Patents

Literature

65results about How to "Workmanship is effective" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Silicon-based negative electrode material, preparation method thereof and application of silicon-based negative electrode material in lithium-ion battery

ActiveCN108054368AInhibit swellingImprove conductivityMaterial nanotechnologyElectrode thermal treatmentPolymer dissolutionAnti solvent

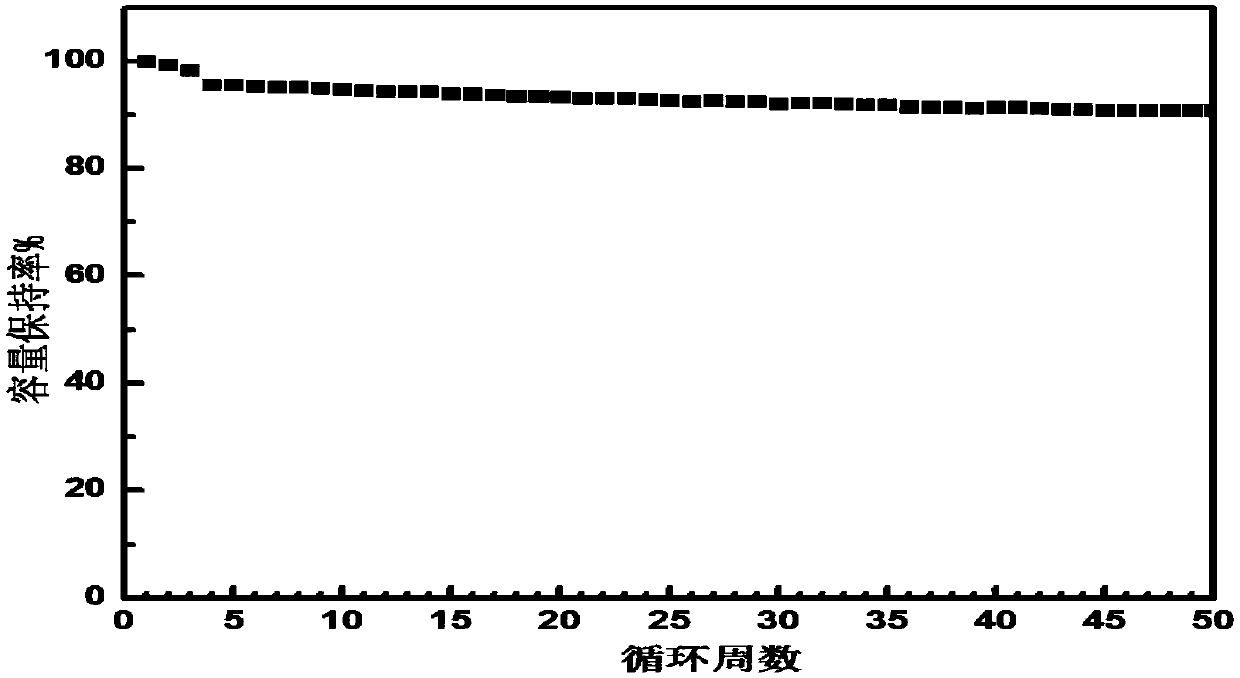

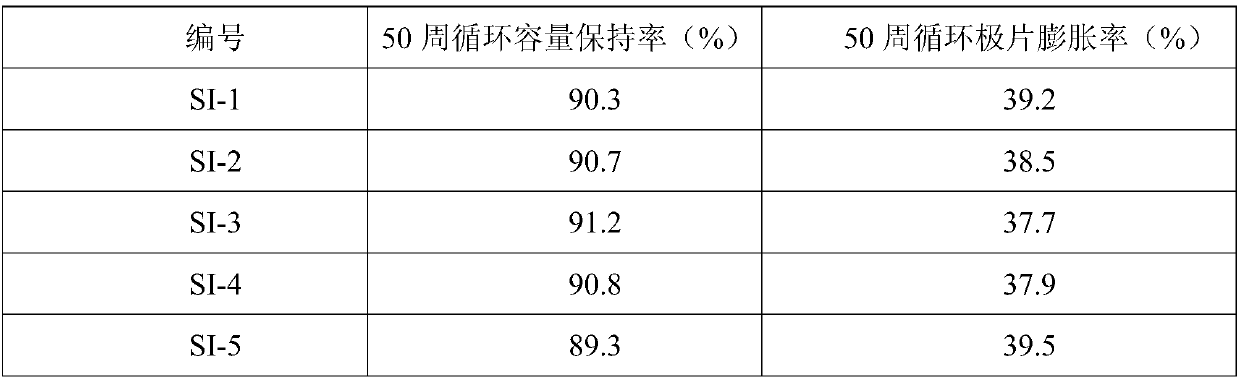

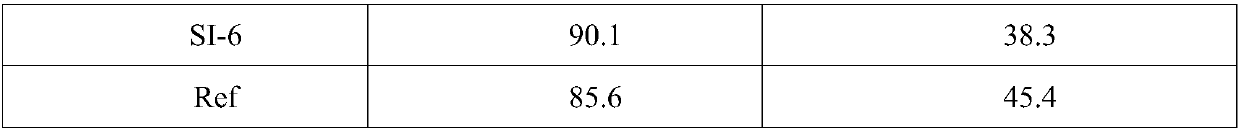

The invention relates to a silicon-based negative electrode material, a preparation method thereof and an application of the silicon-based negative electrode material in a lithium-ion battery. The silicon-based negative electrode material comprises a silicon-based active material and a composite layer, wherein the composite layer coats the surface of the silicon-based active material and is formedby a flexible polymer, flake graphite and a conductive material; and the method comprises the steps of (1) dissolving the flexible polymer into a solvent; (2) adding the flake graphite and the conductive material into a flexible polymer solution obtained in the step (1) under the stirring condition; (3) adding an anti-solvent to a mixed coating solution obtained in the step (2) and stirring; (4)adding the silicon-based active material to the supersaturated mixed coating solution obtained in step (3) under the stirring condition, stirring and separating; and (5) carrying out thermal treatmentto obtain the silicon-based negative electrode material. The silicon-based negative electrode material is simple in preparation method and low in cost, and industrial production is easy to implement;the prepared silicon-based negative electrode material has excellent electrochemical cycle performance and swelling inhibition performance, and the service life of the lithium-ion battery can be prolonged.

Owner:HUI ZHOU BTR NEW MATERIAL TECH

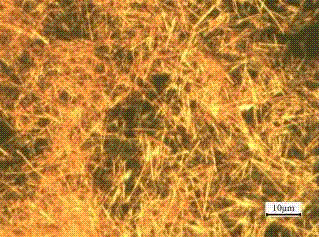

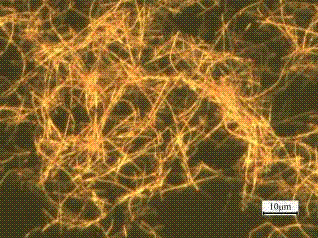

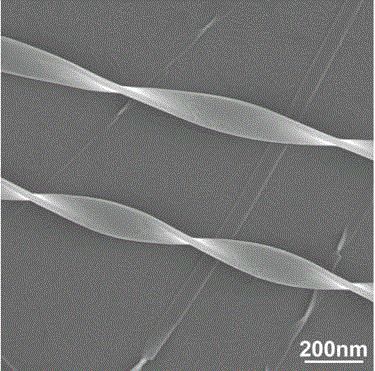

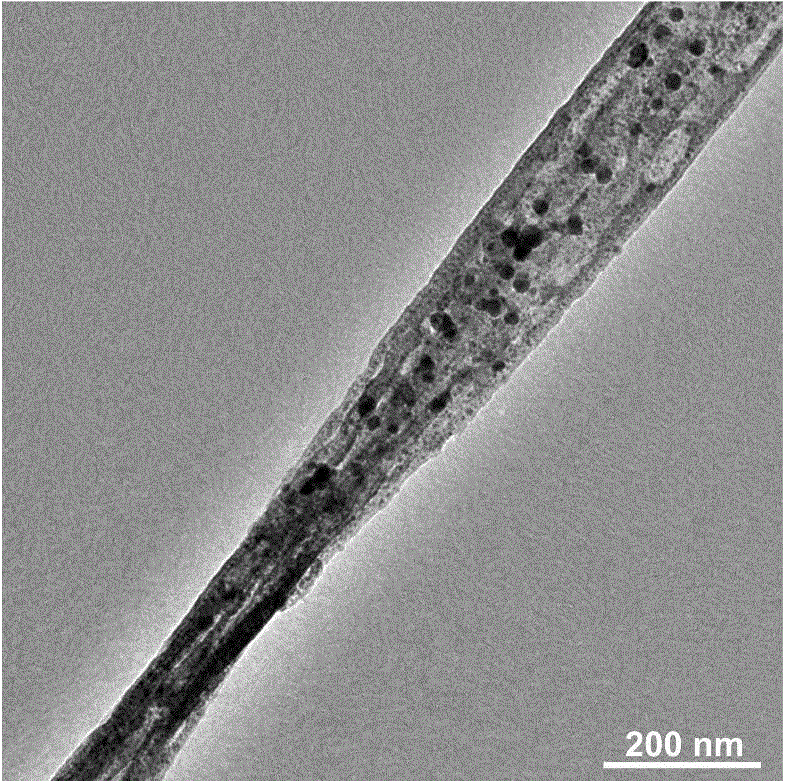

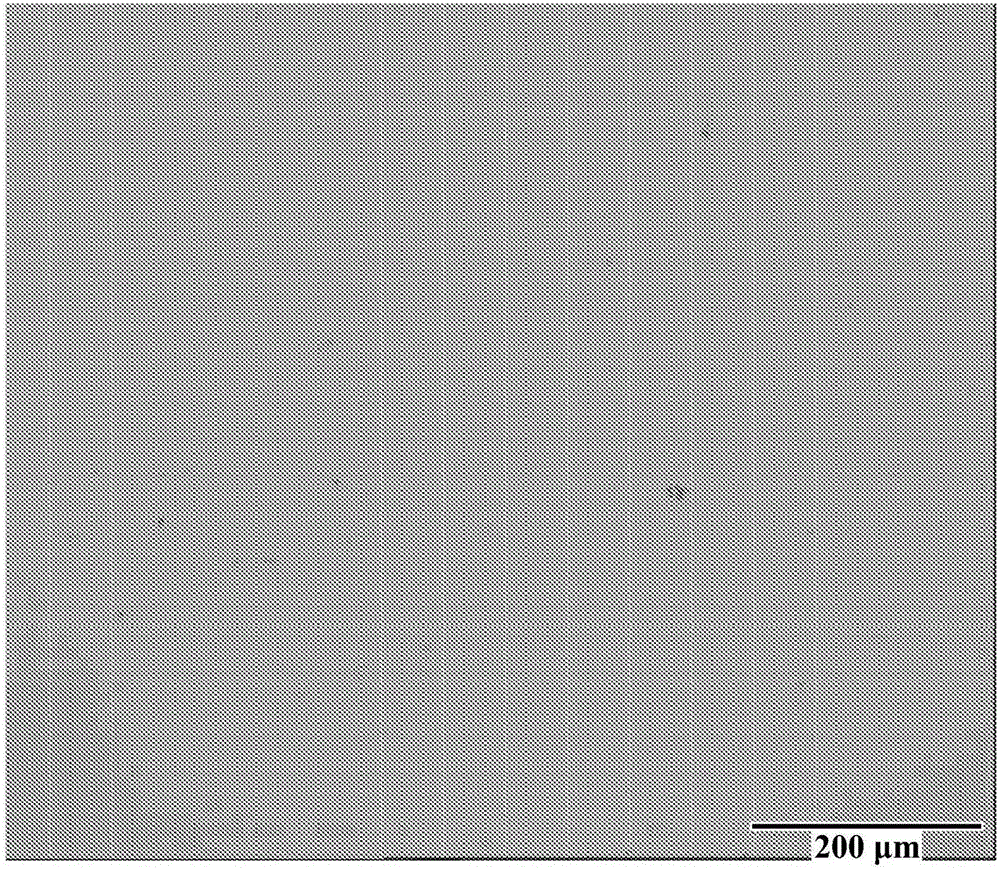

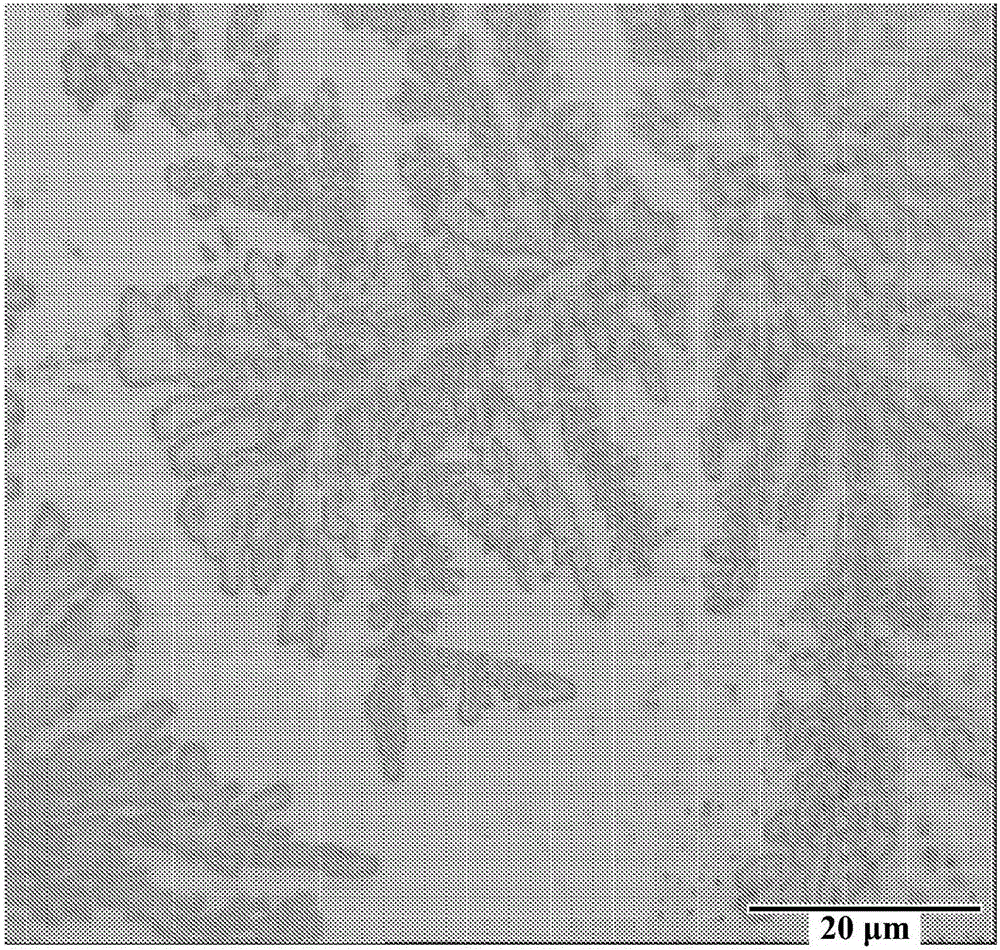

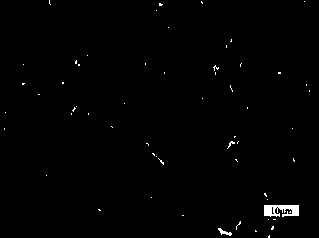

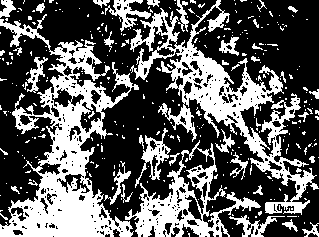

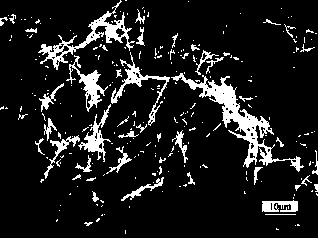

Controllable preparation method of monocrystal copper nanowires

InactiveCN102251278AFlat surfaceUniform radial thicknessPolycrystalline material growthFrom normal temperature solutionsDivalent metalIon

The invention relates to a preparation method of copper nanowires and in particular relates to a controllable preparation method of high-yield monocrystal copper nanowires in a liquid-phase reduction manner. The controllable preparation method comprises the steps: firstly, mixing a divalent metal copper salt solution and ethylenediamine, and heating in a water bath to form a single and stable copper ion chelate compound; mixing a strong base solution with hydrazine hydrate, and preparing a reducing agent in the water bath at the same temperature; then transferring the two mixture solutions into a reaction vessel, fully stirring to reach a uniform state, covering well, and placing in the water bath at the same temperature for heating reaction to prepare the copper nanowires; and fishing out flaky copper nanowires floating on the upper layer of the solution, washing the flaky copper nanowires with deionized water and absolute ethyl alcohol in sequence three times, and drying at room temperature under an Ar gas protection condition to prepare the copper nanowires. The controllable preparation method provided by the invention has the advantages of simple process, low cost and high yield, and the prepared copper nanowires are of monocrystal structures, and have relatively smooth surfaces, uniform radial thickness, and controllable and more uniform length and diameter.

Owner:CHANGZHOU UNIV

Method for improving content of ganoderma triterpenes in ganoderma liquid deep fermentation mycelium

InactiveCN104017852AIncrease dissolved oxygen concentrationImprove permeabilityFungiMicroorganism based processesBiotechnologyMycelium

The invention relates to a method for improving content of ganoderma triterpenes in ganoderma liquid deep fermentation mycelium, and the method is as follows: 1, taking a slant mycelium ganoderma strain, picking a sclertium for inoculating into a seed culture medium, after the inoculation, culturing for 7-14 days to obtain a seed culture liquid; 2, inoculating the cultured seed culture liquid into a fermentation medium according to the inoculum concentration of 5%-15%, after the inoculation, culturing for 3 to 10 days, adding 1vol%-5vol% of oleic acid in the fermentation culturing process to finally obtain ganoderma mycelium for further extract of the ganoderma triterpenes. The method has the advantages of being simple in process and effective, has application value in the industrial production, can successfully achieve significant improvement of yield of an expression product, shortens the fermentation cycle, improves the production efficiency, and has certain guidance and inspiration significance to optimize the fermentation process of other fungal mycelium.

