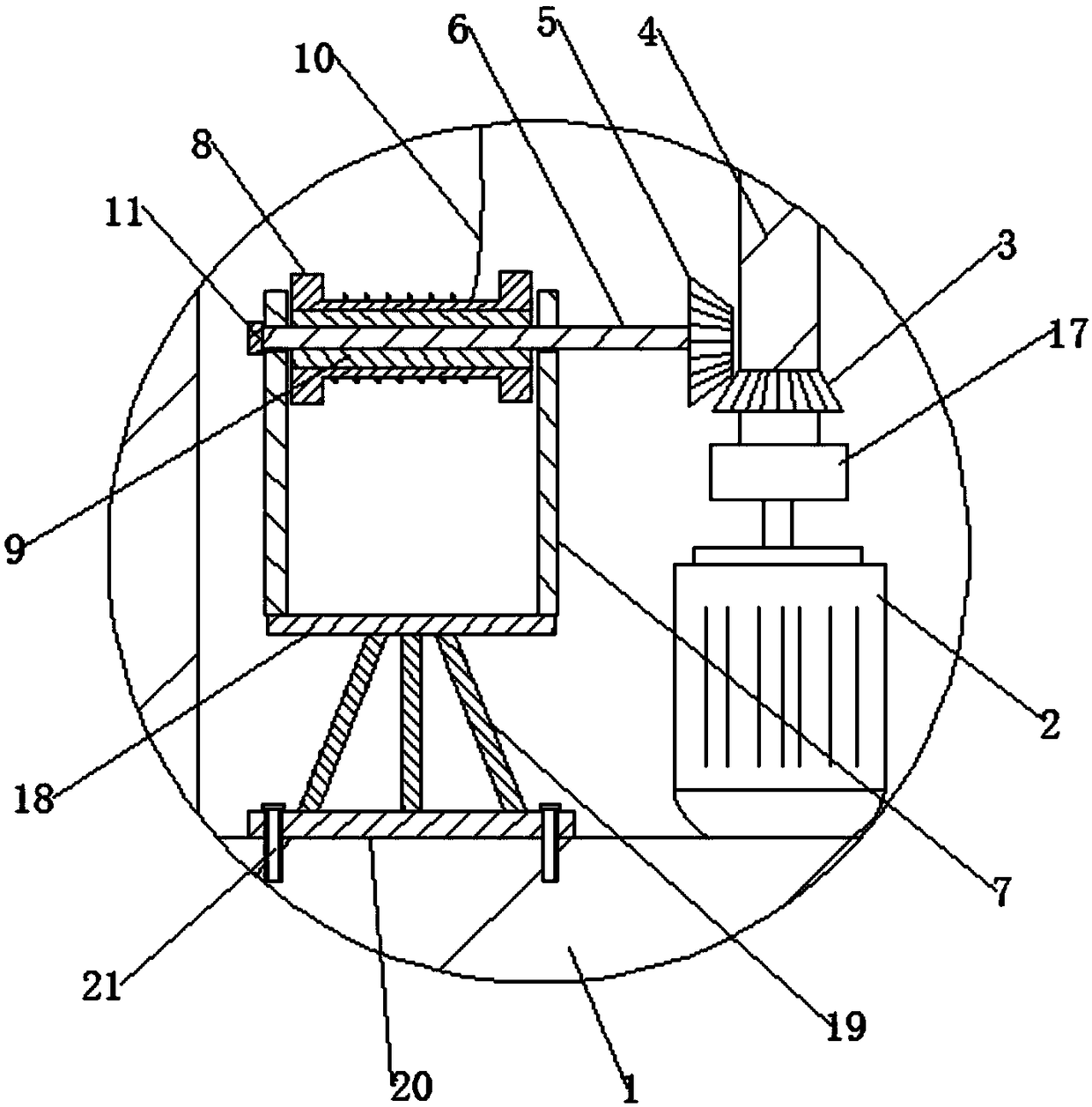

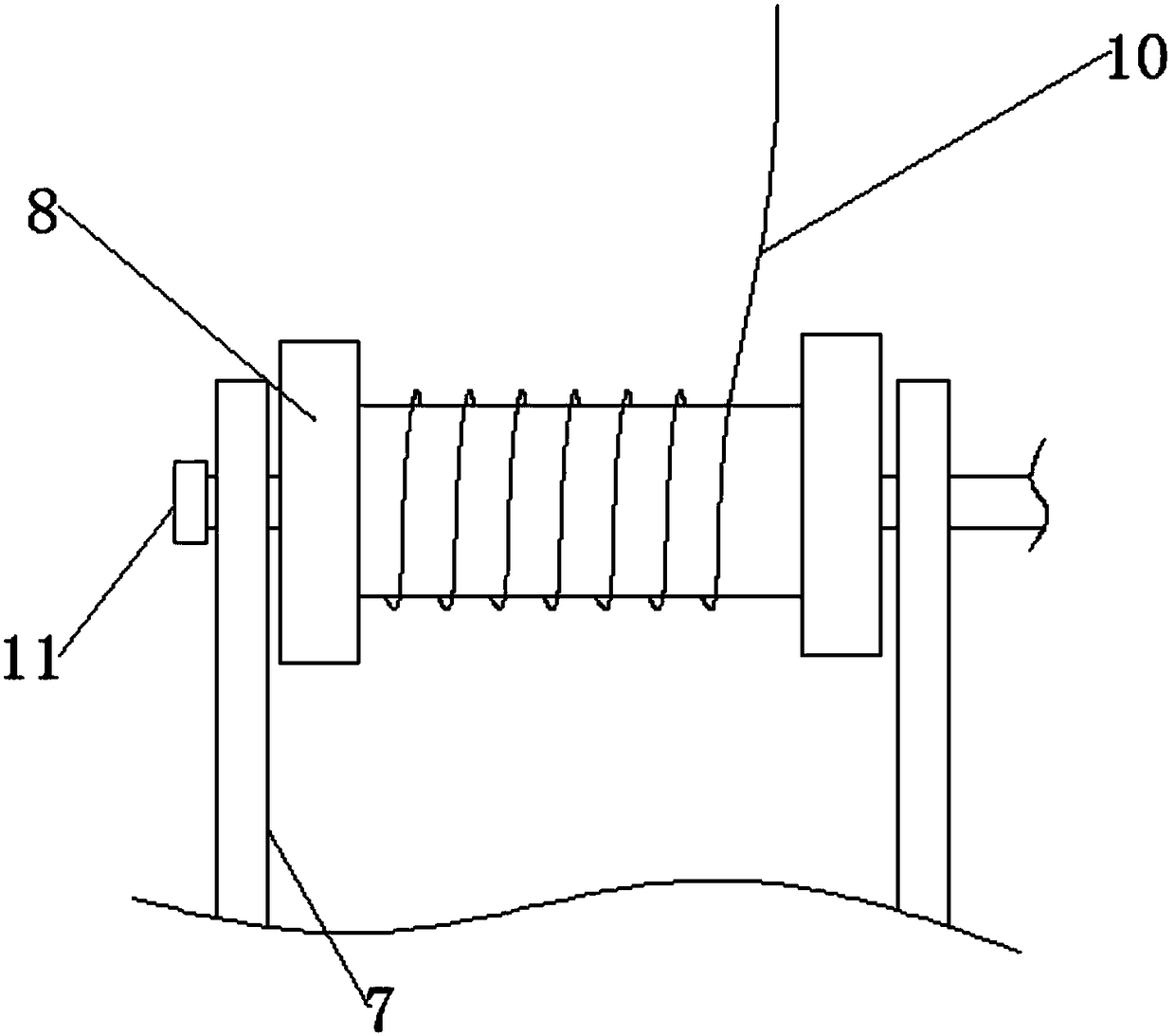

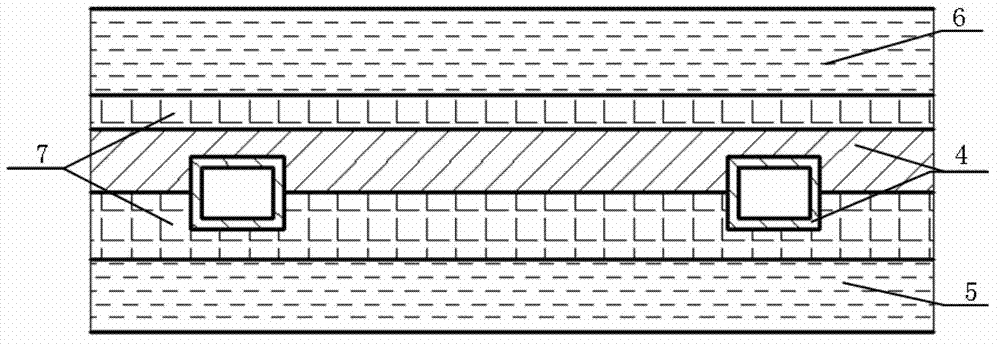

Sleeper with vibration reduction and energy collection characteristics

PendingCN111877057AWith vibration reductionWith characteristicsBatteries circuit arrangementsPiezoelectric/electrostriction/magnetostriction machinesControl theorySteel tube

The invention discloses a sleeper with vibration reduction and energy collection characteristics, and the sleeper comprises a sleeper main body and a vibration reduction and energy collection assemblyarranged in the sleeper main body; the vibration reduction and energy collection assembly comprises a steel box chamber, and a steel pipe, a mass block, a spring, a damper and a piezoelectric unit which are arranged in the steel box chamber; the upper end and the lower end of the steel pipe are respectively and rigidly connected with a top plate and a bottom plate of the steel box chamber; the mass block is slidably connected with the steel pipe, the upper end of the spring is rigidly connected with the lower surface of the mass block, and the lower end of the spring is rigidly connected witha bottom plate of the steel chamber; the two dampers are symmetrically arranged, the upper ends of the dampers are rigidly connected with the lower surface of the mass block, and the lower ends of the dampers are rigidly connected with a bottom plate of the steel box chamber; and the piezoelectric unit is arranged on the upper surface of the mass block and is electrically connected with a rectifier outside the sleeper. By the adoption of the vibration energy recycling device, control over vibration transmitted to the sleeper can be achieved, vibration transmitted to a ballast bed is well attenuated, and vibration energy recycling can be achieved.

