A Copper Plating Bath for Blind and Buried Holes of HDI Laminates

A technology of copper plating bath and blind buried hole, applied in the field of blind buried hole copper plating bath of HDI laminated board, can solve the problems of high production cost, increased brittleness of coating, fracture failure, etc., and achieves high productivity and lower production threshold. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

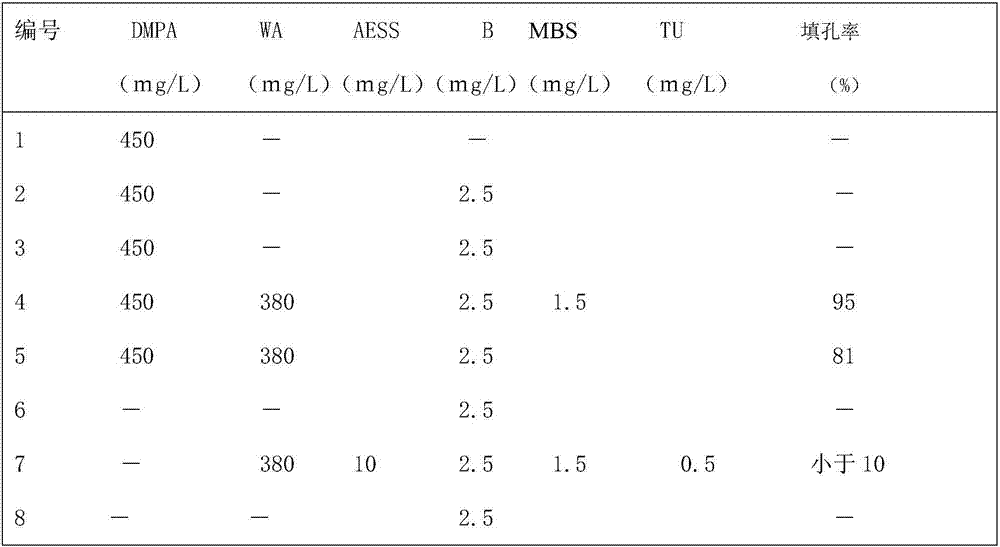

[0025] In this embodiment, the water-soluble copper salt takes copper sulfate pentahydrate as an example, the brightener takes sodium dipropylene sulfide as an example, and the wetting agent takes five-block polyoxyethylene / polyoxypropylene ether as an example, and all components are Analytical pure.

[0026] Penta-block polyoxyethylene / polyoxypropylene ether is a penta-block copolymer CH with butanol as the starting material and ethylene oxide (referred to as EO) and propylene oxide (referred to as PO) as homopolymers. 3 CH 2 CH 2 CH 2 (EO) 8 (PO) 15 (EO) 10 (PO) 15 (EO) 8 .

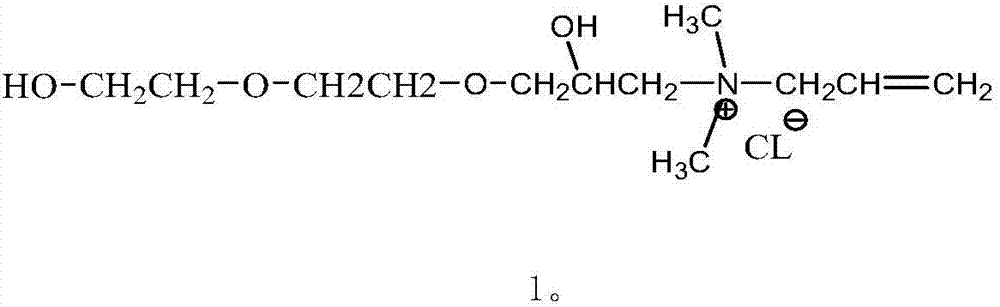

[0027] The chemical name of the leveler is N-(3-diethylene glycol-2 hydroxy)propyl N,N-dimethylallyl ammonium chloride, and the synthesis method is as follows: diethylene glycol (1.0 mole) React with epichlorohydrin (1.02 mol) at 50-60°C to obtain the product, and then react with N,N-dimethyl N-allylamine (1.02 mol) at 70-80°C for quaternization reaction to obtain the product, The yield was 95...