Owner:SHANGHAI ACAD OF AGRI SCI

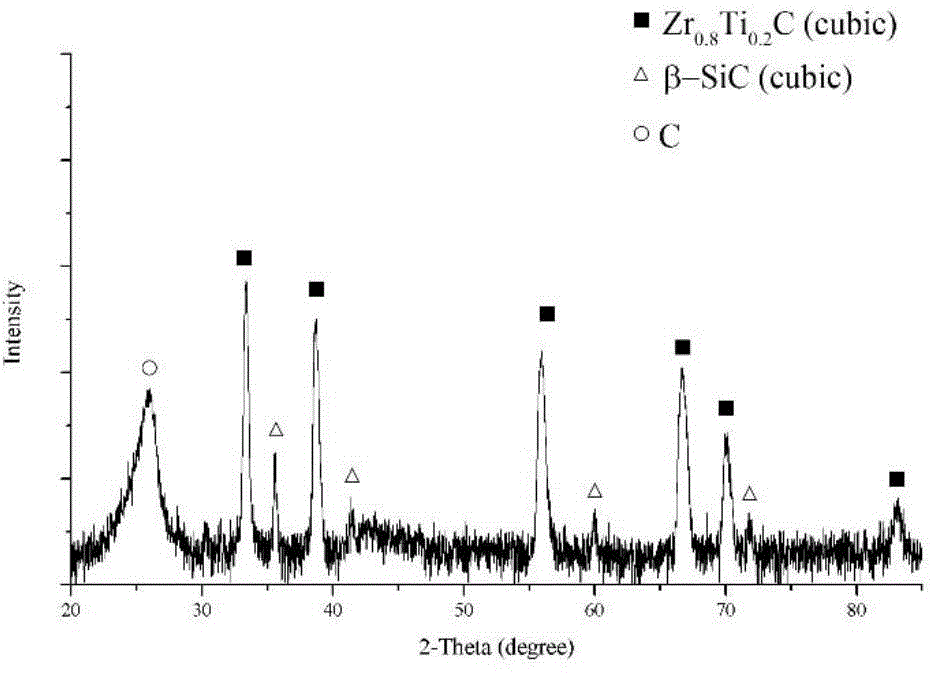

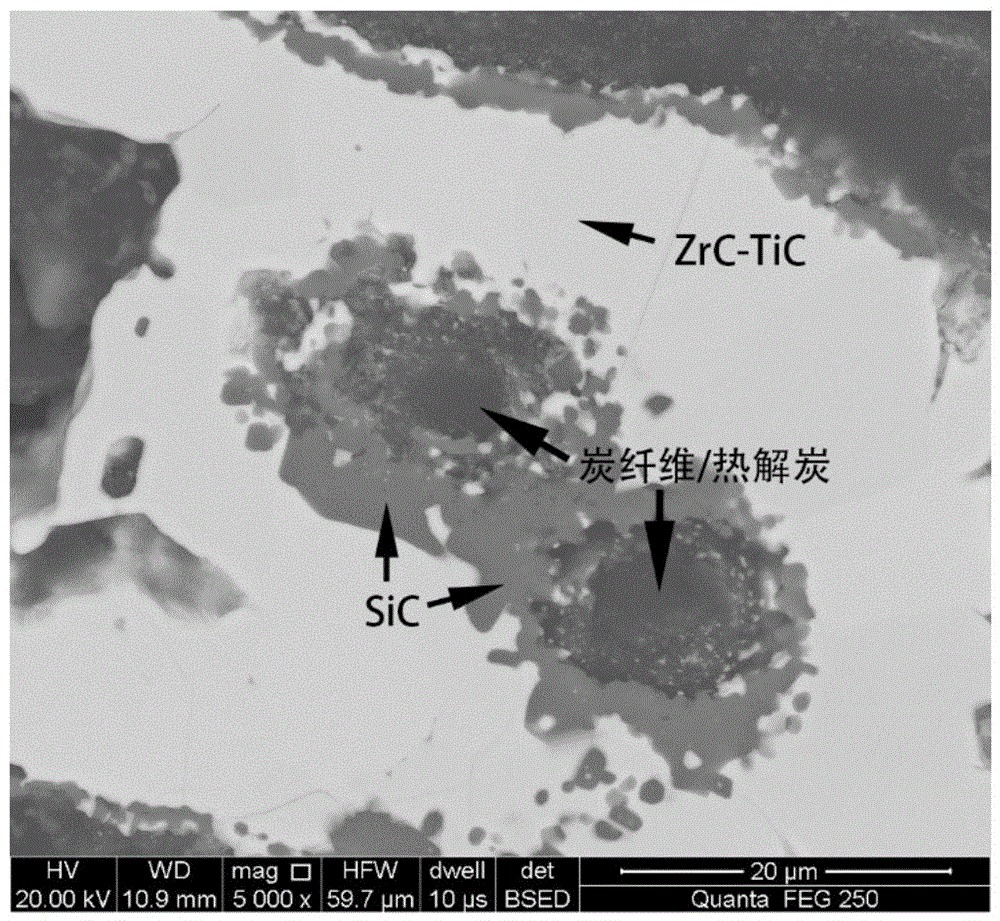

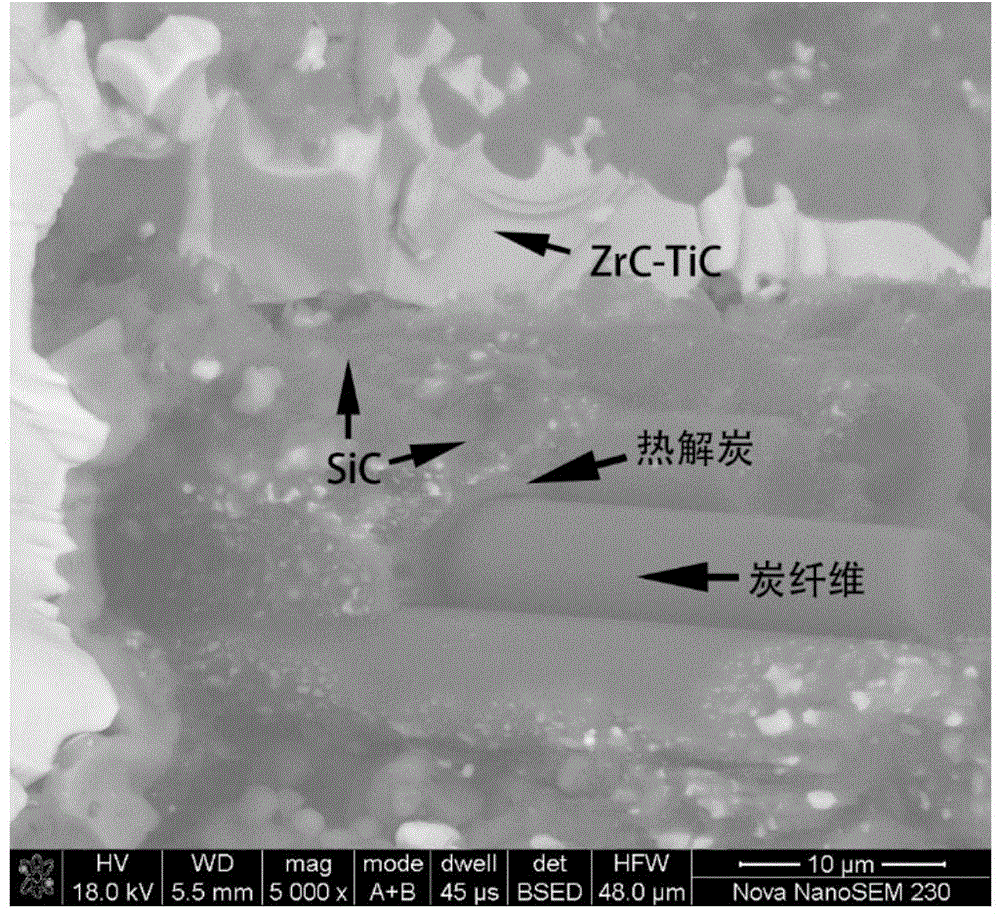

C/C-SiC-ZrC-TiC composite material and preparation method thereof

ActiveCN104671814AReduce thermal mismatchRelieve stress concentrationInterface layerPyrolytic carbon

The invention discloses a C / C-SiC-ZrC-TiC composite material and a preparation method thereof. The composite material is composed of a carbon fibre, a pyrolytic carbon, a main matrix phase ZrC-TiC and a sub matrix phase SiC. The composite material is characterized in that the SiC is used as an interface layer for separating the pyrolytic carbon from the ZrC-TiC. The preparation method comprises the following steps: melting the mixed powder of Zr, Ti and Si, permeating into the inside of the low-density C / C composite material through a capillary action, forming a ceramic phase in a hole through an in situ reaction to obtain the C / C-SiC-ZrC-TiC composite material. The preparation method is rapid and effective and low in cost; the prepared composite material has excellent super-high temperature ablation resistance performance and simultaneously has excellent strength, breaking tenacity and thermal shock resistance.

Owner:深圳金羽先进材料有限公司

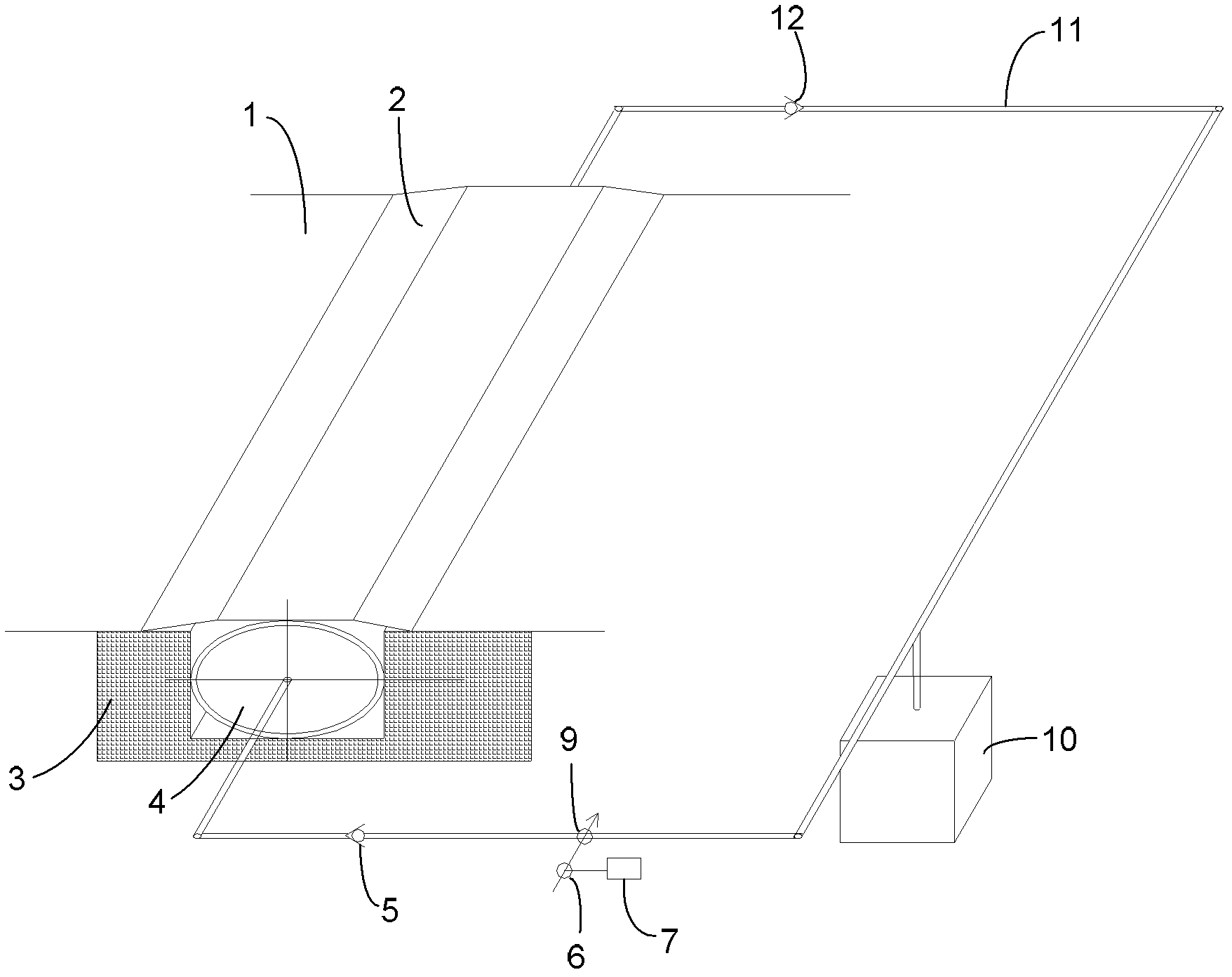

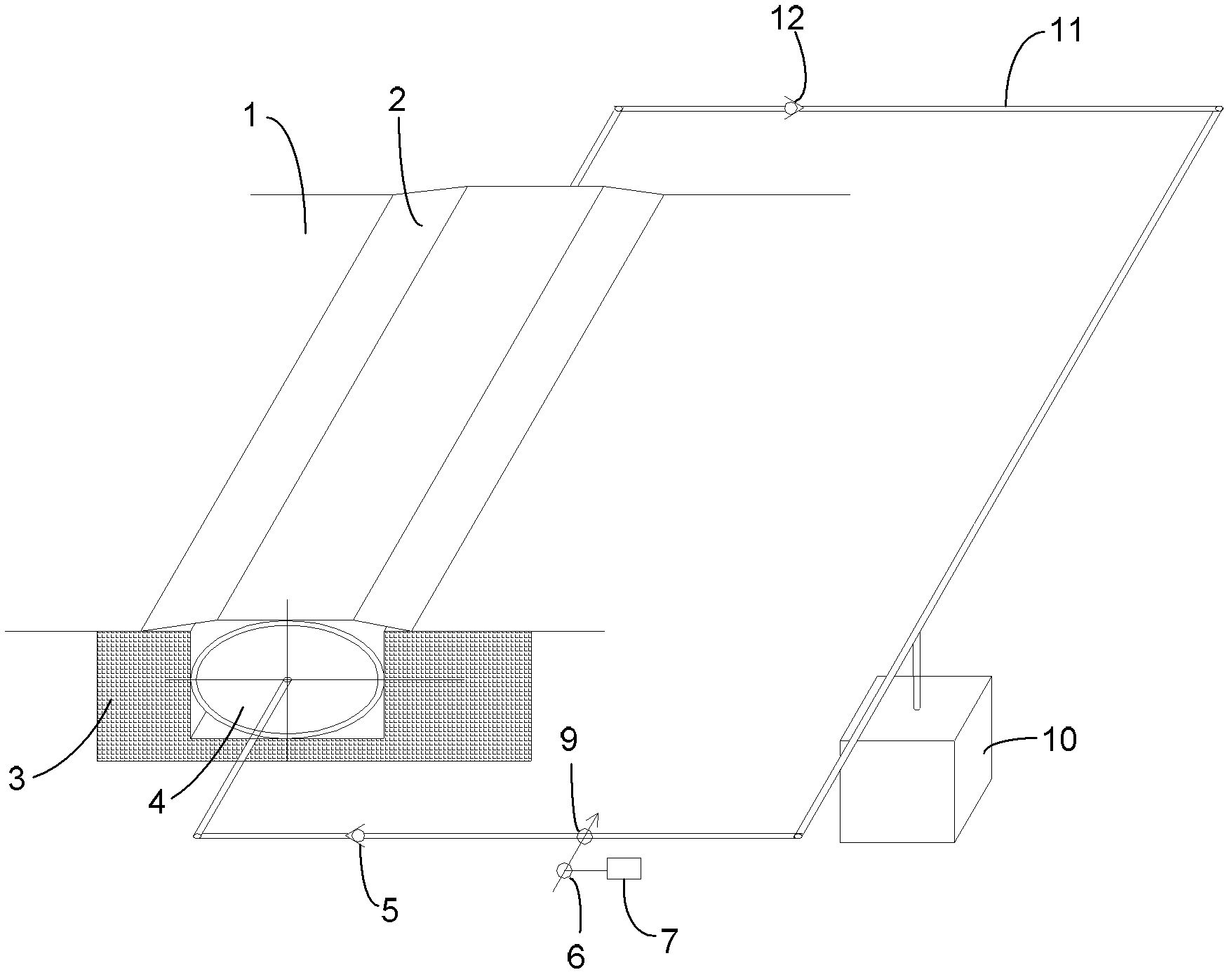

Hydraulic electromagnetic generation device for collecting idle kinetic energy of vehicles

ActiveCN102536691AImprove reliabilityEfficient collectionMachines/enginesMotorsSpeed bumpHydraulic motor

The invention relates to a hydraulic electromagnetic generation device for collecting idle kinetic energy of vehicles, which comprises a protective cover, an energy collector, a one-way valve, a hydraulic motor, an electromagnetic generator, an energy storage device, a pipeline and a buffer device, wherein the buffer device is used for controlling flow rate of fluid in the pipeline, and the energy storage device is an accumulator. The hydraulic electromagnetic generation device is high in energy conversion efficiency, is anti-fatigue, is long in service life and high in reliability, simple in structure, low in production cost, excellent in processing and engineering compatibility, capable of meeting application requirements of vehicle decelerating brake at places such as freeway toll stations, speed bump regions, turning sites and the like, effectively collecting idle kinetic energy generated from the vehicles, has low damage to roadbed and road surfaces, cannot bring any obstacles to running of the vehicles, and can also be used as an emergency power source for power utilization equipment such as lamps on sites such as large-size parking lots, gas station and the like. The energy collector arranged under the road surface can resist corrosion of rainwater and the like so that reliability and stability of power generation floor are improved.

