Foamed aluminum-corrugated plate composite sandwich plate and preparation method thereof

A technology of corrugated board and sandwich board, which is applied in the field of foamed aluminum-corrugated board composite sandwich board and its preparation, can solve the problems of high cutting precision of foamed aluminum, affecting the overall mechanical properties, and high manufacturing cost, so as to improve the resistance to explosion impact Protective performance, low manufacturing process cost, and the effect of reducing structural weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

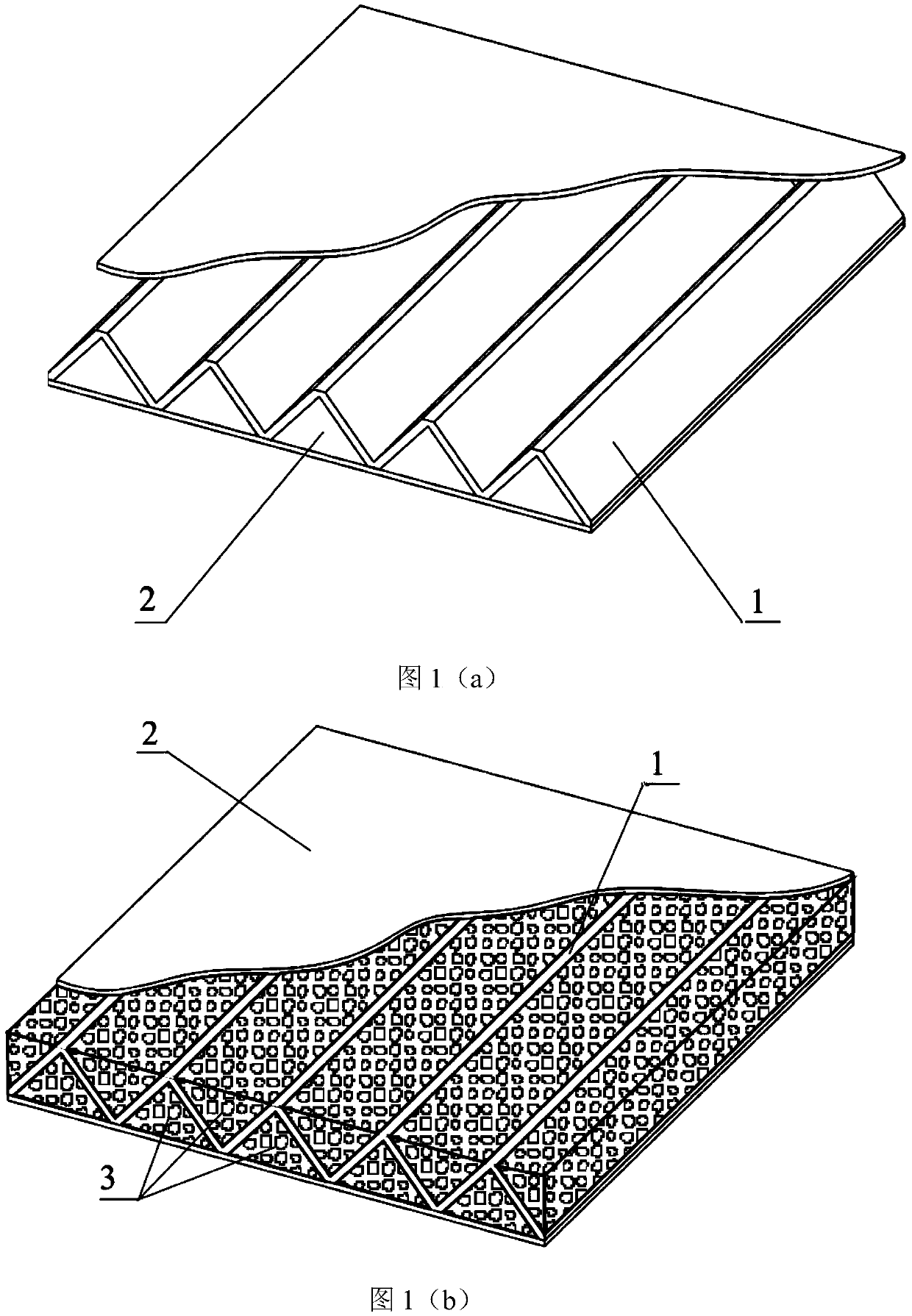

[0027] see figure 1 and figure 2 , 1) First of all, the corrugated core body 1 is made of the flattened carbon steel plate by molding technology. Cleaning off the oil and rust on the corrugated core 1 and the panel 2, and brazing the corrugated core 1 and the panel 2 to form a corrugated plate;

[0028] 2) Secondly, the industrial pure aluminum powder with a particle size of 40-150 microns and titanium hydride (TiH 2 ) after being mixed in a mass ratio of 99:1, mix evenly in the mixer to obtain a mixed powder;