Owner:GUANGZHOU METRO DESIGN & RES INST

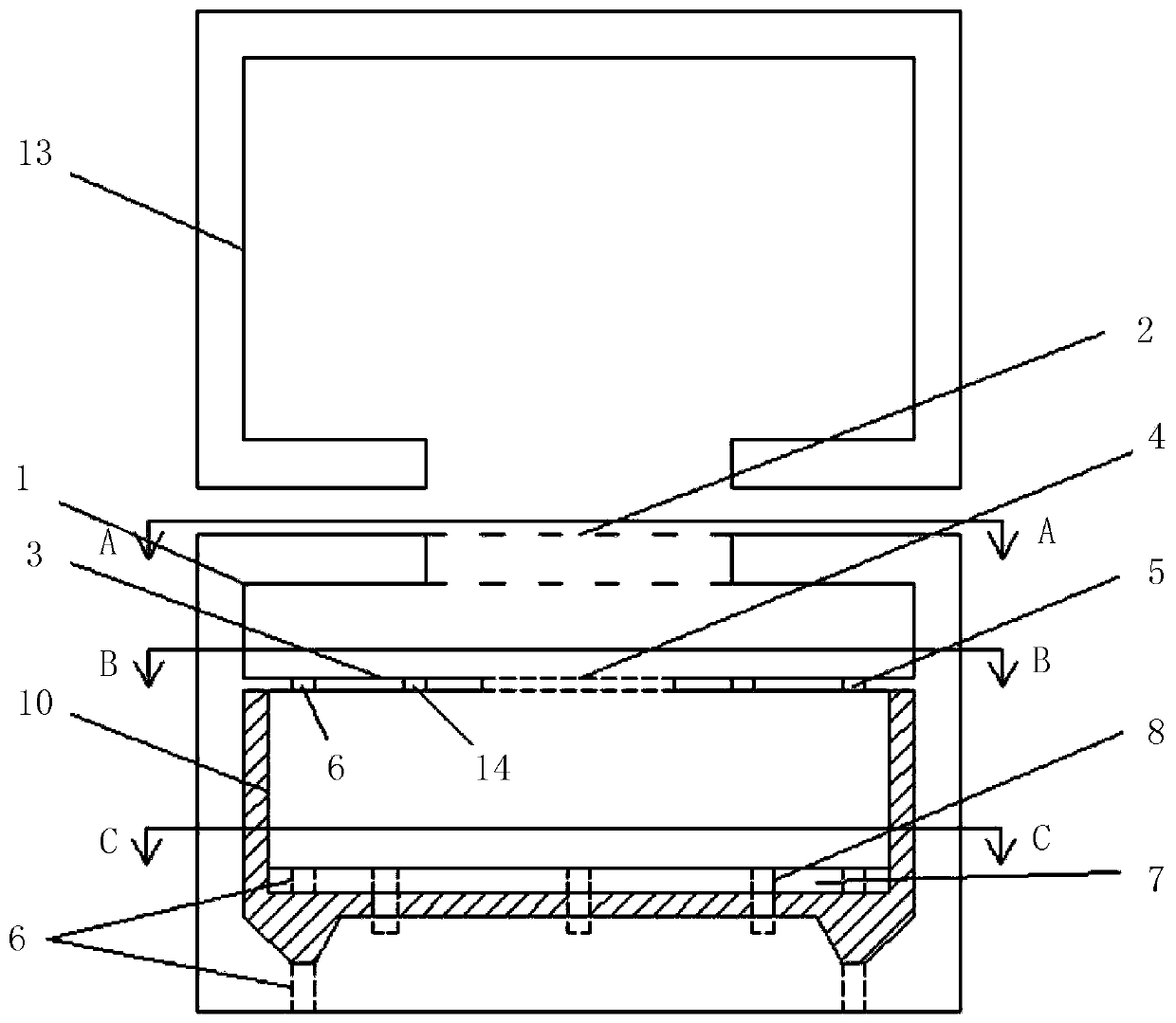

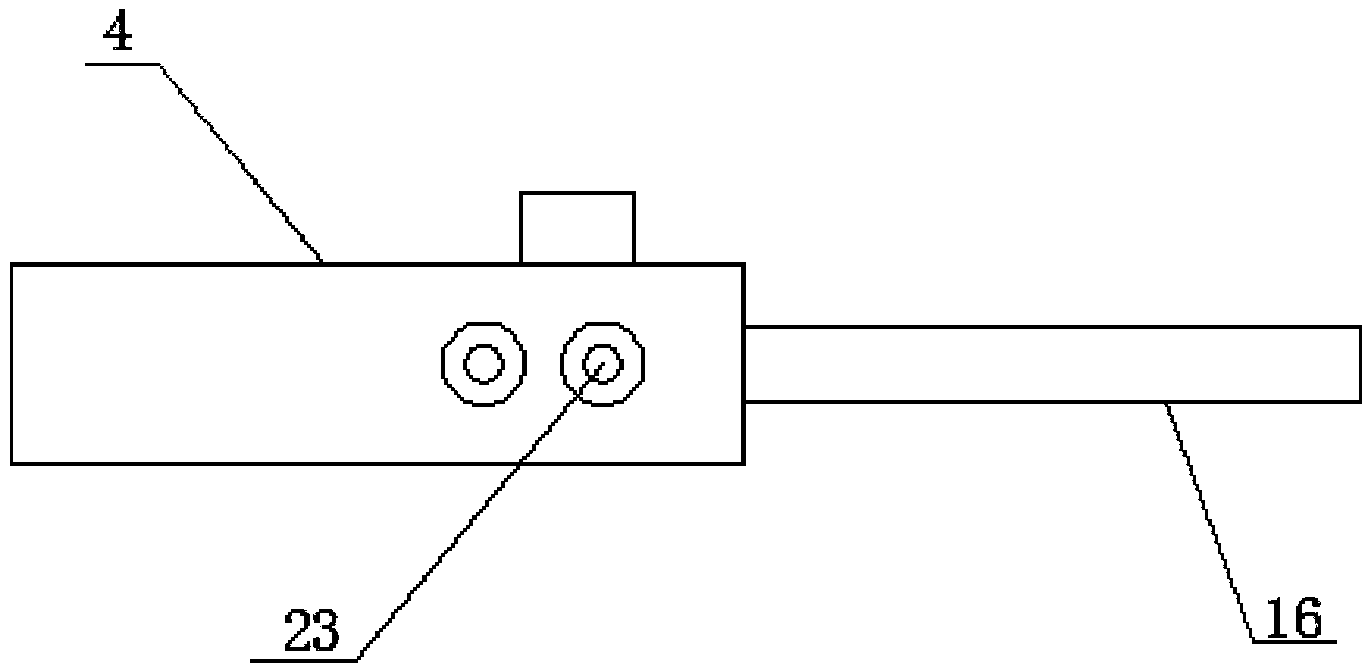

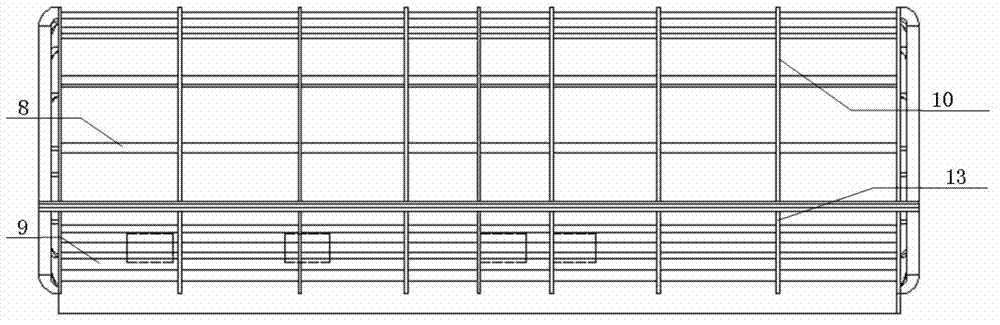

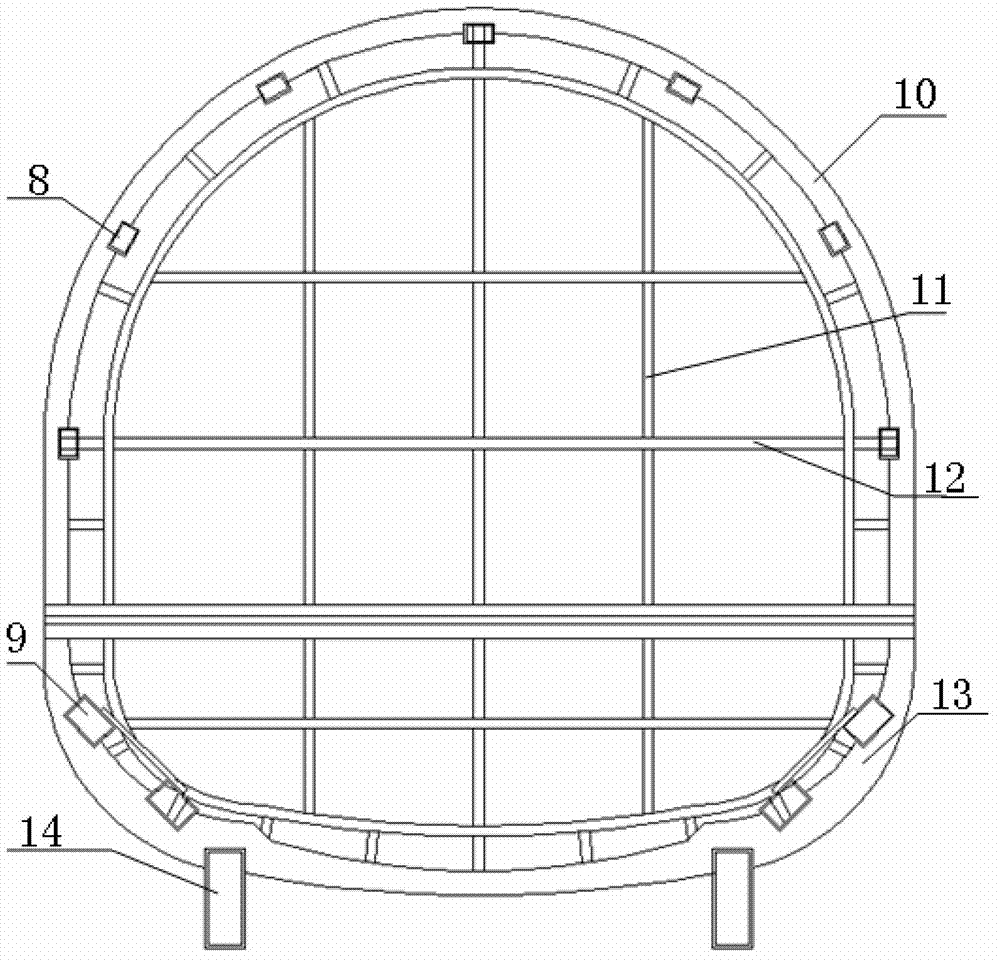

Intelligent lock used for container platform lorry and locking method of intelligent lock

PendingCN109733272AAchieve vibration reductionRealize drainageLoad securingRemote controlEngineering

The invention provides an intelligent lock used for a container platform lorry. The intelligent lock is connected with a corner fitting at the vertex angle of the bottom of a container and comprises alock seat, a motor, a sensor unit and a unit controller, wherein the lock seat comprises a lock seat body and a lock body, and the lock seat body is fixed to the platform lorry and corresponds to thecorner fitting in position; the lock body is of an I-shaped structure, and the two ends of the lock body penetrate through the bottom of the corner fitting and the top of the lock seat and are located in an inner cavity of the corner fitting and an inner cavity of the lock seat; the motor is arranged in the lock seat and drives the lock body to rotate; the sensor unit is connected with the lock seat and obtains container bearing information and lock body on-off state information; and the unit controller is arranged in the lock seat, wirelessly sends the information acquired by the sensor unitto a vehicle-mounted integrated controller and a remote control center, receives commands of the vehicle-mounted integrated controller and the remote control center to drive the motor to work and achieves automatic unlocking and locking functions. The invention further provides a method for locking the container and the platform lorry. The intelligent lock is reliable in use, a container fasteneris intelligent, and work efficiency is improved.