Owner:SHANGHAI MUNICIPAL ELECTRIC POWER CO +2

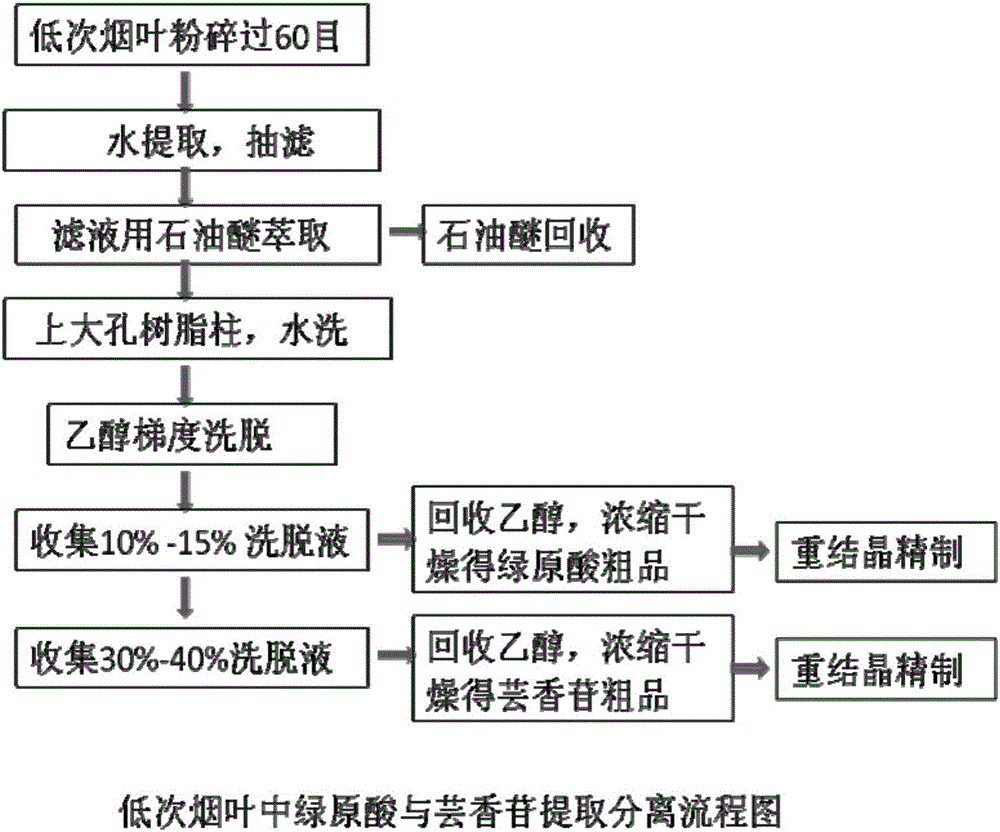

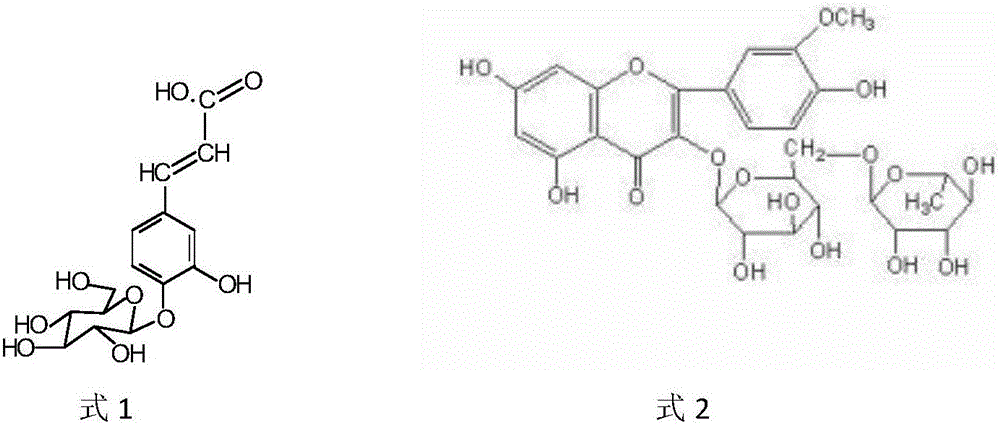

Method for simultaneously separating chlorogenic acid and rutin from tobacco leaves

ActiveCN106496034AReduce extraction costsReduce formationSugar derivativesOrganic compound preparationChlorogenic acidGradient elution

The invention discloses a method for simultaneously separating chlorogenic acid and rutin from tobacco leaves. The method includes: weighting 200g of tobacco leave powder sieved through a 60 mesh sieve, dissolving the tobacco leave powder in water according to a material-liquid ratio of 1:20, setting temperature as 50 DEG C, and stirring and extracting the chlorogenic acid and the rutin for 120min. Petroleum ether is used for extraction and removal of oil-soluble impurities for collected filtrate, and then a chlorogenic acid and rutin extracting solution is obtained. Column chromatography isolation of the chlorogenic acid and the rutin is performed on the upper column of the extracting solution. Water of 5 times of the extracting solution in volume is first used for elution until no sugar can be detected in eluate. After the water is used for the elution, different concentration of ethanol replaces the used eluate for gradient elution. Two types of ethanol eluate 10-15% and 30-40% in concentration are respectively collected so as to obtain a chlorogenic acid solution and a rutin solution. The method for simultaneously separating the chlorogenic acid and the rutin from the tobacco leaves saves raw material and reagents, reduces development cost, and achieves good separating effects.

Owner:CHINA TOBACCO CENTRAL SOUTH AGRICULTURAL EXPERIMENTAL STATION +1

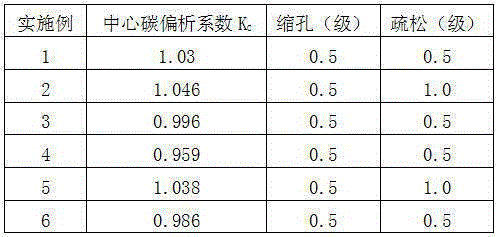

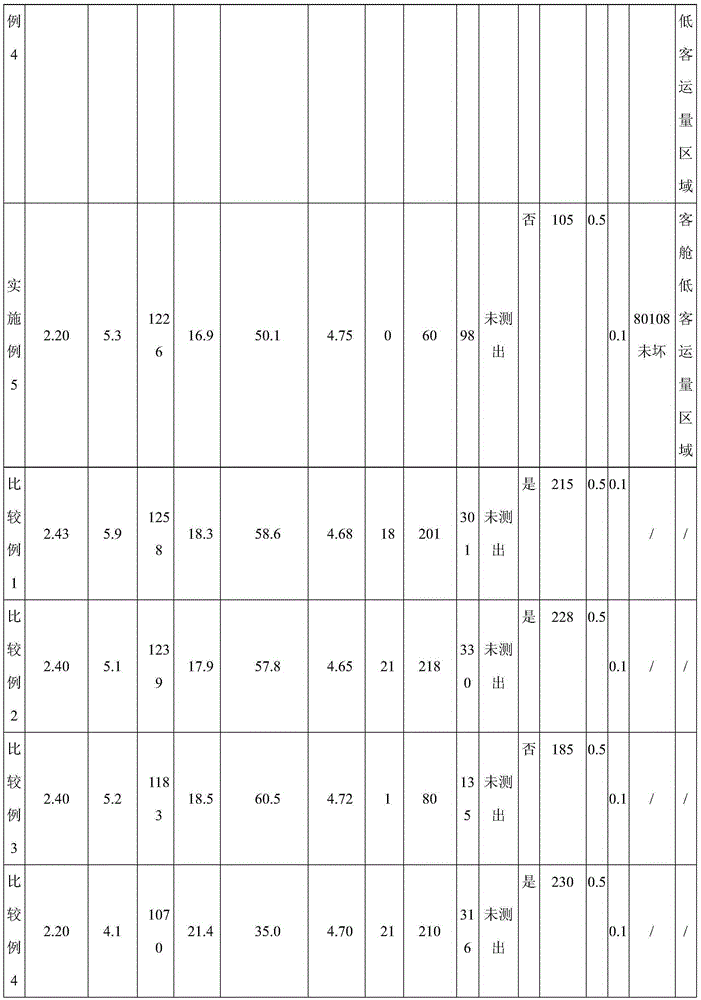

Continuous casting method for controlling center carbon segregation of small high-carbon hard-wire steel square billet

The invention discloses a continuous casting method for controlling center carbon segregation of a small high-carbon hard-wire steel square billet. Crystallizer electromagnetic stirring is adopted in the method. According to the process of the method, the superheat degree of molten steel ranges from 10 DEG C to 35 DEG C, the current of crystallizer electromagnetic stirring ranges from 320 A to 350 A, and the frequency ranges from 3 Hz to 4 Hz; aerial fog cooling is adopted for secondary cooling and the specific water flow ranges from 0.5 L / kg to 0.7 L / kg; and the casting speed ranges from 1.5 m / min to 1.7 m / min. By the adoption of the method, process parameters in the continuous casting process are reasonably adjusted and optimized, the center segregation of the high-carbon hard-wire steel small square billet is obviously improved, a cast blank is sampled for detection, a carbon segregation coefficient KC is controlled between 0.95 and 1.05, and therefore it can be guaranteed that the accidents, caused by center segregation, of net-shaped cementite appearing and breaking are not generated in the following rolling process of the steel billet. Under the conditions that tail-end electromagnetic stirring and soft press are not available, the proper parameters are selected for reasonable adjustment so as to control the continuous casting process, the cast blank defects of center segregation and the like of the small square billet are overcome, and the continuous casting method has the beneficial effects of being simple in process and effective.

Owner:HEBEI IRON AND STEEL

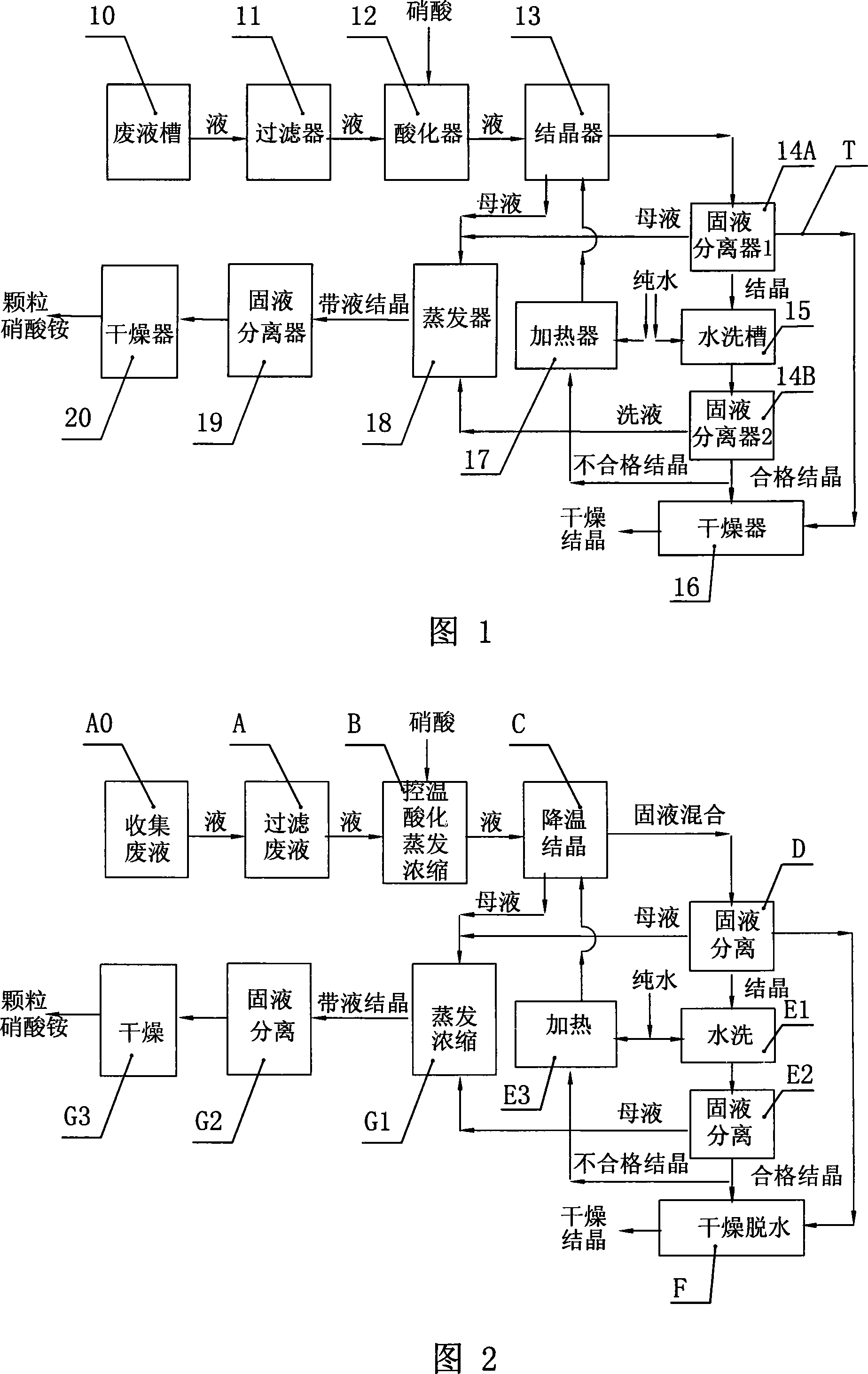

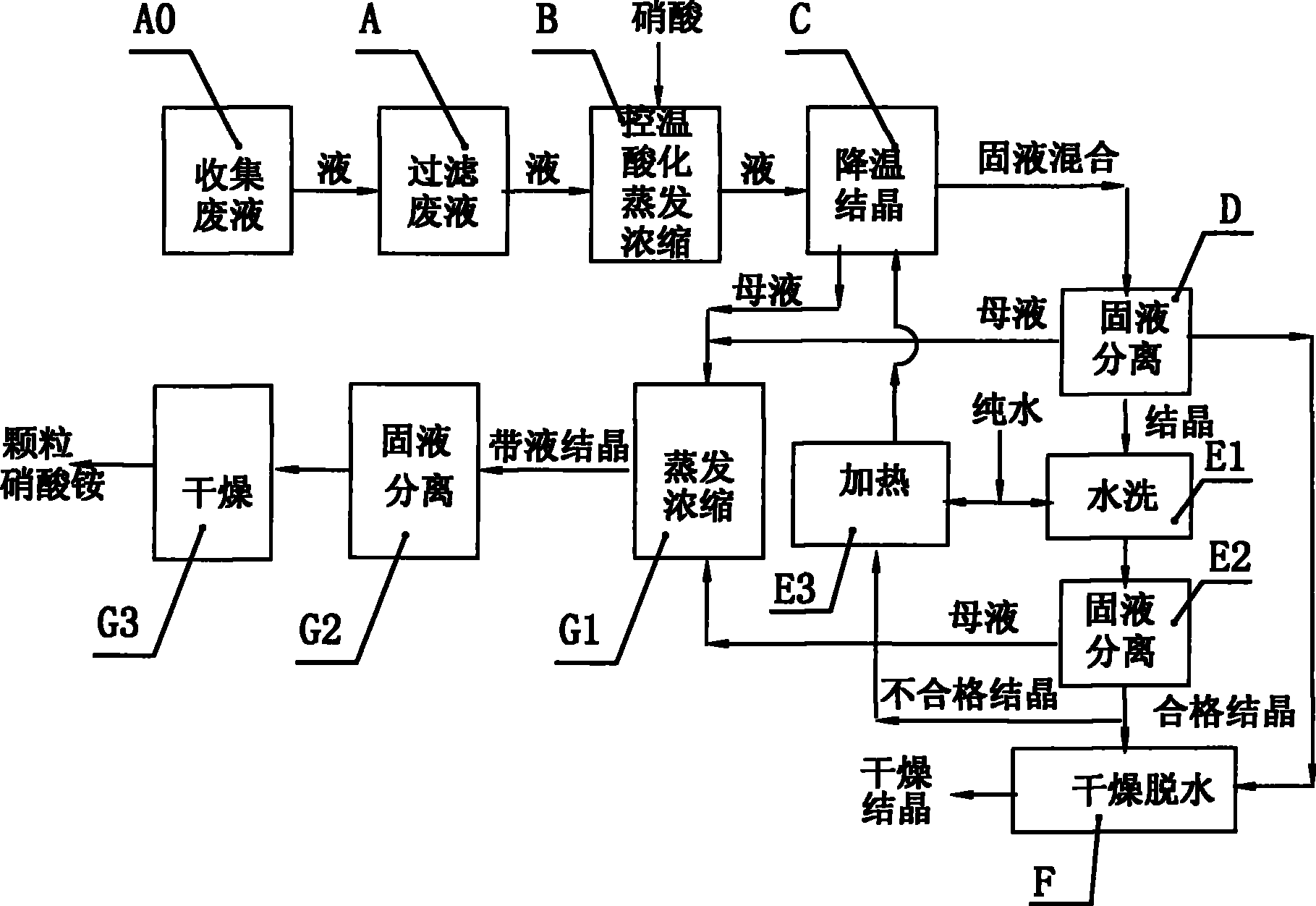

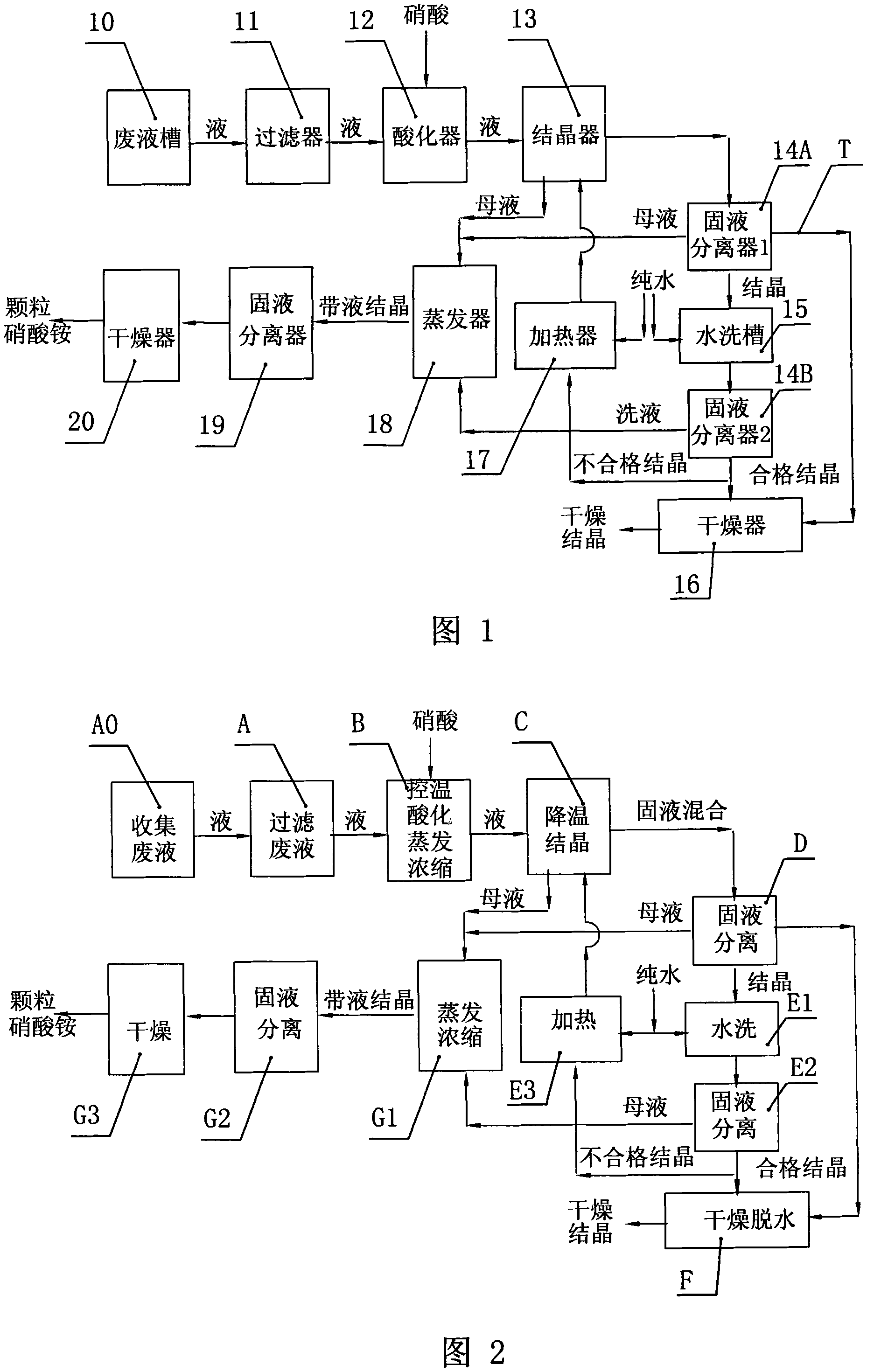

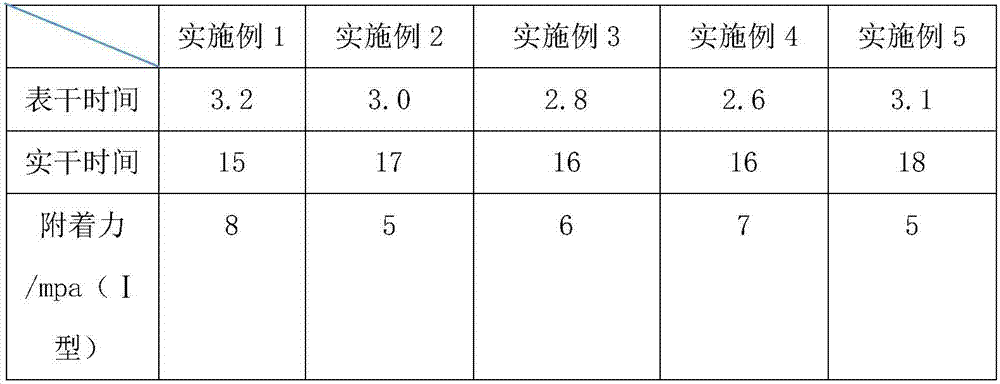

Method for recycling waste liquor of ammonium hexanedioic acid and recycling system thereof

InactiveCN101219946ASimple processGood effectOrganic compound preparationCarboxylic compound separation/purificationAdipic acid / AmmoniumCapacitance

The invention relates to a method and a system for treating and recovering adipic acid ammonium waste liquid and the recovering method comprises the following steps: A. filtering the solid impurities in the waste liquid, B. controlling the temperature of the filtered waste liquid and acidizing the filtered waste liquid, C. decreasing the temperature of the acidulated waste liquid and crystallizing the acidulated waste liquid, D. collecting adipic acid crystal after solid-liquid separation, E. washing to get the adipic acid crystal and collecting the adipic acid crystal after solid-liquid separation. The recovering method and recovering system of the invention have the following advantages: being able to acquire purified adipic acid with standard capacitance; being able to be recycled used in the industries such as an electrolytic capacitor, etc., having a simple and efficient technique and obvious economical benefit and environment protection effect.

