Patents

Literature

116results about How to "Less process investment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

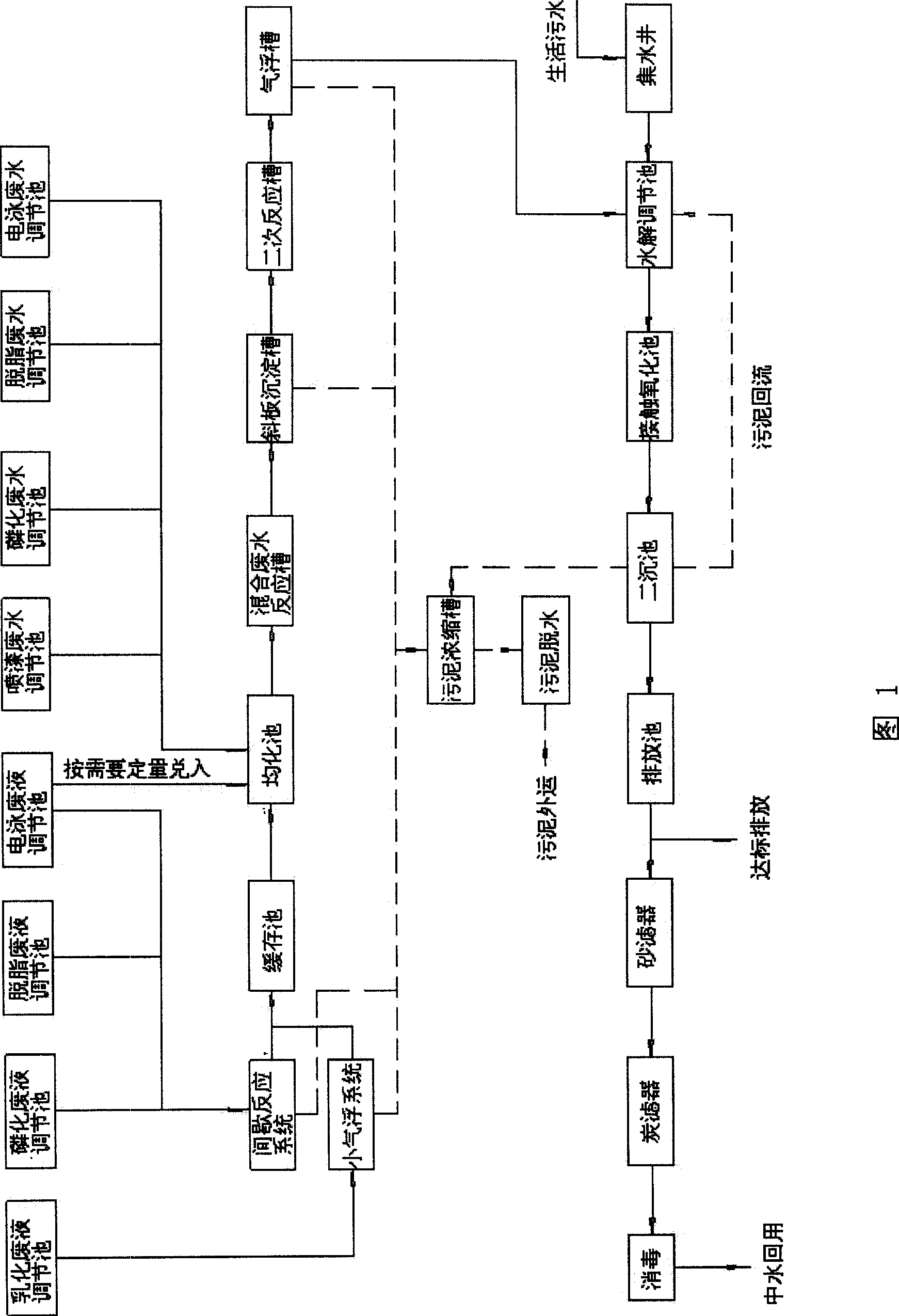

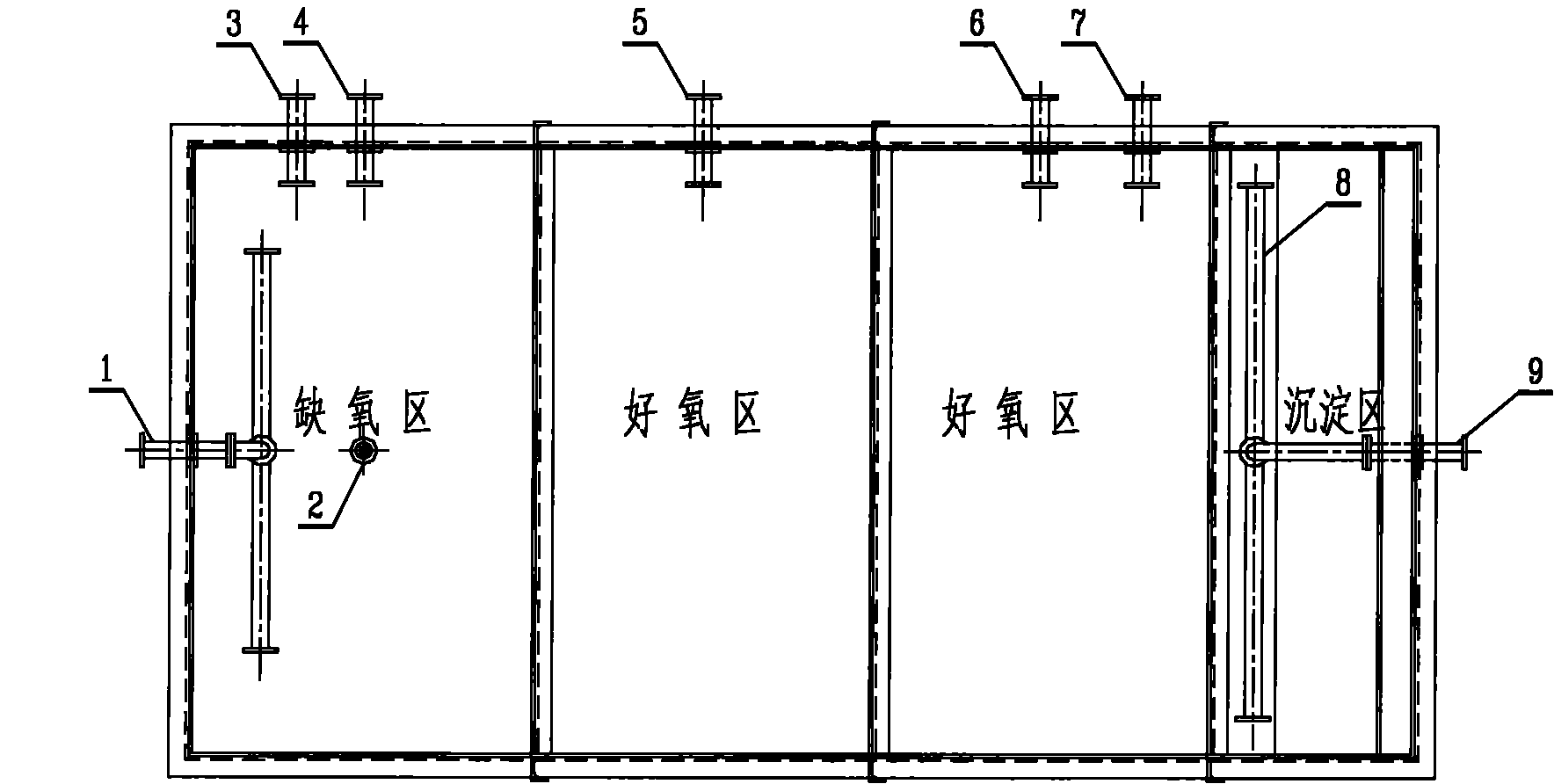

Automobile manufacturer wastewater treatment method

ActiveCN101456647AEasy to handleHigh activityTreatment using aerobic processesDispersed particle separationOperational costsIndustrial waste water

The invention relates to a method for treating wastewater and discloses a method for treating wastewater in an automobile manufacturing plant. A method of pretreatment, two-stage physicochemical treatment, biochemical treatment and advanced treatment is adopted to treat wastewater. The method for treating wastewater in the automobile manufacturing plant has little investment, small occupied area and low operating cost and has good integrated treatment effect on industrial wastewater and domestic sewage discharged from the automobile manufacturing plant.

Owner:SHANGHAI YIKE GREEN ENG

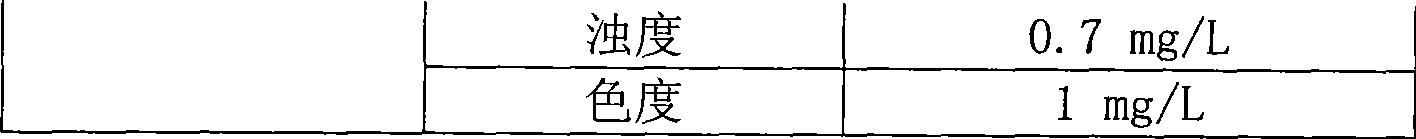

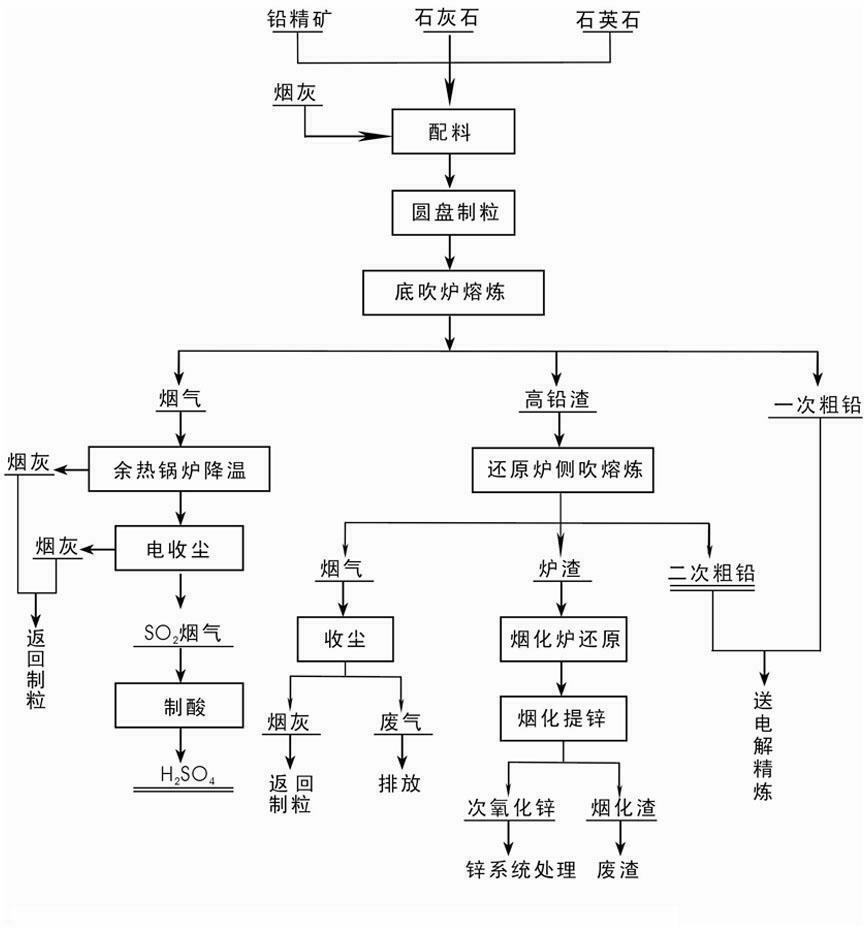

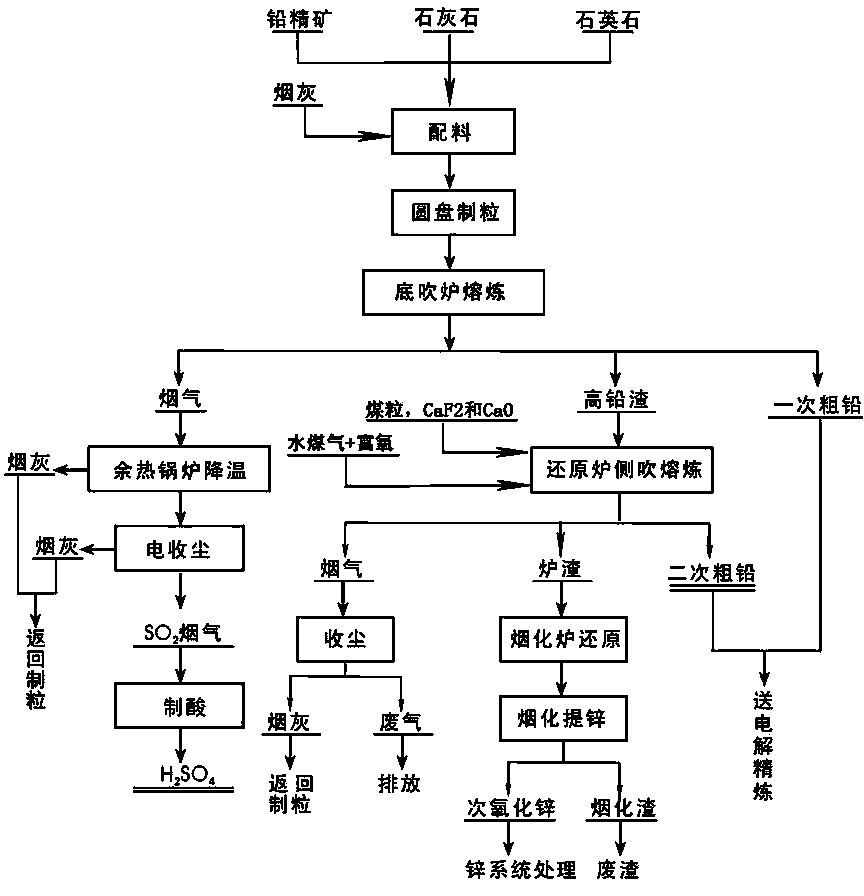

Oxygen bottom-blowing smelting and liquid-state high-lead slag side-blowing direct reduction process