Owner:SHANGHAI MARITIME UNIVERSITY

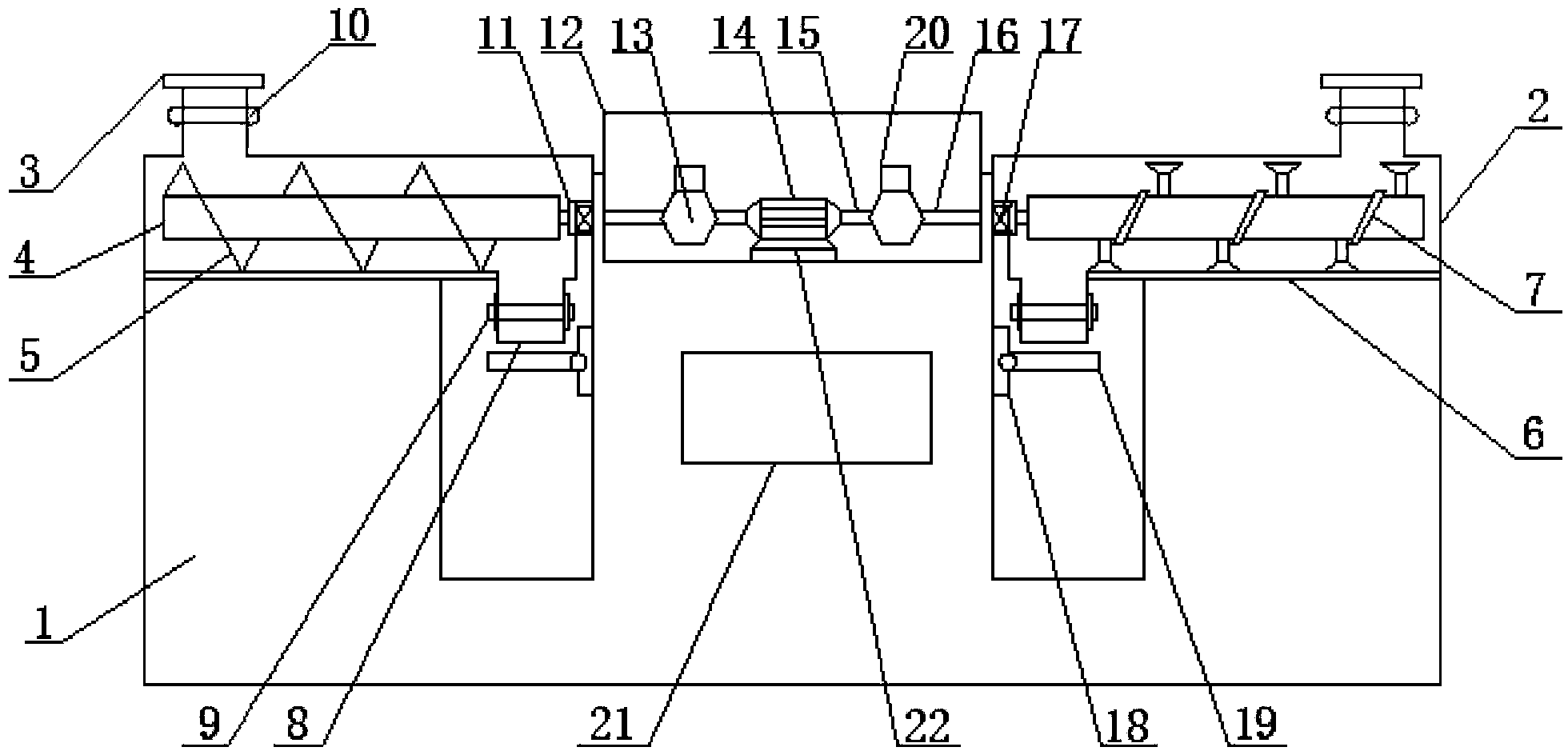

Material seal two-screw conveyer

The invention relates to a material seal two-screw conveyer which structurally comprises a machine base, conveying devices and an electric motor. Two out shafts of the electric motor are connected with the two conveying devices through couplers respectively. Each conveying device comprises a conveying machine shell, a screw rotation shaft and a material trough, the material trough is located in the bottom of the conveying machine shell, the two screw rotation shafts are respectively provided with fully-face type blades or trough paddle type blades, the screw rotation shafts are connected with the couplers through a connecting shaft, and the connecting shaft is connected with the machine base through a bearing. According to the material seal two-screw conveyer, two-screw conveying can be conducted, meanwhile most materials such as powdery materials, granular materials and liquid can be conveyed through the conveyer, and practicability of the conveyer is increased; the conveyer further has the functions of vibration reduction and self-protection, the service life of the conveyer is greatly prolonged, and the conveyer has good leakproofness and can meet certain special work requirements.

