Method for removing clamp strip type stone plates

A strip type, stone material technology, applied in building maintenance, building components, walls, etc., can solve the problems of time-consuming and consumable materials, increase engineering costs, etc., and achieve the effect of saving engineering costs, strong applicability, and simple and effective methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

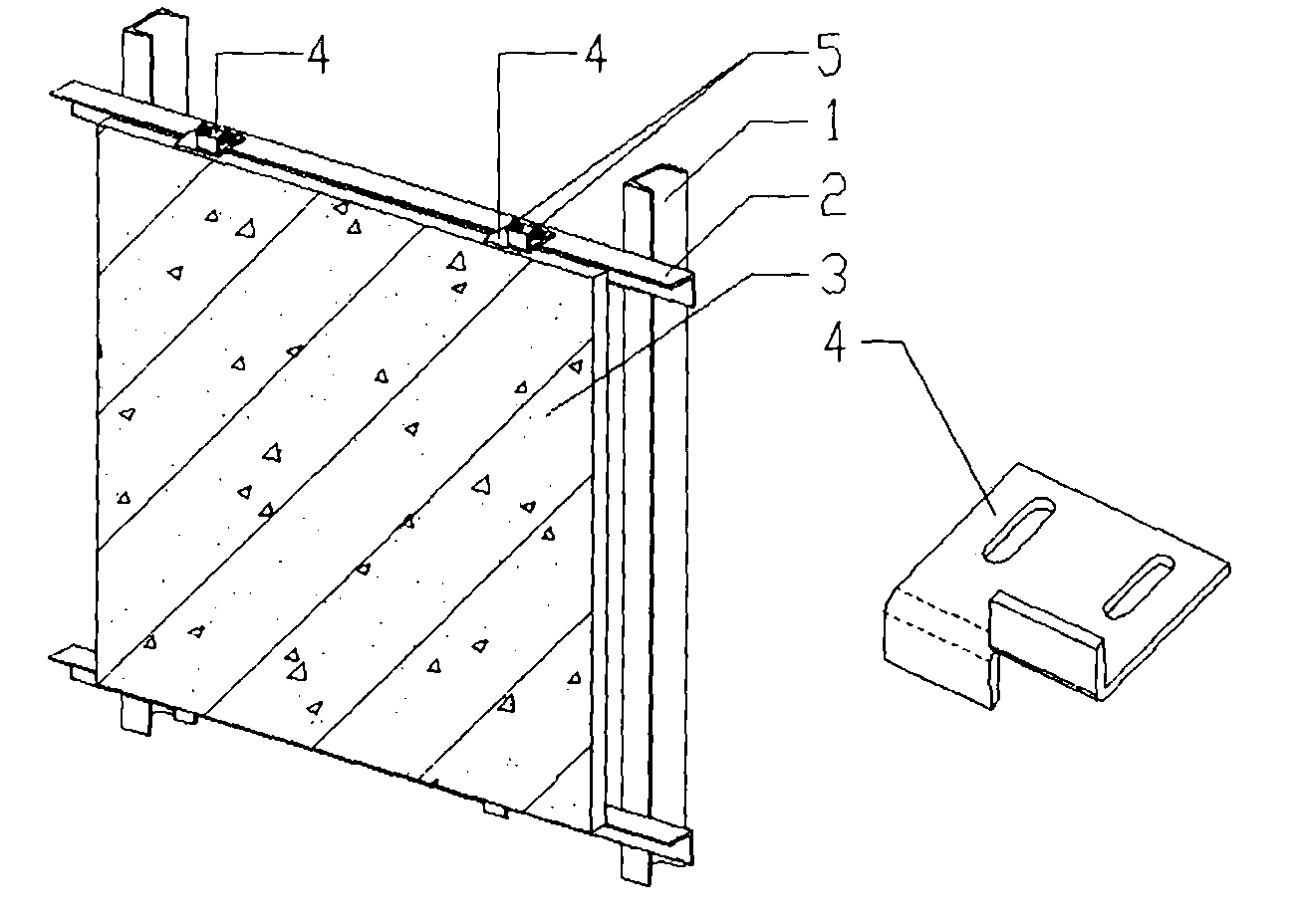

[0022] The specific steps of the present invention to replace the clip-type stone panel are:

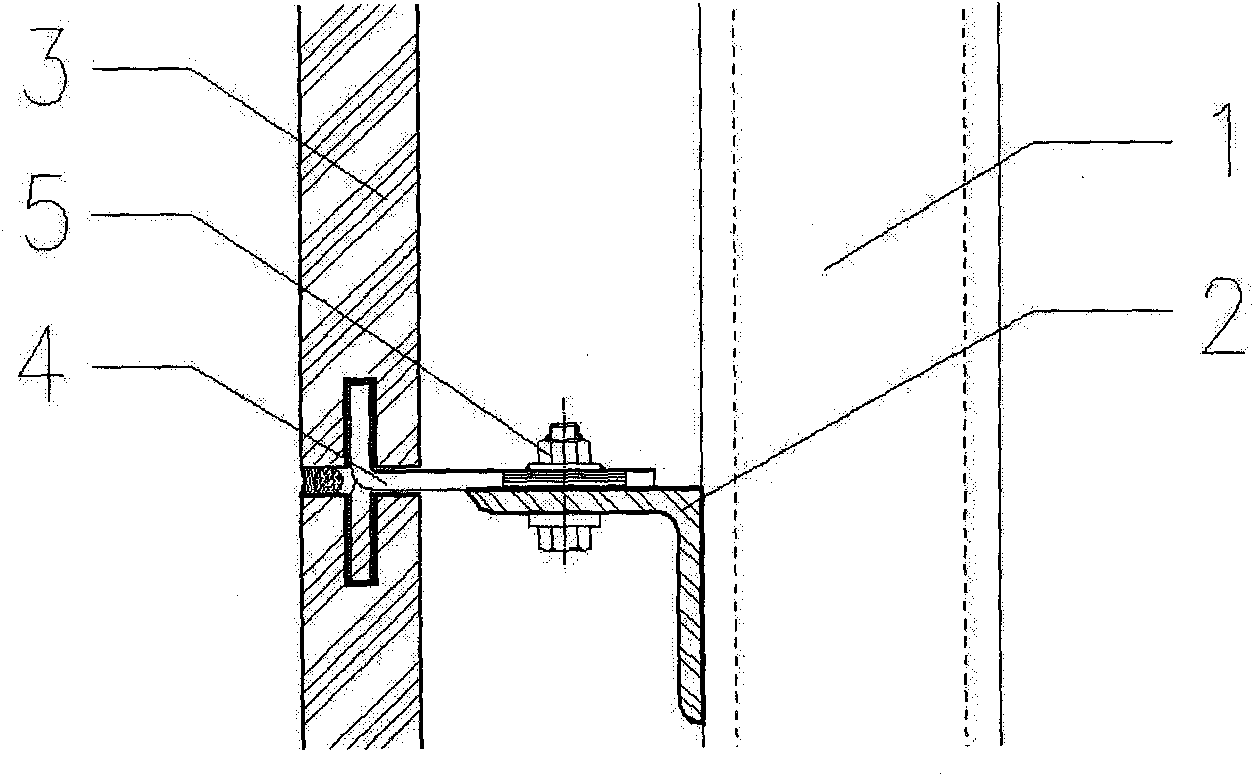

[0023] 7. Remove the damaged panel 3, and cut off the part of the clip 4 used to fix the panel 3, that is, the clip 4 on the upper part of the panel 3 cuts off the downward bend, and the clip 4 on the lower part of the panel 3 cuts off the upward fold. Bend, then clean up the card strip 4;