InactiveCN102634674AEasy to separateShort and easy smelting processProcess efficiency improvementSlagOxygen

The invention relates to an oxygen bottom-blowing smelting and liquid-state high-lead slag side-blowing direct reduction process, belonging to the technical field of metallurgy. The process mainly comprises the steps of: directly injecting liquid-state high-lead slag melt subjected to oxidization smelting by a bottom oxygen blowing smelting furnace into a reduction furnace, and directly reducing liquid-state high-lead slag into secondary lead bullion through side blowing in the reduction furnace by adopting crushed coal as fuel; and after high-sulfur smoke produced by the bottom oxygen blowing smelting furnace is subjected to waste heat recovery by a first waste heat boiler and dust collection by an electric dust collector, and delivering the high-sulfur smoke to a sulfuric acid workshop for acid making. According to the process disclosed by the invention, a blast furnace, a slag casting machine and corresponding auxiliary facilities are omitted, the advantages of little investment and high automation level are achieved, and the industrial production of low pollution and low-carbon and economy is realized.

Owner:HUNAN HUAXIN RAREANDPRECIOUS METALS TECH CO LTD

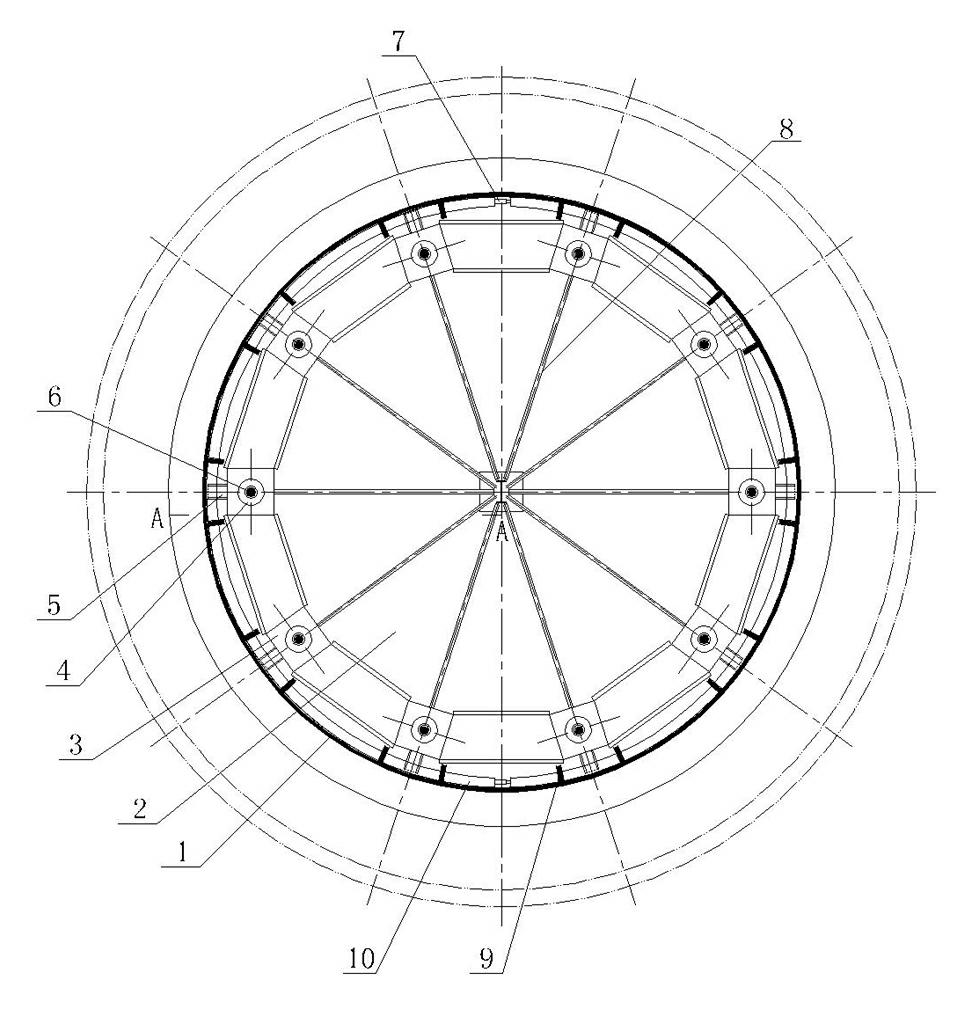

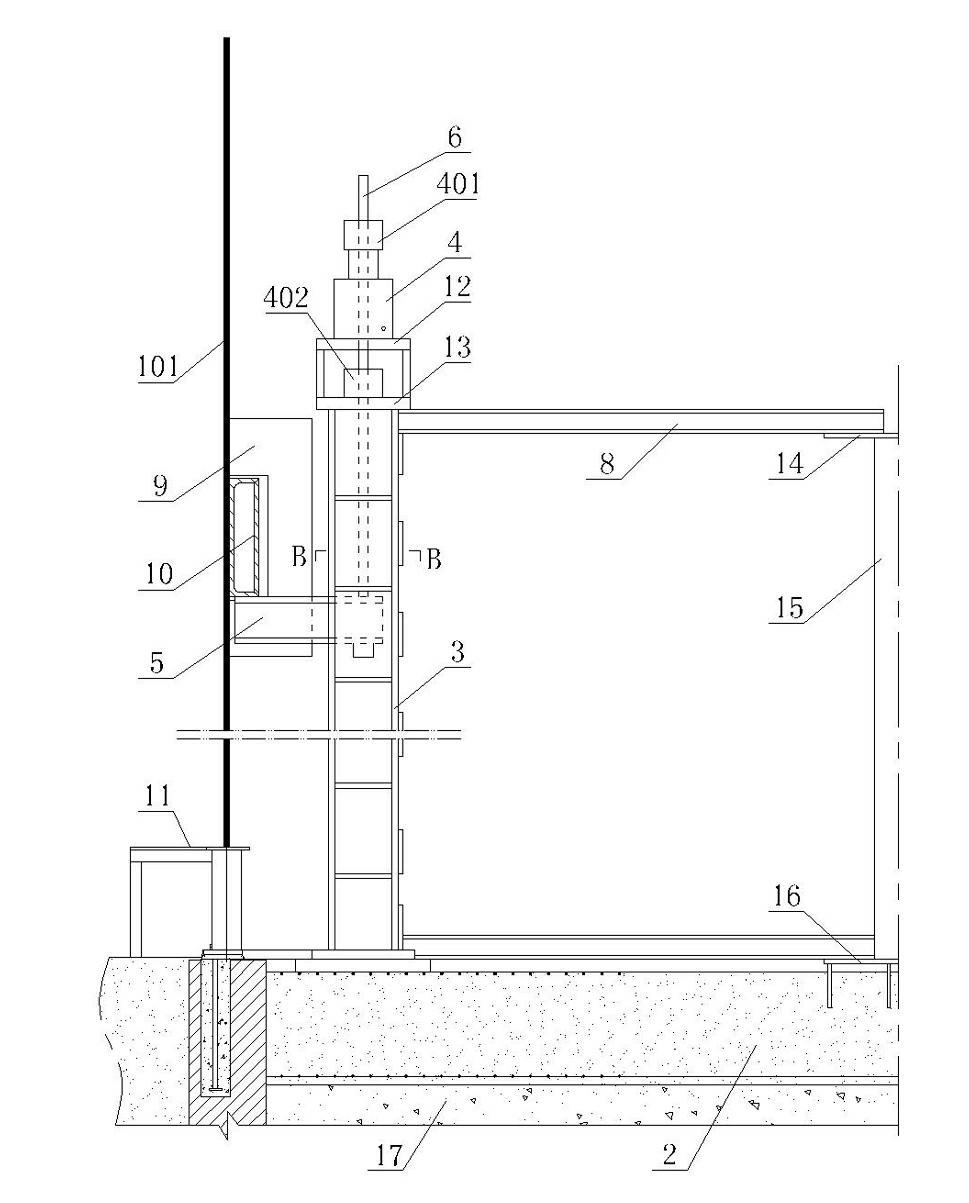

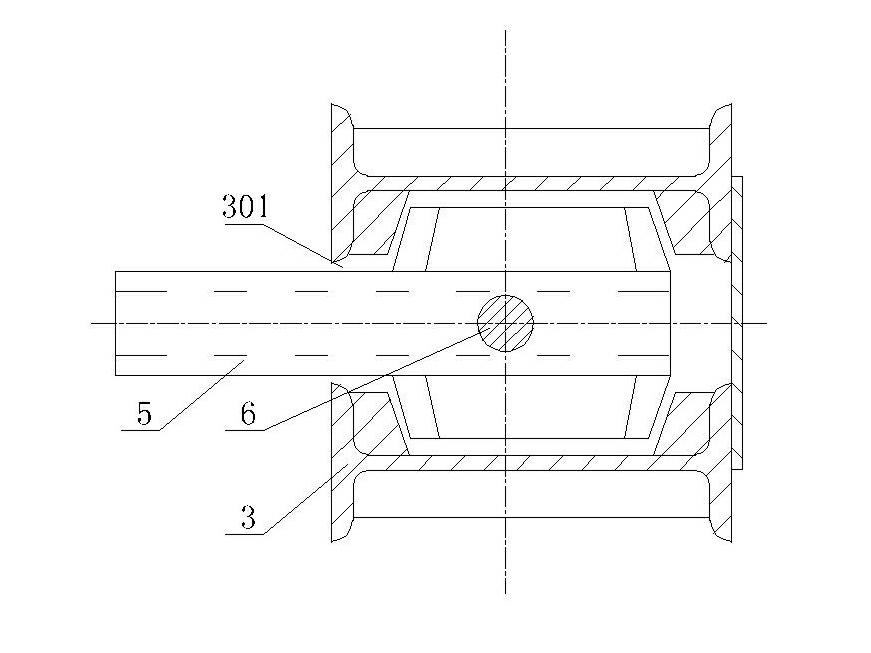

Hydraulic lifting inverted construction method for steel inner cylinder of chimney in thermal power plant

InactiveCN102108737AReduce investmentReduce construction costsBuilding constructionsTowersAnnular beamHydraulic pressure

The invention discloses a hydraulic lifting inverted construction method for a steel inner cylinder of a chimney in a thermal power plant, which comprises the following steps: (1) dividing the steel inner cylinder into a plurality of cylinder sections, and dividing each cylinder section into a plurality of cylinder sheets; (2) manufacturing a jack stand base in the steel inner cylinder, and mounting a hydraulic lifting device and a construction platform on the jack stand base; (3) beginning to assemble the first cylinder section of the steel inner cylinder, welding a plurality of sets of door-shaped clips on the inner wall of the first cylinder section along a circumferential direction, and clipping the horizontal annular beam by the door-shaped clips; (4) lifting the assembled cylinder section to the height of the first cylinder section by using the hydraulic lifting device, assembling a next cylinder section and welding the next cylinder section with the previous cylinder section; (5) cutting off the door-shaped clips and transferring and mounting the door-shaped clips and the horizontal annular beam to the corresponding position of the next cylinder section; and (6) repeatedly circulating the steps (4) and (5), and mounting the subsequent cylinder sections in turn. The method has the advantages that: the construction cost is low; the stress is definite, the operation is simple and convenient, and the safety factor is high; and the construction period is short and the project quality is high.