Owner:DANYANG ZHENGDA OIL

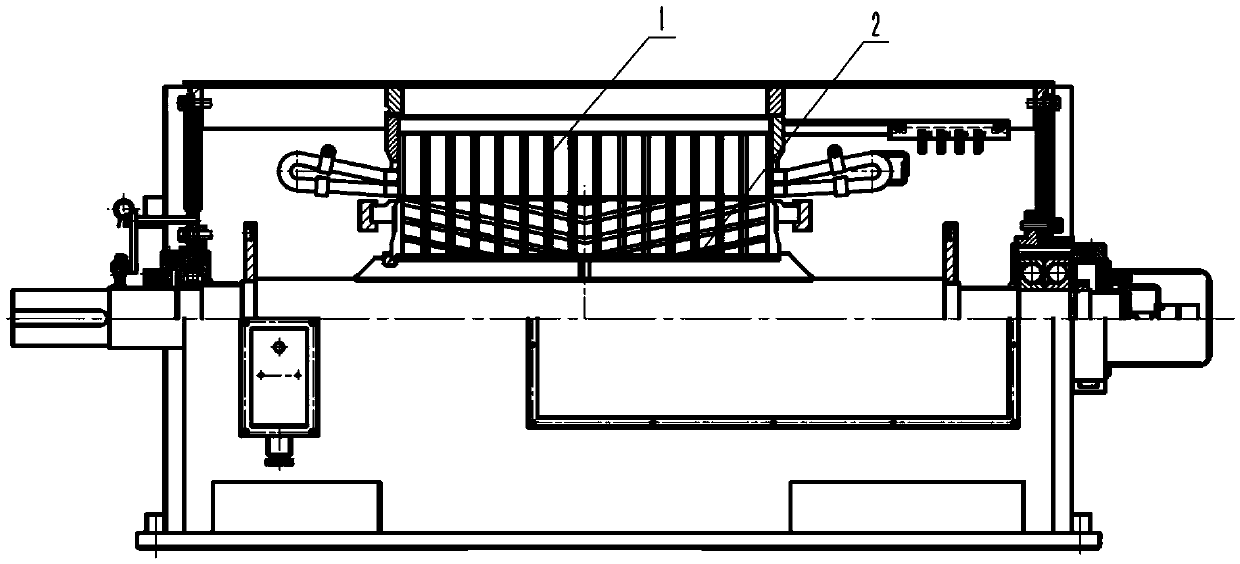

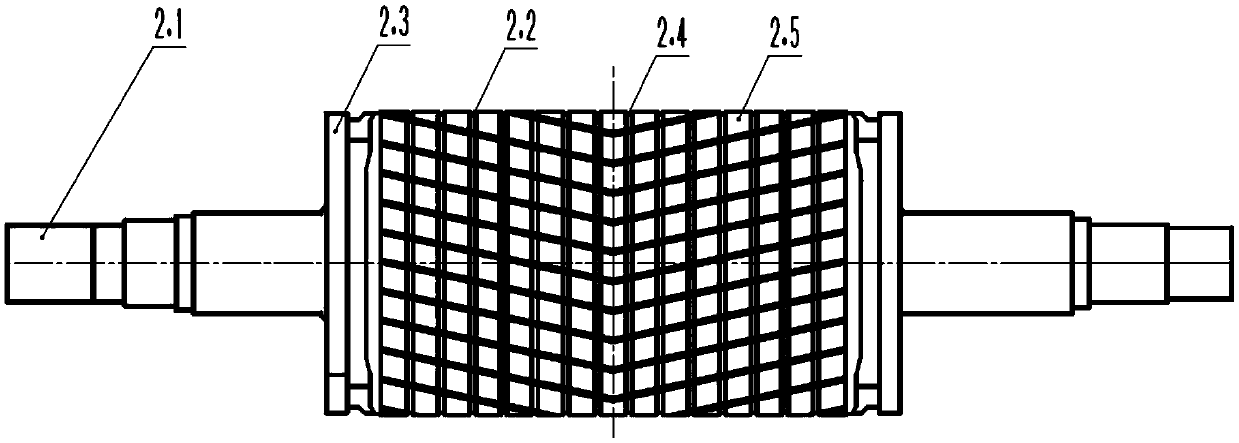

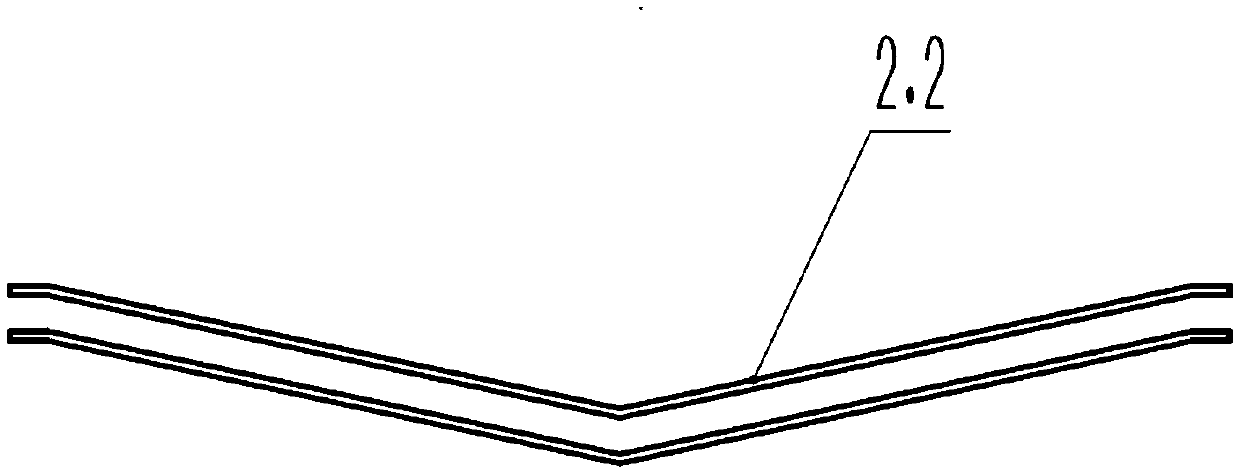

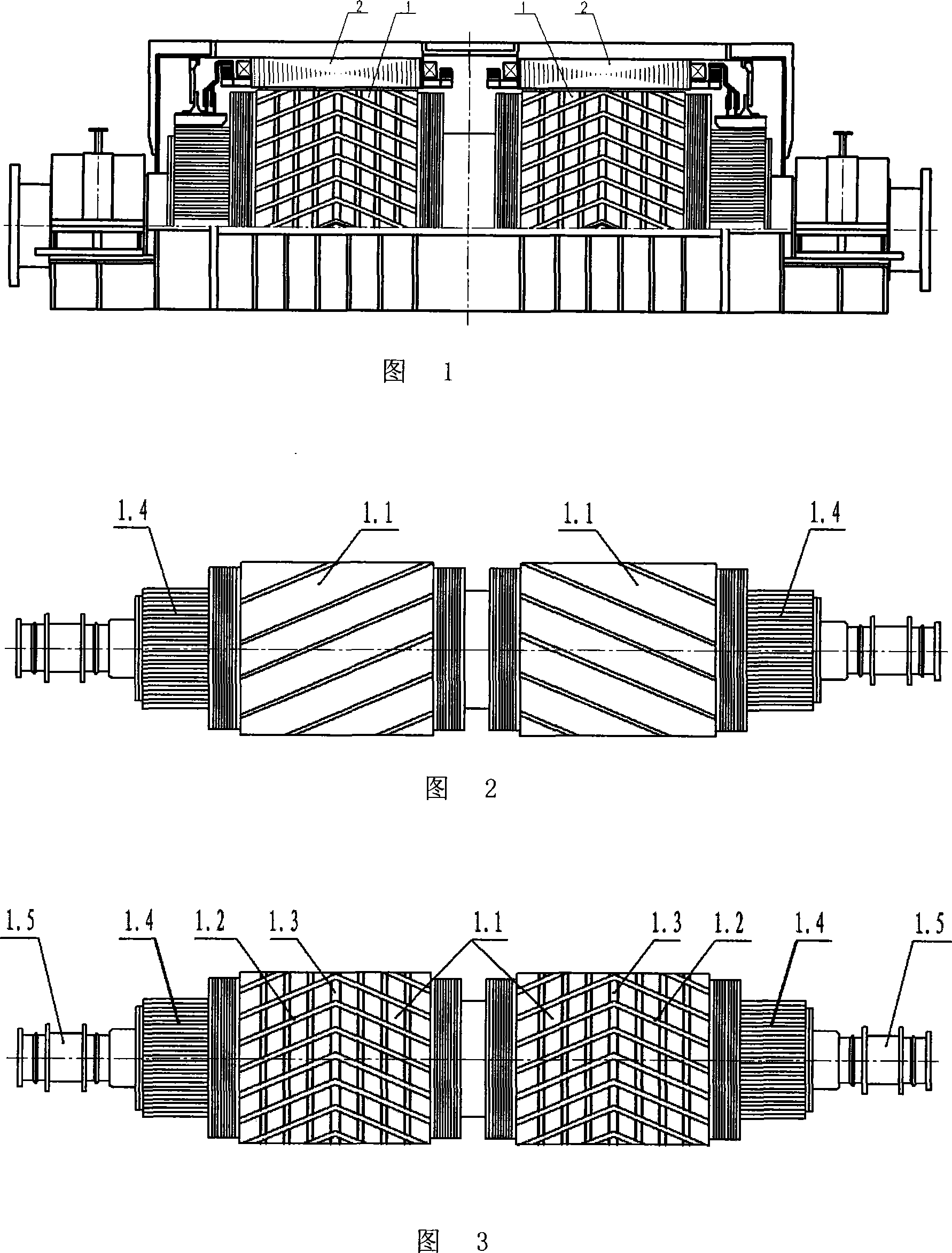

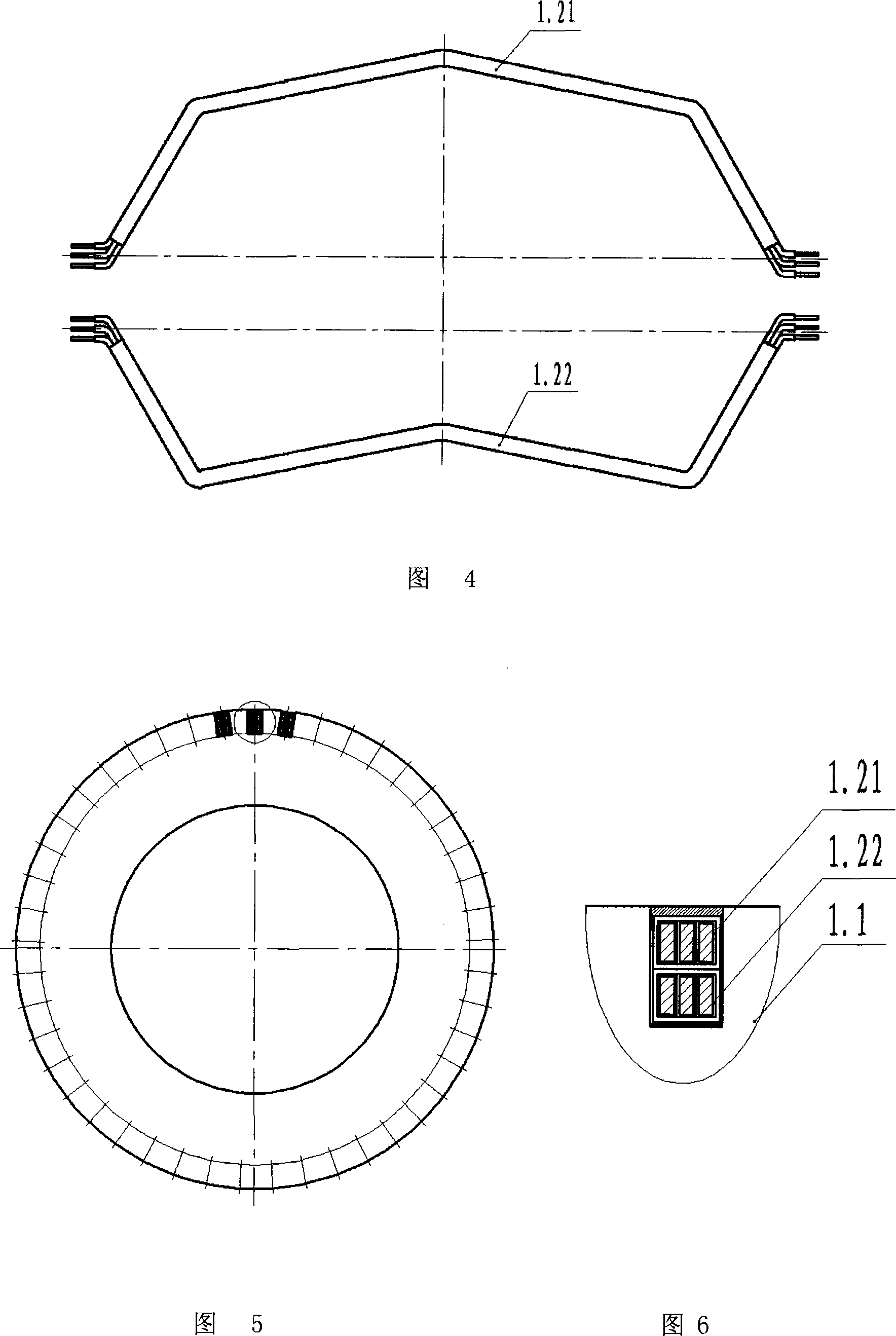

Induction motor

InactiveCN105515236AReduce electromagnetic vibrationEasy to fixMagnetic circuit rotating partsInduction motorWorking environment

The invention discloses an induction motor which comprises a rotor and a stator. The rotor comprises a rotating shaft, two end rings, multiple rotor ventilating groove plates, multiple rotor iron cores, multiple V-shaped guide bars mutually independent, wherein the two end rings are installed on the rotating shaft in a spaced mode, the rotor ventilating groove plates and the rotor iron cores are located between two end rings, installed on the rotating shaft and arranged alternately, the V-shaped guide bars are sequentially installed on the rotor iron cores in the circumferential direction, the two ends of any guide bar are connected with the two end rings in a one-to-one corresponding mode, a plurality of V-shaped installing grooves are uniformly formed in the rotor iron cores in the axial direction, and the guide bars are installed in the multiple installing grooves in a one-to-one corresponding mode. According to the induction motor, the V-shaped installing grooves on the rotor iron cores are symmetrical inclined grooves, radial force can be reduced, amplitude and noise are reduced, working environment is improved, it is ensured that electromagnetic vibration of the motor in the forward and reverse operation process is restrained to the maximum degree, and the operation effect is better.

Owner:CHINA NAT OFFSHORE OIL CORP +1

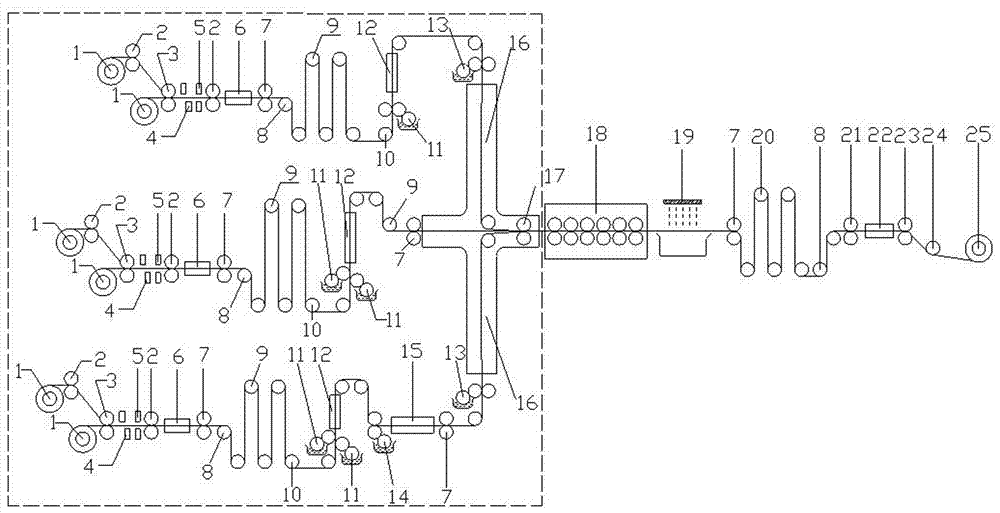

Production method for continuous functional composite material

ActiveCN107571593AImprove surface qualityHigh bonding strengthLamination ancillary operationsPretreated surfacesThermal insulationPipe insulation

The invention provides a production method for a continuous functional composite material. The invention mainly aims to deeply improve and optimize a present production technology and produce two-layer and three-layer functional composite materials with higher applicability and higher bonding property. The product produced according to the method is capable of continuously and stably working at -20 DEG C to 100 DEG C; the product has multiple functions, such as vibration reduction, noise reduction, sound insulation, heat insulation and magnetism resistance; the product is a novel environment-friendly functional composite material and has wide application prospect.

Owner:嘉峪关天源新材料有限责任公司

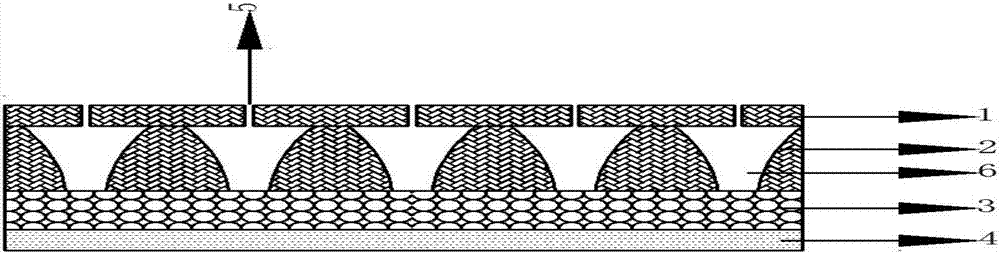

Cavity sound-absorbing material damping plate and preparation method thereof

ActiveCN106926518AReduce transmissionPromote disseminationSynthetic resin layered productsVehicle componentsEpoxySurface layer

The invention provides a cavity sound-absorbing material damping plate and a preparation method thereof. The damping plate is composed of a surface layer, a cavity layer, an EPDM (Ethylene-Propylene-Diene Monomer) foaming sound absorbing layer and a modified epoxy resin adhesive layer which are sequentially arranged from top to bottom. The surface layer is a polyvinyl chloride artificial leather material, and round holes are punched in the surface layer; and a horn type cavity is formed in the cavity layer and is of a structure which is wide in top and narrow in bottom. The cavity sound-absorbing material damping plate disclosed by the invention has the beneficial effects that noise in a vehicle enters a small circular pore diameter structure in the surface layer through sound vibration, and then noise vibration enters the wide space in the horn type cavity again, so that the noise energy is suddenly dispersed and then lost. As the horn type cavity is of the structure which is wide in top and narrow in bottom, the residual sound energy enters the narrow space and then is lost. After the noise vibration passes through the horn type cavity, vibration energy in the noise is absorbed by the EPDM foam layer, and harsh noise on the surface of the EPDM foam layer generates the interference and diffuse reflection phenomenon so as to reduce propagation of the noise.