Owner:RUYUAN YAO AUTONOMOUS COUNTY DONGYANGGUANG FORMED FOIL CO LTD

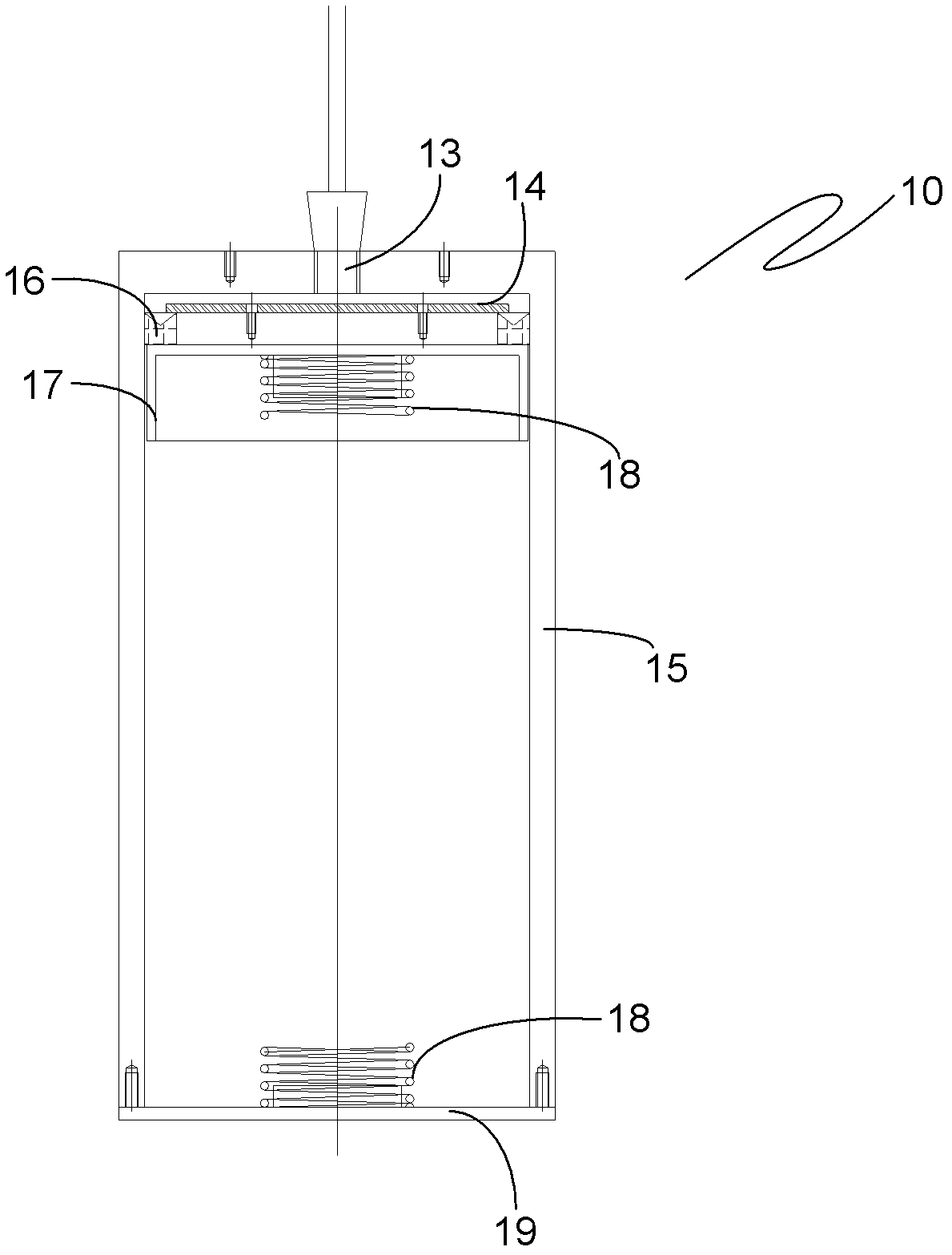

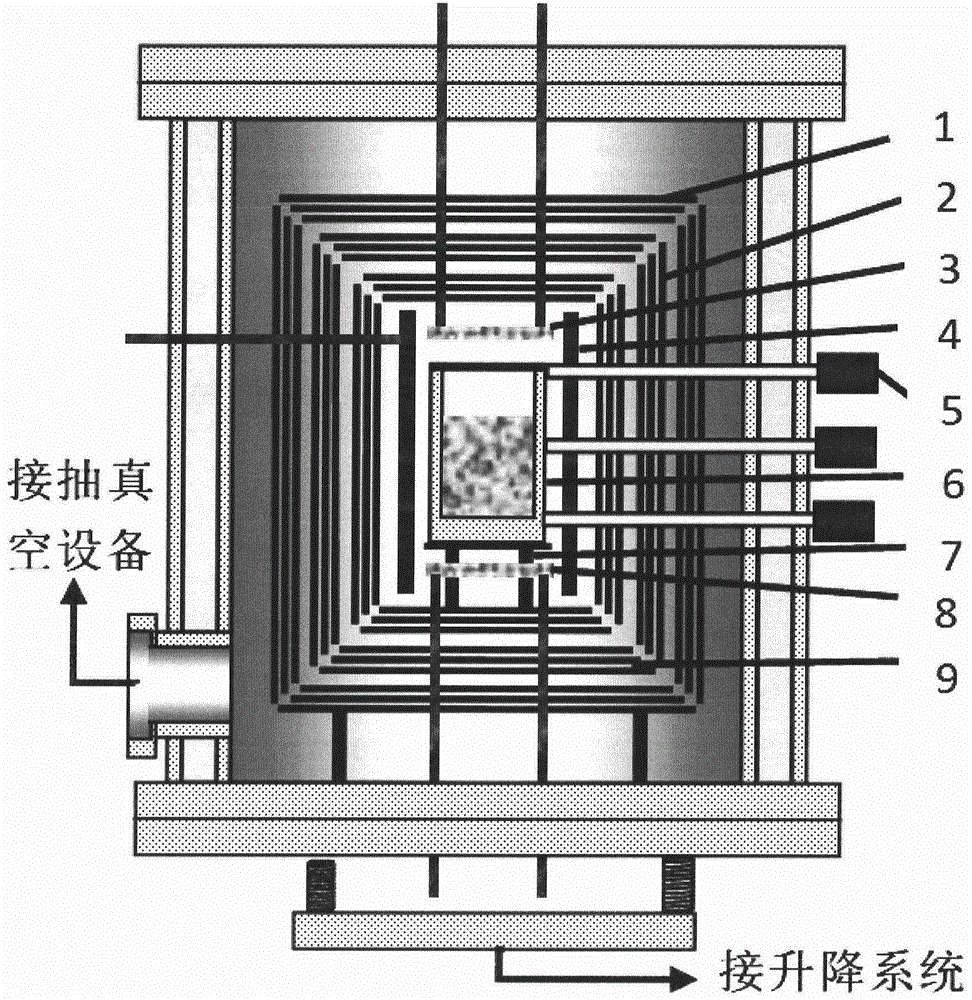

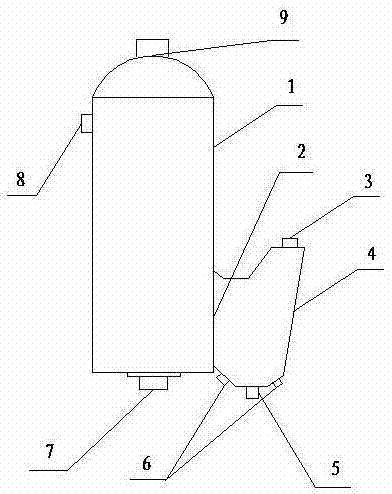

Temperature field controllable aluminum nitride crystal growth device and process

InactiveCN106149057APrecise temperature field controlStrong operabilityPolycrystalline material growthFrom condensed vaporsField conditionsCrystallization

The invention belongs to the field of crystal preparation, in particular to an aluminum nitride crystal growth device and a corresponding process. The invention provides an aluminum nitride crystal growth device and process with controllable temperature field, which has the advantages of precise temperature field control and strong operability, and the corresponding growth process developed thereby conforms to the crystallization characteristics of aluminum nitride crystal. The preparation device comprises a top heater, a middle heater, a bottom heater, a top insulation layer, a side insulation layer, a bottom insulation layer, an infrared thermometer, a crucible and a crucible support. The device controls and adjusts the heating power of the top heater, middle heater and bottom heater according to the temperature signals of three different positions in the growth area returned by the three infrared thermometers, which satisfies the appropriate temperature field for the growth of aluminum nitride crystals condition. The invention provides a suitable growth device and an effective and feasible process for preparing a large-size, high-quality aluminum nitride single crystal.

Owner:SHENZHEN UNIV

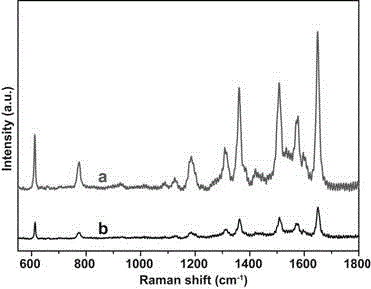

Preparation method of silver-based composite nanomaterial with surface-enhanced Raman activity, product obtained with preparation method and application of silver-based composite nanomaterial

InactiveCN105174211ASimple processEasy to controlIndividual molecule manipulationRaman scatteringChemistrySodium borohydrate

The invention discloses a preparation method of a silver-based composite nanomaterial with surface-enhanced Raman activity, a product obtained with the preparation method and an application of the silver-based composite nanomaterial. The preparation method comprises preparation steps as follows: silver ions and melamine have a coordination polymerization reaction in water, and a coordination polymer is obtained; the coordination polymer is reduced with a sodium borohydride solution, nanosilver is generated on the surface of the coordination polymer, a layer of metal oxide is deposited on the surface of the reduced intermediate product, the deposited product is calcined, and the silver-based composite nanomaterial is obtained. The intermediate product with good morphology is obtained through the simple coordination polymerization reaction, silver sources can be uniformly dispersed in the intermediate product, the intermediate product is taken as a sacrificial template, and the silver-based composite nanomaterial with good morphology is obtained through metal oxide deposition and calcination. A process is simple, particle sizes of the obtained nanosilver particles are small, the nanosilver particles are distributed in a concentrated manner and are not prone to agglomeration under the protection of metal oxide, the stability is high, the SERS (surface-enhanced Raman scattering) effect is remarkable, and the silver-based composite nanomaterial has wide application prospect.

Owner:HAINAN UNIVERSITY

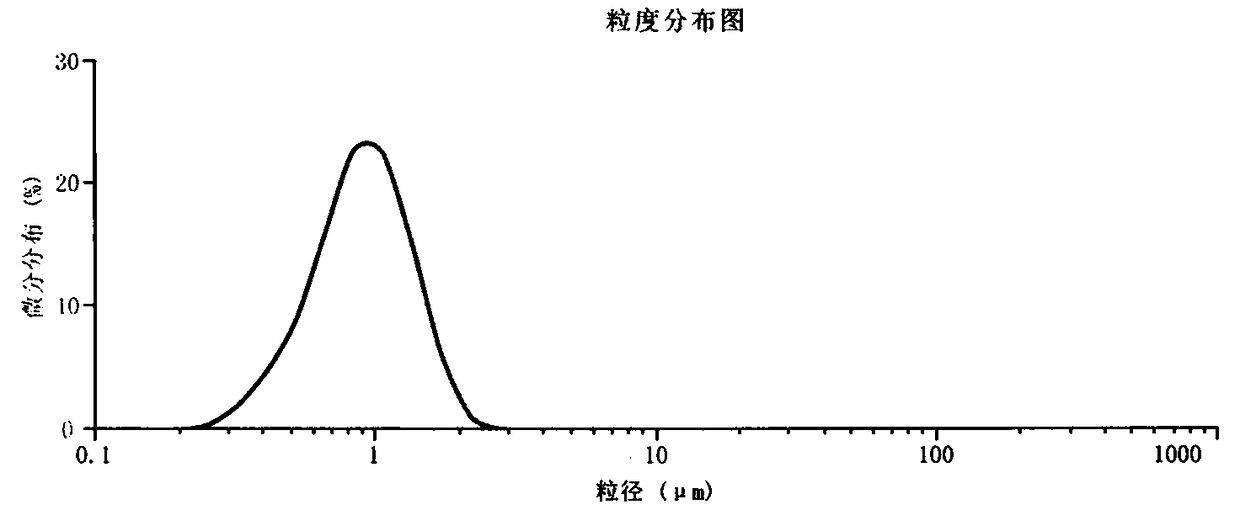

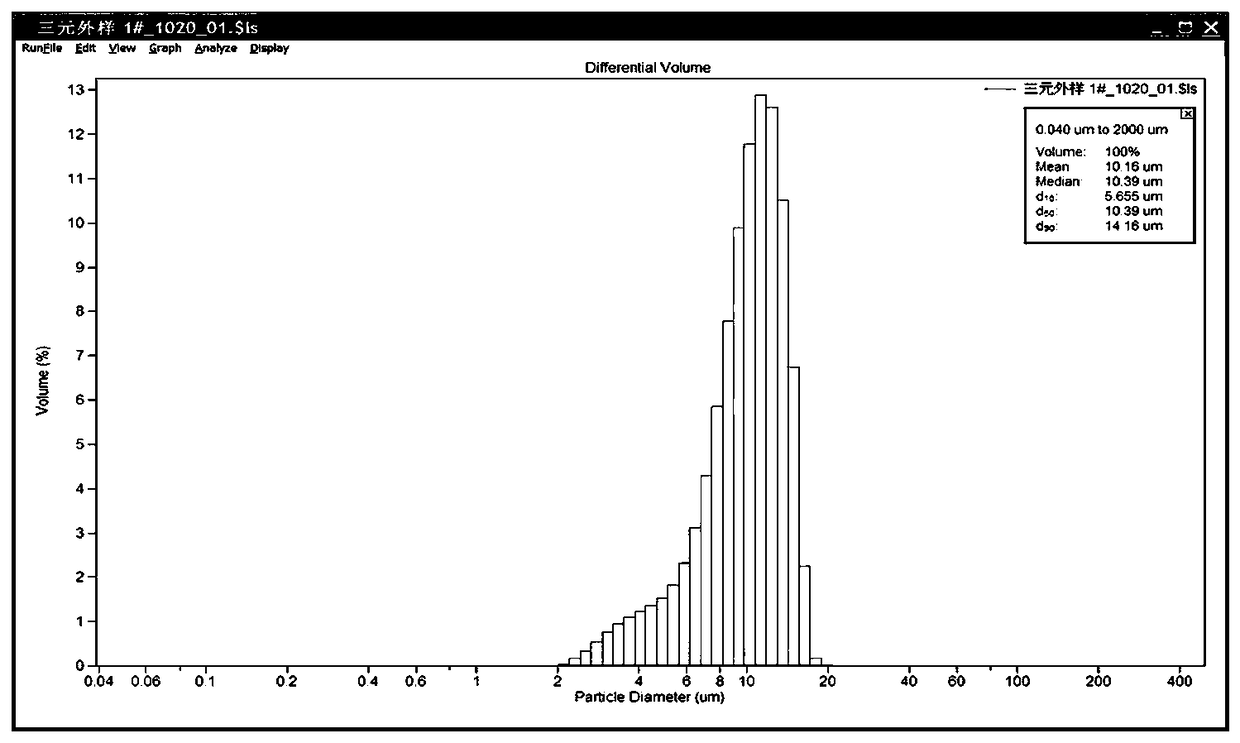

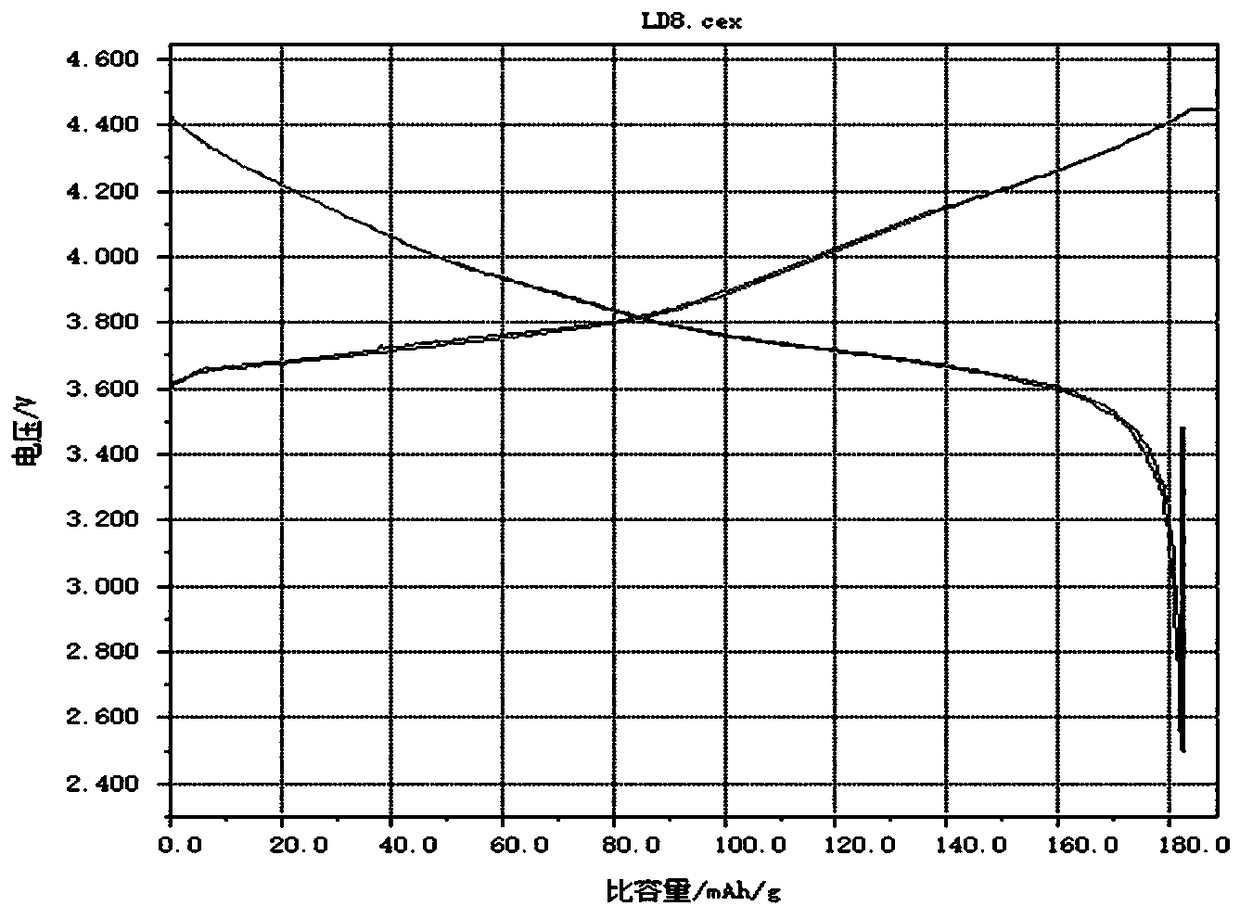

Preparation method of coating slurry based on lithium manganese iron phosphate flexible slurry wrapped ternary material