Owner:DONGDIAN YANTA ENG

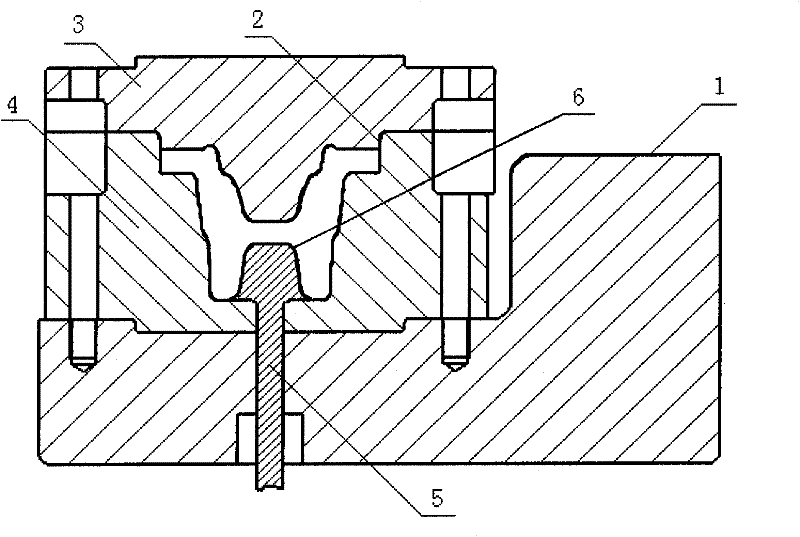

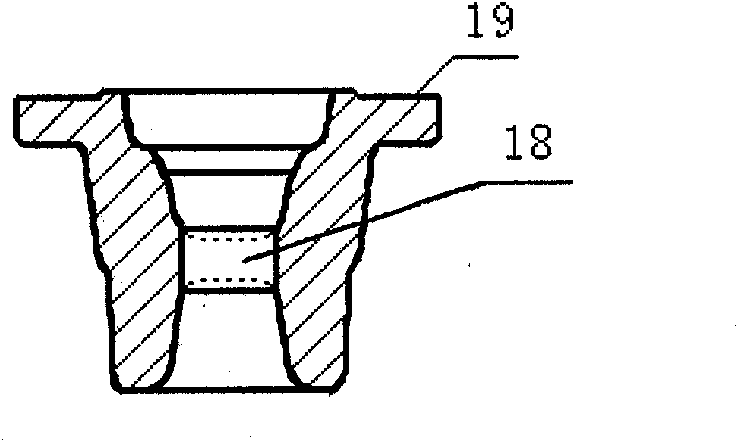

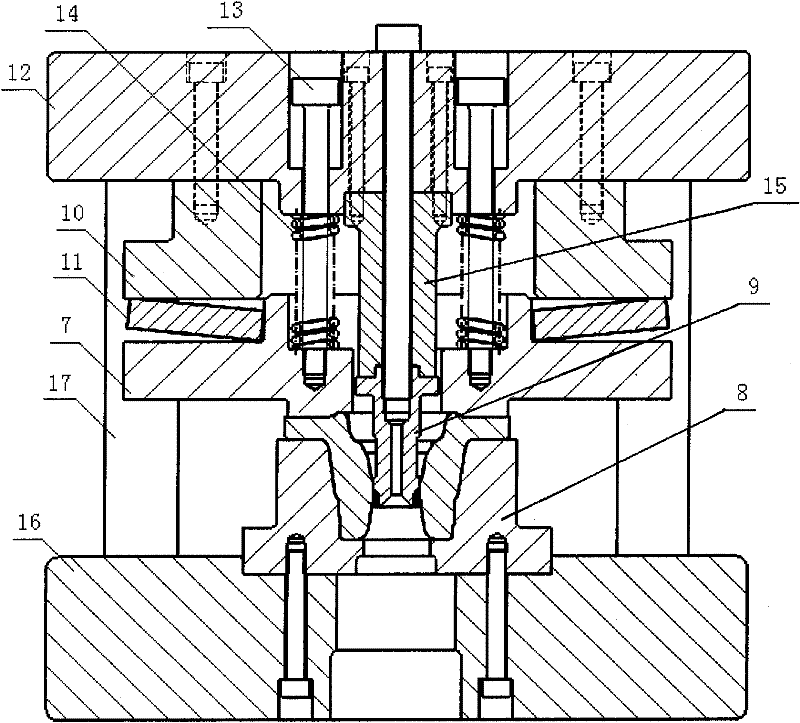

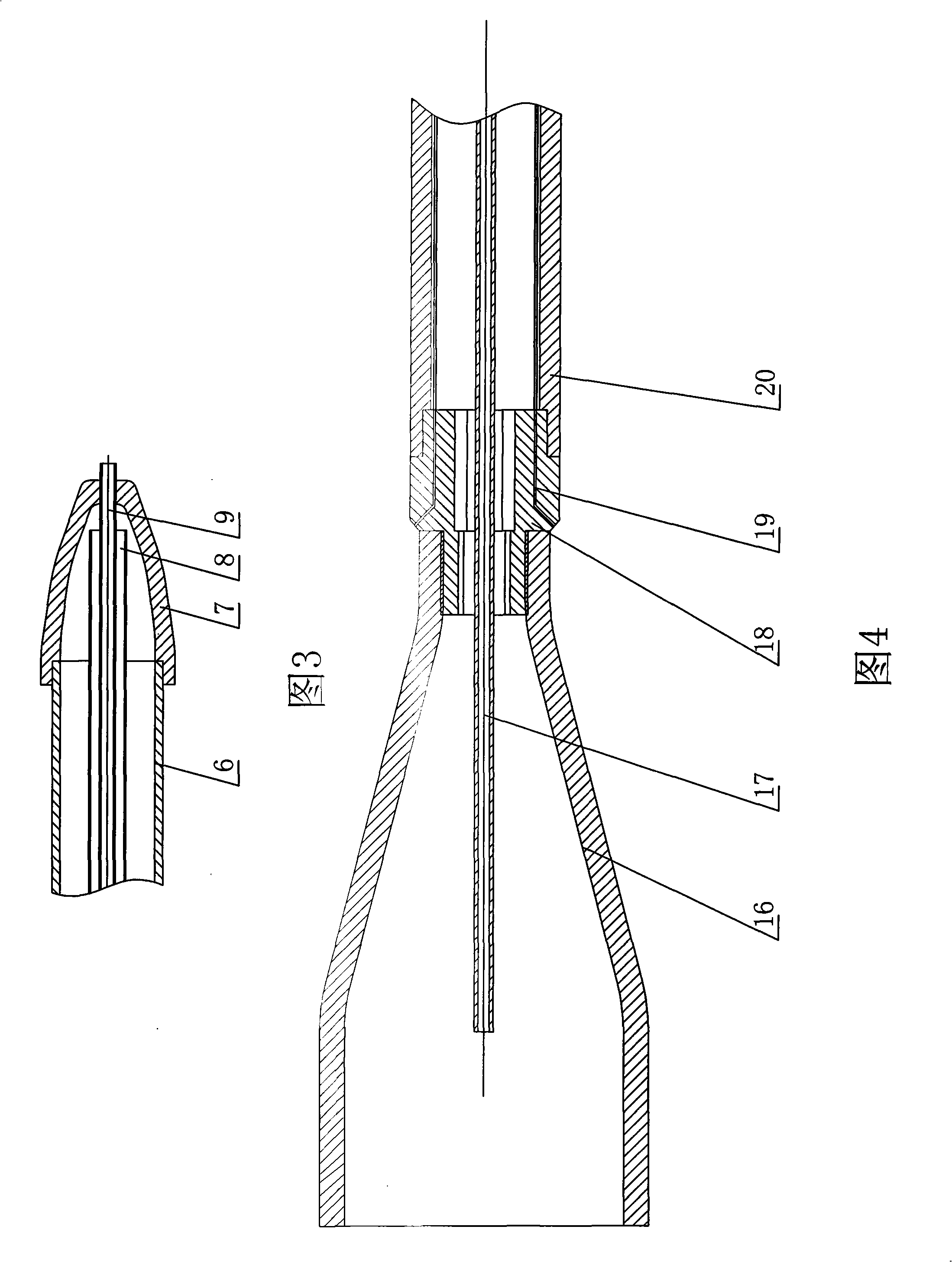

Medium-heavy automobile flange die forging process and punching and calibrating composite die thereof

InactiveCN102240763AImprove productivityExcellent input costShaping toolsPerforating toolsProduction ratePunching

The invention relates to a medium-heavy automobile flange die forging process and a punching and calibrating composite die thereof, which belong to a forging process in the field of manufacturing of machines, in particular to an automobile flange closed die forging process and a punching and calibrating composite die thereof. By the process and the composite die, the problems of low quality, a great number of production processes, low material utilization rate and the like of the conventional production process forgings are solved. The one-time finish forging forming of a closed finish forging die is used, the head of a die ejector beam is manufactured into a boss of the die, the web thickness is reduced, and punching and calibrating are completed in one step on the special punching and calibrating composite die. The punching and calibrating composite die comprises a calibrating male die, a female die, a punch, a belleville spring, a spring compression plate, a pull rod and the like. The die has low invested cost, a reasonable and simple process flow, high product quality, small machining amount and high productivity, and obviously lowers the production cost of products.

Owner:HUBEI TRI RING FORGING

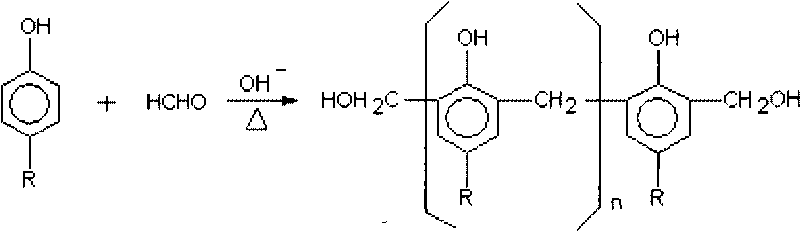

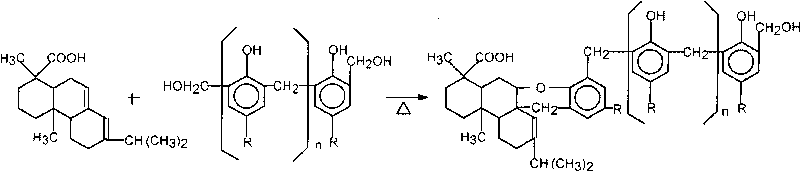

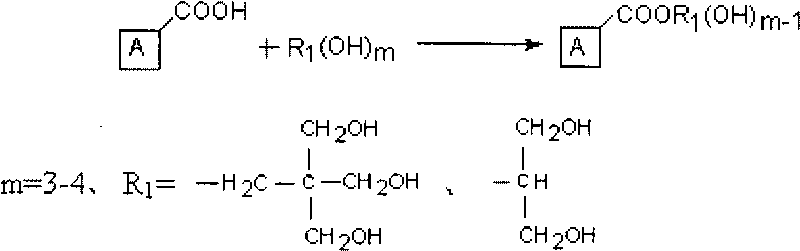

Preparation method of rosin modified phenolic resin

The invention relates to a preparation method of a rosin modified phenolic resin. The method comprises the following three steps of reactions: 1. performing condensation of tert-butylphenol, bisphenol A, tung oil and solid formaldehyde under the action of catalyst magnesium acetate and lime to generate polymer of hydroxymethyl tert-butylphenol; 2. performing an addition reaction with rosin to generate an addition product; and 3. performing esterification of the addition product, pentaerythritol and glycerin under the action of catalyst zinc chloride to generate the rosin modified phenolic resin. The preparation method adopts proper raw material proportioning, reaction temperature, reaction time, catalyst and other technical conditions, thus during the production process, the resin viscosity can be effectively controlled, and the operation is simple and flexible and has good effect. The quality of the product is increased, the oil solubility of resin is good, the oil medium viscosity is high, the normal heptane capacity is 4.5ml / g or more; and the prepared paint film ink has good water resistance and alkali resistance, high hardness, excellent anti-after-binding performance, quick-drying performance, lightness and strong adhesive force. Therefore, the preparation method of the invention is applicable to industrial production.