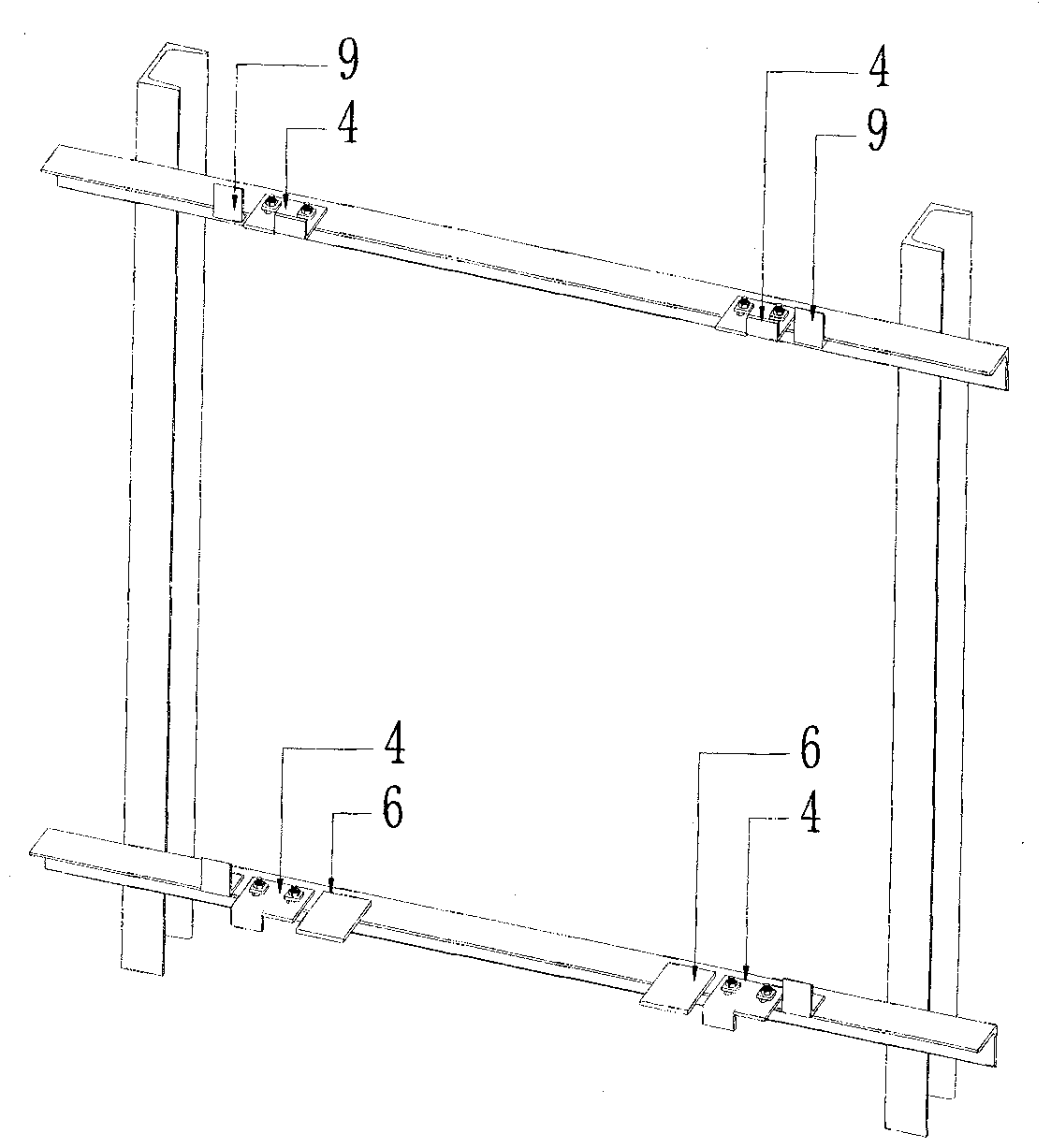

[0024] 8. Weld two steel pallets 6 at the position of the original clip 4 at the lower part of the panel to support the weight of the replaced stone panel 7, and apply anti-corrosion paint to the welded part after welding;

[0025] 9. Weld the inner clamping strip 9 at the position corresponding to the notch of the stone panel 7 on the beam 2, and apply anti-corrosion paint to the welding part after welding. Here, attention should be paid to the connection position of the inner clamping strip and the beam: the upper end surface of the upper inner clamping strip is flush with the lower end surfac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com