Low pressure injection molding method for battery buckle embedded copper sheet

A technology of low-pressure injection molding and copper embedding, which is applied in the manufacture of primary batteries, secondary batteries, battery pack components, etc., can solve problems such as battery buckle breakage, buckle 41 strength that cannot meet the test requirements for drop, etc., to achieve enhanced The effect of intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Below in conjunction with accompanying drawing, the present invention is explained in more detail.

[0016] The present invention provides a low-pressure injection molding method for embedded copper sheets in battery buckles, comprising the following steps:

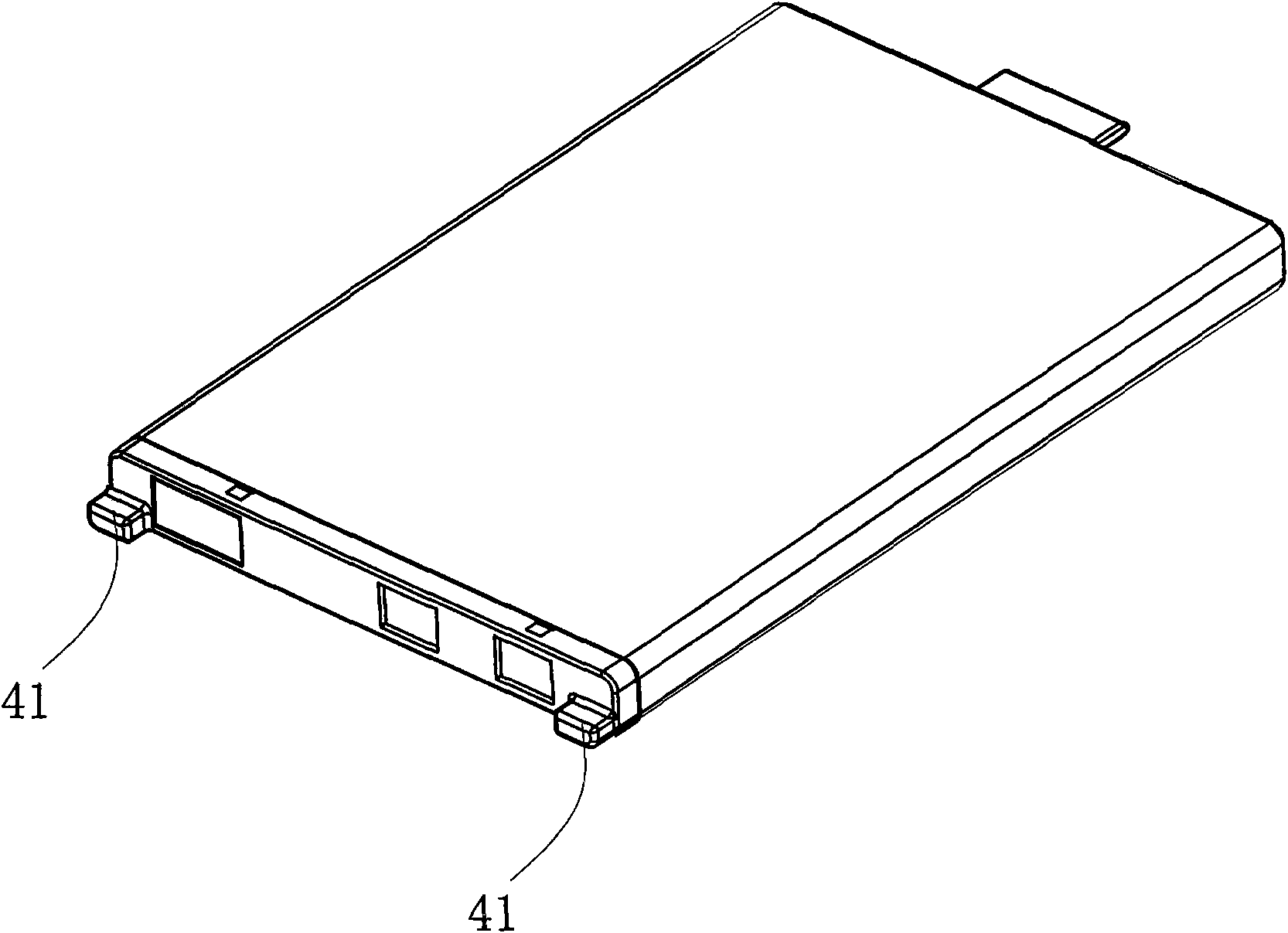

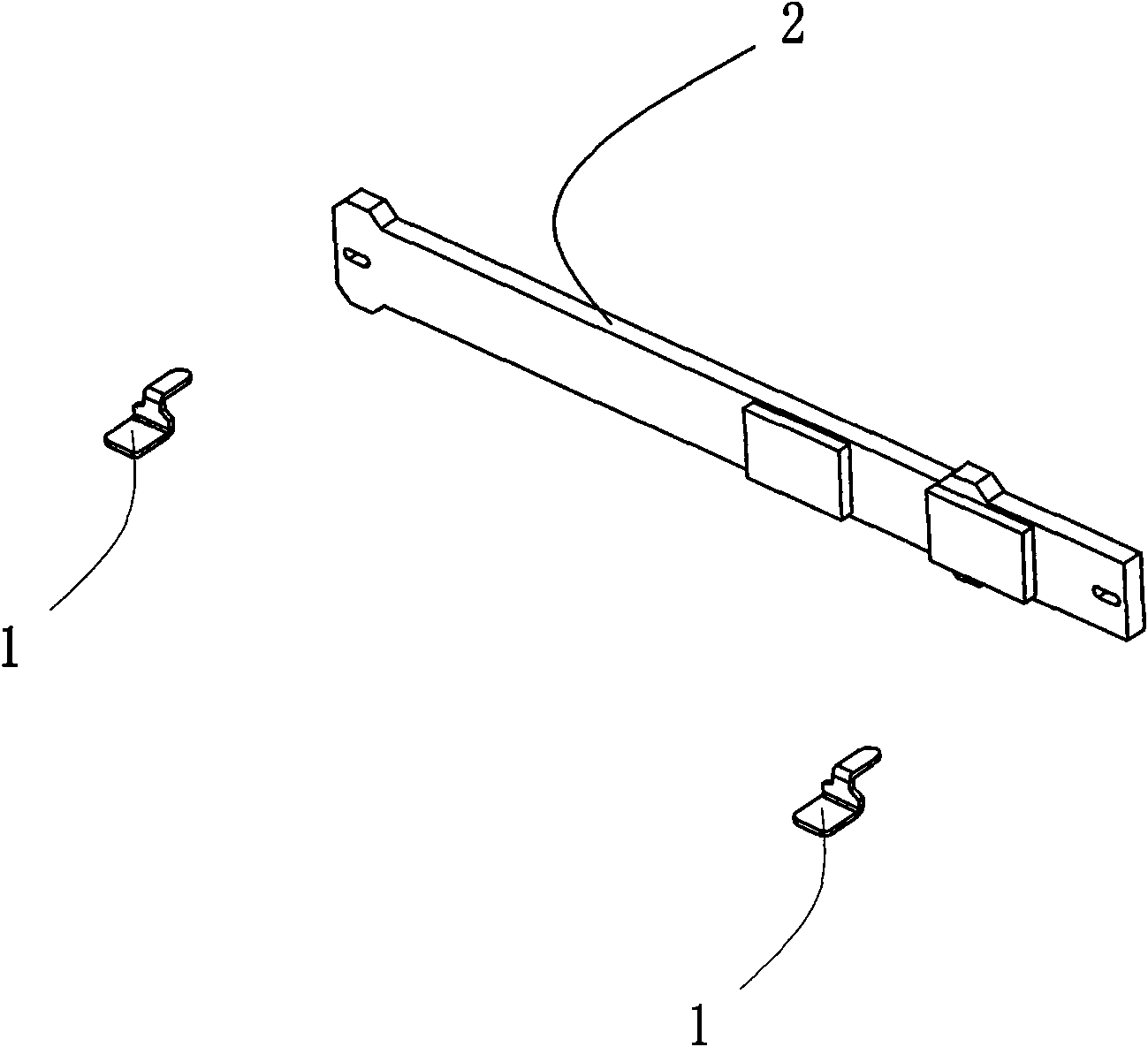

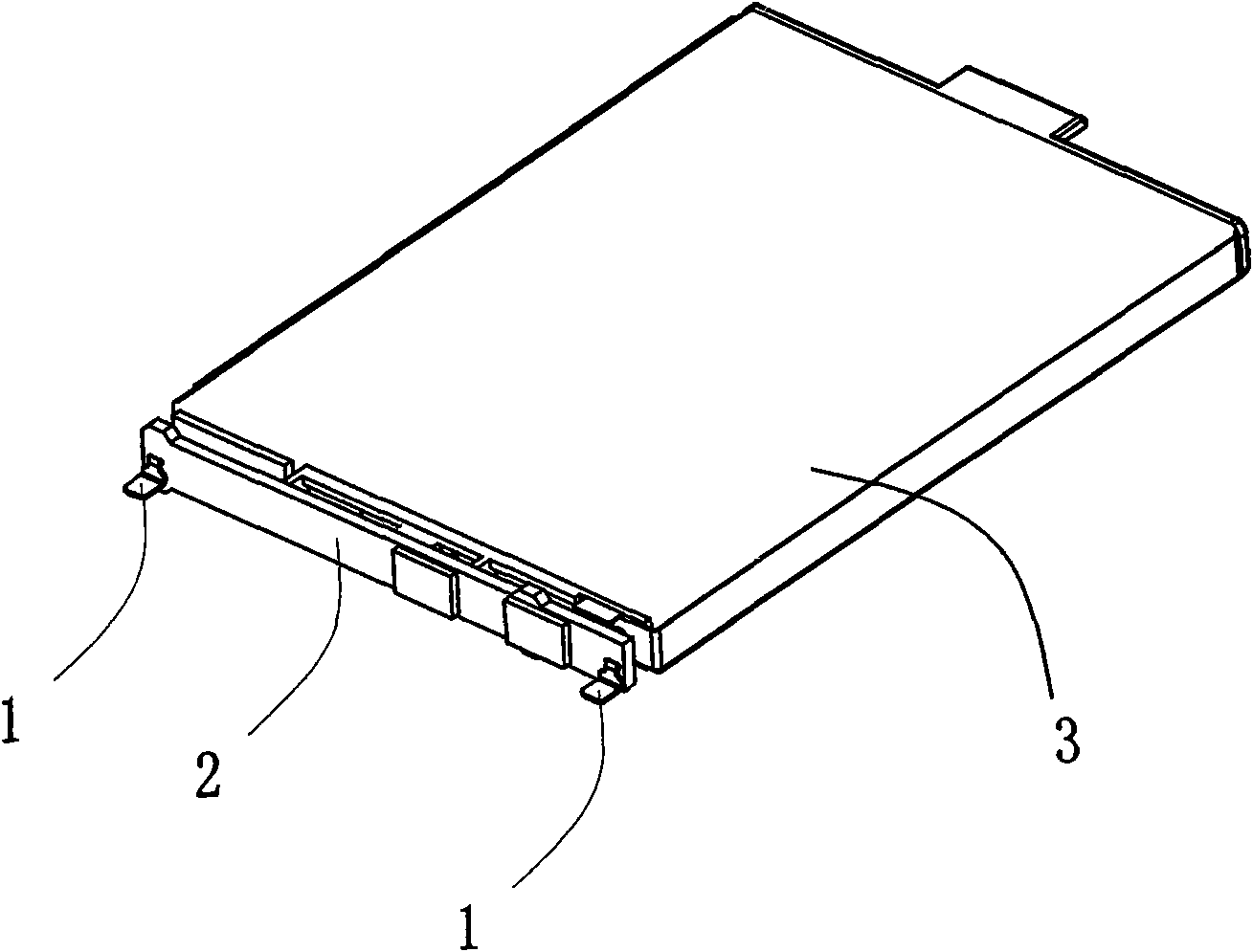

[0017] First, the sheet metal is formed into a preset snap shape, such as figure 2 As shown, the metal sheet adopted in the present invention is copper sheet 1. Obviously, the copper sheet can also be replaced by other other metal sheets with certain strength, such as aluminum alloy sheet; the formed multi-metal sheet is welded on the PCB board of the battery 2; and weld the PCB board 2 and the electric core 3 together (see image 3 ), put it into the injection mold, and adopt the low-pressure injection molding process to form (such as Figure 4 ), the plastic is attached to the metal sheet to form a buckle 4. In the present invention, the low-pressure injection molding process uses an injection pressure of 1.5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com