Owner:SHANGHAI HUAYI FINE CHEM CO LTD

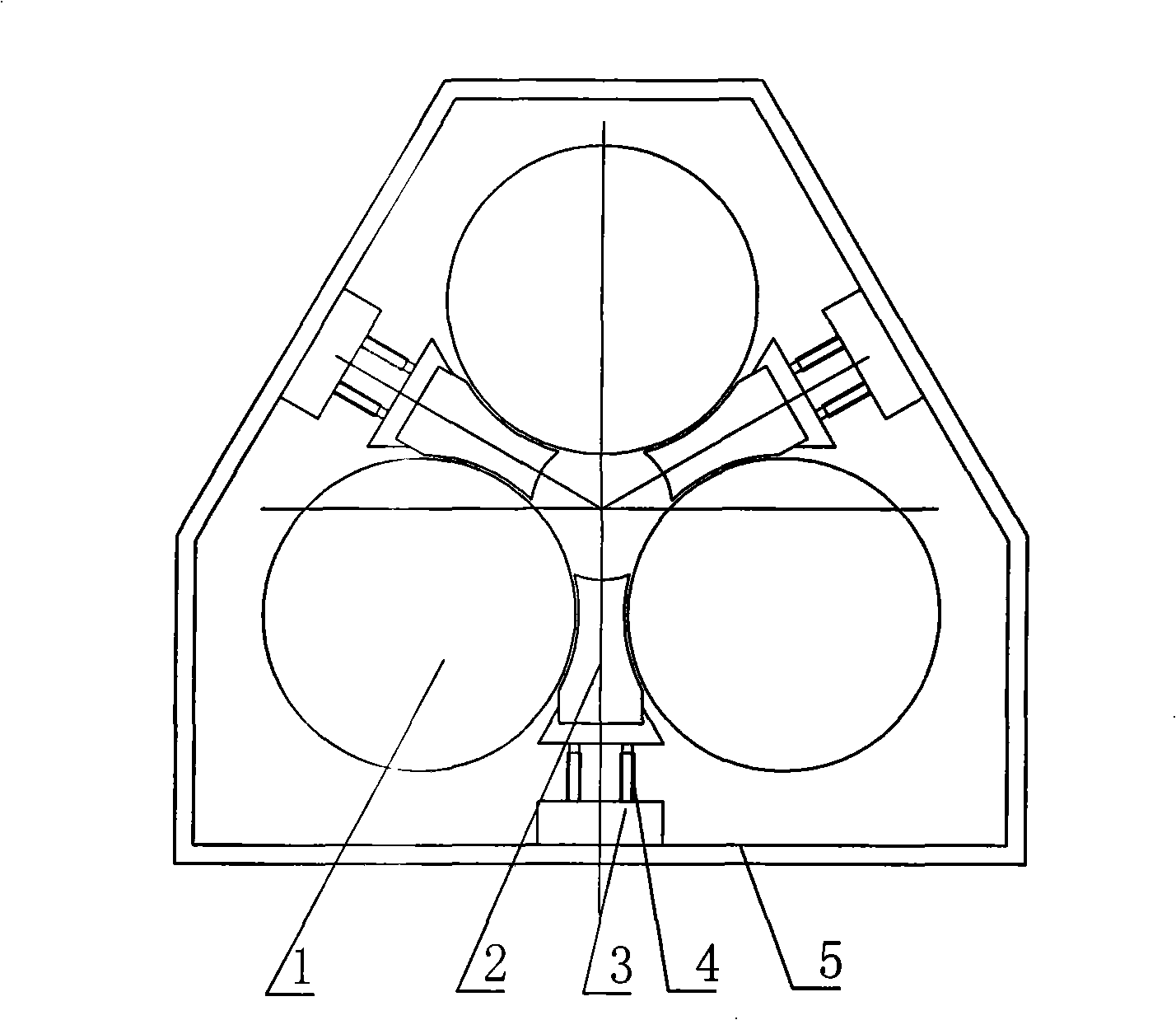

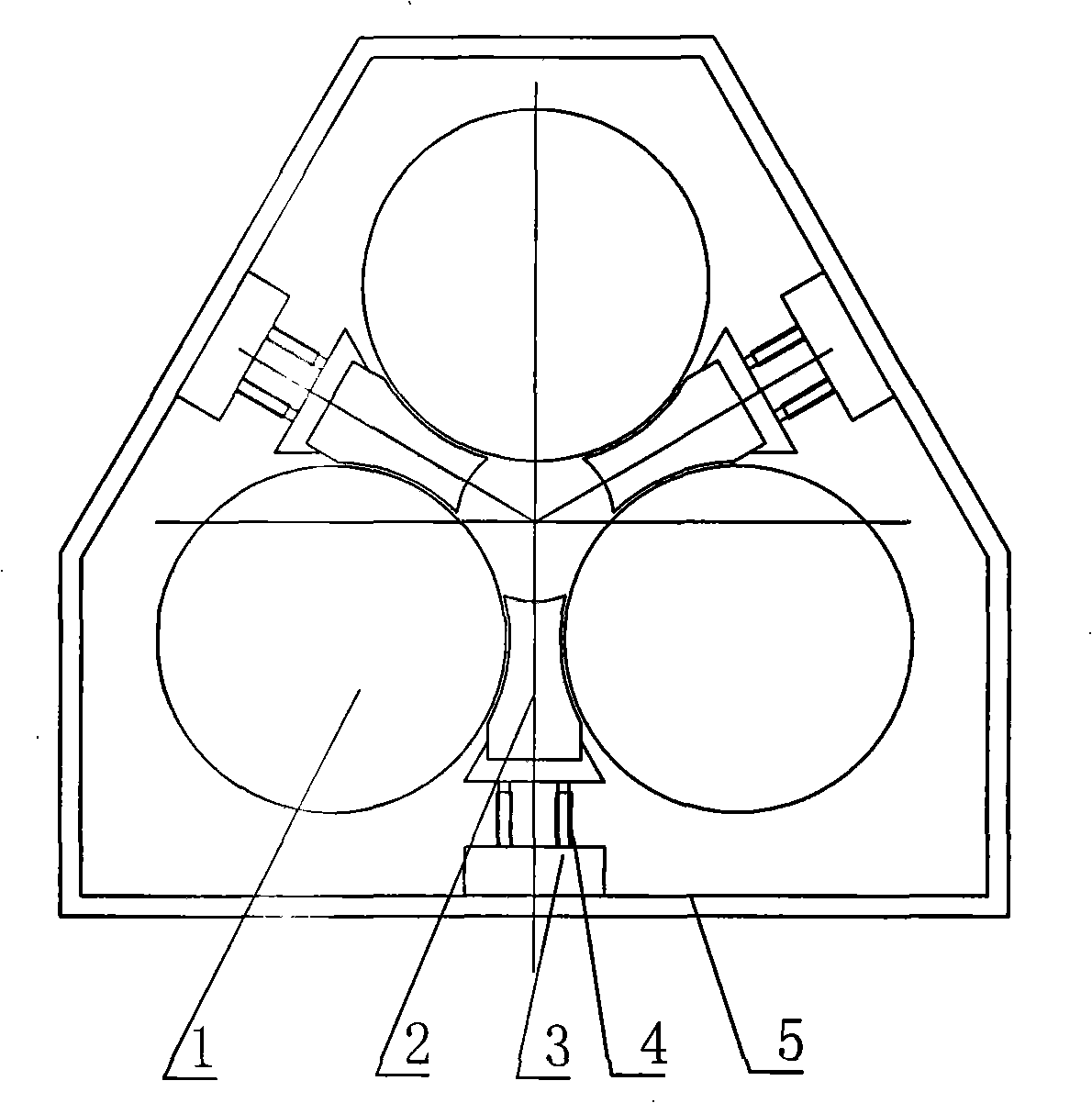

Novel technique for producing large-sized seamless steel pipe

InactiveCN101352728AExtended service lifeQuality improvementGuiding/positioning/aligning arrangementsWork treatment devicesHeating furnaceOrbit

The invention discloses a new production process of a large seamless steel pipe. The process comprises the following steps: pipe billets are preheated to the temperature of 1050-1290 DEG C by a heating furnace, and delivered to a three-roll skew rolling piercing mill for piercing by a skew roll table conveying mechanism to finish diameter expansion and wall reduction rolling, the maximal ratio of diameter to wall D / S is over 32, and hollow billets are produced; the hollow billets are delivered to a three-roll skew rolling elongating finishing mill by a shift oblique orbit conveying mechanism to finish diameter expansion and wall reduction rolling or diameter reduction and wall reduction rolling, and the pierced billets are rolled, straightened, cropped end, cut to length, defect are detected, and the finished products are obtained after passing inspections. The new production process also perfects and improves the conventional three-roll skew rolling seamless steel pipe process, solves the problems of not rolling thin walls and great extension in the three-roll skew rolling process, the diameter expansion and wall reduction rolling can be carried out, and the diameter reduction and wall reduction rolling can be carried out. The new production process is especially suitable for rolling large and oversized seamless steel pipes (Phi is 500-2000mm), the ratio of single reduced diameter and expanded diameter is more than 30%, the reduced wall diameter is more than 70%, and the reduced wall thickness is 5-7 times of that of a longitudinal pipe rolling mill.

