Vibration-attenuation and noise-reduction restrained damping plate manufacturing method and vibration-attenuation and noise-reduction restrained damping plate

A constrained damping, vibration reduction and noise reduction technology, applied in vibration reduction and noise reduction, aviation field, can solve the problems of high processing cost, damping material failure, long delivery cycle, etc., achieve light weight, reduce surface density, and realize light weight sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

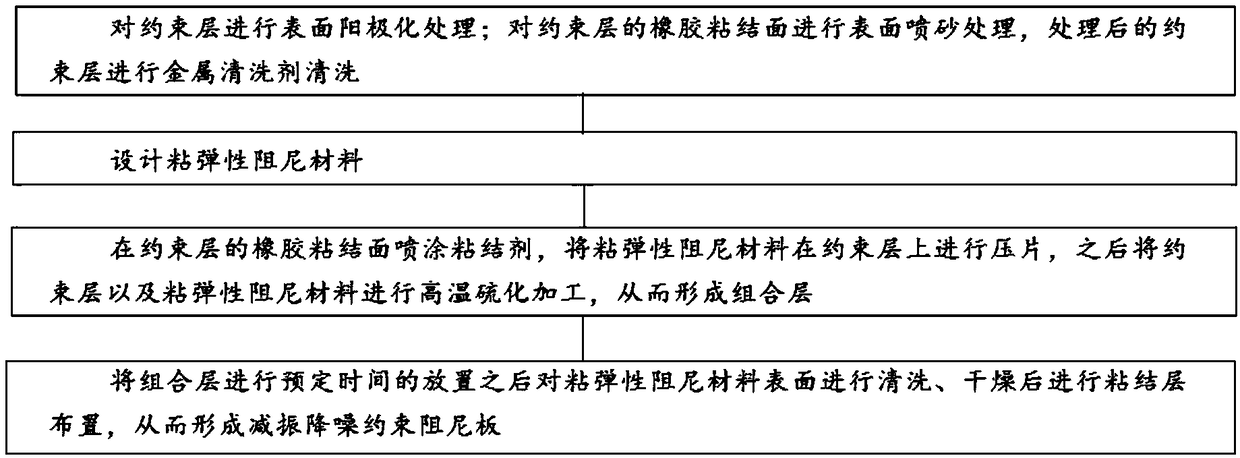

Method used

Image

Examples

Embodiment 1

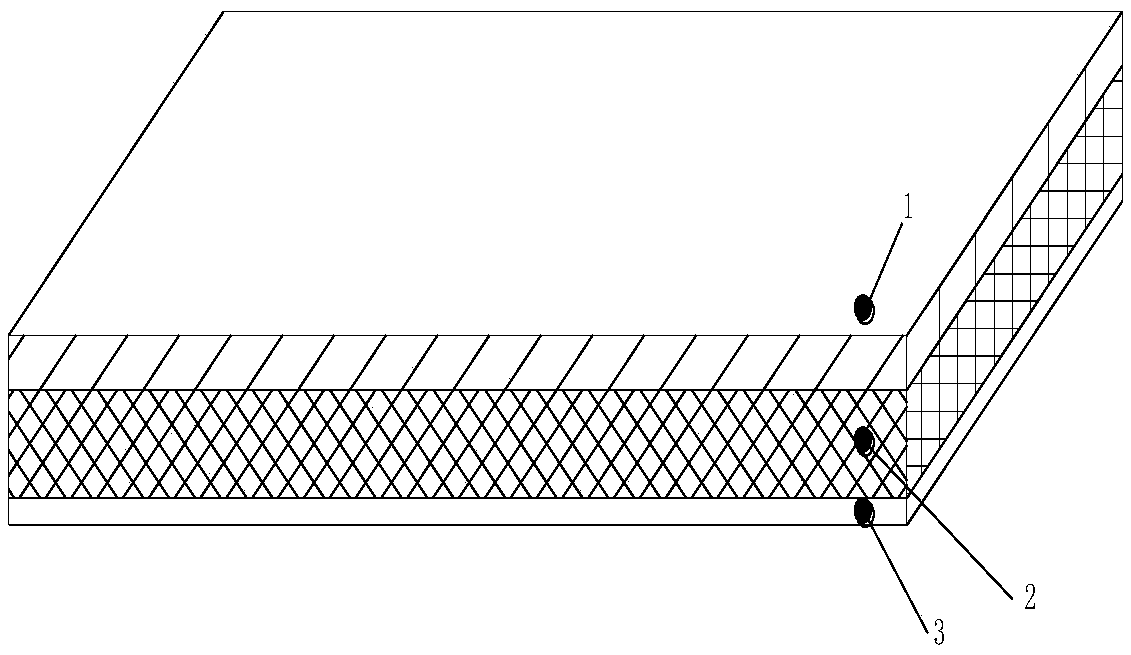

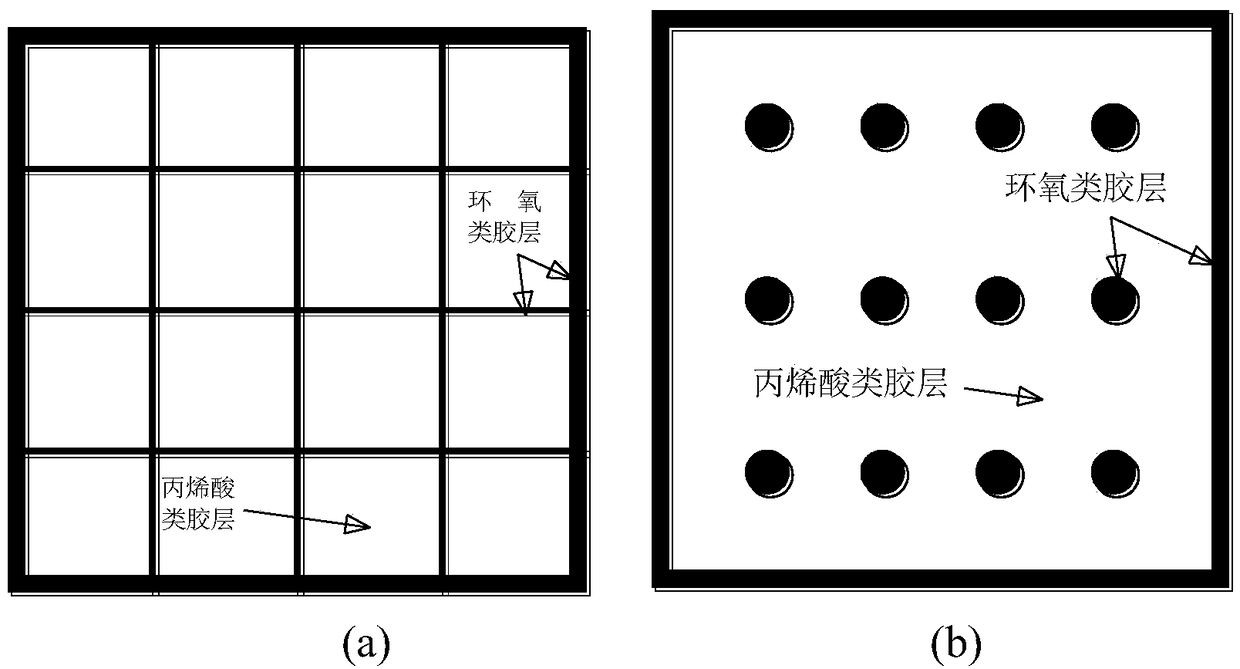

[0076] refer to figure 2 , the thickness of the constrained layer is 1 mm, the thickness of the viscoelastic damping material is 1 mm, the constrained layer is aviation aluminum, the viscoelastic damping material is butyl rubber, the adhesive layer is epoxy and acrylic adhesive layer, the adhesive layer layout is as follows image 3 (a) shown.

[0077] Among them, the ratio of viscoelastic damping materials: butyl rubber: 100, carbon black 50; 201 resin 10; stearic acid 1, zinc oxide 5, AO-80 5, molybdenum disulfide 0.1, mica 2, super fine powder 2, vermiculite powder 2; Add RHA0.1.

[0078] Tested in accordance with relevant standards, after 192 hours of mold test, the surface of the damping plate for vibration and noise reduction is grade 0. At the same time meet the use of -55 ℃ ~ 80 ℃. Vibration and noise reduction Constrained damping plate surface density 4.4kg / m 2 . The vibration and noise reduction constrained damping plate of Example 1 was subjected to a DMA test...

Embodiment 2

