Method for catalyzing 2,5-dichlorotoluene reaction by modified H type molecular sieve

A dichlorotoluene and molecular sieve technology, which is applied in molecular sieve catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of restricting the development and research of downstream products, serious corrosion of reaction equipment, and large consumption of catalysts. Ease of control, low cost of raw materials, and simple reaction steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

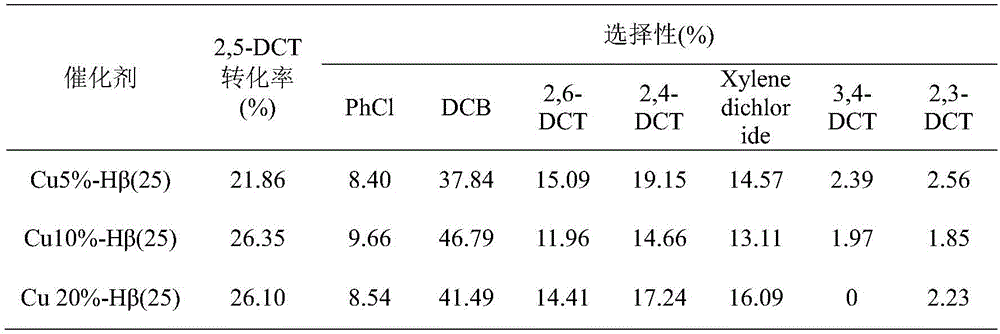

[0033] By changing the amount of loaded metal, we can know the effect of metal loading on the reaction of 2,5-dichlorotoluene catalyzed by the modified H-type molecular sieve, as shown in Table 1:

[0034] Table 1 The effect of the amount of loaded metal on the conversion rate of raw materials and product selectivity

[0035]

[0036] Note: PhCl is chlorobenzene, DCB is dichlorobenzene, 2,6-DCT is 2,6-dichlorotoluene, 2,4-DCT is 2,4-dichlorotoluene, Xylene dichloride is dichloroxylene, 3 , 4-DCT is 3,4-dichlorotoluene, 2,3-DCT is 2,3-dichlorotoluene.

[0037] When the metallic Cu loading is 10%, the reaction temperature is 350 °C, and the carrier gas is N 2 , the volumetric space velocity of the raw material solution is 0.4hr -1 , the conversion rate of 2,5-dichlorotoluene was 26.35%, the selectivity of dichlorobenzene was 46.79%, the selectivity of 2,6-dichlorotoluene was 11.96%, the selectivity of 2,4-dichlorotoluene The selectivity of 3,4-dichlorotoluene is 1.97%.

...

Embodiment 2

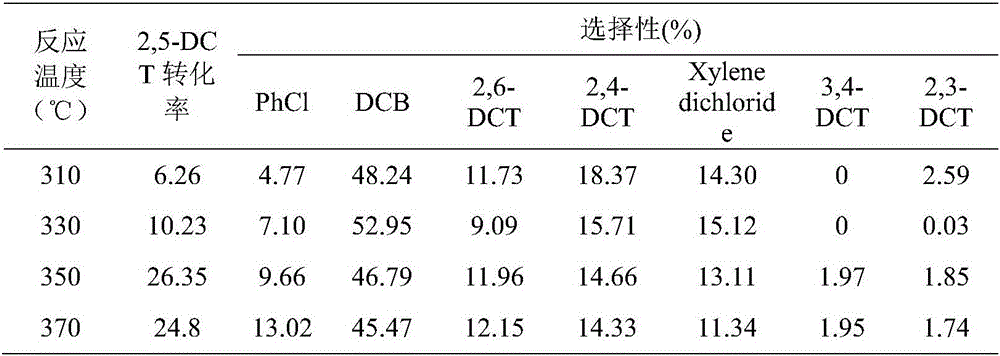

[0040] 2, the process of 5-dichlorotoluene solid-liquid phase reaction adopts the method identical with embodiment 1, Cu10%-Hβ (25), carrier gas is N 2 , the volumetric space velocity of the raw material solution is 0.4hr -1 , but changing the reaction temperature to 310°C, 330°C, and 370°C, we can see the effect of the reaction temperature on the isomerization reaction process of 2,5-dichlorotoluene catalyzed by the modified H-type molecular sieve, as shown in Table 3:

[0041]The influence of table 3 reaction temperature on raw material conversion rate and product selectivity

[0042]

[0043] Note: PhCl is chlorobenzene, DCB is dichlorobenzene, 2,6-DCT is 2,6-dichlorotoluene, 2,4-DCT is 2,4-dichlorotoluene, Xylene dichloride is dichloroxylene, 3 , 4-DCT is 3,4-dichlorotoluene, 2,3-DCT is 2,3-dichlorotoluene.

[0044] When the reaction temperature is 350°C, the conversion rate of 2,5-dichlorotoluene is 26.35%, the selectivity of dichlorobenzene is 46.79%, the selectivit...

Embodiment 3

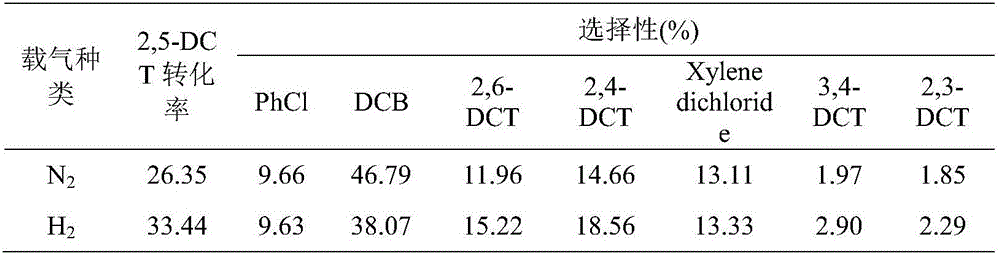

[0047] The process of isomerization of 2,5-dichlorotoluene adopts the same method as in Example 1, Cu10%-Hβ(25), the reaction temperature is 350°C, and the volumetric space velocity of the raw material solution is 0.4hr -1 , but change the type of carrier gas to H 2 , it can be seen that the type of carrier gas affects the isomerization reaction process of 2,5-dichlorotoluene catalyzed by the modified H-type molecular sieve, as shown in Table 3:

[0048] Table 3 The effect of the type of carrier gas on the conversion rate of raw materials and product selectivity

[0049]

[0050] When the carrier gas is hydrogen, the conversion rate of 2,5-dichlorotoluene is 33.44%, the selectivity of dichlorobenzene is 38.07%, the selectivity of 2,6-dichlorotoluene is 15.22%, and the selectivity of 2,4-dichlorotoluene is 33.44%. The selectivity of chlorotoluene was 18.56%, and the selectivity of 3,4-dichlorotoluene was 2.90%.

[0051] The experimental results show that the modified H-typ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com