Cavity sound-absorbing material damping plate and preparation method thereof

A technology of sound-absorbing materials and damping panels, applied in chemical instruments and methods, layered products, transportation and packaging, etc., can solve the problems of chemical corrosion resistance, easy aging, harmful to human body, etc., achieve good sound insulation and noise reduction, light material , the effect of high toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

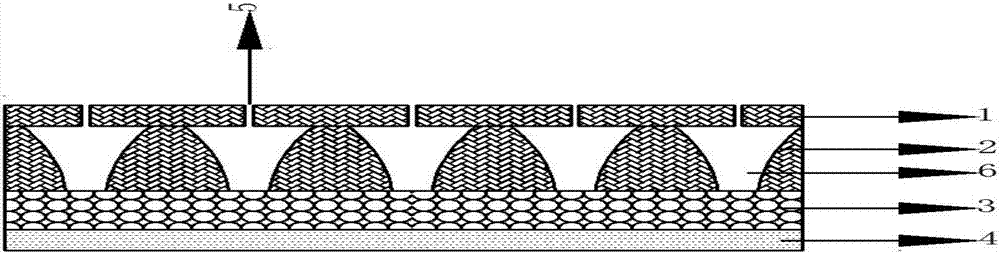

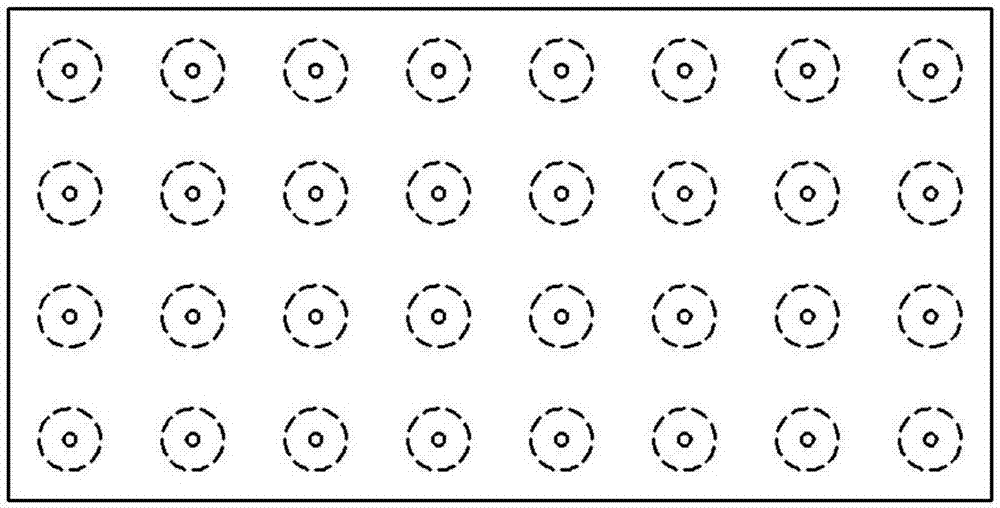

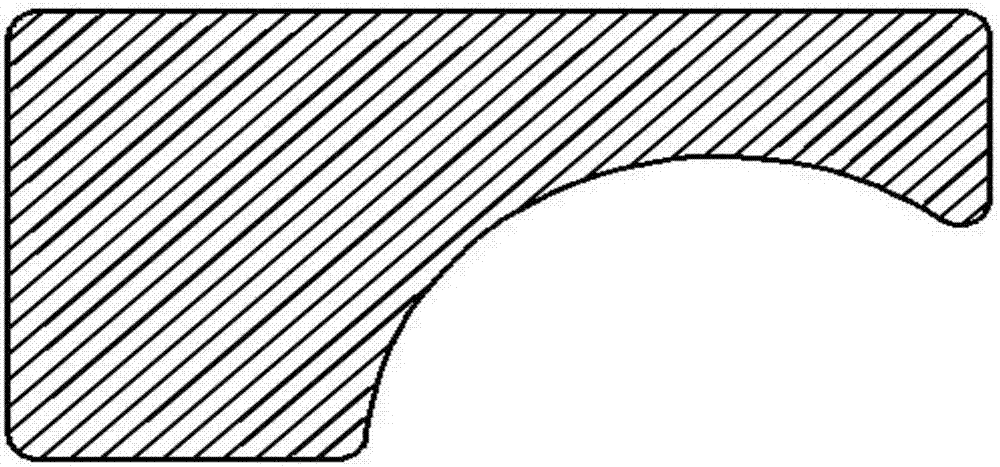

[0040] Such as figure 1 As shown, a cavity sound-absorbing material damping board is composed of a surface layer 1, a cavity layer 2, an EPDM foamed sound insulation layer 3, and a modified epoxy resin adhesive layer 4 arranged in order from top to bottom. The surface layer is made of polyvinyl chloride artificial leather material, and a plurality of circular holes 5 are uniformly spaced on the surface layer; the cavity material is a rigid polyvinyl chloride material, and the cavity layer and the surface layer are uniformly spaced in a one-to-one correspondence. A horn-shaped cavity 6. The horn-shaped cavity is wide at the top and narrow at the bottom.

[0041] The EPDM foam sound insulation layer material is composed of the following formula: EPDM: 100 kg, calcium carbonate: 15 kg, N330 carbon black: 15 kg, foaming agent OBSH: 5 kg, foaming aid NaHCO3: 3 kg, urea: 4 Kg, paraffin wax: 3 kg, antioxidant 2246: 4 kg, stearic acid: 6 kg, zinc oxide: 10 kg, DCP: 6 kg, short basalt fi...

Embodiment 2

[0052] The difference from Example 1 is:

[0053] The EPDM foam sound insulation layer material is composed of the following formula: EPDM: 100 kg, calcium carbonate: 5 kg, N330 carbon black: 5 kg, blowing agent OBSH: 3 kg, foaming aid NaHCO3: 1 kg, urea: 2 Kg, paraffin wax 0.5 kg, antioxidant 2246: 0.5 kg, stearic acid: 2 kg, zinc oxide: 2 kg, DCP: 2 kg, short basalt fiber: 5 kg, white sugar: 3 kg. The short basalt fiber has a diameter of 0.01-0.05mm and a length of 10-20mm. White granulated sugar needs to be ground to a particle size of 200-225 mesh.

[0054] 1. Add the above-mentioned materials to a 75-liter internal mixer for mixing, the mixing temperature is 85-90℃, and the mixing time is 7-9min. To be used in the calendering process.

[0055] 2. Put the mixed EPDM film into a drum vulcanizer to foam the EPDM layer within 20 minutes at 140-160℃.

[0056] 3. Put the foamed EPDM foamed sound insulation layer into boiling water in a water tank and boil it for 5 minutes. After boi...

Embodiment 3

[0063] The difference from Example 1 is:

[0064] The EPDM foam sound insulation layer material is composed of the following formula: EPDM: 100 kg, calcium carbonate: 10 kg, N330 carbon black: 8 kg, blowing agent OBSH: 3.5 kg, foaming aid NaHCO3: 2 kg, urea: 3 Kilogram, paraffin wax: 1 kg, antioxidant 2246: 2 kg, stearic acid: 4 kg, zinc oxide: 5 kg, DCP: 3 kg, short basalt fiber: 5.5 kg, starch: 5 kg. The short basalt fiber has a diameter of 0.01-0.05mm and a length of 10-20mm. Starch needs to be ground to a particle size of 200-225 mesh.

[0065] 1. Add the above-mentioned materials to a 75-liter internal mixer for mixing, the mixing temperature is 85-90℃, and the mixing time is 7-9min. To be used in the calendering process.

[0066] 2. Put the mixed EPDM film into a drum vulcanizer to foam the EPDM layer within 20 minutes at 140-160℃.

[0067] 3. Put the foamed EPDM foamed sound insulation layer into boiling water in a water tank and boil for 5 minutes. After boiling, the starch...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com