Owner:天津市浩迪橡塑科技有限公司

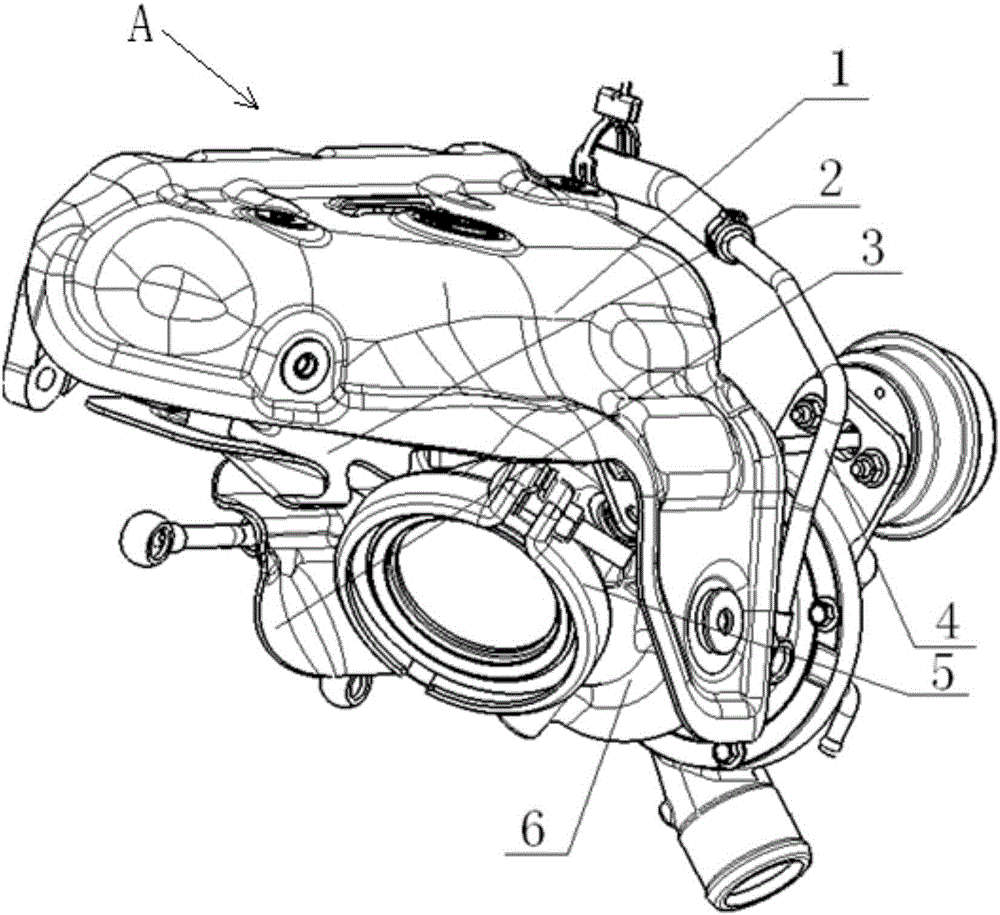

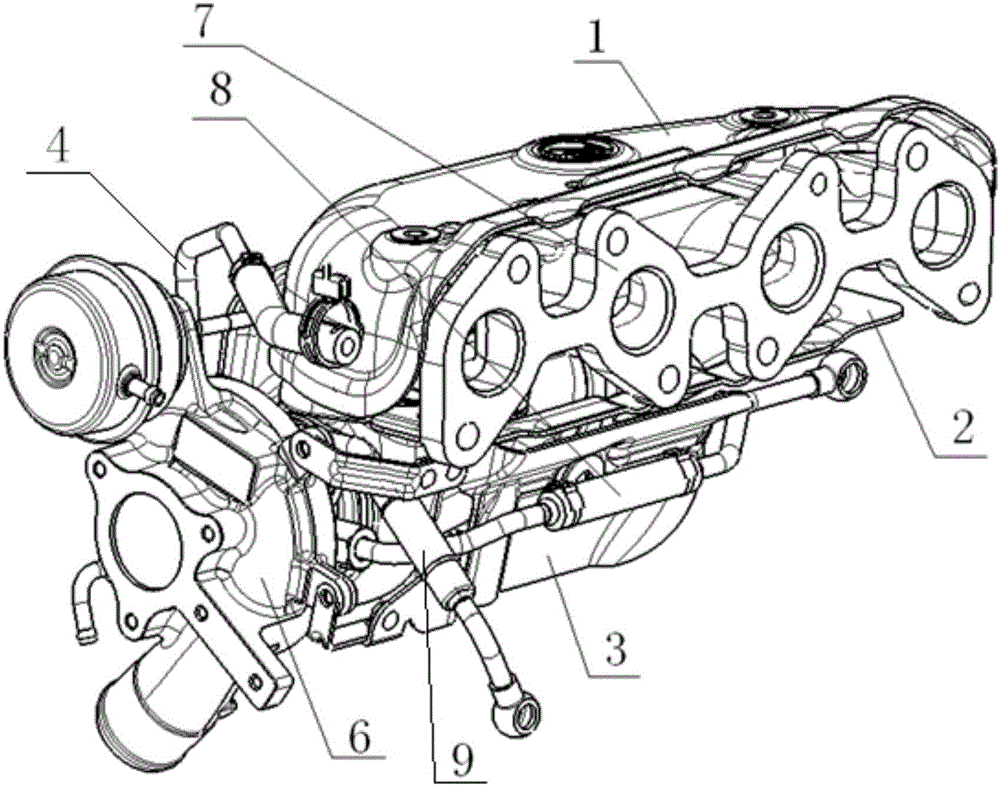

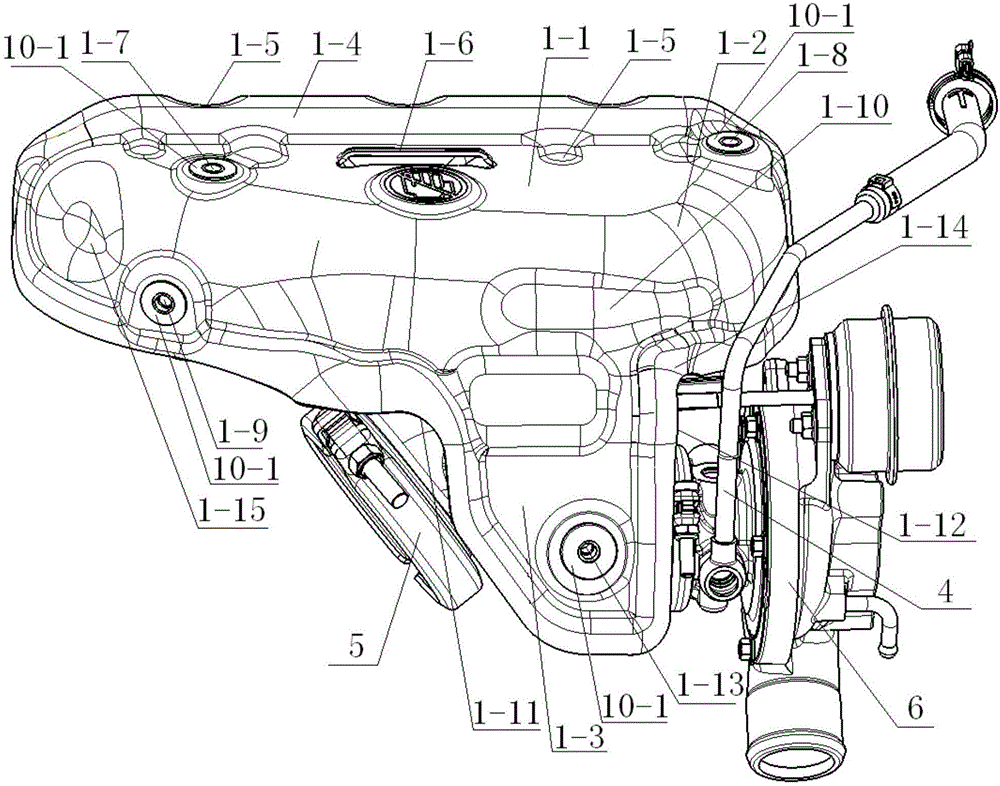

Thermal shroud assembly of supercharged engine

ActiveCN106703963AGood NVH performanceWith vibration reductionExhaust apparatusNon-rotating vibration suppressionNoise, vibration, and harshnessEngineering

The invention discloses a thermal shroud assembly of a supercharged engine. The thermal shroud assembly comprises an upper exhaust manifold shroud, a lower exhaust manifold shroud and a lower supercharge shroud, wherein the upper exhaust manifold shroud consists of a flat plate, a transition arc-surface plate and a rear side plate; an arc convex rib is arranged on the front edge of the flat plate; a vent hole is formed in the middle of the flat plate; an avoiding bulge is arranged on the right side of the transition arc-surface plate; a hoop avoiding notch is formed in the left part of the rear side plate; a return water tube avoiding notch is formed in the right part of the rear side plate; an abdication groove is formed in the front side of the lower exhaust manifold shroud; an abdication arc surface is arranged on the left part of the rear side of the lower exhaust manifold shroud; an avoiding arc surface is arranged at the right part of the rear side of the lower exhaust manifold shroud; the lower supercharger shroud comprises a first bracket, a second bracket and a lower shroud body; an abdication notch is formed in the right side of the lower shroud body; a connecting arm is arranged at the right end of the upper side of the lower shroud body; a triangular connecting plate is arranged at the right end of the lower side of e lower shroud body; an arc avoiding groove is formed in the lower side of the lower shroud body. By adopting the thermal shroud assembly, thermal conduction can be effectively cut off under the condition that a sufficient part assembling space is ensured, and meanwhile the thermal shroud assembly has good NVH (Noise Vibration and Harshness) performance.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

DC propulsion motor

InactiveCN101114790AGood technical effectNormal functioningDC commutatorWorking environmentEngineering

The invention relates to a direct current propulsion motor which belongs to the field of motor technology, which is particularly suitable for the direct current propulsion motor which is used for medium vessel and large vessel. The invention comprises a rotor and a stator, wherein the rotor comprises an armature core, an armature winding, a radical ventilation duct, a commutator and a rotating shaft; the armature winding which is distributed on the external circumference surface of the armature core is inverted 'V'-shaped; the inverted 'V'-shaped armature winding consists of an inverted 'V'-shaped upper coil of winding insulation and an inverted 'V'-shaped lower coil of winding insulation which are both of half-style structure and are embedded into an inverted 'V'-shaped skewed slot of the armature core. The invention has the advantages that: the radial electromagnetic force of the motor is reduced; the amplitude and the vibration noise are reduced; the working environment is improved; the electromagnetic vibration of a whole motor base is reduced; the electromagnetic vibration in the whole speed range of the motor is assuredly promoted to be restricted to the greatest degree; the operation effect is better; and the function is much better exerted.