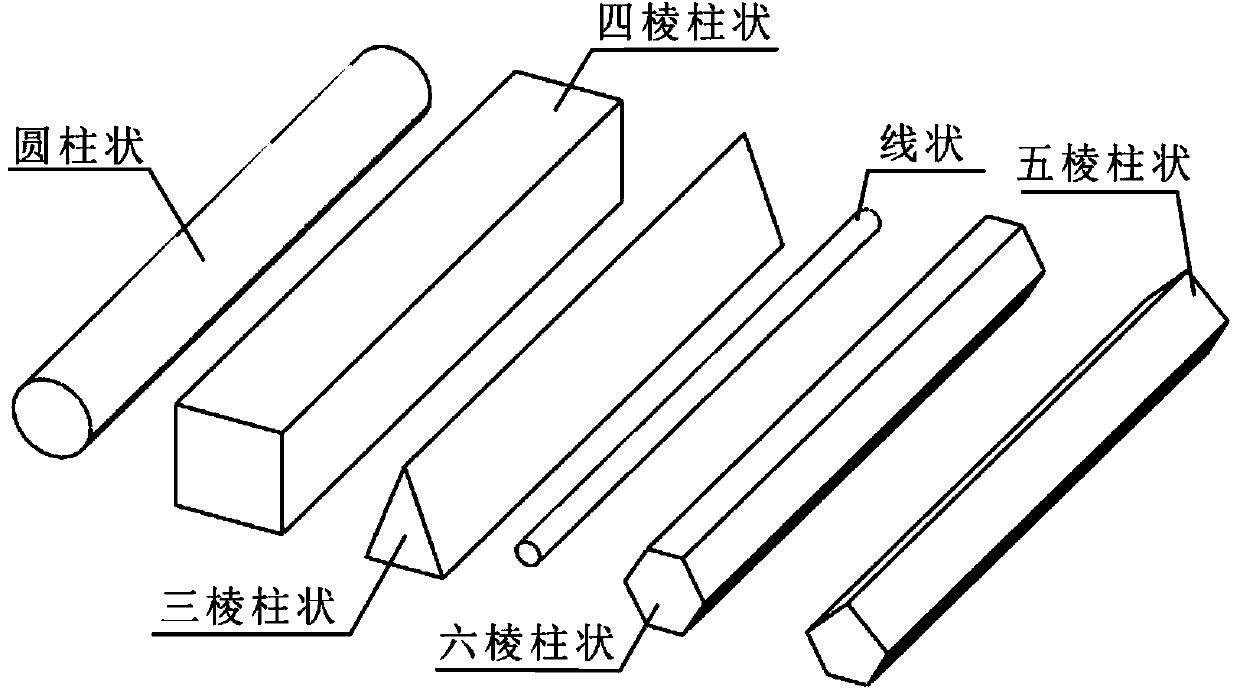

[0029] 3) Next, inject the mixed powder into the extrusion die, control the extrusion ratio to 12, and extrude a Φ8mm billet through continuous extrusion process, and the compactness is greater than 99%. Then the obtained blank is put into a molding die, pressurized to 200MPa and molded into a triangular prism-shaped foamable preform.

[0030] 4) Again, acid and alkali wash the corrugated board and the foamable preform to remove the surface oxide film. After dryin...

Embodiment 2

[0033] 1) Firstly, the flattened stainless steel plate is made into the corrugated core 1 by folding technology. Clean off the oil and rust on the corrugated core 1 and the panel 2, and weld the corrugated core 1 and the panel 2 by laser welding to form a corrugated plate;

[0034] 2) Secondly, the industrial purity aluminum powder with a particle size of 40-150 microns and titanium hydride (TiH 2 ) is mixed by the mass ratio of 99.4:0.6 and injected into the blender to mix evenly to obtain the mixed powder;

[0035] 3) Next, inject the mixed powder into the extrusion die, control the extrusion ratio to 13, and extrude a Φ8mm billet through continuous extrusion process, the compactness is greater than 99%, and then put the obtained billet into the molding die Inside, it is pressurized to 300MPa and molded into a quadrangular prism-shaped foamable preform.

[0036] 4) Again, wash the corrugated board and the foamable preform with acid and alkali to remove the oxide film on th...

Embodiment 3

[0039]1) Firstly, the flattened titanium plate is made into a corrugated core 1 by folding technology. Clean off the oil and rust on the corrugated core 1 and the panel 2, and weld the corrugated core 1 and the panel 2 by laser welding to form a corrugated plate;

[0040] 2) Secondly, industrially pure aluminum powder, silicon powder and titanium hydride (TiH 2 ) after being mixed in a mass ratio of 93:6:1, put into a mixer and mix evenly to obtain a mixed powder;

[0041] 3) Next, inject the mixed powder into the extrusion die, control the extrusion ratio to 11, and extrude a Φ8mm billet through continuous extrusion process, the compactness is greater than 99%, and then put the obtained billet into the molding die Inside, it is pressurized to 300MPa and molded into a cylindrical foamable preform.

[0042] 4) Again, acid and alkali wash the corrugated board and the foamable preform to remove the surface oxide film. After drying, fill the foamable preform into the corrugated ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com