ActiveCN108666545AAvoid security issuesIncrease capacityCell electrodesSecondary cellsTotal solid contentEmulsion

The invention discloses a preparation method of coating slurry based on a lithium manganese iron phosphate flexible slurry wrapped ternary material. The preparation method comprises the following steps of: (1) weighing a flexible film-forming material, adding N-methyl pyrrolidone, dissolving and preparing a viscous emulsion with a mass percentage of 2% to 10%, stirring and dispersing or ball milling; (2) weighing the conductive agent of SUPER-P, conductive graphite or conductive carbon powder of which a total solid content of a design system is 0%-10%; (3) weighing the lithium manganese iron phosphate material of which the total solid content of the design system is 5% to 50%; (4) adding the weighed lithium manganese iron phosphate into the prepared viscous emulsion, and preparing a uniform viscous film-forming slurry wrapped emulsion by dispersing and stirring, or ultrasonic dispersion, or ball milling and homogenizing; and (5) weighing the ternary material of which the solid contentof the design system is 50% to 95%, adding the ternary material into the prepared coating emulsion, and stirring and dispersing the mixture uniformly, so as to prepare the lithium iron manganese phosphate flexible coating ternary material that can be used for direct coating. According to the preparation method of coating slurry based on a flexible coating ternary material containing lithium manganese phosphate, the safety problem of the ternary materials is effectively solved, the cycle life and energy density are improved, and the method is simple and reliable and is suitable for industrial production.

Owner:南阳逢源新能源科技有限公司

Method for recycling waste liquor of ammonium hexanedioic acid and recycling system thereof

InactiveCN101219946BSimple processWorkmanship is effectiveOrganic compound preparationCarboxylic compound separation/purificationCapacitanceAdipic acid / Ammonium

The invention relates to a method and a system for treating and recovering adipic acid ammonium waste liquid and the recovering method comprises the following steps: A. filtering the solid impurities in the waste liquid; B. controlling the temperature of the filtered waste liquid and acidizing the filtered waste liquid; C. decreasing the temperature of the acidulated waste liquid and crystallizing the acidulated waste liquid; D. collecting adipic acid crystal after solid-liquid separation; E. washing to get adipic acid crystal and collecting the adipic acid crystal after solid-liquid separation. The recovering method and recovering system of the invention have the following advantages that the recovering method and recovering system of the invention are able to acquire a purified adipic acid with standard capacitance and able to be circularly used in the industries such as an electrolytic capacitor, etc. with a simple and efficient technique and obvious economical benefit and environment protection effect.

Owner:RUYUAN YAO AUTONOMOUS COUNTY DONGYANGGUANG FORMED FOIL CO LTD

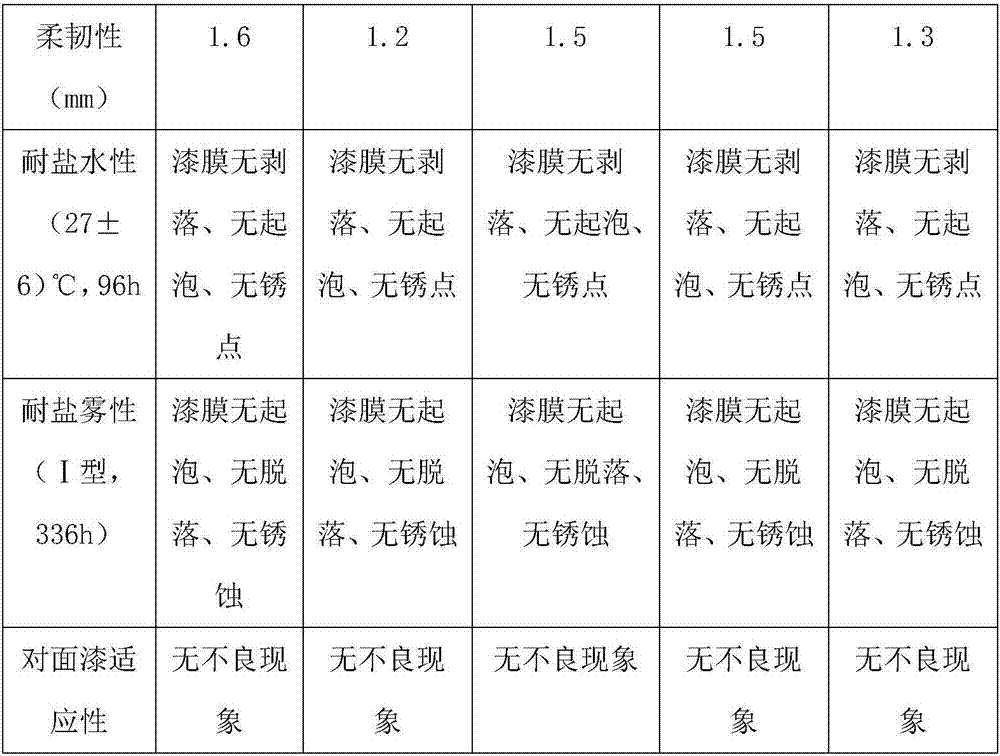

Antirust coating for steel facilities under oceanity condition and preparation method thereof

InactiveCN107384136AEvenly dispersedSimple methodAnti-corrosive paintsEpoxy resin coatingsEpoxyPetrochemical

The invention provides an anti-rust coating for steel facilities under an oceanity condition and a preparation method thereof. The anti-rust coating provided by the invention is prepared from the following components in percentage by mass: 26-28 percent of diphenol propane epoxy resin, 5-8 percent of vapor-phase corrosion inhibitor, 13-18 percent of organic solvent, 43-55 percent of pigment and filler and 1-3 percent of auxiliary agent. The technical scheme provided by the invention overcomes the defect that the traditional anti-rust pigment has great toxicity while improving corrosion resistance of a coating layer, can quickly act on a metal surface, provides corrosion inhibition protection, has long-lasting protection and has a high utilization rate. The anti-rust coating can be applied to the protection of steel facilities under the oceanity condition, such as the construction and maintenance of of ships, petrochemical facilities and large bridges.

Owner:ZHEJIANG YUTONG NEW MATERIAL

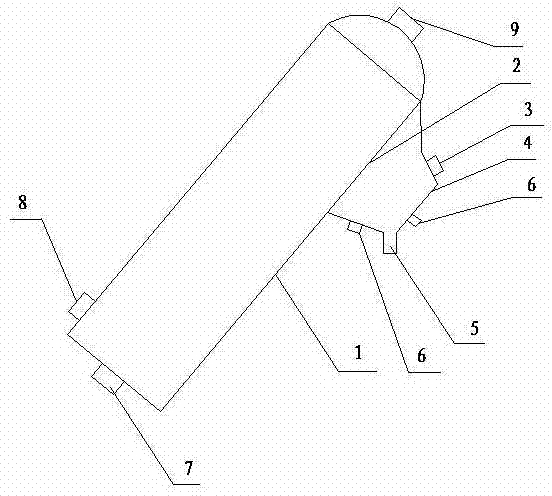

Device and process for making gas and reducing iron through coal derived fusion melting bed

InactiveCN102409128AWill not polluteImprove carbon conversionProcess efficiency improvementMetallurgyCoal

The invention relates to a device for making gas and reducing iron through a derived fusion melting bed. The device is characterized by comprising a reduction furnace and a gasification furnace which are fixedly connected, wherein the reduction furnace is internally provided with a reduction chamber; the upper and lower parts of the reduction furnace are respectively provided with a feed inlet, afeed outlet and an air outlet; the gasification furnace is a fusion bed gasification furnace which is internally provided with a gasification chamber; the gasification furnace is provided with a coalnozzle, an air nozzle and a deslagging port; and the joint of the reduction furnace and the gasification furnace is provided with a grate plate which is provided with an air vent communicating the reduction chamber with the gasification chamber. The invention also relates to a process for making gas and reducing by using the device. The device is reasonable in design and high in coal gasificationrate and can be used for saving energy sources effectively.

Owner:刘元生

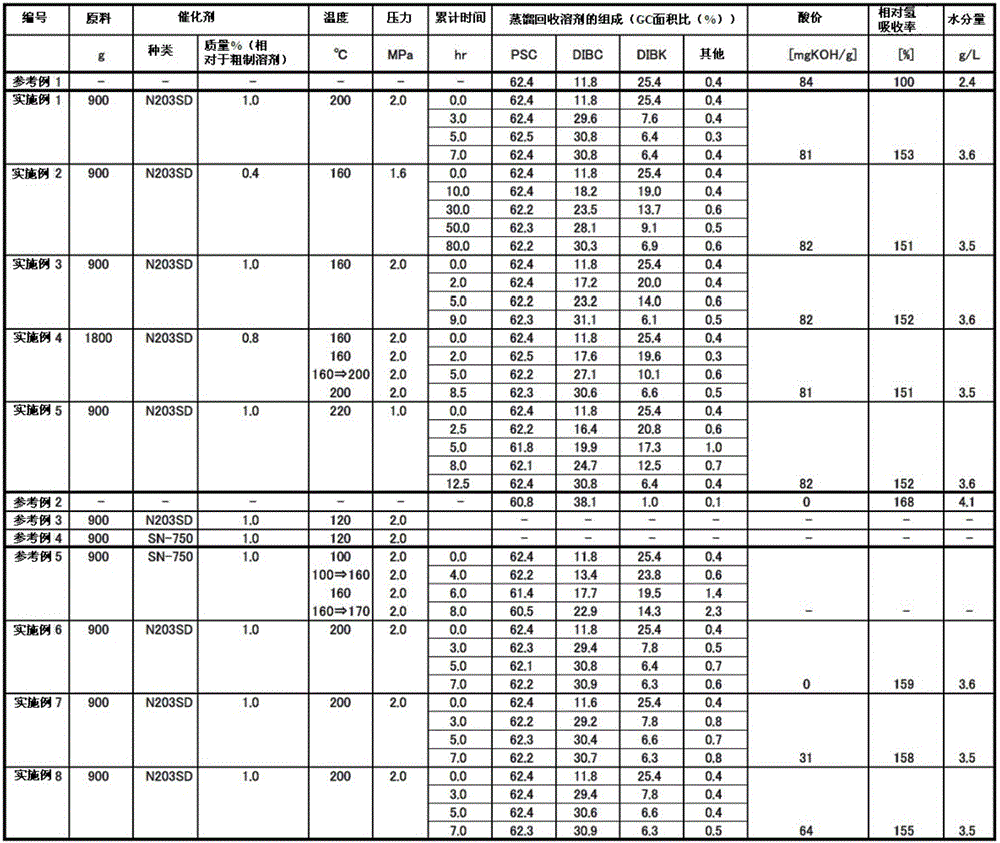

Method for regenerating working solution used for production of hydrogen peroxide and method for producing hydrogen peroxide using regenerated working solution

InactiveCN105916804AReduce riskReduce manufacturing costMolecular sieve catalystsOrganic compound preparationSolubilitySolvent

In the production of hydrogen peroxide, a higher alcohol component in an organic solvent changes into a ketone body and increase in the ketone bodies reduces water content of a working solution and causes deterioration of catalytic activity. In addition, increase in the ketone bodies may obstruct stable and safe operation during the production of hydrogen peroxide due to decrease in the solubility of anthrahydroquinones, crystallization, precipitation, etc. The objective of the present invention is to provide a method for improving hydrogen peroxide production efficiency by regenerating an altered substance (ketone body) derived from a polar solvent in the working solution used for the production of hydrogen peroxide by the anthraquinone method to the original alcohol component. Hydrogen peroxide can be produced more efficiently by distilling off the organic solvent component including the ketone body from the working solution which has been used over time and hydrogenating the same under the presence of a metal catalyst to regenerate to the original alcohol component.

Owner:MITSUBISHI GAS CHEM CO INC

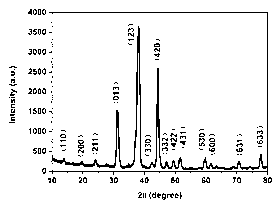

Method for preparing CoSb3 nanometer particle film

InactiveCN102796994ANo need to deal withImprove conductivityNanotechnologyChemical vapor deposition coatingThermoelectric materialsGas phase

The invention relates to a CoSb3 thermoelectric material, in particular to a method for preparing a CoSb3 nanometer particle film. The method comprises the following steps of: firstly, weighing CoC12.6H2O powder and Sb powder according to the molar ratio of 1:3; respectively filling the powder into respective crucible; putting the crucibles and glass slide substrates into a quartz pipe; placing the quartz pipe into a horizontal pipe type furnace; vacuumizing and aerating mixed air of 95 percent of argon and 5 percent of hydrogen for multiple times and removing oxygen in the quartz pipe; raising the temperature of the tubular pipe; performing chemical vapor deposition on the glass slide substrates in a low-pressure state to acquire the CoSb3 nanometer particle film; and testing Seebeck coefficient, conductivity and heat conductivity of the CoSb3 nanometer particle film and calculating a zone time (ZT) value of the CoSb3 nanometer particle film. According to the invention, the CoSb3 nanometer particle film is synthesized by one step, the process is simple, and the diameter of the prepared CoSb3 nanometer particle is between 200 and 400nm; and moreover, the CoSb3 thermoelectric material has good conductivity and low heat conductivity, can be directly used for thermoelectricity researches, and is used for novel high-efficiency thermoelectric conversion devices.

