Stator wire rod insulation onsite repairing method for large generator

A generator stator and wire rod insulation technology, which is applied in the manufacture of motor generators, stator/rotor bodies, electrical components, etc., can solve the problem of ensuring the electrical strength and long-term insulation performance of the main insulation on site, and the curing temperature of epoxy glue. Difficult to fully solidify, damage to the main insulation of the stator bar, etc., to achieve the effects of shortening the repair period, good mechanical strength and process performance, and saving repair costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The invention is a field repair method for the insulation of a large generator stator bar, which includes the following process steps:

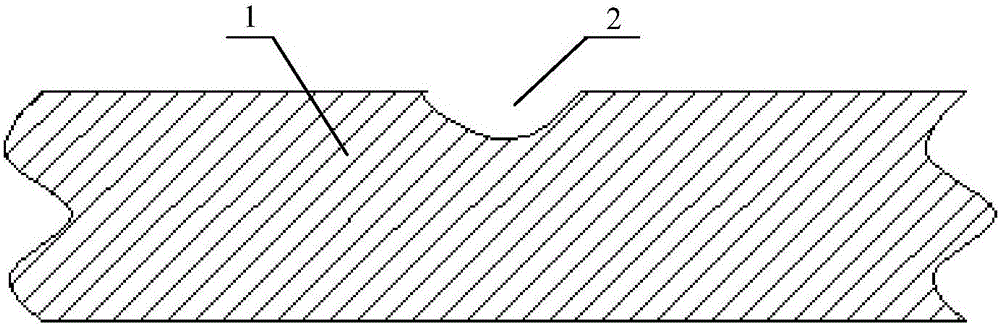

[0038] a. Clean up the damaged part of the stator bar: the damage of the bar is as follows: figure 1 As shown, the part shown in the serial number 1 is the anti-corona layer of the stator bar, and the part shown in the serial number 2 is the damaged part of the stator bar. The damaged part 2 of the stator bar is cleaned comprehensively and carefully, and the damaged bar is first cleaned with a vacuum cleaner. Clean up near point 2, then wipe it carefully with a white cloth dipped in absolute ethanol, and proceed to the next step after confirming that the absolute ethanol has completely evaporated;

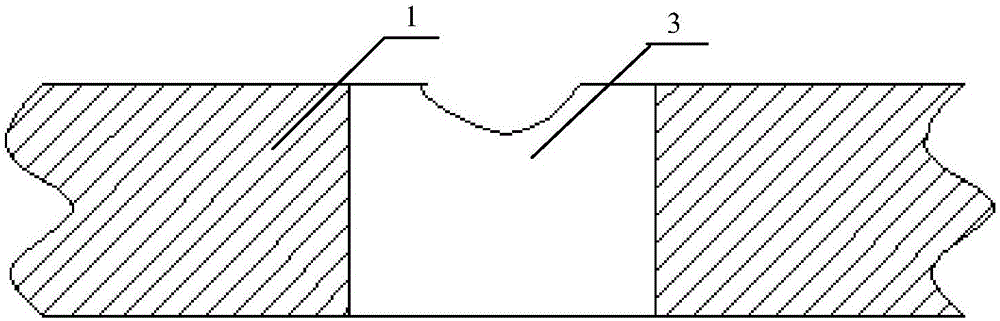

[0039] b. Grind off the anti-corona layer 1 of the damaged part 2 of the wire rod and clean it up: figure 2 As shown, use fine sandpaper to polish off the anti-corona layer 1 on the circumference of the damaged part 2. The part shown in s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com