Wall body vacuum insulation plate and preparation method thereof

A technology of vacuum insulation board and vacuum insulation board, which is applied in the directions of heat preservation, climate change adaptation, insulation improvement, etc. It can solve the problem that VIP special composite barrier bags are easy to be worn or punctured, and cannot be directly applied in the field of energy-saving buildings, installation and use Harsh conditions and other issues, to achieve the effect of enhanced wear resistance, small thickness, and high mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

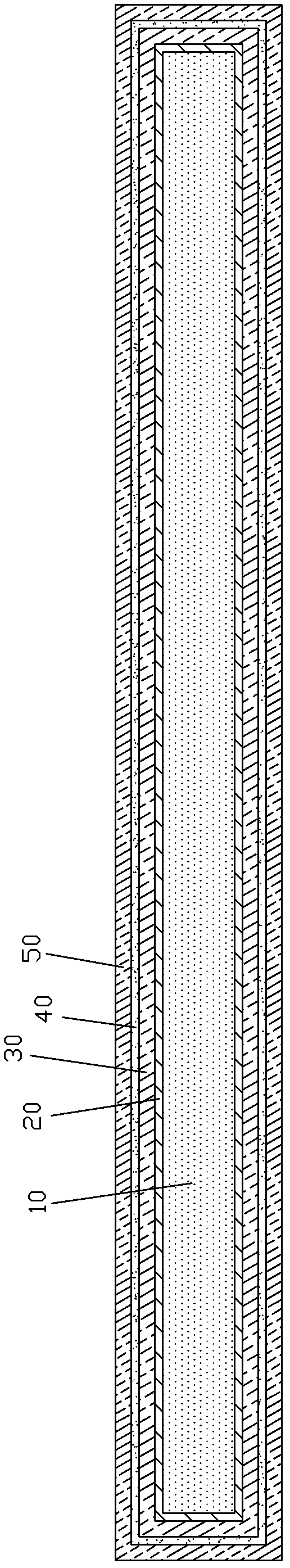

[0027] A kind of wall vacuum insulation board, refer to figure 1 , including a powder layer 10, a non-woven fabric bag 20, a high-barrier packaging bag 30, an adhesive 40 and a fiber-reinforced composite barrier bag 50 from the inside to the outside, and its preparation method is as follows:

[0028] Step 1, the fumed white carbon black powder that has been mixed uniformly quantitatively, glass fiber (its diameter is 7 μ m) is packed in the non-woven fabric bag 20 according to mass ratio 110:5, is placed in the molding machine that has set Extrude in the middle to obtain the heat insulation core material of the required size, put the heat insulation core material in an oven to dry, and set aside;

[0029] Step 2: Take out the dried core material from the oven and quickly put it into the high-barrier packaging bag 30, and perform a vacuum seal in a vacuum sealing machine, the vacuum degree of which is greater than 0.1 Pa during sealing, to obtain a vacuum insulation panel;

[...

Embodiment 2

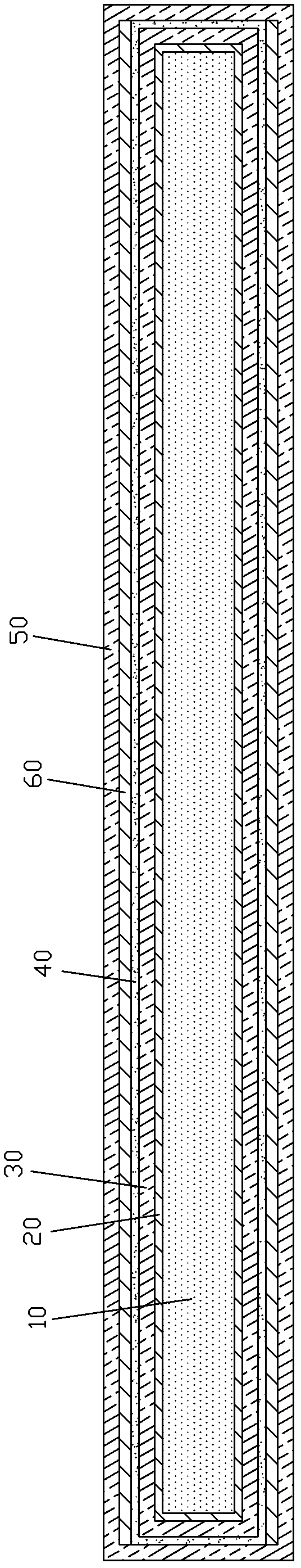

[0033] A kind of wall vacuum insulation board, refer to figure 2 , comprising a powder layer 10, a non-woven fabric bag 20, a high-barrier packaging bag 30, an adhesive 40, glass fiber reinforced plastics 60 and a fiber-reinforced composite barrier bag 50 from the inside to the outside in sequence, and its preparation method is as follows:

[0034] Step 1, the fumed white carbon black powder that has been mixed uniformly quantitatively, glass fiber (its diameter is 7 μ m) is packed in the non-woven fabric bag 20 according to mass ratio 110:5, is placed in the molding machine that has set Extrude in the middle to obtain the heat insulation core material of the required size, put the heat insulation core material in an oven to dry, and set aside;

[0035] Step 2: Take out the dried core material from the oven and quickly put it into the high-barrier packaging bag 30, and perform a vacuum seal in a vacuum sealing machine, the vacuum degree of which is greater than 0.1 Pa during ...

Embodiment 3

[0039] The difference from Example 2 is that the fiber-reinforced composite barrier bag has heat shrinkability. After the wall vacuum insulation board is prepared in step 4, the wall vacuum insulation board is placed in an oven at 65-70°C for 10-15 seconds, and it is ready to take out. Can.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com