Owner:CHANGZHOU UNIV

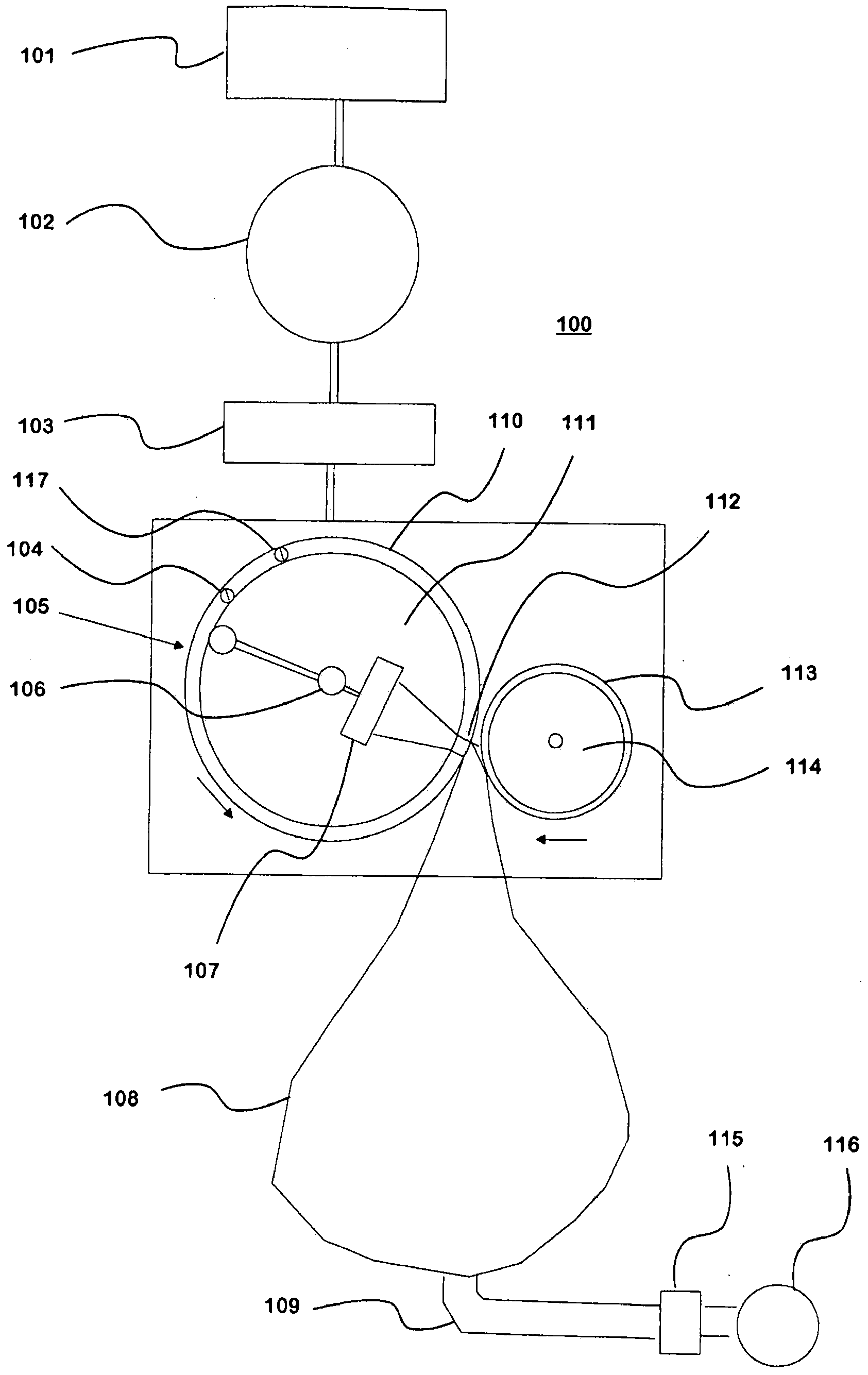

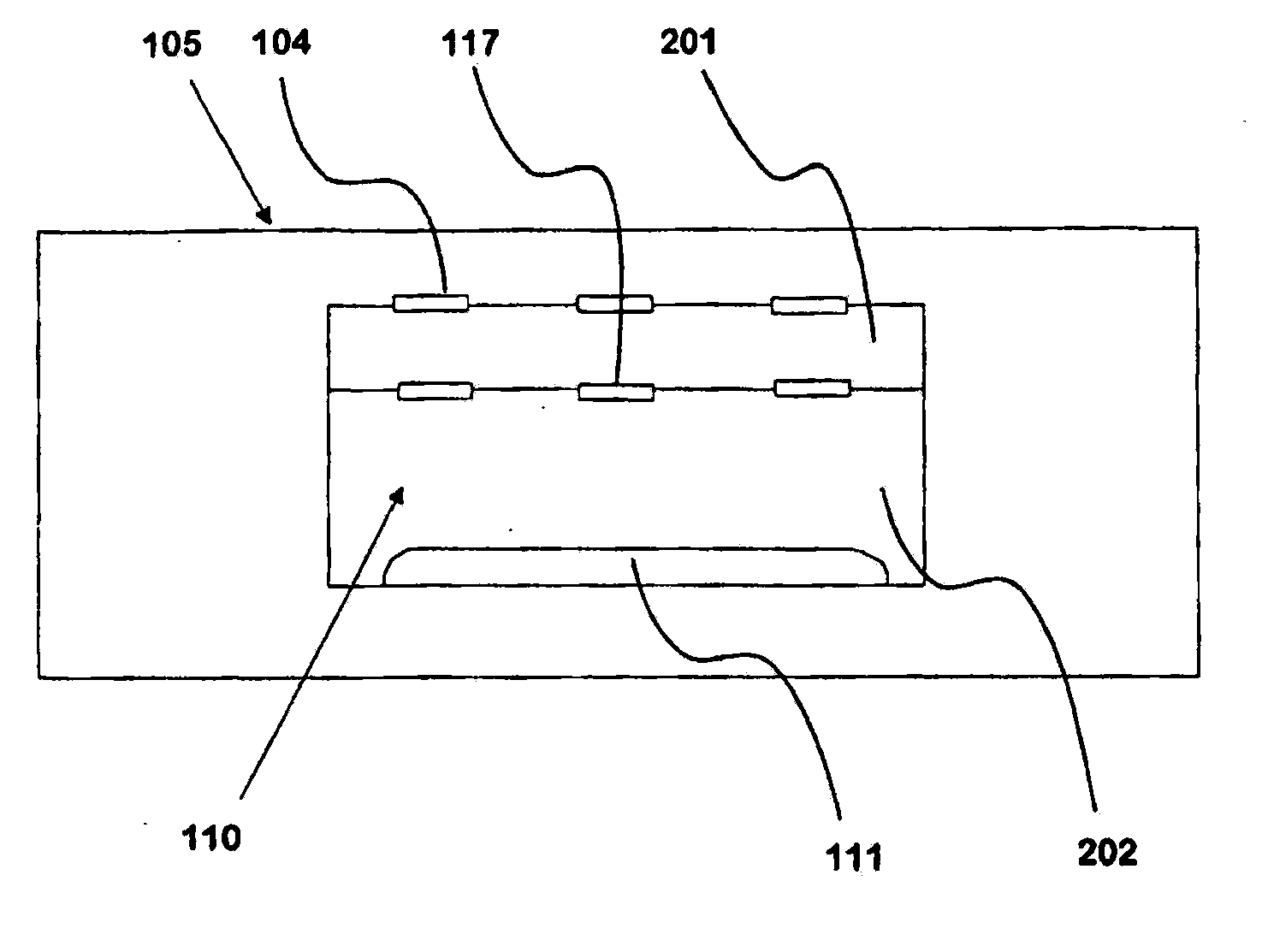

Discharge device for an elastic packing container and method for discharging an elastic container

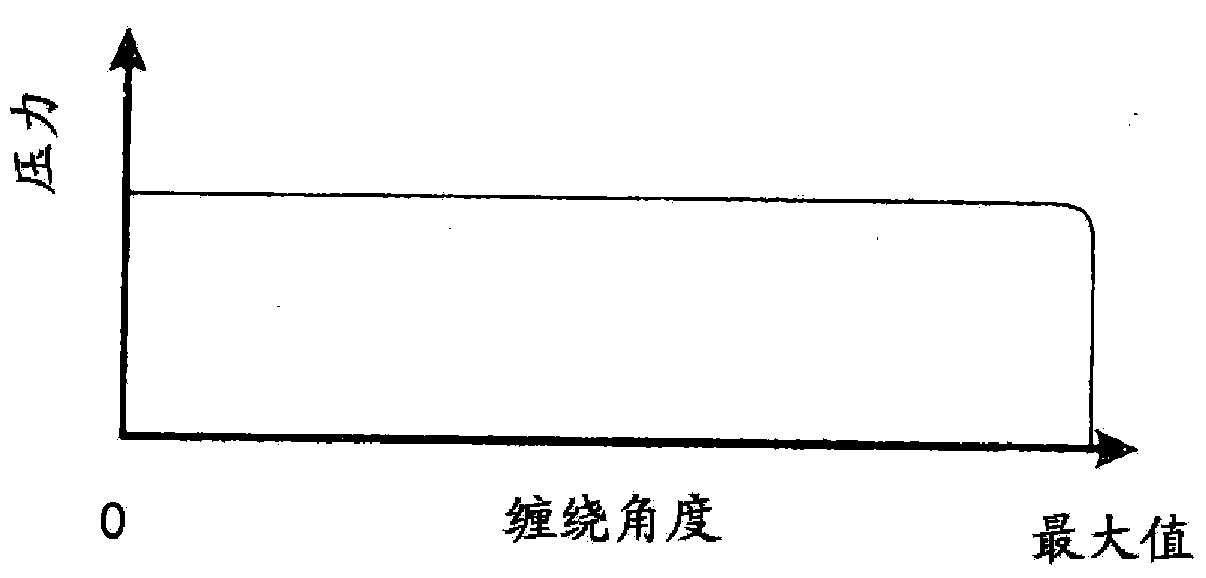

ActiveCN103889848AWorkmanship is effectiveImprove reliabilityLiquid transferring devicesUnpacking by expelling contentsActuatorMechanics

The invention has a discharge device (100) for discharging a container (108) containing a viscous substance and having an elastic shell material. The discharge device has a winding roller (105) and a counter pressure roller (114) and an actuator (102) for rotating the winding roller and a control part (101) for controlling the actuator. The inner part (111) of the winding roller is hollow, a there is therein an attaching arrangement (106), where the shell material of the container to be discharged is attached. Additionally the shell of the winding roller has an opening, in which opening there is a lid part (110) which can be opened, and the lid part has a shape (112) for the shell material of the container attached to the attaching arrangement. The winding roller is rotated so that the shell material of the container attached to the attaching arrangement is wound around the winding roller. The winding roller and counter pressure roller are pressed against each other so that the shell material of the container winding around the winding roller passes between the rollers. The emptying is adjusted so that the flow of content discharged from the container remains at a set constant. This adjustment is controlled with a control curve stored in the control part, which curve has at least the torque of the winding roller as a function of the turning angle.

Owner:PRO HYDRO

Method for concentrating titanium dioxide waste acid by adopting reverse osmosis process

ActiveCN104176714AHighlight substantive featuresSignificant progressSulfur compoundsSulfate radicalsReverse osmosis

The invention relates to a method for concentrating titanium dioxide waste acid by adopting a reverse osmosis process. The method comprises the following steps: pressing titanium dioxide waste acid with acid concentration of about 20% in a filter to remove micro-grained suspended matters, pressurizing through a high-pressure pump, enabling a small part of titanium dioxide waste acid to penetrate through a reverse osmosis membrane through a reverse osmosis device to prepare clean fresh water, and feeding the clean fresh water to a clean fresh water storage tank for later use; reserving sulfate radicals and other impurities for a large part of titanium dioxide waste acid, feeding into a cooling crystallizing groove, stirring, fully separating out and settling the impurities, conveying concentrated waste acid into a pressure filter, and putting concentrated waste acid subjected to impurity removal into a circulating groove for reverse osmosis treatment; when the acid concentration is more than 40%, feeding titanium dioxide waste acid to a sulfuric acid production device, mixing with concentrated acid for increasing the concentration, and removing the impurities to prepare 98% concentrated sulfuric acid. According to the method, titanium dioxide waste acid is effectively concentrated until 98% concentrated sulfuric acid is prepared, so that the difficult problem of recycling of titanium dioxide waste acid is solved; and the method has the advantages of being low in process energy consumption, simple, effective, stable to perform, remarkable in economic and environmental benefits and the like.

Owner:梧州佳源实业有限公司

Acid soluble fish skin collagen and its preparing method

ActiveCN100345867CWorkmanship is effectiveSimple processConnective tissue peptidesFiberHydroxyproline

The acid soluble fish skin collagen is prepared with sea fish skin as material and through the steps of cutting, NaCl solution soaking to eliminate impurity, alcohol and acetone defatting, soaking in mixed citric acid-acetic acid solution to extract, centrifugally separating to obtain acid soluble fish skin collagen solution, solid NaCl salt separation to obtain acid soluble fish skin collagen precipitate, dissolving in acetic acid solution, dialysis in Na2HPO4 solution or ultrafiltering with hollow acetate fiber film of molecular weight greater than 60 KDa, and vacuum freeze drying to obtain the product. The product is white, without fishy smell and spongy, and has purity over 97 %. It contains rich glycin, proline and hydroxyproline, as well as physiologically active peptide in its hydrolysate, and the collagen has molecular weight greater than 60 KDa.

Owner:DALIAN POLYTECHNIC UNIVERSITY

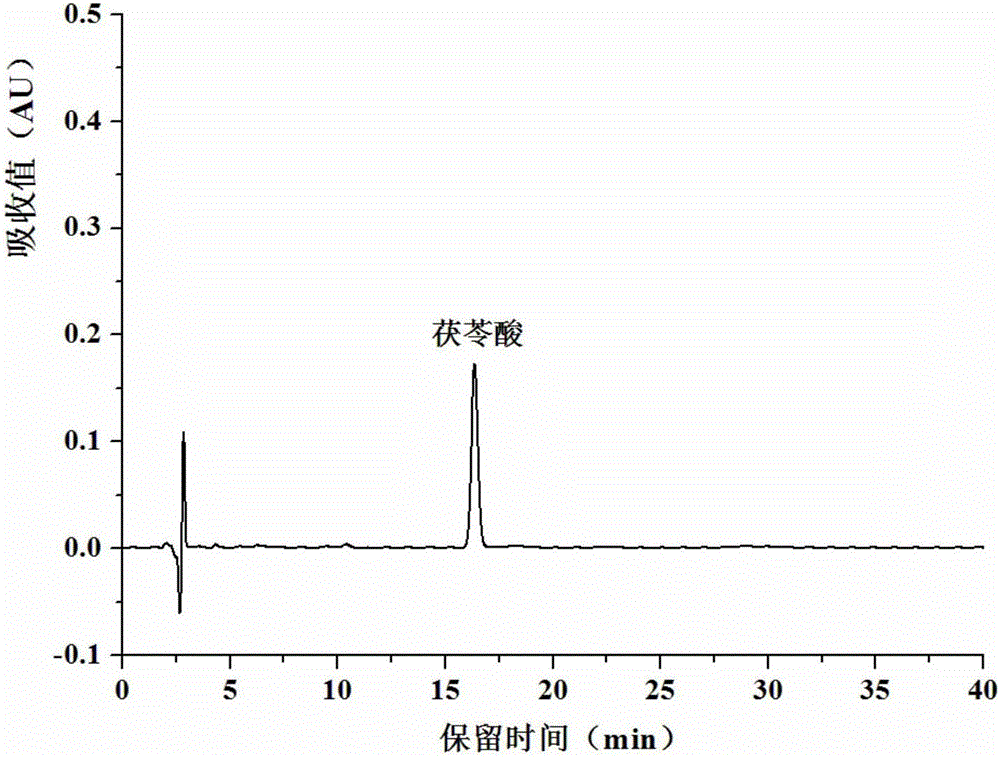

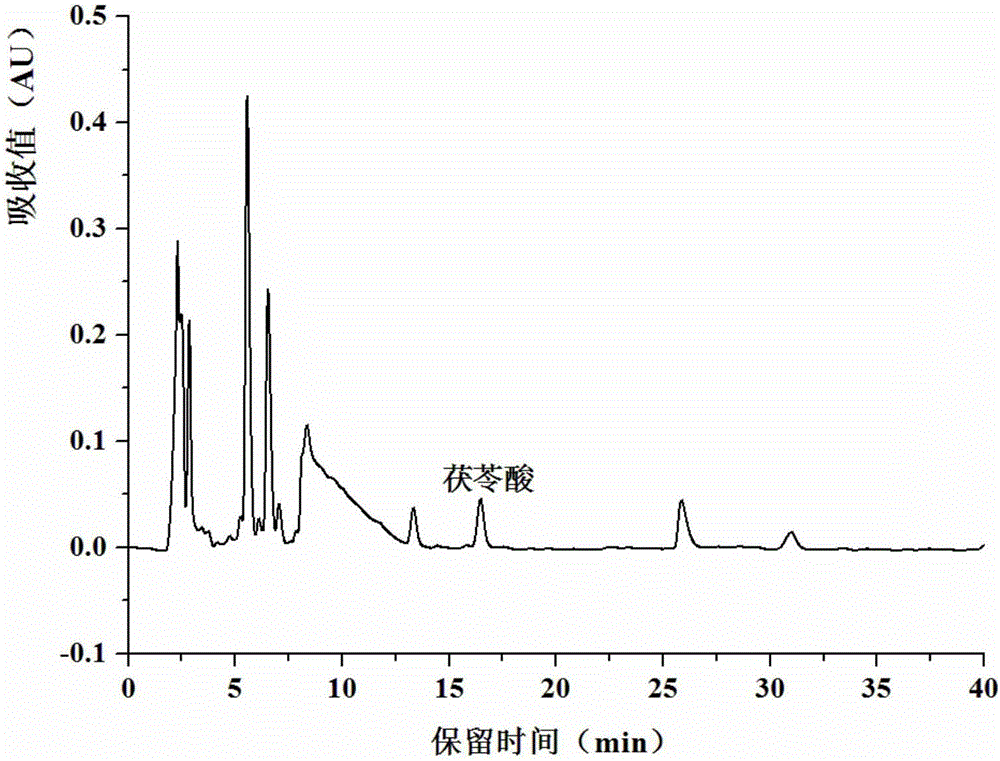

Method for increasing yield of pachymic acid of poria cocos liquid fermented mycelium

ActiveCN106676032AIncrease productionIncrease contentBacteriaMicroorganism based processesPinus thunbergiiMycelium

The invention relates to a method for increasing the yield of pachymic acid of poria cocos liquid fermented mycelium. The method comprises the steps of performing liquid fermentation on the a poria cocos bacterial strain ZJ2, and adding a masson pine extract, cellulose and composite vitamin B into a liquid seed culture medium and / or a liquid fermentation culture medium for poria cocos fermentation. By the method provided by the invention, the yield of the poria cocos mycelium can be optimized and maximized, the pachymic acid content of the mycelium is increased, industrialized production of the mycelium can be realized, the problem of damage to wild pine forest resource caused by the fact that poria cocos sclerotium is cultivated by pine tree pockets is solved, and foundation is laid and technical guarantee is provided for comprehensive development and industrialized production of the medical and edible value of the poria cocos ; the method is simple in process, effective and short in fermentation cycle, has application value in industrialized production, and can successfully fulfill the aim of obviously increasing the yield of the expression products.

Owner:HUAIHUA UNIV

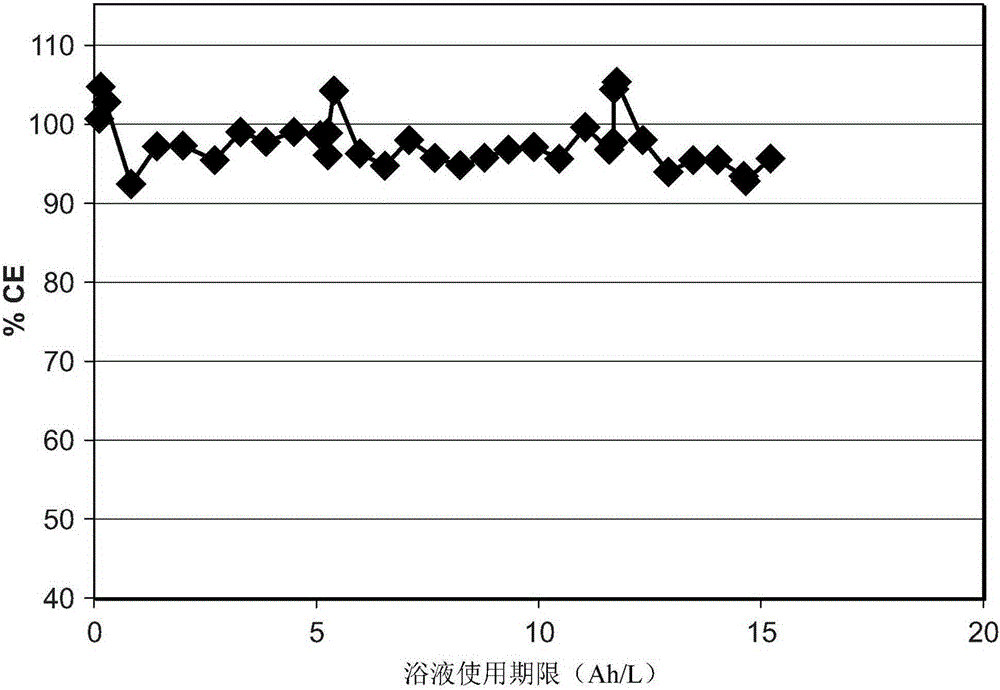

Cyanide-free electroplating baths for white bronze based on copper (I) ions

Copper alloy electroplating baths include one or more sources of copper (I) ions and one or more sources of tin ions to electroplate copper / tin alloys of mirror bright white bronze. The copper alloys may also include one or more sources of silver ions to electroplate ternary alloys of bright white bronze containing copper / tin / silver. The copper alloy electroplating baths are cyanide-free.

