Polyurethane composite material doped by nickel-titanium memory alloy and carbon nanotube and preparation method thereof

A technology of carbon nanotube composite and nickel-titanium memory alloy, which is applied in the field of nickel-titanium memory alloy and carbon nanotube composite doped polyurethane composite material and its preparation, can solve the problem of failure to fully consider the temperature adaptation characteristics of resin-based composite materials, solvent difficulties, etc. Solve the problems of complete volatilization removal and low preparation efficiency, achieve good damping characteristics and shape memory recovery characteristics, low cost, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The following examples describe the present invention in more detail:

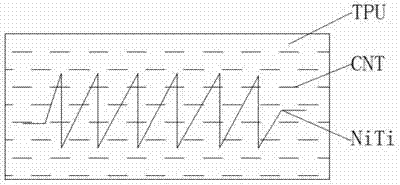

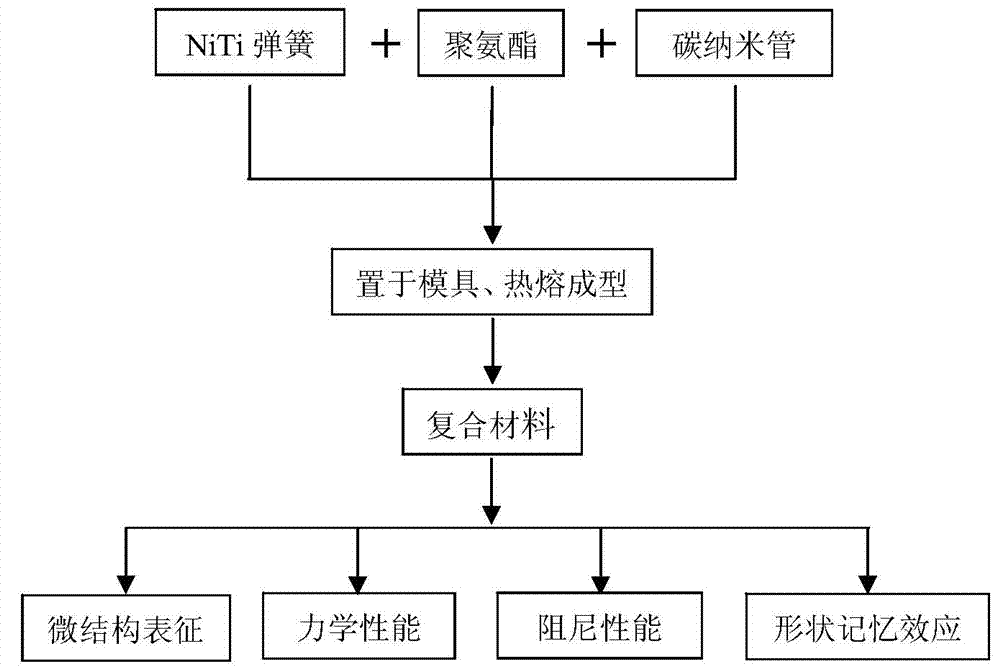

[0028] combine figure 2 , the preparation process route of NiTi memory alloy spring and carbon nanotube composite doped polyurethane composite material is:

[0029] (1) Ni with a wire diameter of 0.2mm 50.9 Ti 49.1 The alloy wire is wound into a spring structure on a spring winding machine, and the spring diameter and spring distance of the spring are both 1mm.

[0030] (2) The coiled spring is heat-treated at 450°C for 30 minutes to obtain superelasticity at room temperature.

[0031] (3) Mix the multi-walled carbon nanotubes containing carboxyl groups with 8185 (Yantai Wanhua Polyurethane Co., Ltd.) thermoplastic polyether polyurethane elastomer particles by mechanical stirring, so that the CNTs are uniformly coated on the surface of the TPU particles, and the CNT content is 0.3 wt%.

[0032] (4) Apply silicone oil to the inner surface of the hot-melt forming stainless steel mold to facilita...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com