Method for concentrating titanium dioxide waste acid by adopting reverse osmosis process

A titanium dioxide waste acid, reverse osmosis technology, applied in chemical instruments and methods, inorganic chemistry, non-metallic elements, etc., can solve the problems of unstable operation, difficult maintenance, and high requirements for equipment materials, and achieve a simple and effective process. , significant environmental benefits, significant economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

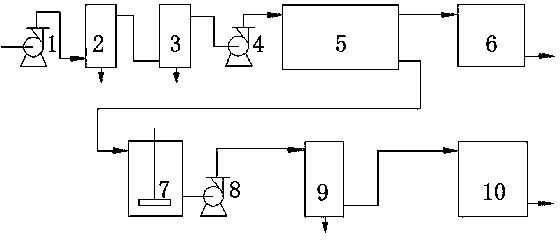

[0020] Use the corrosion-resistant dilute acid pump 1 to press the titanium white waste acid with an acid concentration of about 20% into the coarse filter 2 and the fine filter 3. After removing the suspended particles, pressurize through the corrosion-resistant high-pressure pump 4, and pass through reverse osmosis. Device 5, wherein a small part passes through the reverse osmosis membrane to make clean fresh water, walks the clean water side, and directly sends clean fresh water storage tank 6 for storage; most of them retain sulfate radicals and other impurities, so the concentration of sulfuric acid increases, Go to the concentrated water side, directly send the waste titanium white acid with an acid concentration of 30% to the cooling crystallization tank 7, and stir slightly at the same time to fully separate out and precipitate impurities, and then use the corrosion-resistant concentrated acid pump 8 to pump the concentrated waste The acid is poured into the filter pres...

Embodiment 2

[0022] Use the corrosion-resistant dilute acid pump 1 to press the titanium white waste acid with an acid concentration of about 20% into the coarse filter 2 and the fine filter 3. After removing the suspended particles, pressurize through the corrosion-resistant high-pressure pump 4, and pass through reverse osmosis. Device 5, wherein a small part passes through the reverse osmosis membrane to make clean fresh water, walks the clean water side, and directly sends clean fresh water storage tank 6 for storage; most of them retain sulfate radicals and other impurities, so the concentration of sulfuric acid increases, Go to the concentrated water side, send the waste titanium white acid with an acid concentration of 40% directly to the cooling crystallization tank 7, and stir slightly at the same time to fully separate out and precipitate impurities, and then use the corrosion-resistant concentrated acid pump 8 to pump the concentrated waste The acid is poured into the filter pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com