Owner:ROHM & HAAS ELECTRONICS MATERIALS LLC

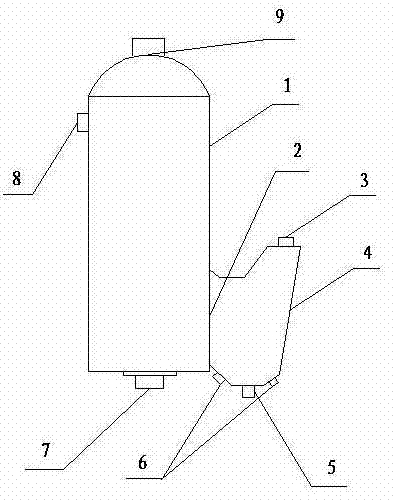

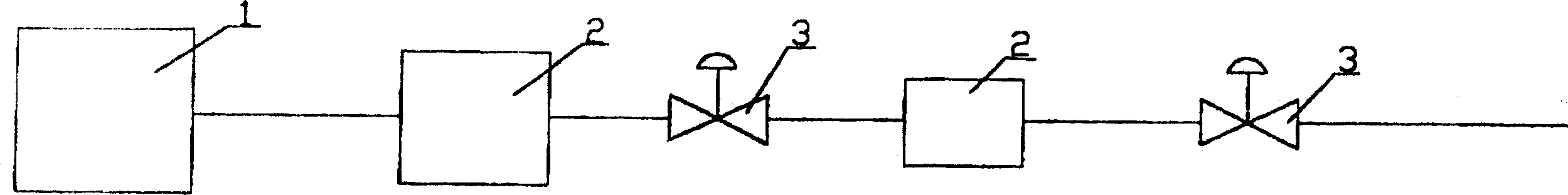

Energy-saving decompression gas supply method for natural gas and its equipment

InactiveCN1400415ASimple processImprove utilization efficiencyPressure vesselsContainer discharging from pressure vesselsProcess engineeringNatural gas

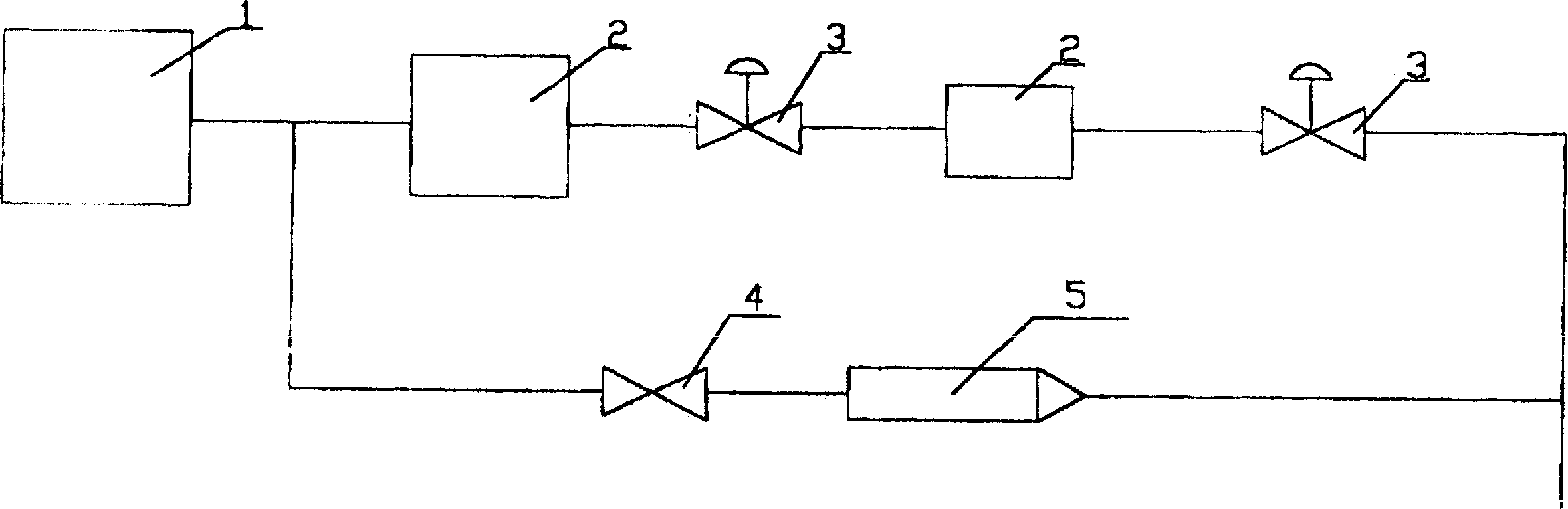

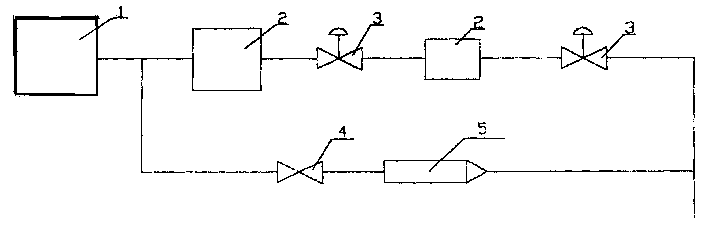

The present invention relates to an energy-saving decompression gas-supplying method of natural gas and its equipment, including the processes of two-stage pressure regulation and twice temperature compensation of carriage-unloading of natural gas skid carriage, and is characterized by that at the same time of two-stage pressure regulation and twice temperature compensation a jet-pipe decompression by-pass with valve is parallelly-connected. Said invention possesses the following advantages: its process is simple, easy to implement and effective, said carriage-unloading mode can greatly raisethe utilization rate of skid carriage, and can solve the problem of that the skid carriage can not be cleanly unloaded.

Owner:HUASHEN GAS BURNING IND TIANJIN

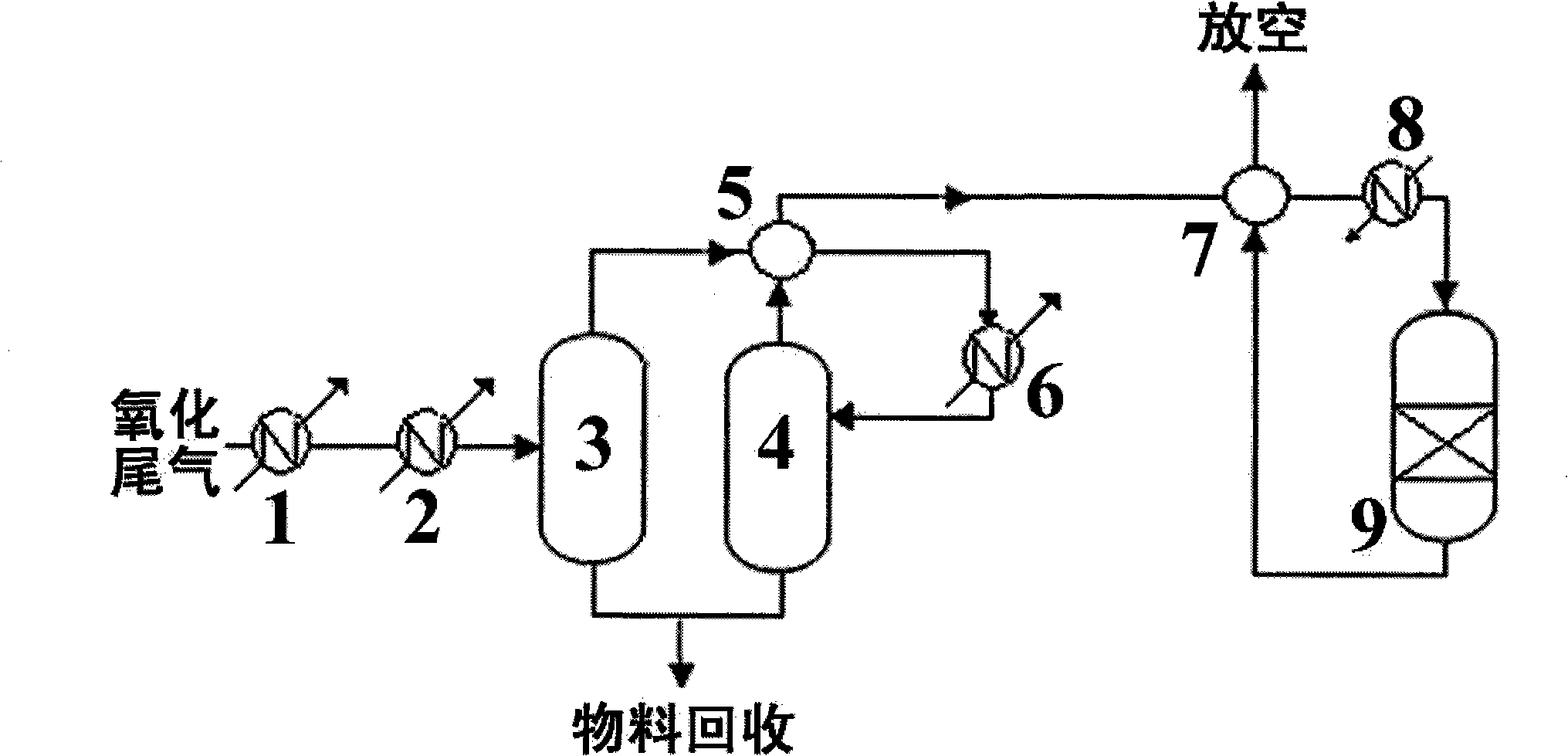

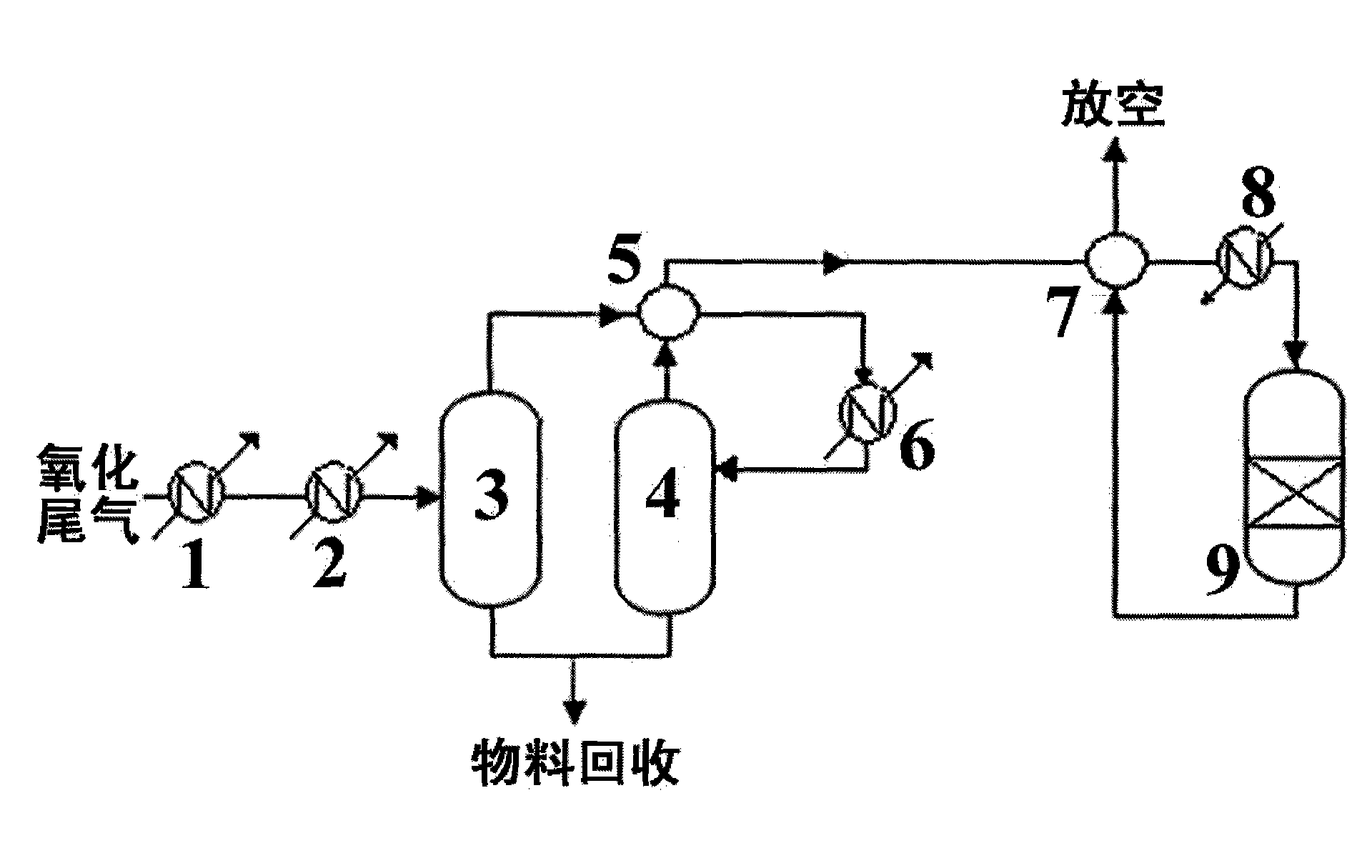

Process for treating oxidized exhaust gas

ActiveCN101543684BReduce the temperatureFully convertedOrganic compound preparationChemical industryLoss rateDevice material

The invention discloses a novel method for recovering and treating oxidized exhaust gas generated in phenol production, which comprises the following steps: adopting deep cooling to achieve liquefaction separation of organic matters by reducing the temperature of the exhaust gas to below 5 DEG C, wherein the material recovery rate reaches more than 95 percent; and adopting a Pt catalyst to decompose residual total hydrocarbons and cumene in the exhaust gas at a temperature of between 220 and 450 DEG C to achieve emission after reaching standards. The method can improve the exhaust emission quality, recover effective components in the exhaust gas, and reduce the device loss rate and the device material consumption on the basis of raw water cooling and activated carbon adsorption.

Owner:CHINA PETROLEUM & CHEM CORP

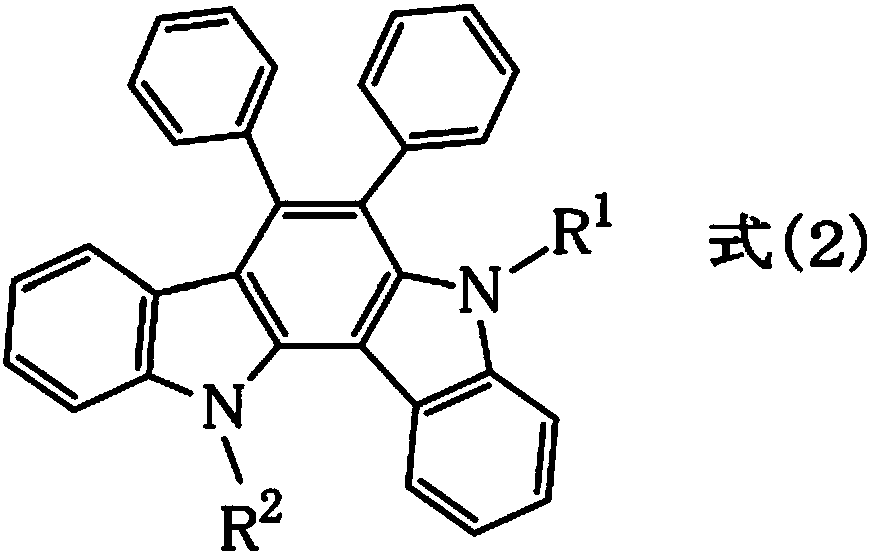

Resist underlayer film forming composition containing indolocarbazole novolak resin

ActiveCN108292098APattern in good shapeAnti-reflection propertiesSemiconductor/solid-state device manufacturingPhotomechanical exposure apparatusPolymer scienceCarbazole

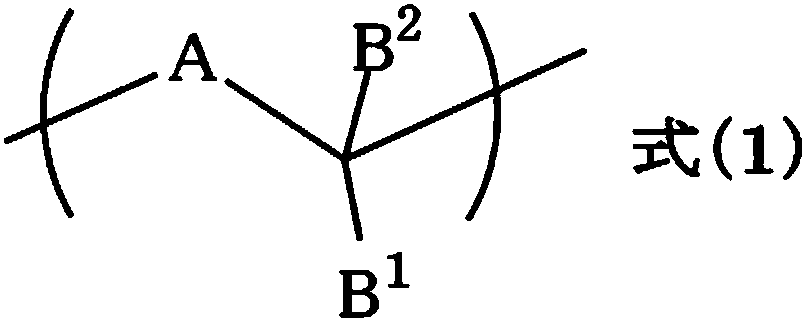

The present invention provides a resist underlayer film forming composition. The resist underlayer film forming composition contains a polymer including a structural unit represented by formula (1) (in formula (1), A is a divalent group including at least two amino groups, wherein the group has a condensed ring structure and is derived from a compound having an aromatic group that is substituted for a hydrogen atom on the condensed ring; each of B1 and B2 independently indicates a hydrogen atom, an alkyl group, a benzene-ring group, a condensed ring group, or a combination thereof; and, alternatively, B1 and B2 may form rings together with carbon atoms to which the aforementioned components are bonded).