Owner:沈阳东方钢铁有限公司

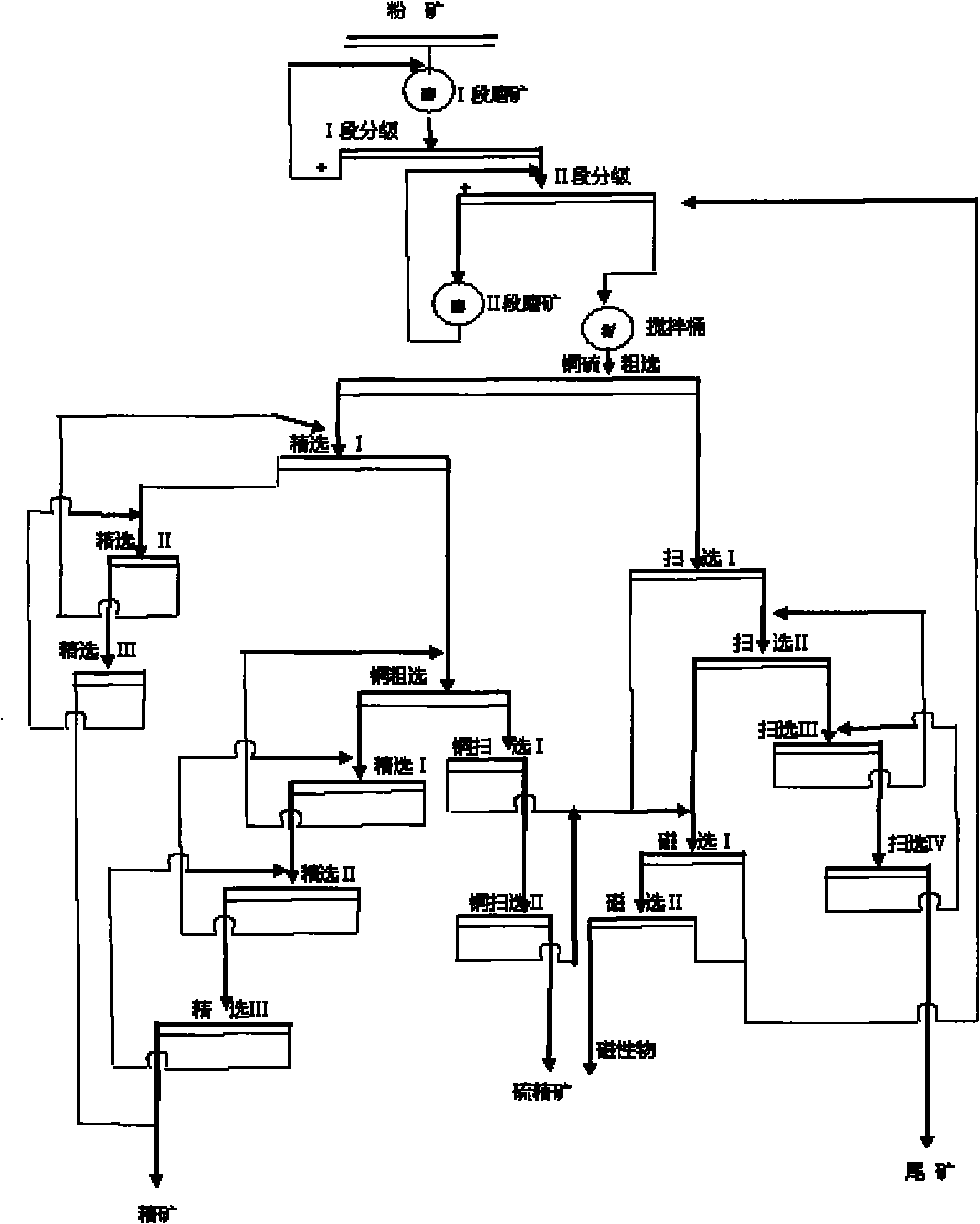

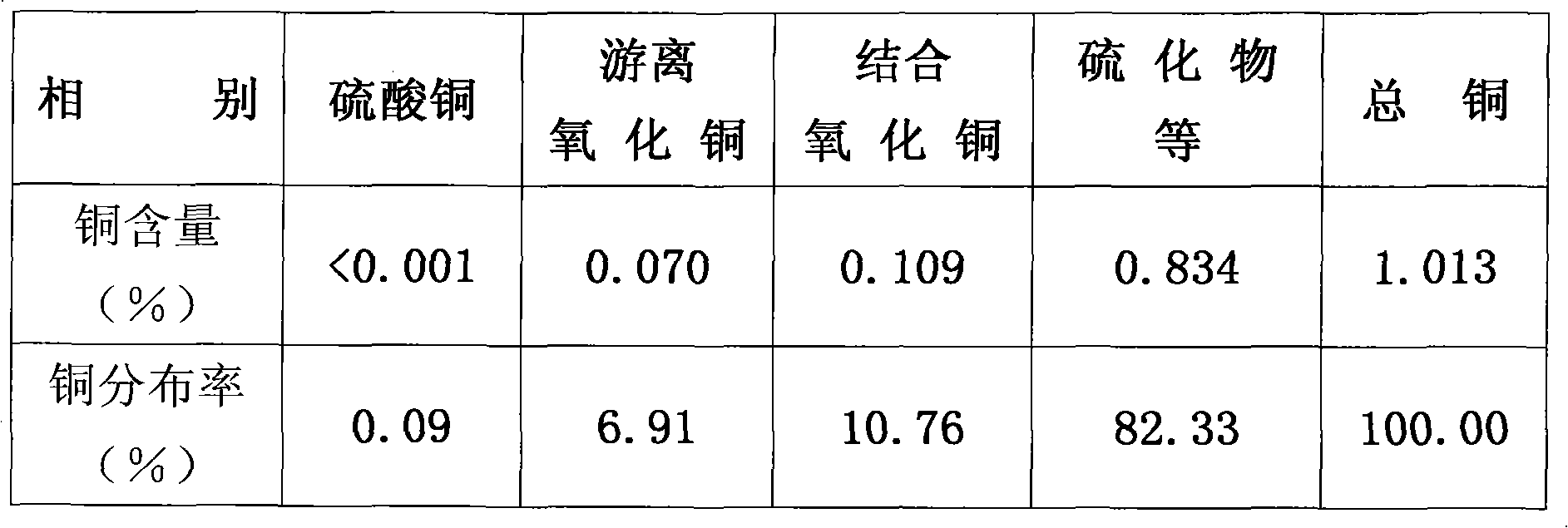

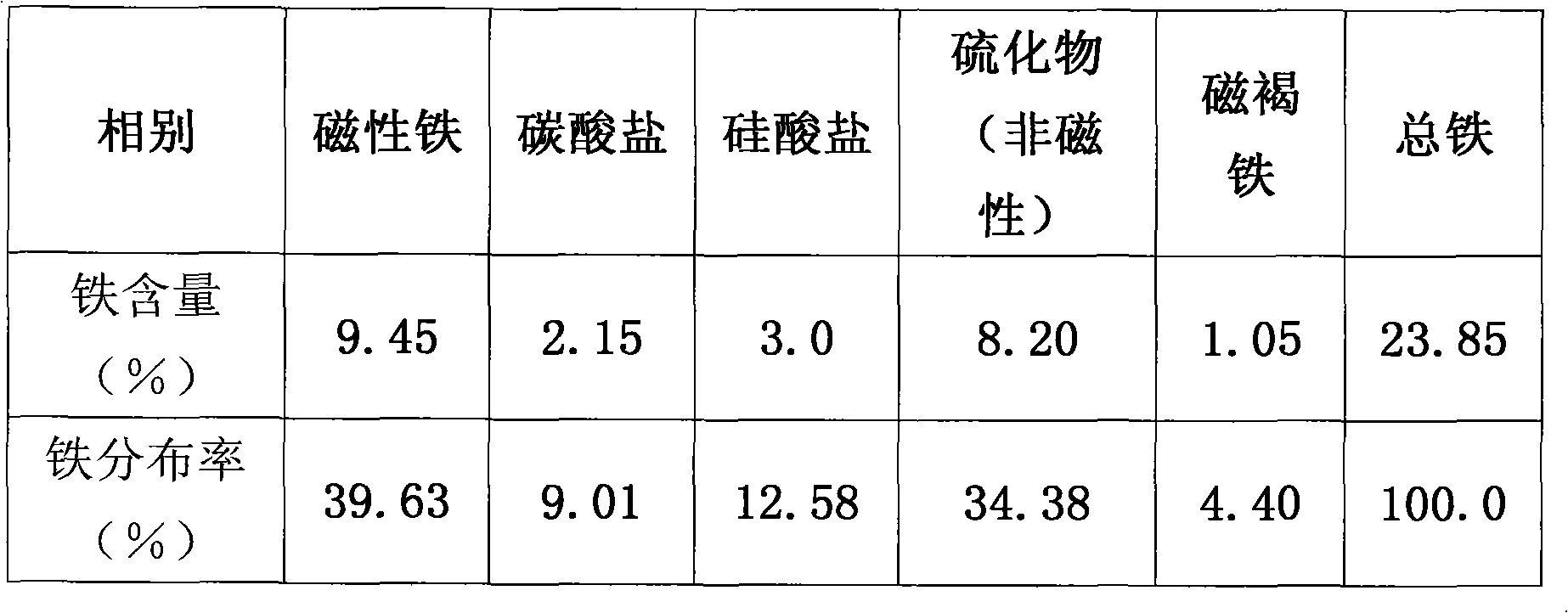

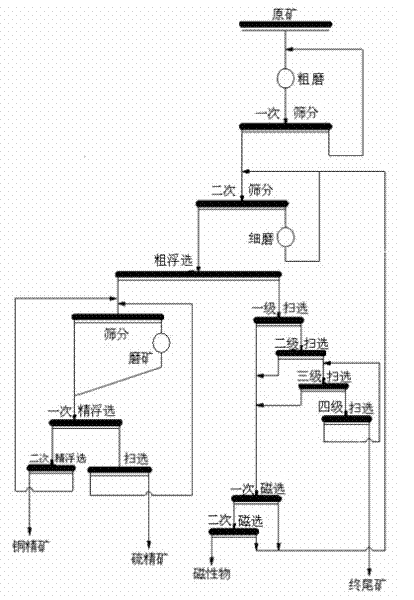

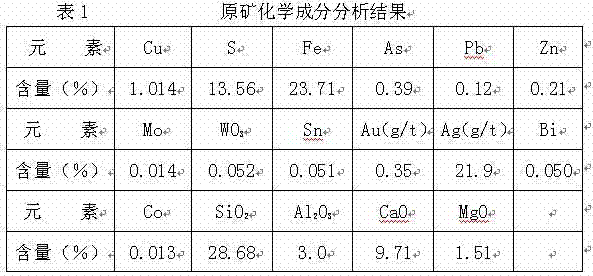

Comprehensive treatment method for high-mud content high-combination rate mixed copper ore

The invention provides a comprehensive treatment method for high-mud content high-combination rate mixed copper ore, which comprises the following steps of: grinding the mixed copper ore and roughing copper sulfur so as to obtain copper sulfur ore and tailings; concentrating the copper sulfur ore to obtain the copper ore and middlings; concentrating the copper ore to obtain the copper concentrate, and performing copper rough concentration on the middlings to obtain the copper ore and middlings simultaneously; concentrating the copper ore to obtain the copper concentrate, and performing copper scavenging on the middlings to prepare sulfur concentrate for recovery; performing magnetic separation on the middlings subjected to the copper scavenging so as to obtain magnetic for recovery, and returning the tailings to copper sulfur roughing. In the method, the pyrite (sulfur concentrate) is separated from the copper concentrate successfully in the flotation process for the first time so as to obtain high-quality copper concentrate; meanwhile, a large amount of magnetic pyrite is separated from the middlings subjected to flotation through the magnetic separation step, the iron sulfur content in the middlings is reduced to the greatest degree, the middlings become high-quality sulfur concentrate which can be directly used as raw materials for producing sulfuric acid, the tailings subjected to magnetic separation return to the system for recycled production, and valuable resources are fully recycled.

Owner:YUNNAN DIQING MINING DEV

Separating and analyzing method for high purity cellulose without pollution

The invention relates to a separation and analyzing method for high purity cellulose without contamination, it uses wood fiber as material; it decomposes the wood cellulose and semi-cellulose in system with acetic acid and nitric acid but without chlorine and contamination, acquires the cellulose with high purity. The invention uses acetic acid and nitric acid as catalyst, the weight percentage density of acetic acid is 80%, the weight of nitric acid is 1-8% of the acetic acid weight, they are processed for 18-22 minutes in 100-120deg.C, separates them and acquires the cellulose preparations; then carries on detection to the cellulose preparations with special viscosity, molecular weight, FT-IR, CP-MAS13C-NMR and energetics analysis. The process is simple and quick, has no contamination, the cellulose has a high purity, which can be applied to the separation and analysis of cellulose in wood fiber material.

Owner:SOUTH CHINA UNIV OF TECH

A comprehensive treatment method for mixed copper ore

The invention provides a comprehensive treatment method for mixed copper ore, which successfully separates sulfur concentrate and copper concentrate through the process steps of rough grinding, screening, fine grinding, rough flotation, fine flotation, magnetic separation, and sweeping. , so as to obtain high-quality copper concentrate, and then select a large amount of pyrrhotite from the middling ore through the magnetic separation step, which minimizes the iron and sulfur content of the middling ore, and can make the middling ore a high-quality Good sulfur concentrate can be directly used as raw material for sulfuric acid production, and the tailings after magnetic separation can be returned to the system for circular production, so that valuable resources can be fully recycled, and the tailings are discharged to the tailings dam after multi-stage screening Storage, to overcome the problems of heavy production load caused by the return of tailings, low concentrate grade and low recovery rate, the comprehensive recovery rate of copper is over 80%, the concentrate grade is over 19%, and the gold content of copper concentrate is 6g / t Above, the gold recovery rate is over 45%, the copper concentrate contains more than 418g / t of silver, and the silver recovery rate is over 50%.

Owner:YUNNAN DIQING MINING DEV

Liquid-state high-lead slag side-blowing water-gas reduction process

ActiveCN103361491AEasy to separateSignificant synergistic effectProcess efficiency improvementLiquid stateSlag

The invention relates to a liquid-state high-lead slag side-blowing water-gas reduction process, and belongs to the technical field of metallurgy. The process mainly comprises the steps of: directly injecting liquid-state high-lead slag melt subjected to oxidization smelting by a bottom blowing furnace into a reduction furnace, and directly reducing liquid-state high-lead slag into secondary lead bullion through side blowing in the reduction furnace by adopting combination of water gas and oxygen-enriched air. The reduction process is simple in technology, low in production cost and good in reduction controllability, and helps to realize low-pollution low-carbon-economy industrialized production.

Owner:HUNAN HUAXIN RAREANDPRECIOUS METALS TECH CO LTD

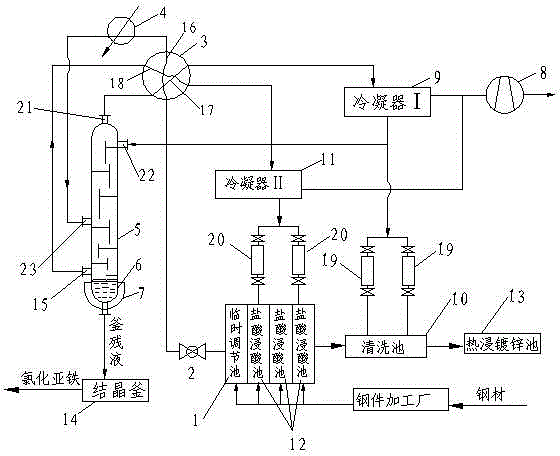

Recycling treatment process for chlorohydric acid pickling liquid waste

InactiveCN103553256ASolve inseparableVolatileChlorine/hydrogen-chlorideWaste water treatment from metallurgical processLiquid wasteChloride

The invention discloses a recycling treatment process for chlorohydric acid pickling liquid waste. The process comprises the following steps: adjusting the acidity of CaCO3 of the chlorohydric acid pickling liquid waste to 99.65-124.56g / L; adding ferrous chloride so as to enable ferrite to be in a saturation condition; heating to the bubble point, then feeding the mixture into a rectifying tower and separating, wherein the pressure in the rectifying tower is 61.05-67.50Kpa; recovering a 10-15% diluted hydrochloric acid liquid and ferrous chloride crystals. Through reasonable parameter control and decompressing and rectifying processes, hydrochloric acid liquor applicable to acid pickling steel pieces as well as a coagulant capable of being used for sewage and wastewater treatment or a chemical raw material ferrous chloride can be recovered just by means of materials generated in the steel piece acid pickling process without spending other raw materials, so that the cost is greatly saved. The process is process-investment-saving, low in energy consumption and easy for mastering of operation, and can be continuously operated or intermittently operated in batches, thereby realizing automatically controlled operation.

