Carbon fiber-enhanced high-temperature-resistance high-strength light hybrid ceramic-resin composite material pipe

A technology of resin composite materials and composite materials, applied in the direction of pipes/pipe joints/fittings, pipes, rigid pipes, etc., can solve the problem that the surface cannot withstand high temperature, poor shock resistance and vibration damping effect, poor heat resistance and heat insulation performance, etc. Problems, to achieve high temperature resistance and heat resistance, improve temperature resistance and impact resistance, and good temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

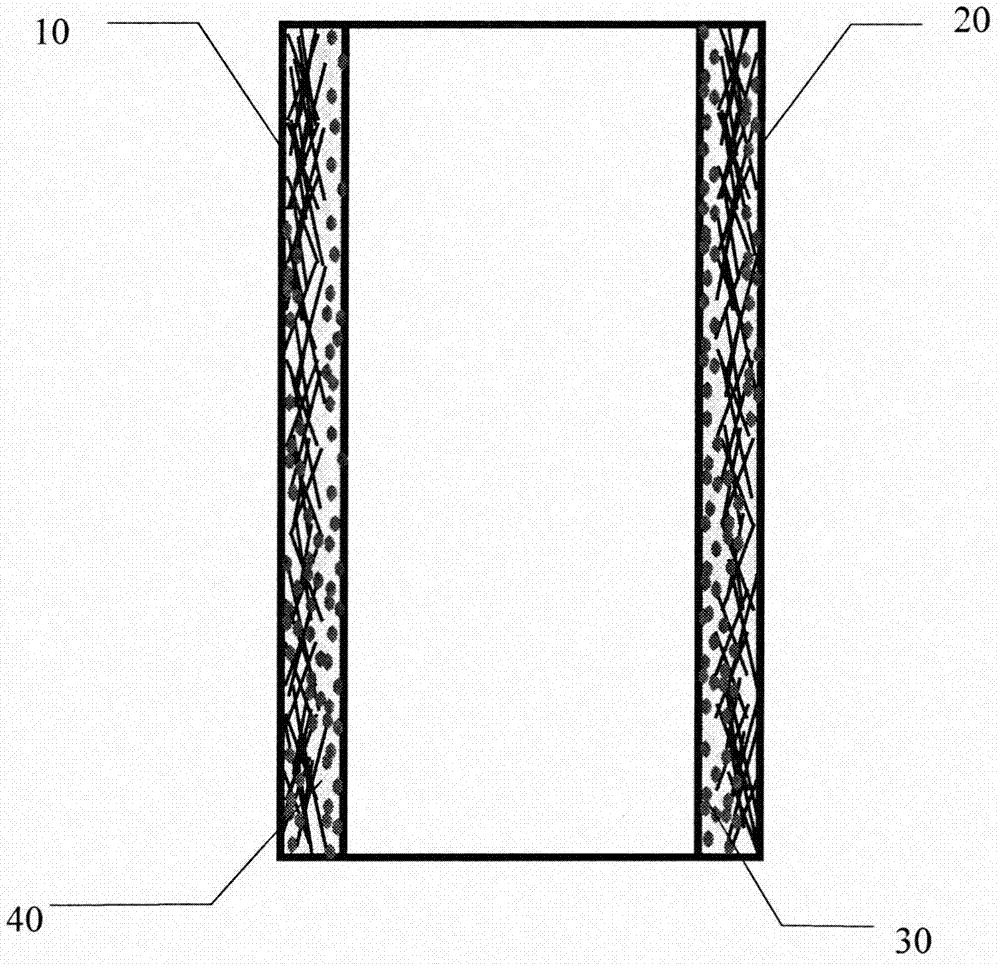

[0016] refer to figure 1 , is a carbon fiber-reinforced high-temperature-resistant, high-strength, lightweight hybrid ceramic-resin composite pipe fitting, 10 is ceramic matrix composite material, 20 is ceramic component, 30 is resin filler, 40 is resin matrix composite material, composite material The pipe density is 1.5g / cm 3 , with the ceramic matrix composite material as the outer shell, the resin matrix composite material as the inner shell, and the outer shell and the inner shell are nested to form a composite structure. The inner and outer walls of the pipe fittings have smooth surfaces and a wall thickness of 3 mm; The thickness direction of the wall is distributed in a gradient. The volume fraction of ceramics on the outer surface of the pipe fittings is 45%, which gradually decreases inwards, and the volume fraction of ceramics decreases to 2% at 1 / 2 of the thickness of the pipe fitting shell; the resin component in the composite material along the tube The directio...

Embodiment 2

[0020] refer to figure 1 , is a carbon fiber-reinforced high-temperature-resistant, high-strength, lightweight hybrid ceramic-resin composite pipe fitting, 10 is ceramic matrix composite material, 20 is ceramic component, 30 is resin filler, 40 is resin matrix composite material, composite material The pipe density is 2.0g / cm 3 , with the ceramic matrix composite material as the outer shell, the resin matrix composite material as the inner shell, and the outer shell and the inner shell are nested with each other to form a composite structure. The thickness direction of the wall is distributed in a gradient, and the volume fraction of ceramics on the outer surface of the pipe fittings is 55%, which gradually decreases inwards, and the volume fraction of ceramics decreases to 4% at 1 / 3 of the thickness of the pipe fitting shell; the resin component in the composite material along the tube The direction of wall thickness also presents a gradient distribution. The volume fraction...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com