Owner:NISSAN CHEM IND LTD

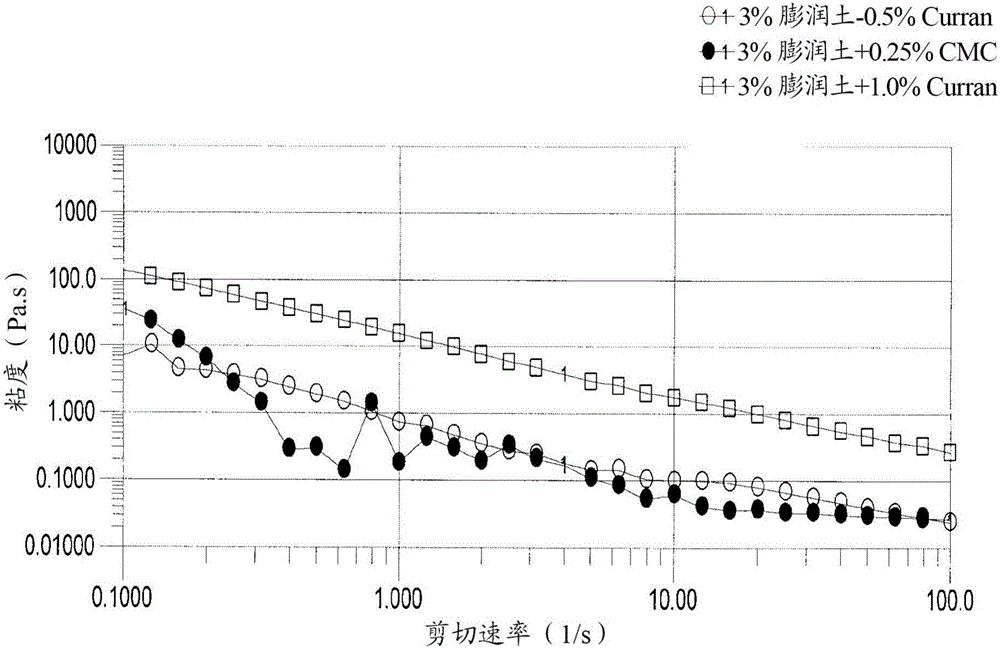

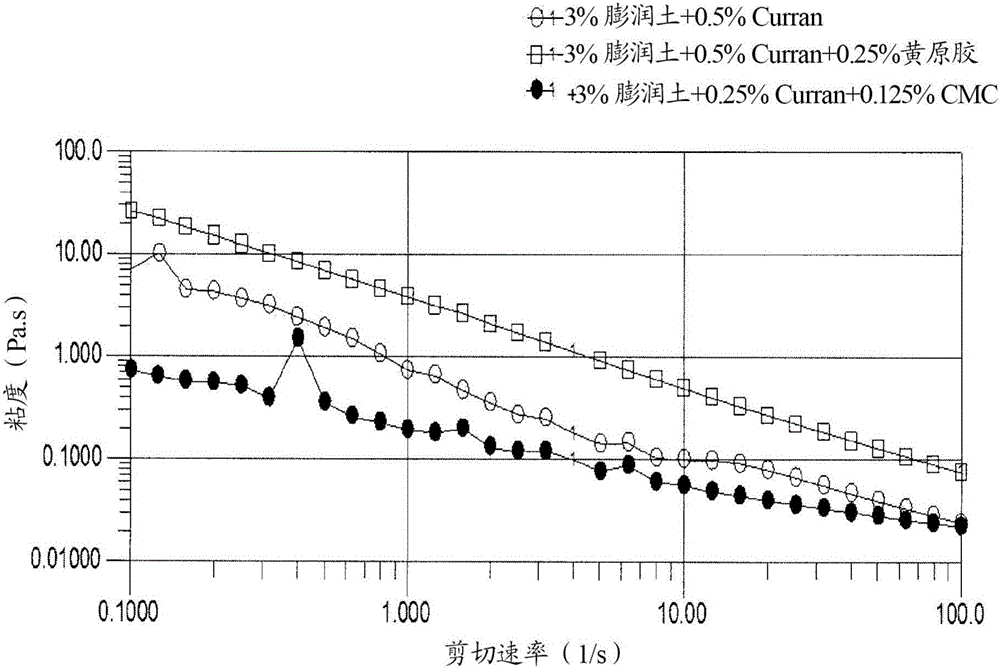

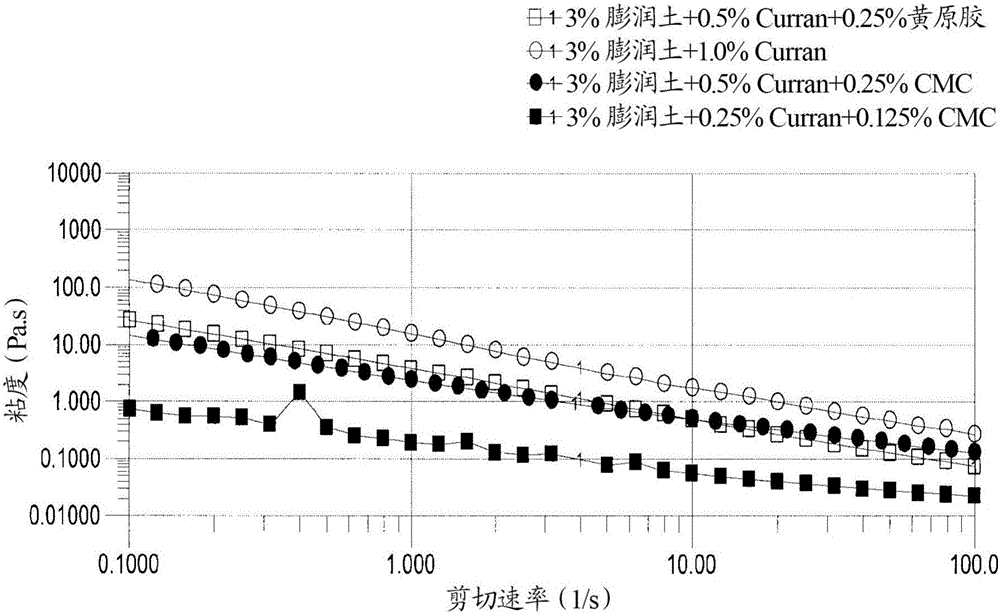

Compositions comprising parenchymal cellulose particulate material

ActiveCN106795328AWorkmanship is effectiveSimple processPretreatment with oxygen-generating compoundsDrilling compositionCelluloseWater dispersible

The invention relates to a composition comprising a plant-derived cellulose particulate material comprising less than 30 wt% extractable glucose; and extractable xylose in an amount of at least 3 % of the amount of extractable xylose in the starting plant material, and an agent selected from the group comprising natural ionic polymersor natural non-ionic polymers; synthetic water dispersible polymers, and / or associative thickeners, and its various uses, including as a drilling fluid.

Owner:SELLYUKOMP LTD

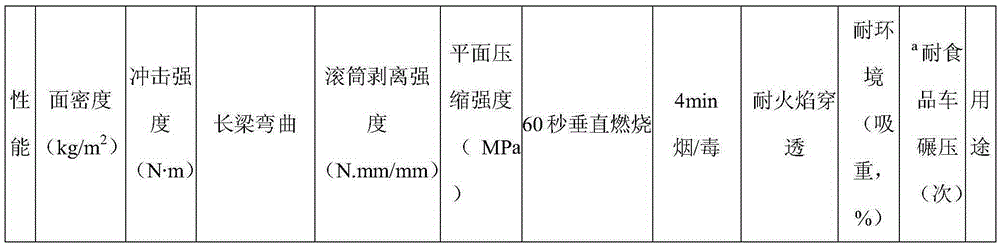

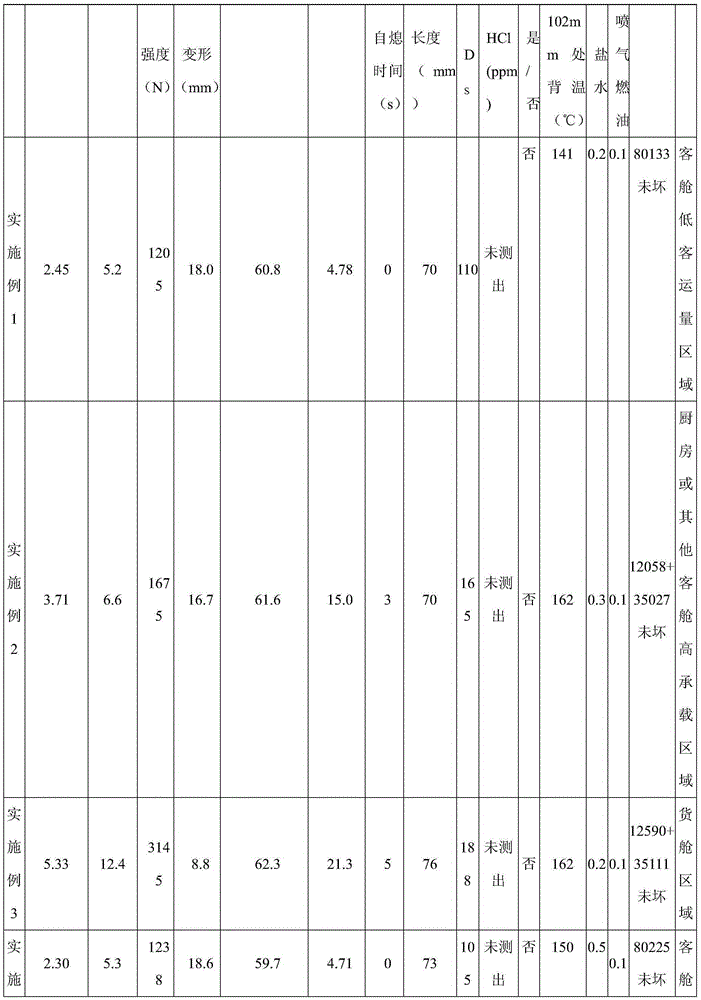

A kind of flame-retardant composite material floor and preparation method thereof

ActiveCN103979098BImprove flame retardant performanceRetain impact resistanceAircraft floorsEpoxyHoneycomb

The invention relates to a flame-retardant composite material floor board as well as a preparation method thereof, and belongs to the technical field of composite material floor boards. The floor board has a sandwiched structure, and comprises skin, a core material as well as flame-retardant structure glue for bonding the skin and the core material; the material of the skin is continuous fiber reinforced epoxy resin prepreg; the material of the core material is aramid fiber honeycomb; the flame-retardant structure glue is epoxy resin. According to the invention, the fiber material prepreg which is prepared from halogen-free flame retardant and toughening modified epoxy resin acts as the material of the skin, so that the sandwiched layer structure composite material has a favorable flame-retardant effect, and the excellent mechanical performance of shock resistance, bending and pressing resistance, abrasion resistance and the like of epoxy materials are kept for the material.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

Controllable preparation method of monocrystal copper nanowires

InactiveCN102251278BImprove uniformityReduce process parametersPolycrystalline material growthFrom normal temperature solutionsEthylenediamineWater baths

The invention relates to a preparation method of copper nanowires and in particular relates to a controllable preparation method of high-yield monocrystal copper nanowires in a liquid-phase reduction manner. The controllable preparation method comprises the steps: firstly, mixing a divalent metal copper salt solution and ethylenediamine, and heating in a water bath to form a single and stable copper ion chelate compound; mixing a strong base solution with hydrazine hydrate, and preparing a reducing agent in the water bath at the same temperature; then transferring the two mixture solutions into a reaction vessel, fully stirring to reach a uniform state, covering well, and placing in the water bath at the same temperature for heating reaction to prepare the copper nanowires; and fishing out flaky copper nanowires floating on the upper layer of the solution, washing the flaky copper nanowires with deionized water and absolute ethyl alcohol in sequence three times, and drying at room temperature under an Ar gas protection condition to prepare the copper nanowires. The controllable preparation method provided by the invention has the advantages of simple process, low cost and high yield, and the prepared copper nanowires are of monocrystal structures, and have relatively smooth surfaces, uniform radial thickness, and controllable and more uniform length and diameter.

Owner:CHANGZHOU UNIV

Novel material of abrasion-resistant tire and preparation method thereof

The invention belongs to the technical field of new materials, and provides a new wear-resistant tire material and a preparation method thereof. The wear-resistant tire comprises the following raw materials in parts by weight: 50-85 parts of natural rubber, 12-28 parts of chlorohydrin rubber, 8-12 parts of alkali-free glass fiber, 8-23 parts of silicon dioxide, 7-21 parts of carbon black, 1-8 parts of stearic acid, 2-18 parts of octyl oleate, 1-9 parts of magnesium salt whisker, N 2-12 parts of tert-butyl-2-benzothiazole sulfonamide, 0.08-0.23 parts of silane coupling agent, 1-3 parts of protective wax, 0.1-1.9 parts of leveling agent, the crystals of the magnesium salt whiskers The whisker diameter is less than 1 μm, the alkali-free glass fiber is chopped fiber, and the leveling agent includes the following raw materials in parts by weight: 30-40 parts of sodium urealate polymer, 12-15 parts of hexamethylenetetramine, Sodium chloride 1.8-2.5 parts. The above-mentioned raw materials are kneaded and heated to form new tire materials, and the Acron wear is between 0.18-0.24cm3, achieving the effect of improving wear resistance.

Owner:河南颇文商贸有限公司

Method for concentrating titanium white waste acids through gas-liquid contact technology

InactiveCN105858621AHighlight substantive featuresSignificant progressSulfur-trioxide/sulfuric-acidVapor–liquid separatorTitanium

The invention relates to a method for concentrating titanium white waste acids through a gas-liquid contact technology. The method concretely comprises the following steps: the white waste acids are pressed in a titanium white waste acid tank into a gas-liquid contact evaporator, the titanium white waste acids are jetted through nozzles to form mist, high temperature hot wind is sent to a gas-liquid contact evaporator through a blower, directly upwardly contact titanium white waste acid droplets jetted by the nozzles and is rapidly cooled, and water in the waste acids is massively evaporated to concentrate diluted waste acids; a gas and liquid mixture at the upper portion of the gas-liquid contact evaporator enters a gas-liquid separator and undergoes rotation and separation, the obtained gas is discharged through the discharge port of the gas-liquid separator, and condensed water is recovered; the concentrated waste acids at the lower portion of the gas-liquid contact evaporator are sent to a vacuum flash evaporation tank, and are concentrated and cooled; and the flash-evaporated steam enters a vacuum condensation jet pump, and the concentrated waste acids are sent to a storage tank, and are stored to be treated. The method effectively solves the titanium white waste acid recycling problem, and has the advantages of low energy consumption, simplicity, effectiveness, stable operation, and substantial economy and environment benefits.

Owner:钮德明

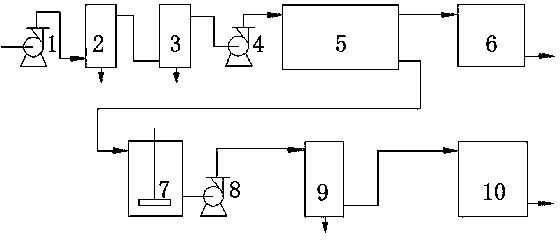

Emergency rapid water treatment method

ActiveCN104609611AGuaranteed reliabilityGood water qualityTreatment involving filtrationMultistage water/sewage treatmentPoor qualityWater treatment

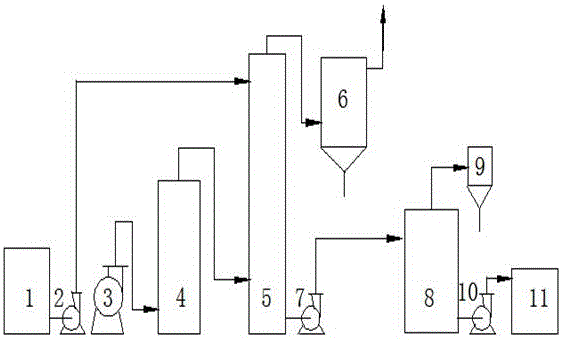

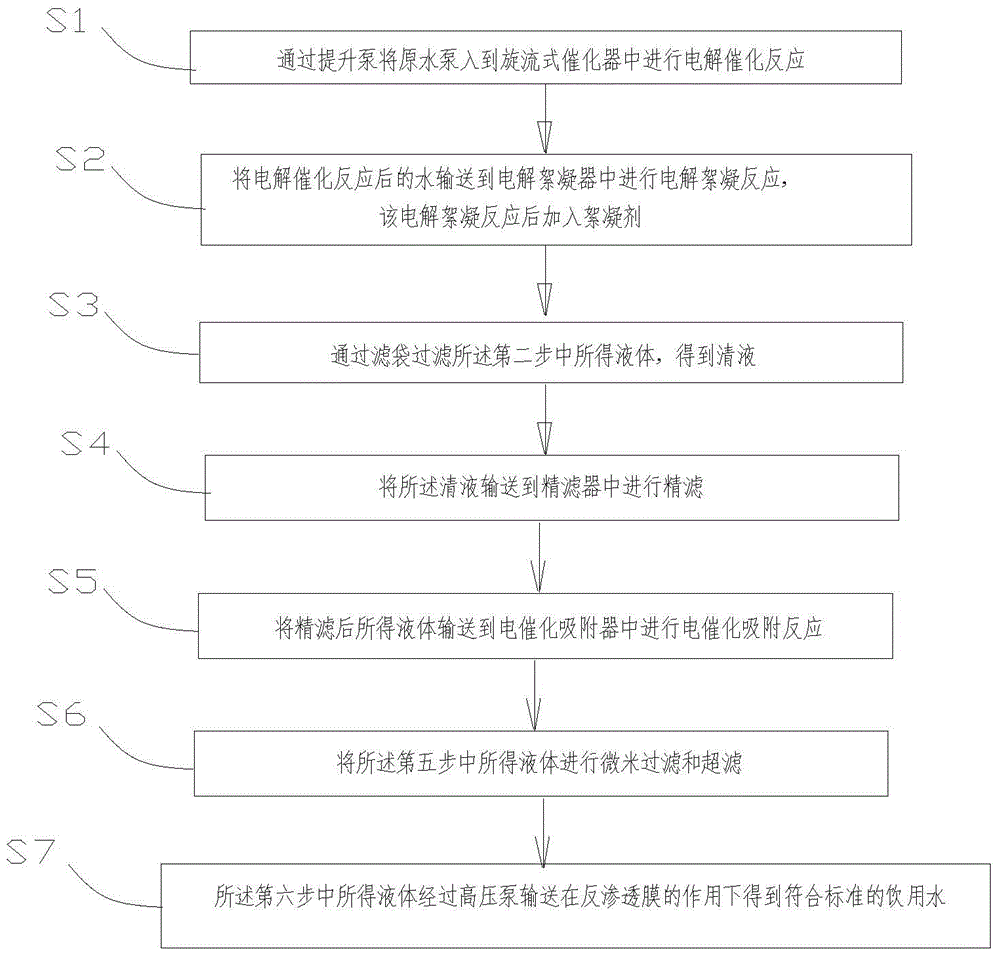

The present invention discloses an emergency rapid water treatment method, wherein a variety of pollution water or poor quality water can be treated through the process of the present invention, and the effluent quality can meet the national drinking water standard. The method comprises: 1, pumping raw water into a cyclone-type catalysis device through a lifting pump to carry out an electrolysis catalysis reaction; 2, conveying the water after the electrolysis catalysis reaction to an electrolysis flocculation device to carry out an electrolysis flocculation reaction, and adding a flocculant after the electrolysis flocculation reaction; 3, filtering the liquid obtained in the step 2 through a filtering bag to obtain a clear liquid; 4, conveying the clear liquid to a fine filter to carry out fine filtration; 5, conveying the liquid obtained in the step 4 to an electrocatalysis adsorber to carry out an electrocatalysis adsorption reaction; 6, carrying out micro-filtration and ultra-filtration on the liquid obtained in the step 5; and 7, conveying the liquid obtained in the step 6 through a high pressure pump, and obtaining the drinking water meeting the standard under the effect of a reverse osmosis membrane.

Owner:YUAN QING SHANGHAI ENVIRONMENTAL PROTECTION TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com