Three-dimensional color high-speed printer

A printer and color technology, applied in the field of rapid prototyping equipment, can solve the problems of not entering the industrialization stage, lack of methods and equipment for three-dimensional color inkjet printers, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The content of the present invention will be further described below in conjunction with the accompanying drawings, but the actual application form of the present invention is not limited to the illustrated embodiment.

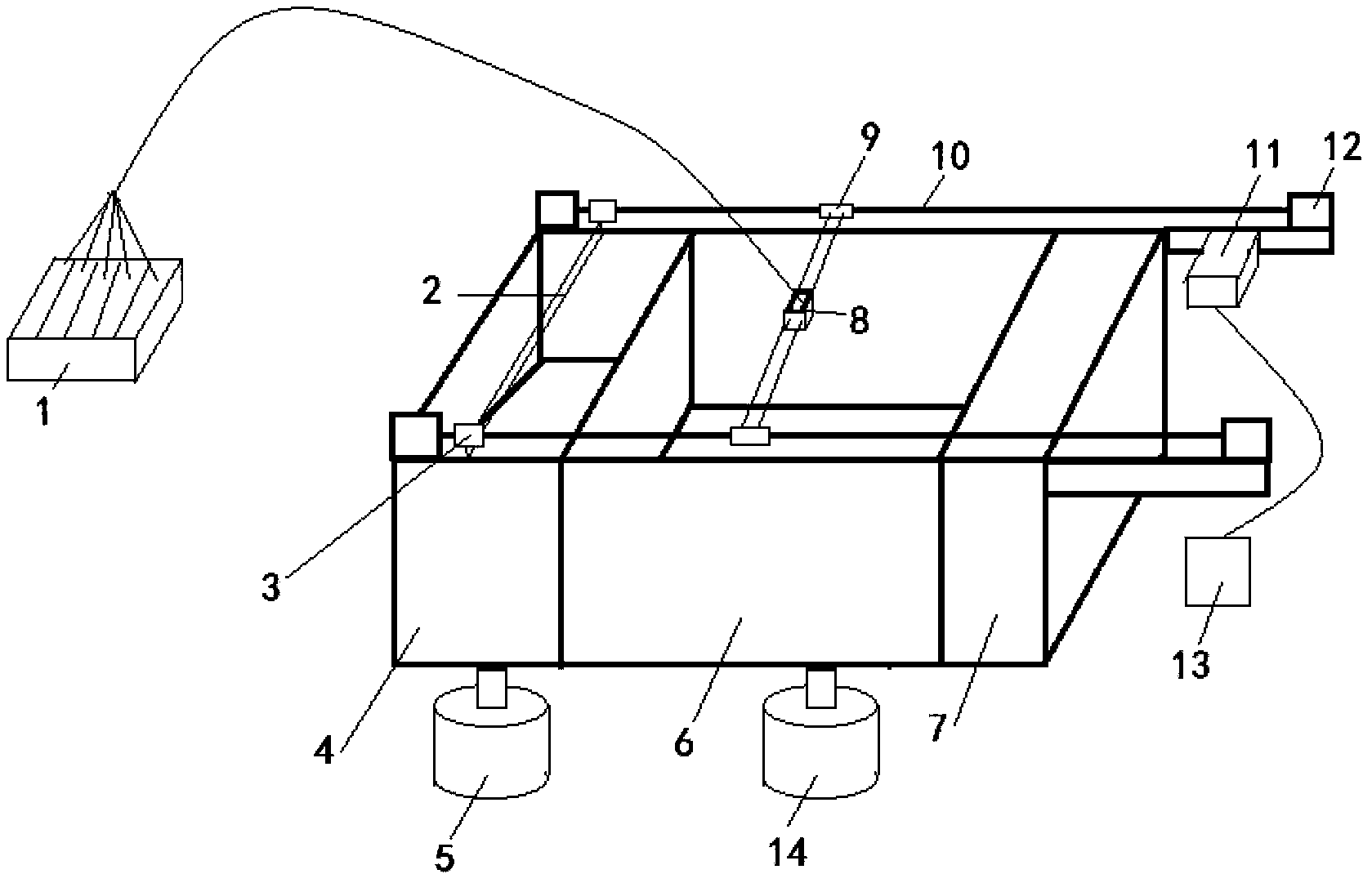

[0044] Referring to the accompanying drawings, the three-dimensional color high-speed printer of the present invention is composed of a mobile printing nozzle 8, a color separation ink supply cartridge 1 with an ink supply pump, a working tank, a computer and peripheral circuits and the like. The working tank is composed of a powder supply tank 4, a forming tank 6 and an overflow tank 7 arranged side by side along the horizontal equal height. A liftable powder supply plate driven by a supply piston 5 is arranged in the powder supply tank 4. In the forming tank, 6 is provided with a liftable production platform driven by piston 14, and two transverse bracket guide rails 10 are horizontally arranged on both sides on the working tank. Two transverse bracke...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com