Owner:中国船舶重工集团公司第七一二研究所

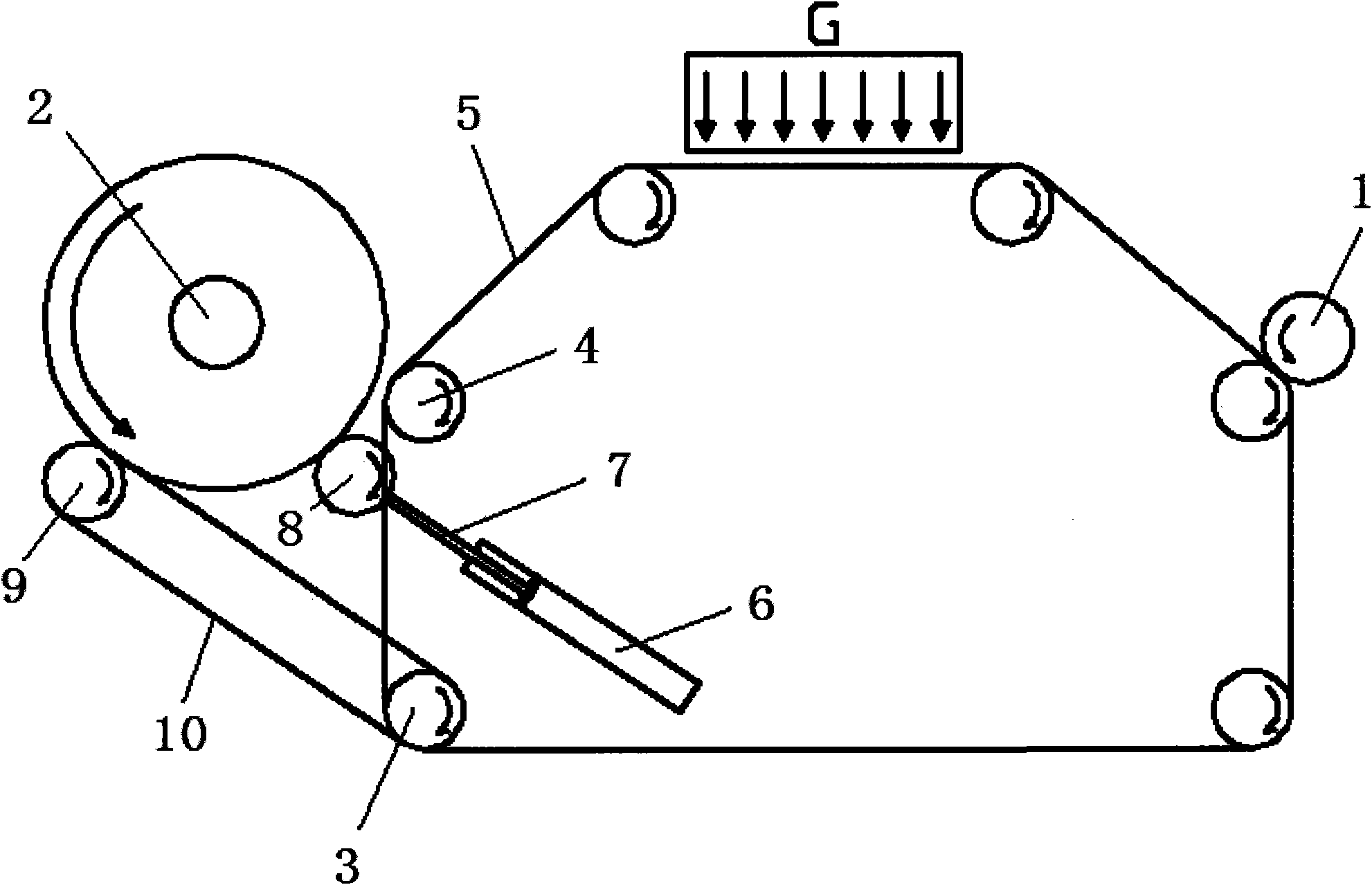

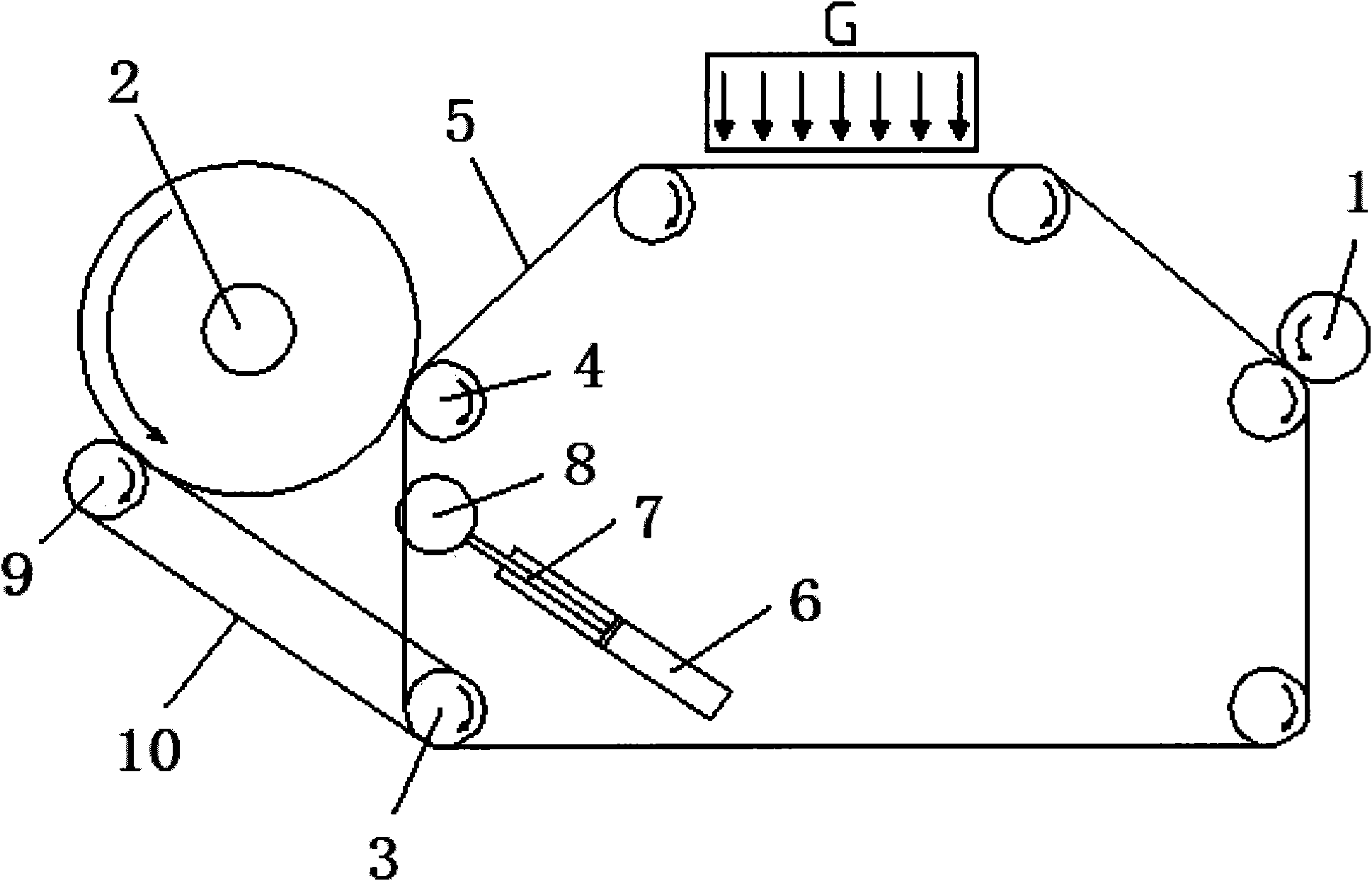

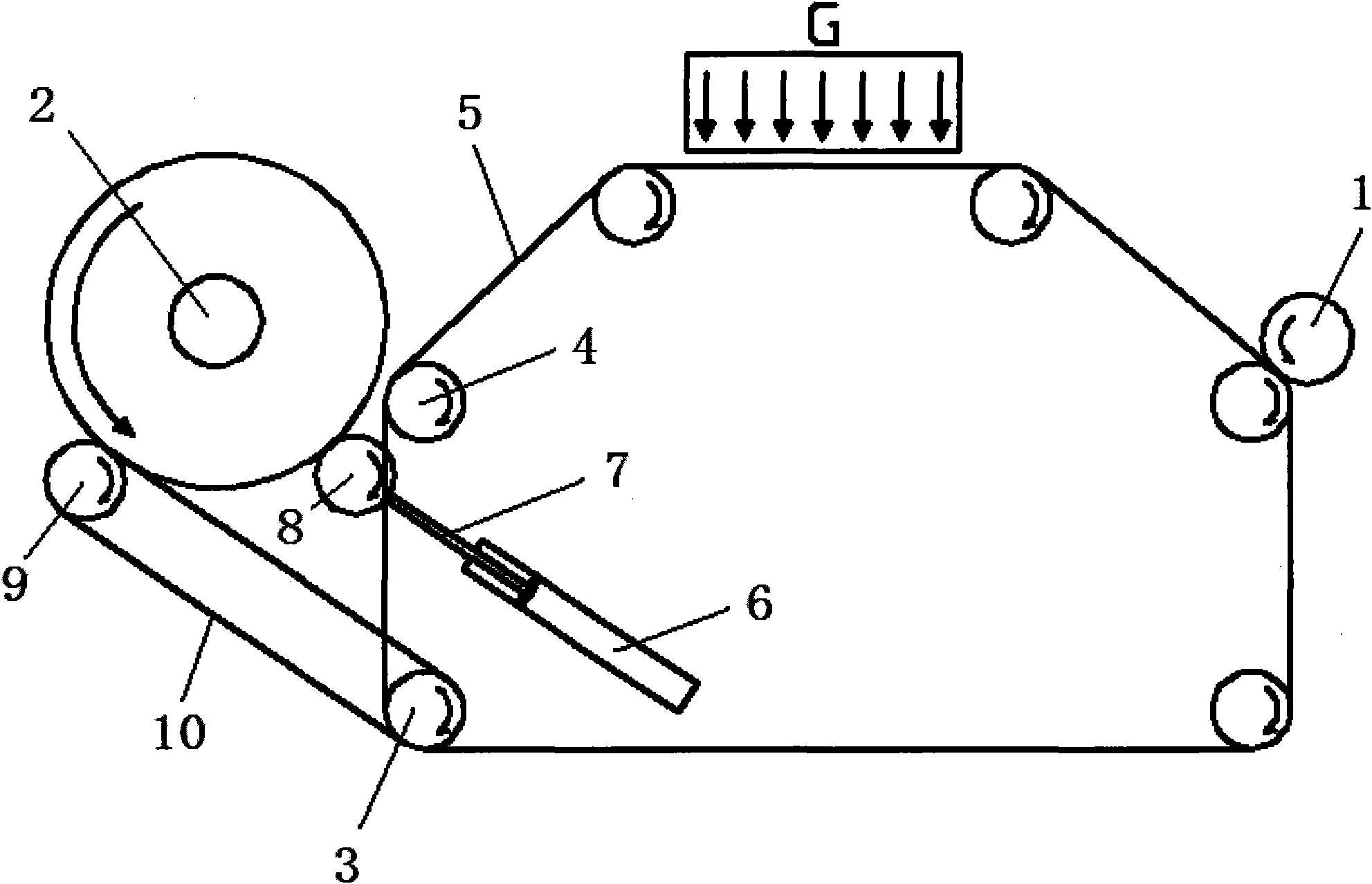

Synchronous rolling device of thin material punching machine

InactiveCN101955079AAccurate transmissionSmooth transmissionArticle deliveryWebs handlingPaper sheetWork status

The invention discloses a synchronous rolling device of a thin material punching machine. A rolling shaft and an unrolling shaft are respectively positioned at both ends of a synchronous belt wheel paper feeding mechanism and can be nestled to a main circulating conveyor belt on the synchronous belt wheel paper feeding mechanism and driven to rotate by friction of the main circulating conveyor belt, wherein the unrolling shaft can be synchronously released from or nestled to the main circulating conveyor belt to act under the drive of an unrolling shaft drive mechanism so as to be converted between two working states; in the first working state, the unrolling shaft can not be driven to rotate by the friction of the main circulating conveyor belt; in the second working state, the unrolling shaft can be driven to rotate by the friction of the main circulating conveyor belt; and the rolling shaft can be freely released from or nestled to the main circulating drive belt to act. The invention provides the synchronous rolling device of the thin material punching machine, which can achieve zero meter start under the premise of not wasting the thin material.

Owner:苏州市博海激光科技有限公司

Novel screw elevator

The invention relates to the field of elevators, and discloses a novel screw elevator. The novel screw elevator comprises a mounting frame; the mounting frame is of a hollow structure, and the right end of the mounting frame is open; the lower end in the mounting frame is fixedly connected with a motor; a screw is arranged on the upper side of the motor; the upper end in the mounting frame is sequentially fixedly connected with a first fixed pulley and a second fixed pulley from left to right; the power output end of the motor is fixedly connected with a first conical gear, and the upper end of the first conical gear is fixedly connected with the screw; the left end of the first conical gear is connected with a second conical gear in an engaged mode; the left end of the second conical gearis fixedly connected with a rotating rod; and a pair of fixing rods is fixedly connected to the lower end in the mounting frame and located on the left side of the second conical gear. A wire windingrope pulls a fixing circular ring at the upper end of a car to disperse the weight of the car during cargo loading or people loading, the pressure of a transmission nut during transmission is reduced, and the safety of the screw elevator during conveying is improved.