[0082] refer to figure 2 , the thickness of the constrained layer is 0.5mm, the thickness of the viscoelastic damping material is 1mm, the constrained layer is aviation aluminum, the viscoelastic damping material is butyl rubber, the adhesive layer is epoxy and acrylic adhesive layer, the adhesive layer layout is as follows image 3 (b) shown.

[0083] Among them, the ratio of viscoelastic damping materials: butyl rubber: 100, carbon black 50; 201 resin 10; stearic acid 1, zinc oxide 5, AO-80 10, molybdenum disulfide 0.5, mica 5, super fine powder 5, vermiculite powder 5; add RHA0.5.

[0084] Tested in accordance with relevant standards, after 192 hours of mold test, the surface of the damping plate for vibration and noise reduction is grade 0. At the same time meet the use of -55 ℃ ~ 80 ℃. Vibration and noise reduction Constrained damping plate surface density 2.8kg / m 2 . The tensile modal DMA test was carried out on the vibration reduction and noise reduction constrain...

Embodiment 3

[0088] refer to figure 2 , the thickness of the constrained layer is 0.5mm, the thickness of the viscoelastic damping material is 2mm, the constrained layer is aviation aluminum, the damping layer is brominated butyl rubber, the adhesive layer is epoxy and acrylic adhesive layer, the adhesive layer layout is as follows image 3 (b) shown.

[0089] see Figure 7 , wherein the ratio of viscoelastic damping materials: butyl rubber: 100, carbon black 50; 201 resin 10; stearic acid 1, zinc oxide 5, AO-80 20, molybdenum disulfide 1, mica 10, super fine powder 5, leech Stone powder 5; add RHA0.5.

[0090] Tested in accordance with relevant standards, after 192 hours of mold test, the surface of the damping plate for vibration and noise reduction is grade 0. At the same time, it can be used in an environment of -55°C to 80°C, and the surface density of the vibration and noise reduction constraint damping plate is 3.3kg / m 2 . Comparing the DMA test of Example 3 vibration reductio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com