Owner:YUNNAN AGRICULTURAL UNIVERSITY +1

Method for absorbing vacuum tailed gas in production of polystyrene

InactiveCN101073742ALess process investmentImprove efficiencyUsing liquid separation agentActivated carbonPolystyrene

The invention is concerned with the absorbing method for vacuum tail-gas in the polystyrene production, it is: the tail-gas passes the white oil slot, the overflow gas of the white oil slot enters the bottom of the absorbing tower and countercurrent touches with the spray white oil, the gas from the absorbing tower absorbs by the activated carbon and then vents. The invention can absorb over 98% of the tail-gas during the production.

Owner:江苏中信国安新材料有限公司

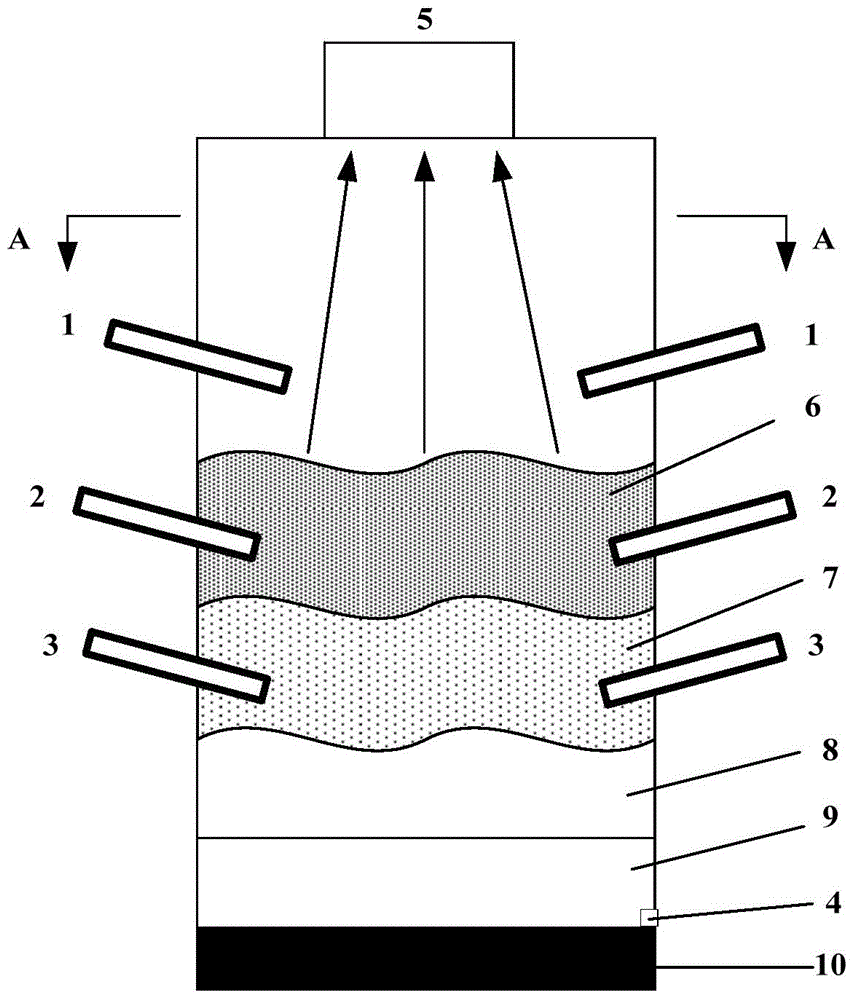

Multilayer slag smelting reduction ironmaking method and apparatus thereof

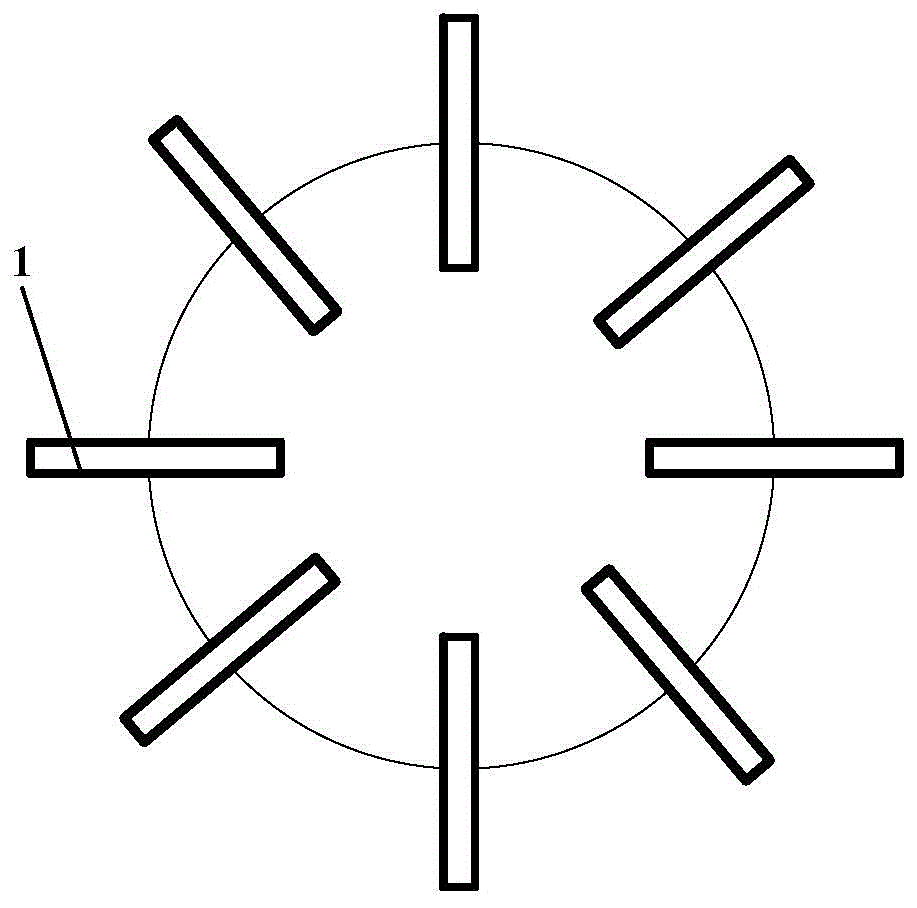

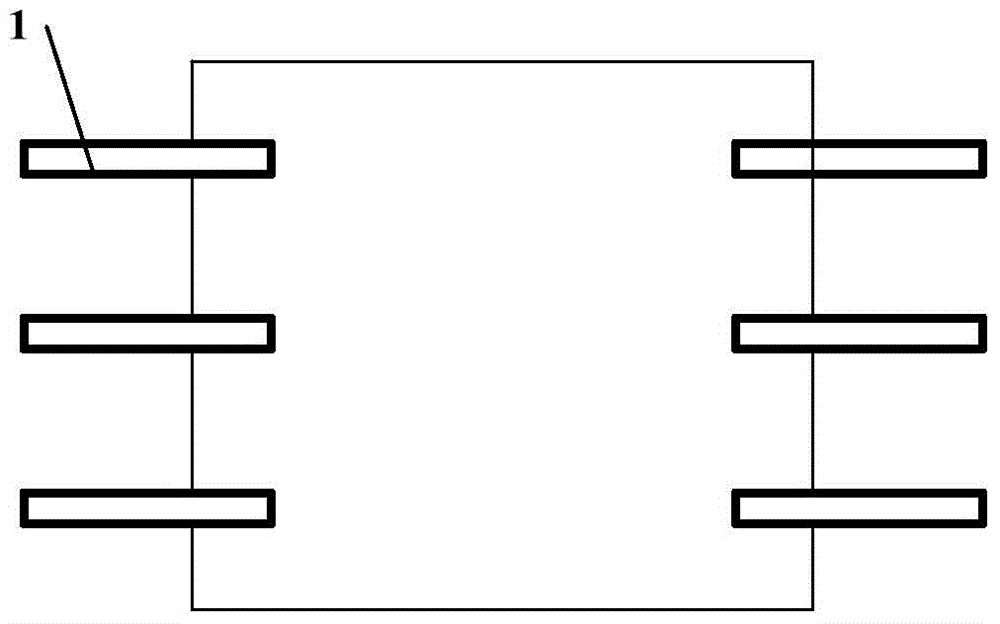

ActiveCN104894322AOmit the front-end process such as sinteringSimplify the smelting reduction processFluidised-bed furnacesFluid couplingCombustion

The invention belongs to the ironmaking field, and relates to a multilayer slag smelting reduction ironmaking method and an apparatus thereof. The method is characterized in that in a vertical-type melting furnace, a mixture of combustion-supporting gas, ore powder and a flux and combustion-supporting gas as well as fuel and combustion-supporting gas are respectively performed with fluid coupling to an upper spray gun (1), a middle layer spray gun (2) and a lower layer spray gun (3) arranged on the vertical-type melting furnace, the prepared materials are simultaneously injected to the vertical-type melting furnace by the three layers of spray guns to generate molten iron and slag through a reaction, a fusing slag layer (6), a reducing slag layer (7), a standing slag layer (8), a molten iron layer (9) and a molten iron layer (10) are respectively formed in the furnace from top to down; and iron or slag can be discharged at an iron / slag outlet (4) arranged at the molten iron layer (9) positioned at lower part of the furnace. The method is the one step method smelting reduction ironmaking method with advantages of high efficiency, energy saving and low cost, the apparatus design is simple, and is easily realized.

Owner:CENT IRON & STEEL RES INST +1

Manufacturing method of composite board base for rolling composite board

The invention relates to a manufacturing method of a composite board base for rolling a composite board, belongs to the technical field of composite board rolling methods, and is used for manufacturing the composite board base of the rolled composite board. According to the technical scheme, the manufacturing method comprises the steps that a plurality of board bases are overlapped up and down, gaps in the periphery of the board bases are sealed in a welding mode, vacuumizing steel tubes are reserved between welding beads, and vacuumizing treatment is conducted on gaps between the board bases through the vacuumizing steel tubes; and finally, the vacuumizing steel tubes are sealed and welded to enable the gaps between the board bases to form a vacuum state, then heating is conducted through a heating furnace, and finally, the composite board base is rolled together and formed by a rolling mill. According to the manufacturing method of the composite board base for rolling the composite board, the imagine that the vacuum state is achieved between the board bases under a non-high vacuum condition is achieved, breakthrough and progress are achieved in an existing process technology, and the equipment investment for manufacturing the composite board base is greatly reduced; and further, the operation technology is simplified, technical assurance is provided for expansion of the production scale and promotion of the product output, conditions are created for meeting demands of rapid development of current production, and excellent popularizing and using values in the industry are achieved.

