Support plate hole filling process based on metal imprinting

A carrier plate and metal technology, which is applied in the field of hole filling process of carrier plate based on metal imprinting, can solve problems such as low efficiency, stress concentration, affecting filling efficiency, etc., and achieve simple and convenient process steps, matching thermal expansion coefficient, and improving filling efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

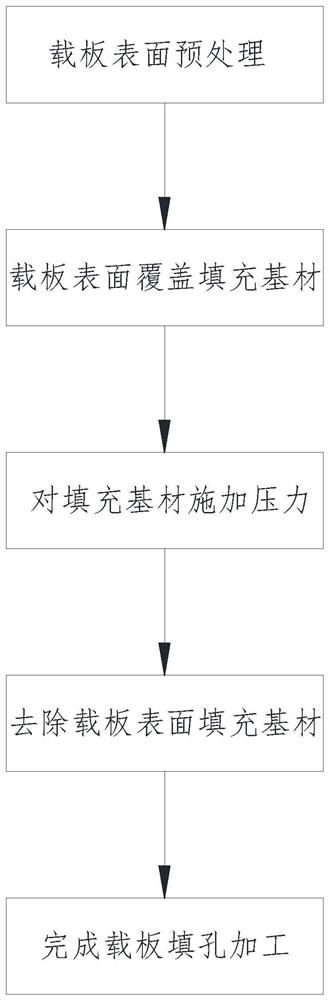

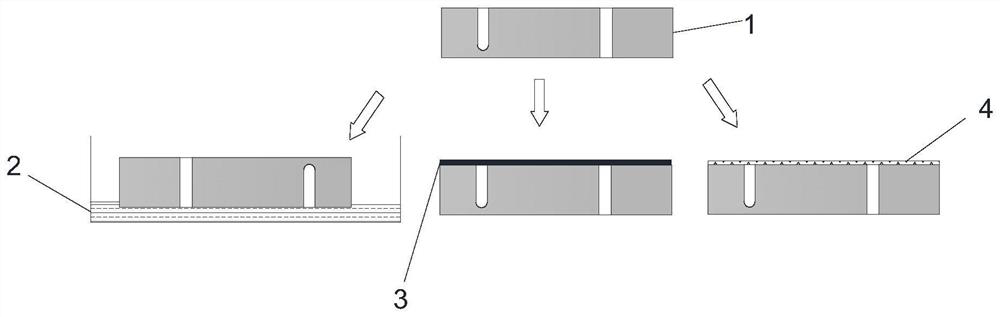

[0036] see Figure 1-Figure 4 , the carrier board hole filling process based on metal imprinting in this embodiment is characterized in that it includes the following steps:

[0037] (1) Pretreatment is performed on the surface of the substrate 1 to be filled, so that the surface of the substrate 1 and the metal do not have bonding force.

[0038] (2) Covering the filling base material 5 made of metal evenly on the surface of the carrier plate 1 .

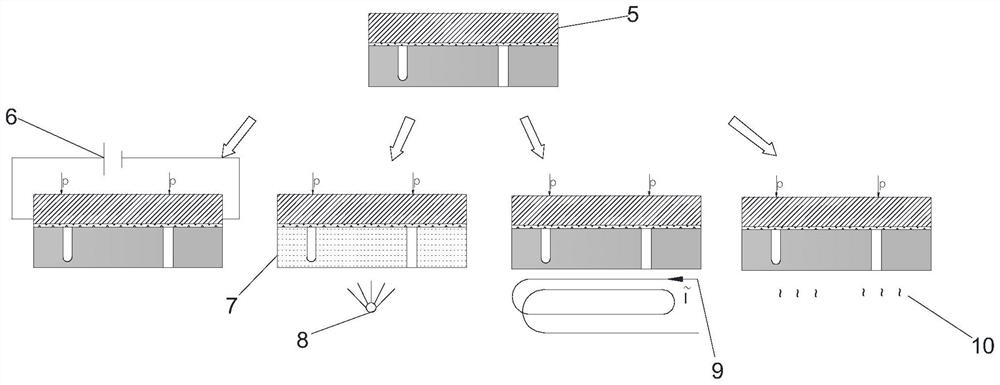

[0039] (3) Under a controllable atmosphere, apply a downward pressure perpendicular to the surface of the carrier plate 1 on the filling substrate 5, the pressure range is 0-500Mpa; at the same time, localized heating is performed on the filling substrate 5, and the heating temperature control range is at room temperature -2000°C, so that the filling substrate 5 is deformed and pressed into the through hole or blind hole on the carrier plate 1 .

[0040] (4) Separating the carrier board 1 and the filling substrate 5 covering the s...

Embodiment 2

[0057] This embodiment discloses a specific example of hole filling on a carrier: the carrier is a ceramic carrier, and the ceramic carrier is provided with through holes with a diameter of 30 μm and a depth of 100 μm. specifically:

[0058] (1) Depositing a layer of graphite with a thickness of 10 nm on the surface of the ceramic carrier, so that the surface treatment layer of the ceramic carrier has no binding force with the metal.

[0059] (2) A copper block (filling base material) with a flat surface and a thickness of 20 nm is covered on the ceramic carrier.

[0060] (3) In a nitrogen environment, apply a pressure of 200MPa perpendicular to the ceramic carrier to the copper block, and at the same time apply a 20MHz alternating electric field to one side of the ceramic carrier to heat the surface of the copper block near the ceramic carrier, As a result, the copper block is deformed and pressed into the via, completing the filling.

[0061] (4) The copper block on the su...

Embodiment 3

[0064] This embodiment discloses another specific example of hole filling on a carrier: the carrier is a ceramic carrier, and the ceramic carrier is provided with through holes with a diameter of 15 μm and a depth of 50 μm. specifically:

[0065] (1) Deposit a layer of graphite with a thickness of 30nm on the surface of the ceramic carrier, so that the surface treatment layer of the ceramic carrier has no binding force with the metal.

[0066] (2) A copper block (filling base material) with a flat surface and a thickness of 100 nm is covered on the ceramic carrier.

[0067] (3) In a nitrogen environment, apply a pressure of 100 MPa perpendicular to the carrier plate to the copper block, and control the ambient temperature to 150°C, so that the overall temperature of the copper block will be deformed and pressed into the through hole to complete the filling.

[0068] (4) Grinding off the copper block on the surface of the ceramic carrier plate by means of mechanical grinding, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com