Owner:迅立达电梯有限公司

Preparation method of cork and solid wood cabinet boards

InactiveCN103568100AMoisture-proofMildew proofWood working apparatusFlat articlesSolid woodSurface layer

The invention provides a preparation method of cork and solid wood cabinet boards. The preparation method comprises the steps as follows: firstly, a cork and solid wood cabinet board surface layer particle fabric and a cork and solid wood cabinet board surface layer pattern fabric are prepared, and then the surface layer particle fabric and the surface layer pattern fabric are composited on the cabinet boards for pressurization, drying and trimming; or firstly, the surface layer particle fabric is prepared, then two surfaces of the surface layer particle fabric are composited on the cabinet boards by polyurethane glue, and the cork and solid wood cabinet boards with various patterns are printed by a printing machine. With the adoption of the preparation method, the cork and solid wood cabinet boards with different colors and various patterns can be prepared.

Owner:何永明

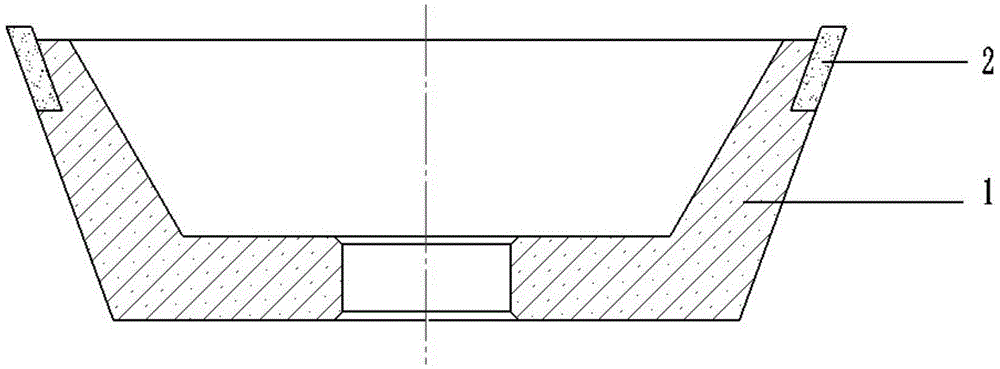

Engine packaging box with sealing function

InactiveCN102951372AHumanized structure designHigh protection levelPackaging vehiclesDomestic cooling apparatusHigh humidityMetal framework

The invention relates to an engine packaging box with a sealing function, which comprises a box body (1), a fixed bracket (2) and a damping device (3), wherein the box body (1) comprises a box bottom (9) and a box cover (8) which are connected by a hasp; the fixed bracket (2) is arranged in the box body (1); the damping device (3) is arranged between the fixed bracket (2) and the box body (1); the box body (1) comprises a metal frame (4), a glass reinforced plastic inner layer (5), a glass reinforced plastic outer layer (6) and a thermal insulating layer (7); the glass reinforced plastic inner layer (5) is arranged inside the metal frame (4); and the thermal insulating layer (7) and the glass reinforced plastic outer layer (6) are arranged on the outer layer of the metal frame (4) from near position to far position. The engine packaging box with the sealing function, which is specially provided by the invention, has a humanized structural design; the protection level can be improved, so that the packaging box can be used for storing and transporting aircraft engines in various harsh environments (such as high temperature, high humidity and high salt mist) without being limited by the environmental conditions.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

Graphene-reinforced PMI foam-pyramid sandwich panel composite structure and preparation method thereof

InactiveCN108638604AHigh tensile strengthImprove bending strengthMetal layered productsGrapheneSandwich panel

The invention discloses a graphene-reinforced PMI foam-pyramid sandwich panel composite structure and a preparation method thereof. The graphene-reinforced PMI foam-pyramid sandwich panel composite structure comprises panels and a pyramid lattice core body. The pyramid lattice core body is arranged between the two panels so that a pyramid lattice sandwich plate is formed. Graphene-reinforced PMI foam interstitially fills the pores of the pyramid lattice core body and reinforcing phase graphene is added to the graphene-reinforced PMI foam. The preparation method has a low cost, is easy to industrialize, and has wide application prospects in the fields of safety protection, transportation, machinery manufacturing, aerospace and the like.

Owner:XI AN JIAOTONG UNIV

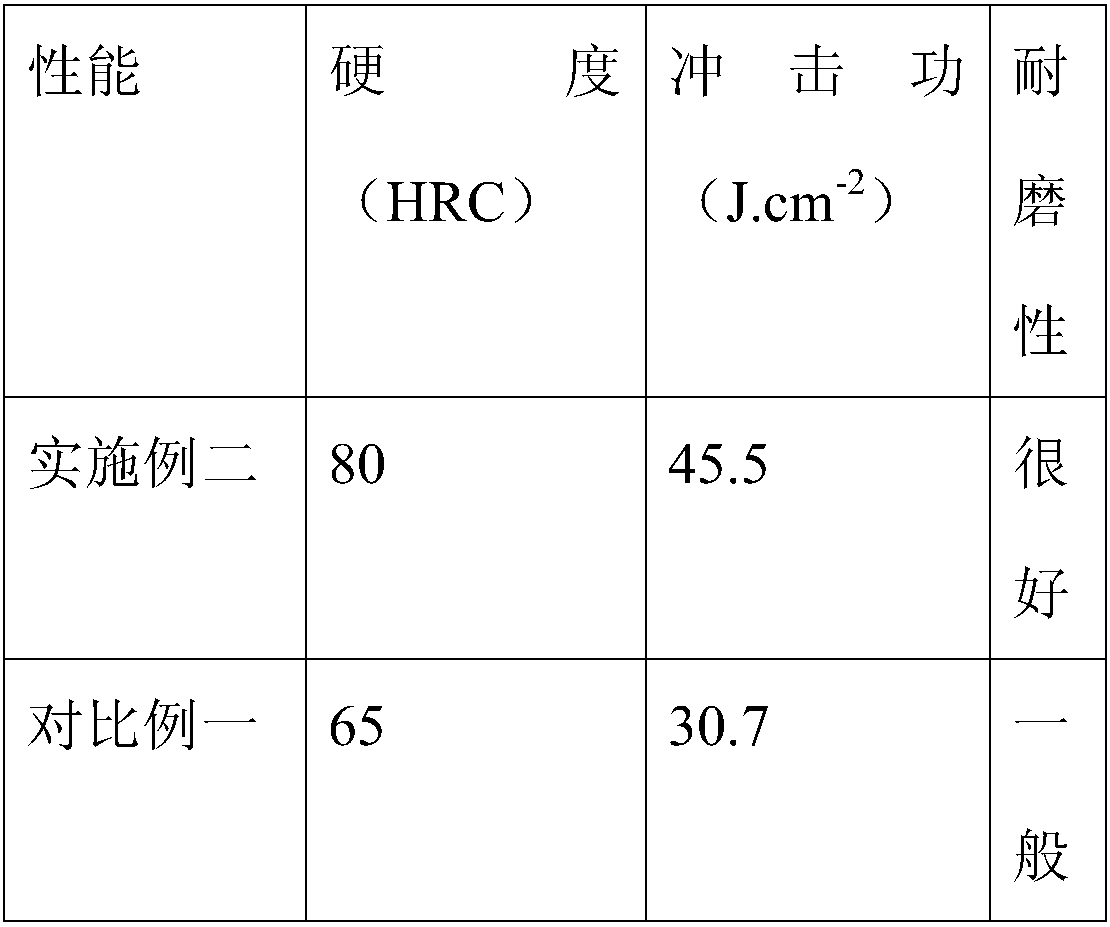

A kind of preparation method of iron-based composite material for automobile gear

ActiveCN106282853BImprove mechanical propertiesSound-absorbingLiquid/solution decomposition chemical coatingGear wheelThermal treatment

The invention discloses a preparation method of an iron-based composite material for an automobile gear. The preparation method sequentially comprises the following steps of 1, weighing ingredients by weight part to obtain a mixture; 2, performing pressing to obtain a workblank; 3, sintering the prepared workblank to obtain a sintered alloy block; 4, performing thermal treatment on the alloy block obtained after being treated in the third step and obtaining the iron-based composite material for the automobile gear. The method adopts the specific formula and technology, and the obtained iron-based composite material for the automobile gear is good in mechanical property, has the functions of sound absorption and vibration reduction and is particularly suitable for preparing the automobile gear.