Owner:HBIS COMPANY LIMITED HANDAN BRANCH COMPANY

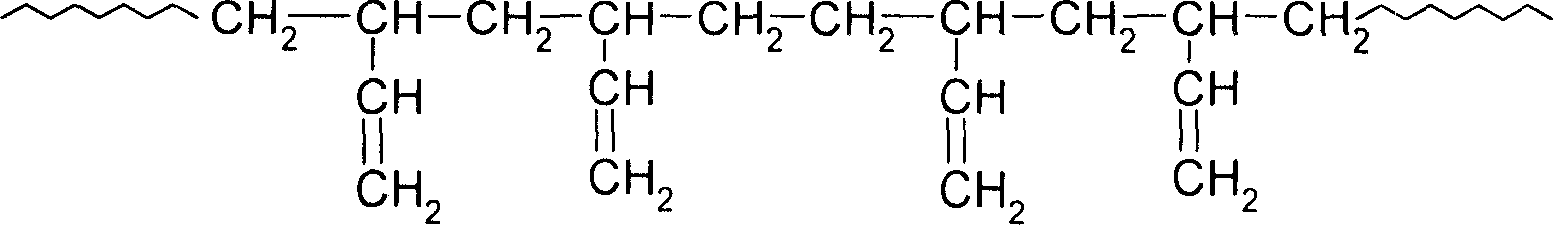

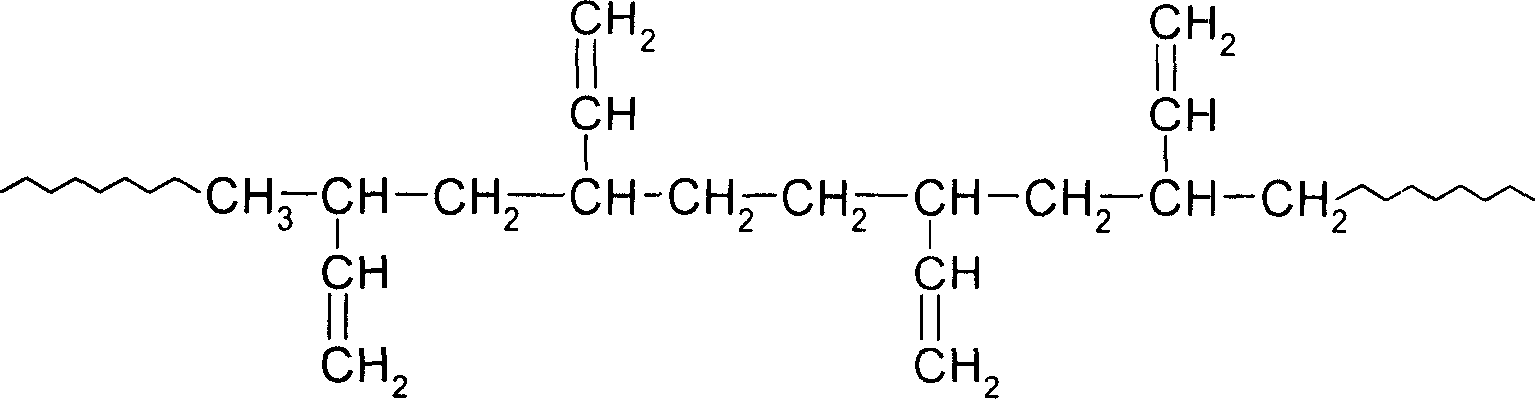

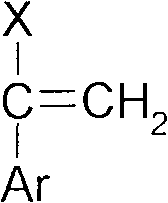

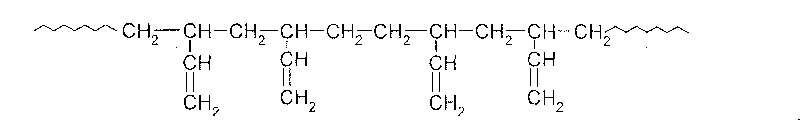

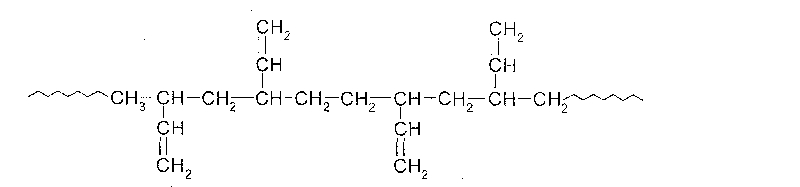

Continuous bulk polymerization process for preparing extruded acrylonitrile-butadiene-styrene graft copolymer

The present invention is continuous bulk polymerization process for preparing extruded acrylonitrile-butadiene-styrene graft copolymer. In the presence of organic peroxide, rubber solution of the mixture of alkyl vinyl arene monomer and unsaturated vinyl nitrile monomer are reacted at 90-170 deg.c for 8-12 hr, the polymer is made to pass through rubber grafting and grafted rubber phase transfer to reach monomer conversion rate of 65-85 %, and the un-reacted monomer and solvent are further eliminated from the polymer melt to obtain ABS resin product with rubber content of 12-18 %. The said process can obtain ABS resin product with high brightness, high extinction, high heat resistance, high impact strength and good machining performance, and the product is suitable for making pipe, plate, etc, especially lining of refrigerator.

Owner:太仓中化环保化工有限公司

Process for compacting wheel rim by plate instead of hot rolling steel

InactiveCN1631607ALow costProduct quality is stable and reliableMetal-working apparatusOther manufacturing equipments/toolsEngineeringProduction line

The invention is a technics pressing wheel covets with sheet material instead of hot rolling steel. Its features lay on that: first process the sheets into strip material and tempering at 580 to 620 deg. C; and then with oid press over 500 T, obtain the product through rolling, covering, head cutting, close dot welding, welding, pre-compressing, expanding, welding gap abrading, compressing, punching the air valve hole and assembling shaping. Pressing wheel covets with this technics will save hot rolling steel while the sheet material price is 40 percent lower than it of hot rolling steel, and so to lower the cost by 5 to 11 percent. Its production efficiency is the same as section steel production line with products of reliable quality, moreover it is of low investment without any large facilities and just a set of wheel covet moulds and an oil press is needed.

Owner:钟锋

Method for treating energetic material synthetic wastewater

InactiveCN103693804ASimple processEasy to operateMultistage water/sewage treatmentFenton reactionFerrous salts

The invention discloses a method for treating energetic material synthetic wastewater, belonging to the field of environmental protection. The method for treating the energetic material synthetic wastewater comprises the steps of a, performing neutralizing treatment before a Fenton reaction; b, performing the Fenton oxidization reaction, namely adding a ferrous salt into filtered wastewater, and dropwise adding oxydol to perform catalytic oxidation reaction under the reaction condition that the temperature is 20-70 DEG C, the pH value is 3-4, the mole ratio of H2O2 to COD is 3:1 to 2:1, the mole ratio of Fe<2+> to H2O2 is 1:7 to 1:8, the reaction time is 4-6 h, and the inlet water COD is 5000-120000 mg / L; c, performing neutralizing treatment after the Fenton reaction; d, performing solid-liquid separation; e, performing facultative anaerobe degradation; and f, performing aerobic degradation. The method can be used for treating various types of energetic material synthetic wastewater, and particularly has good performance on treatment of characteristic nitro-sulfuric acid wastewater; the method is suitable for wastewater with a wide range of indexes and salt contents that the COD is 500-120000 mg / L, and the total salt content is 1000-220000 mg / L.

Owner:XIAN MODERN CHEM RES INST

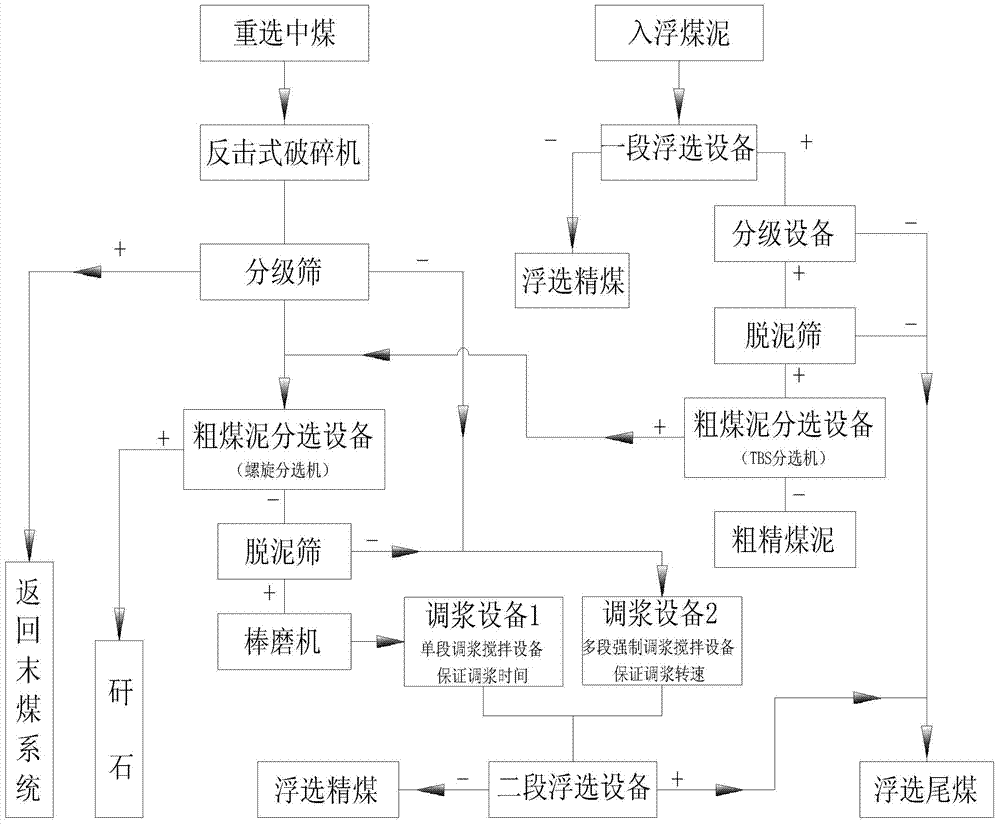

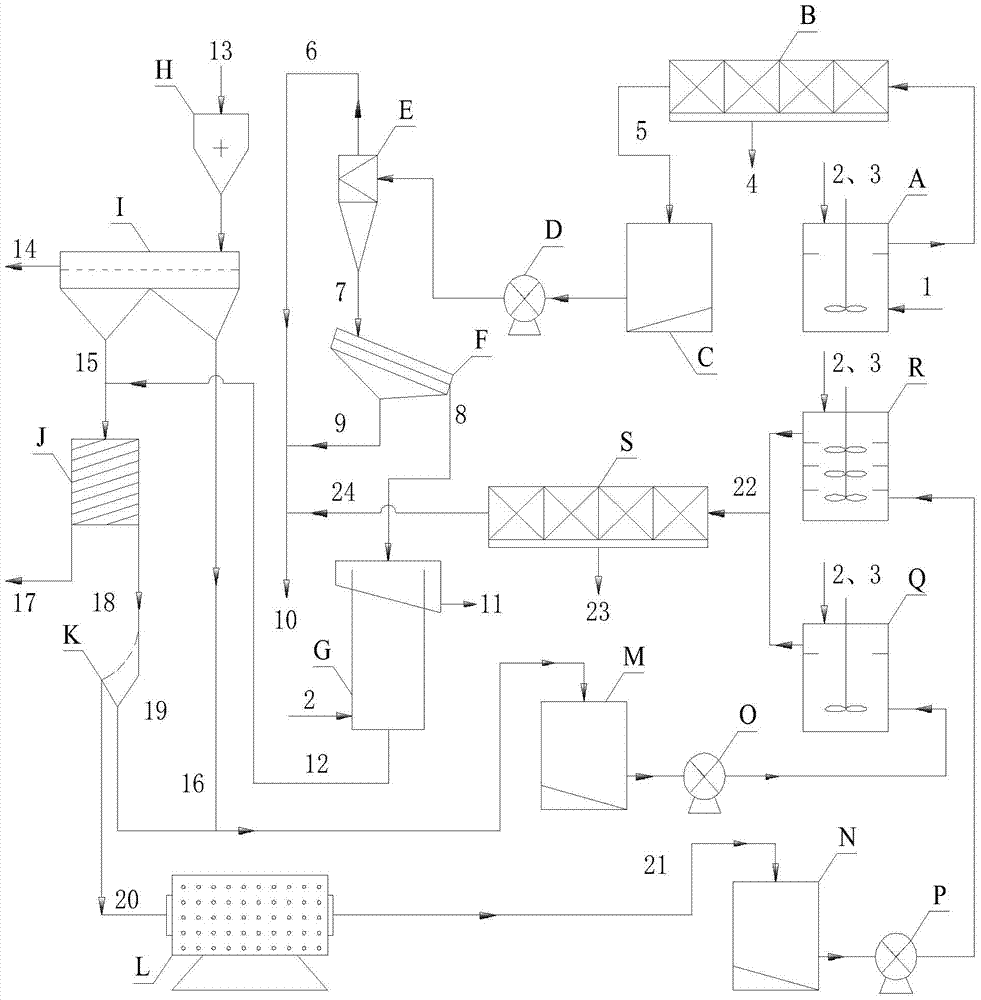

Coking middling coal dms-flotation combined separation process

The invention discloses a coking middling coal dms-flotation combined separation process, and belongs to the technical field of coking middling coal separation. The process comprises the steps of 1, primary size mixing flotation operation, 2, hierarchical dewatering operation, 3, crushing and screening operation, 4, coarse slime separation operation, 5, desliming operation, 6, ore grinding dissociation operation, 7, secondary size mixing operation and 8, secondary flotation operation. The coking middling coal dms-flotation combined separation process is simple in procedure, small in investment, low in energy consumption, little in operation cost, high in separation efficiency and remarkable in economic benefit.