Embodiment 2

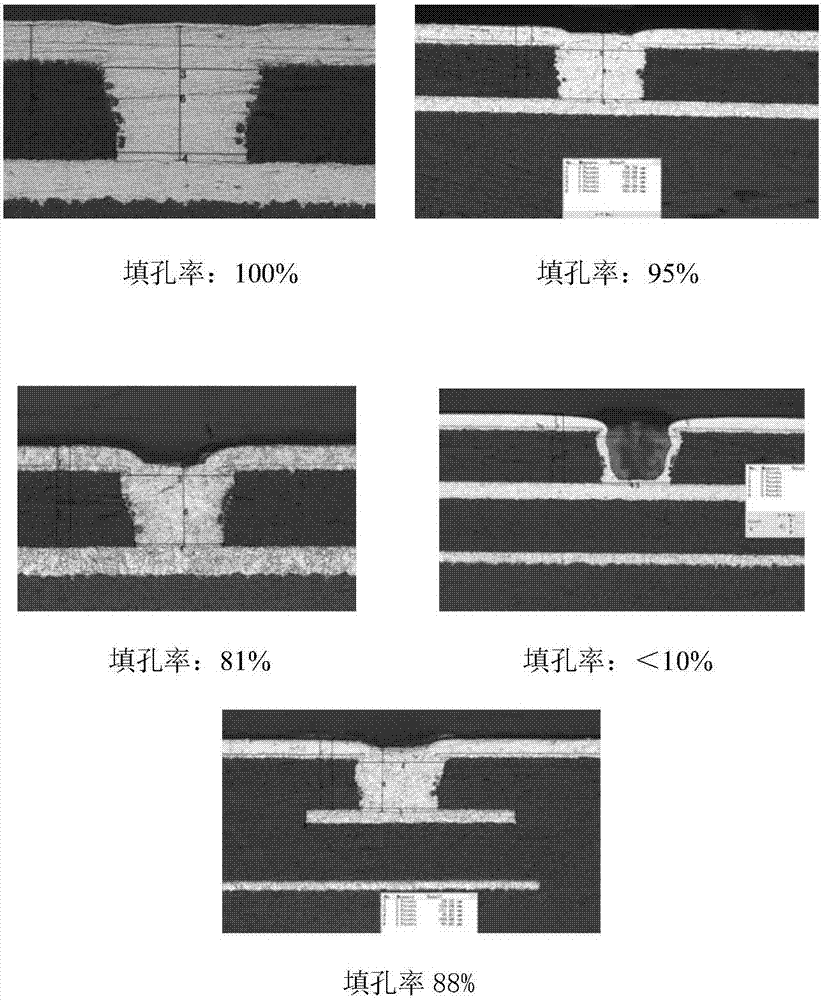

[0043] With reference to Example 1, the difference is that the copper plating bath is made up of the raw materials of the following mass proportions: copper sulfate pentahydrate 200g / L, mass fraction is 98% sulfuric acid 40g / L, sodium chloride 0.05g / L, two Sodium dipropylenesulfonate sulfide 1.5㎎ / L, block polyether 300㎎ / L, N-(3-diethylene glycol-2 hydroxy)propyl N,N-dimethylallyl ammonium chloride 350 ㎎ / L, isophthalic acid 1.0㎎ / L, and the balance is water. After 60 minutes of hole filling and electroplating copper, the hole filling rate is 88%. For the effect of blind and buried hole filling, see figure 1 .

Embodiment 3

[0045] With reference to Example 1, the difference is that the copper plating bath is made up of the following mass ratio raw materials: copper sulfate pentahydrate 240g / L, mass fraction is 98% sulfuric acid 60g / L, sodium chloride 0.12g / L, two Sodium dipropylenesulfonate sulfide 4.0㎎ / L, block polyether 450㎎ / L, N-(3-diethylene glycol-2 hydroxy)propyl N,N-dimethylallyl ammonium chloride 550 ㎎ / L, isophthalic acid 3.0㎎ / L, and the balance is water. After 60 minutes of hole filling and electroplating copper, the hole filling rate is 100%. For the effect of blind and buried hole filling, see figure 1 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com