Owner:宁波新睦科技有限公司

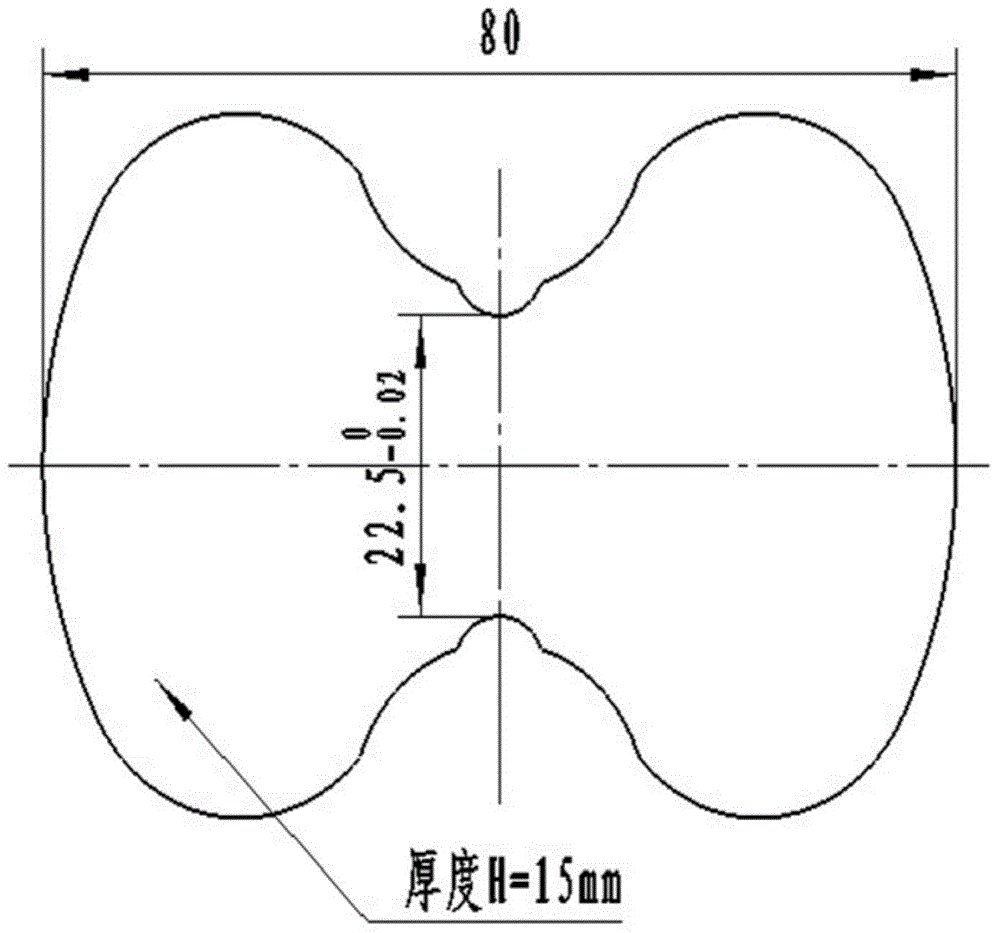

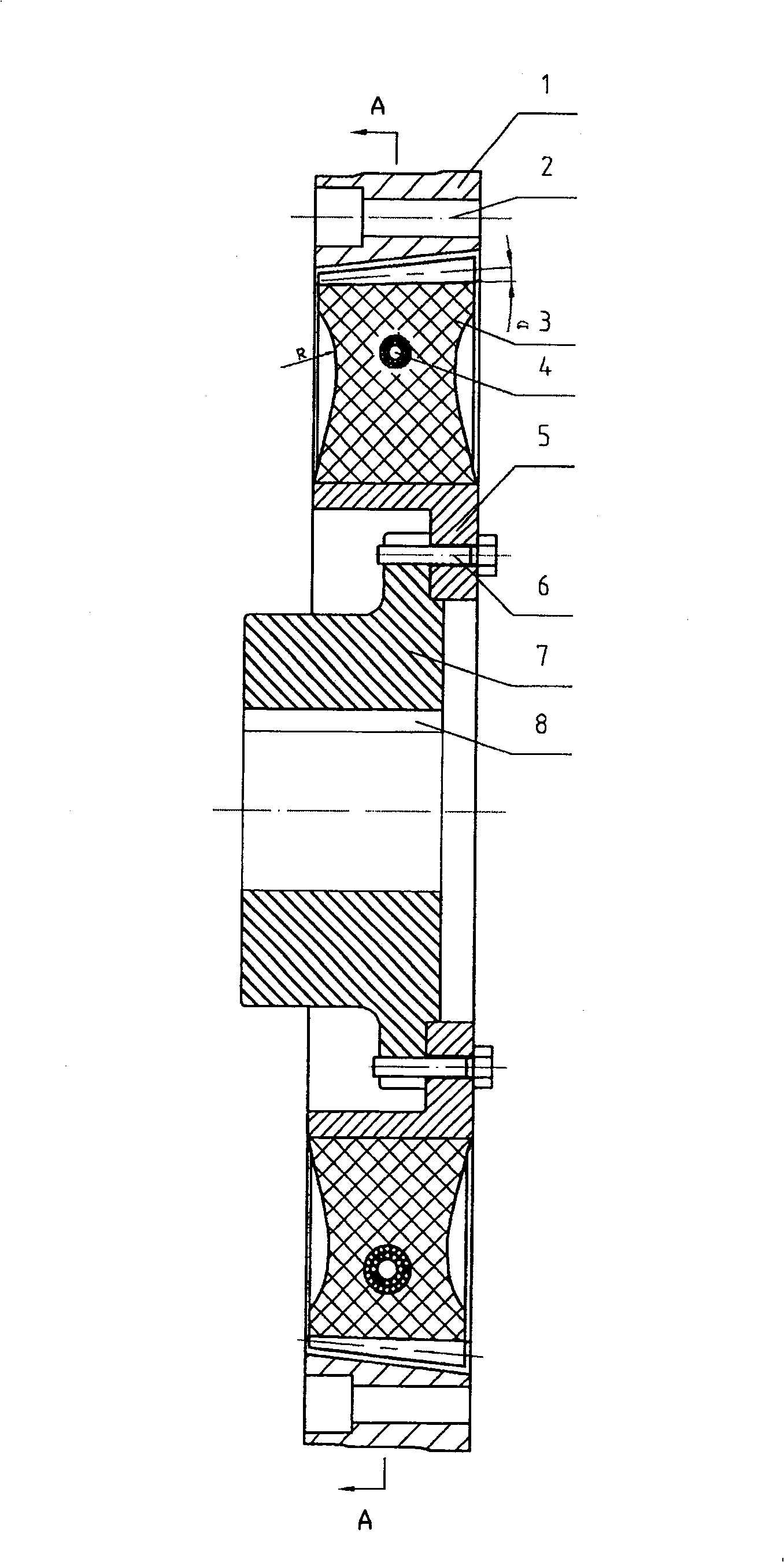

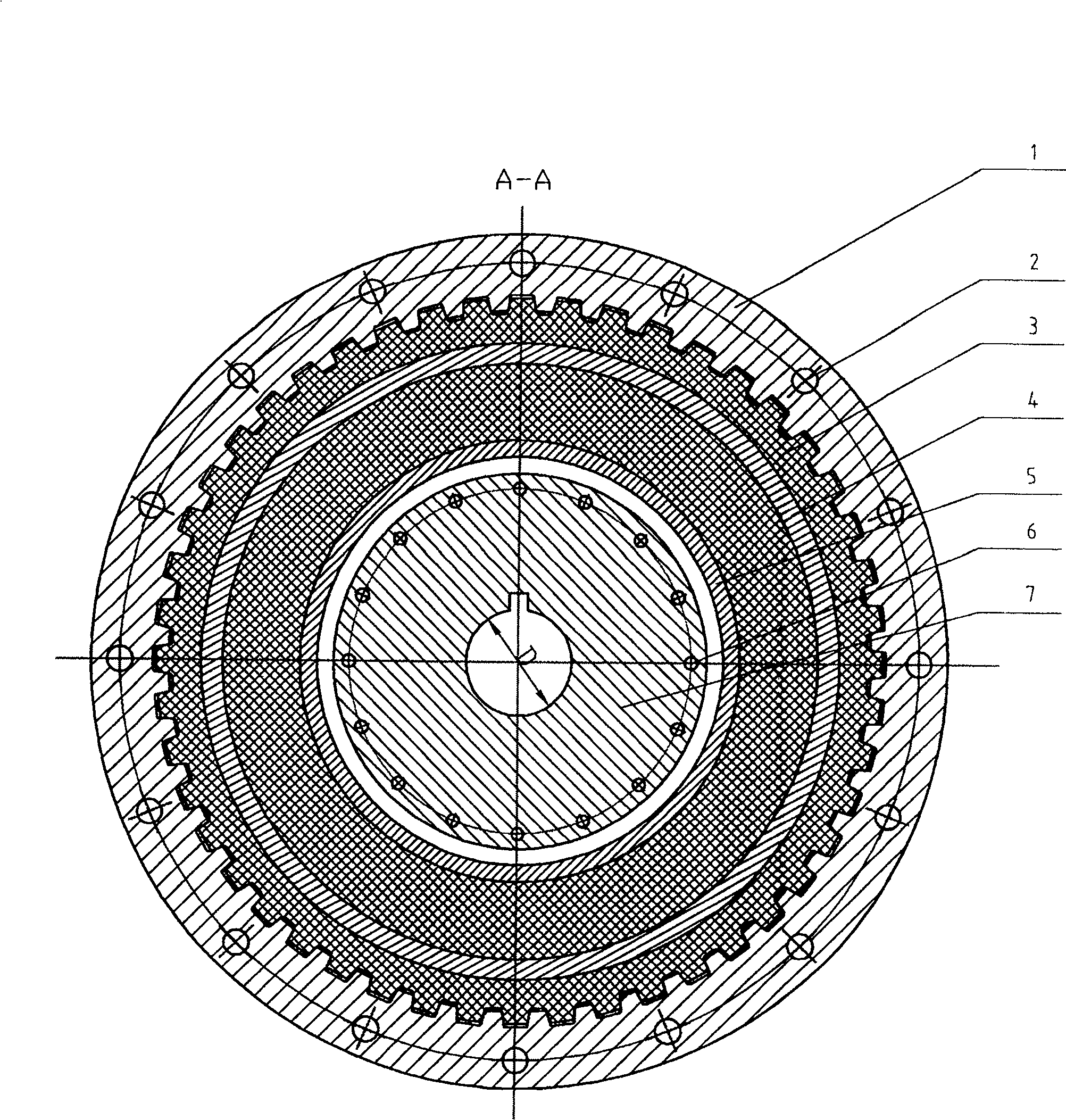

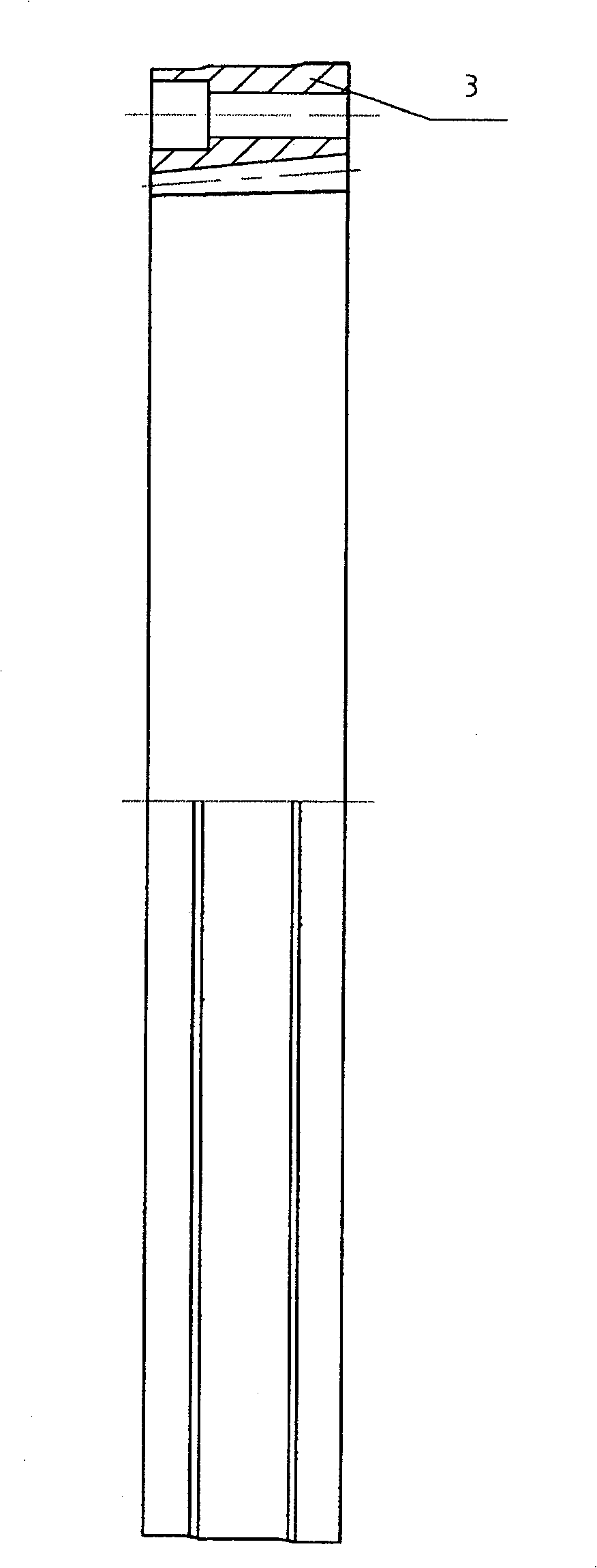

High elastic rubber alloy shaft coupling device

ActiveCN100478574CEnhanced torsional vibration strengthReduce unbalanced momentsYielding couplingElastomerDrivetrain

A high elastic rubber alloy shaft coupling, comprising a input shaft flange plate (1), elastic body (3), output coupling plate (5) and a output coupling cover (7). Inner toothing circular trapeziform tooth surface of the input shaft flange plate (1) and the external toothing trapeziform tooth surface of the elastic body (3) present an axial tapering slide fit, the elastic body (3) is bonded with the output coupling plate (5) into an integral body in a high strength. The elastic body (3) is a new type engineering composite material, the two-axial end face indent radian radius R is 40 to 60 millimeters, which is embedded with a steel wire ring (4), the torisonal vibration strength is intensified, the torsion angle is controlled in a moderate extent, which can adaptively adjust and compensate non-alignment error of shaft installment, non-counterbalance moment during power transmission is reduced greatly. Advantages of the shaft coupling are vibration damping, noise reduction, safe, reliable, highly effective, energy-saving, using life is long and installment is simple. The shaft coupling of the invention can be applied for power transmission systems of machinery warships, vehicles, petroleum, water conservancy and national defence weapons.

Owner:CHONGQING UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com