A kind of preparation method of iron-based composite material for automobile gear

An iron-based composite material, automotive gear technology, applied in metal material coating process, liquid chemical plating, coating and other directions, can solve the problems of reducing the working reliability of gears, shortening the service life of gears, slow transmission response, etc. Good vibration and sound absorption performance, reduce vibration and noise, and fully dissipate heat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Preparation of embodiment one copper-coated carbon fiber

[0030] The copper-plated carbon fiber is prepared by performing copper-plating treatment on the carbon fiber through the following steps, which include in turn:

[0031] Step A: Carbon Fiber Pretreatment

[0032] Surface degumming: soak in the boiling acetone solution in the Soxhlet extractor and stir continuously with a stirring porcelain, the temperature is controlled at 70°C, and the stirring time is 240min to ensure that the acetone degumming is complete;

[0033] Surface degreasing: put the degummed carbon fiber in 10% NaOH solution, stir at room temperature for 30 minutes, wash the taken out carbon fiber with ethanol and deionized water successively, and dry it for later use;

[0034] Surface roughening: Use potassium persulfate solution with a mass fraction of 10% as the roughening solution, immerse the degreased carbon fiber, and stir continuously for 60 minutes; the roughened carbon fiber is cleaned wi...

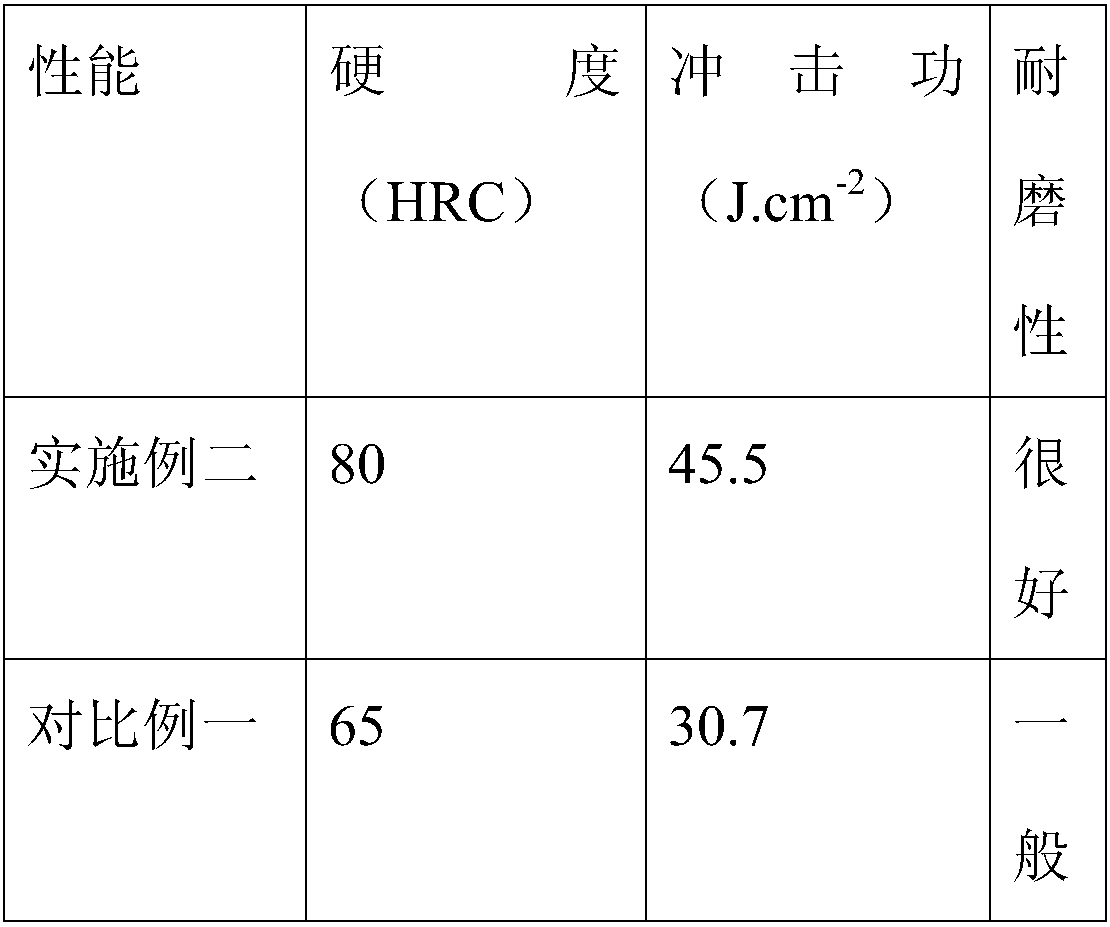

Embodiment 2

[0039] Embodiment 2 A kind of preparation method of iron-based composite material for automobile gear

[0040] In this embodiment, a method for preparing an iron-based composite material for automobile gears comprises the following steps in sequence:

[0041] Step 1, weighing the following ingredients in parts by weight: 5 parts of copper-plated carbon fiber prepared in Example 1, 5 parts of tantalum nitride, 2.2 parts of nickel powder, 2 parts of copper powder and 200 parts of Fe powder; The nickel powder particle size is 150-200 mesh, the Fe powder particle size is 250-300 mesh, and the copper powder particle size is 150-200 mesh; then add 5 parts by weight of zinc stearate for ball milling, mixing Time is 5 hours; Obtain mixture;

[0042] Step 2, pressing the mixture prepared in the step 1 under a pressure of 1000Mpa; obtaining a blank;

[0043] Step 3, sintering the blank prepared in the step 2, the sintering includes early sintering and later sintering: the early sinter...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com