Owner:CHINA UNIV OF MINING & TECH

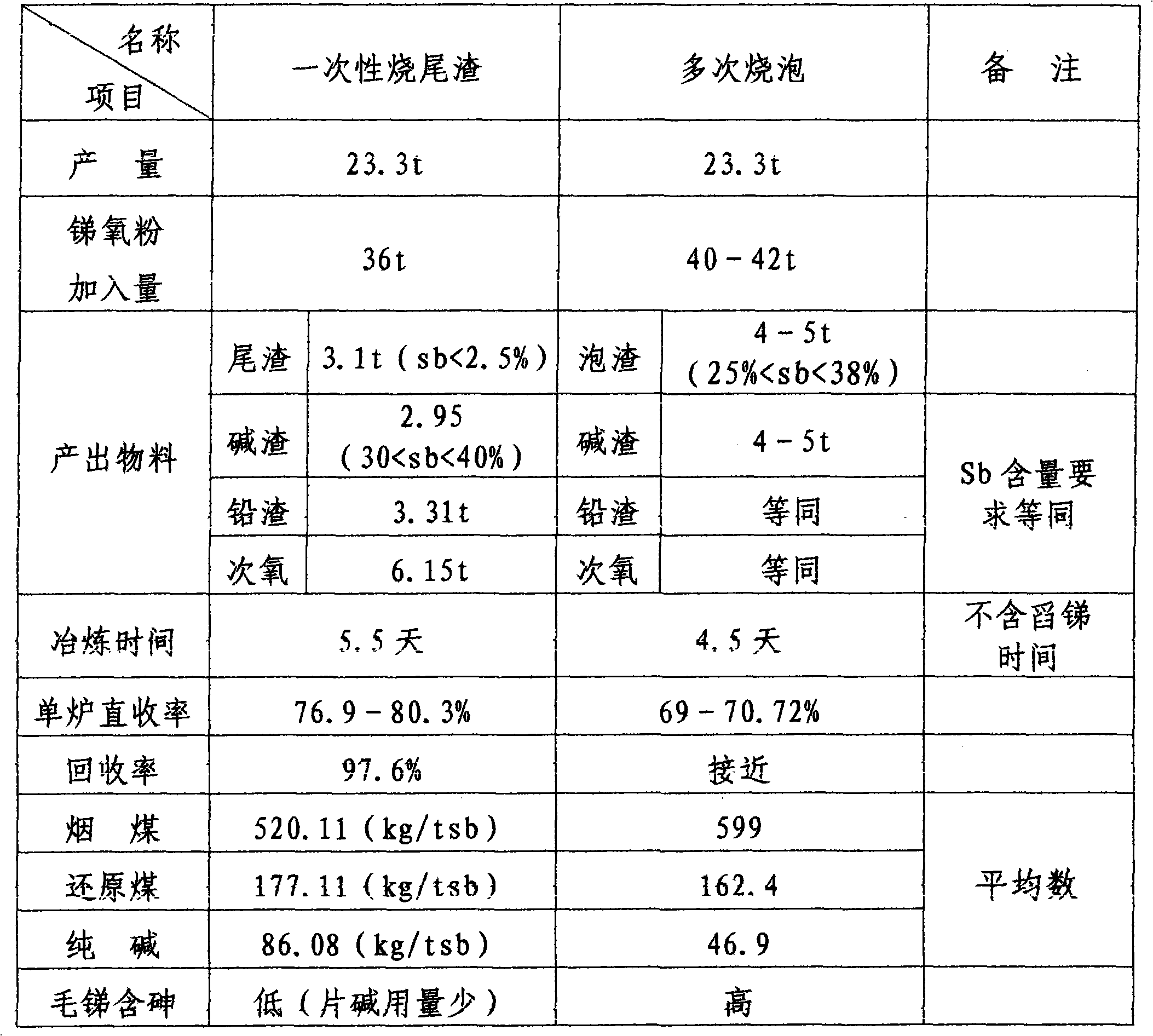

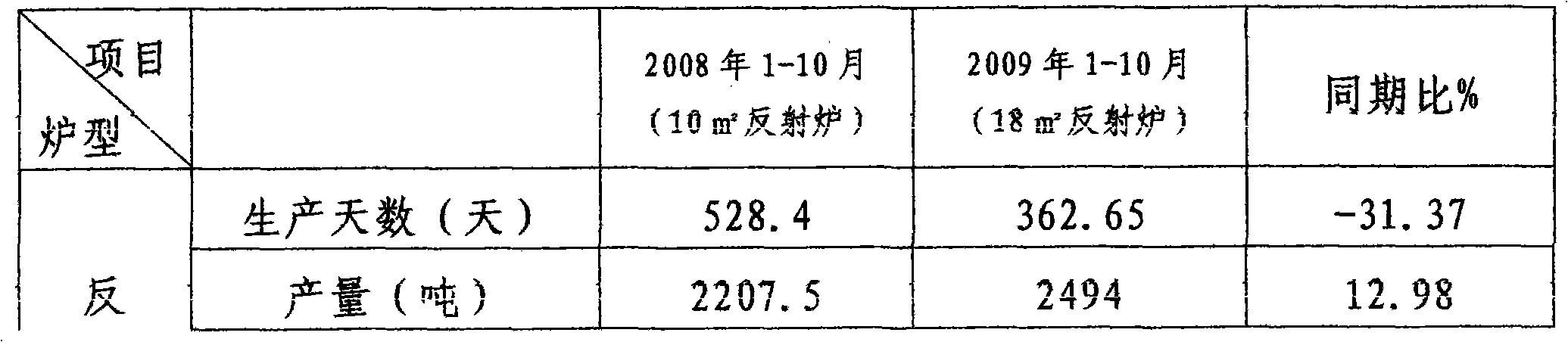

Production technology for one-time tailing combustion in stibium reverberatory furnace

InactiveCN101812600AImprove direct yieldSave antimony resourcesProcess efficiency improvementSludgeReverberatory furnace

The invention discloses a production technology for one-time tailing combustion in a stibium reverberatory furnace, which belongs to the technical field of smelting. The technical process comprises the following steps: A. heating the reverberatory furnace with coal by using a thin coal multi-combustion method; B. adding arsenic caustic sludge, and adding antimony oxide powder at different stages; C. comprising 4-6% of reducer, 1-3% of flux and balance of antimony oxide powder in the antimony oxide powder; D. carrying out reduction, continuing to adding the reducer at different stages, wherein the quantity of the reducer in the whole process does not exceed 10-20% of the weight of the antimony oxide powder; and E. sampling and assaying, and when the content of Sb in the laboratory report is lower than 2%, opening the sludge notch to discharge the tailings. The invention can increase the stibium content and recovery rate, does not need to process the arsenic caustic sludge by a wet process, reduces the environmental pollution and the production cost, and can be used for smelting crude stibium.

Owner:湖南东港锑品有限公司

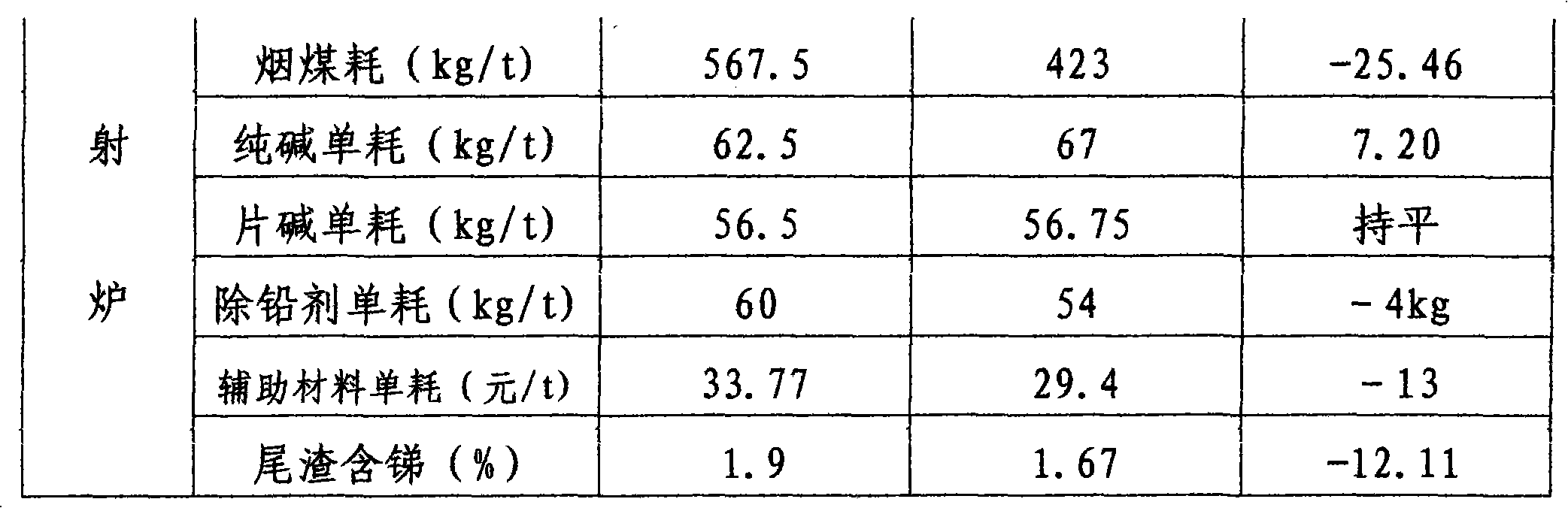

Garbage sorting compressing environmental processing technology

InactiveCN101823071AReduce investmentHazard reductionWaste processingSolid waste disposalSocial benefitsLitter

The invention provides a garbage sorting compressing environmental processing technology. Comprehensive sorting treatment is carried out on garbage, garbage is sequentially subject to four stages of recycling, composting, residue compression sealing landfill and penetrating liquid treatment, then a plurality of processes of sorting, bag-breaking screening, compression packaging and winding packaging are carried out on the garbage, density volume reduction is adopted to realize simplification of garbage treatment, the garbage is daily treated, storage capacity is effectively reduced, and the existing landfill time is prolonged for more than seven years. The invention has reasonable design, simple construction member, strong practicability and convenient and easy operation, no large-scale dump site is required to be established, the existing dump site landfill storage capacity can be directly utilized to carry out sorting, compression and sealing on garbage, funding is reduced, and the penetrating liquid produced by garbage is purified, harmfulness of various harmful substances can be reduced to minimum, no secondary pollution to the environment is produced, and the technology has obvious social benefit and economic benefit.

Owner:广东昕旺环保科技发展有限公司

Continuous bulk polymerization process for preparing extruded acrylonitrile-butadiene-styrene graft copolymer

The present invention is continuous bulk polymerization process for preparing extruded acrylonitrile-butadiene-styrene graft copolymer. In the presence of organic peroxide, rubber solution of the mixture of alkyl vinyl arene monomer and unsaturated vinyl nitrile monomer are reacted at 90-170 deg.c for 8-12 hr, the polymer is made to pass through rubber grafting and grafted rubber phase transfer toreach monomer conversion rate of 65-85 %, and the un-reacted monomer and solvent are further eliminated from the polymer melt to obtain ABS resin product with rubber content of 12-18 %. The said process can obtain ABS resin product with high brightness, high extinction, high heat resistance, high impact strength and good machining performance, and the product is suitable for making pipe, plate, etc, especially lining of refrigerator.

Owner:太仓中化环保化工有限公司

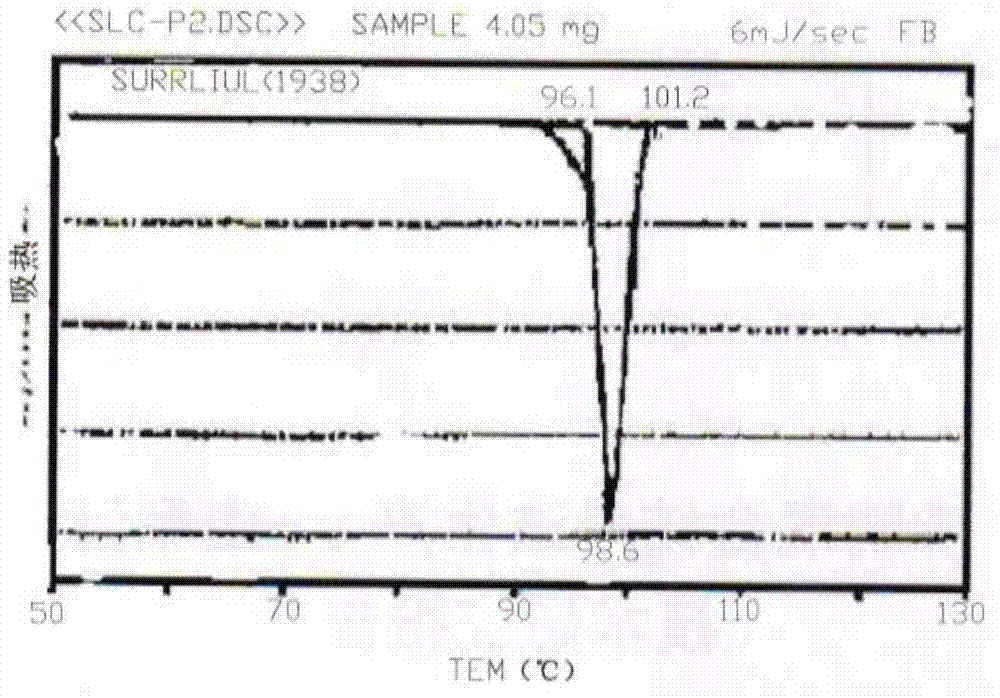

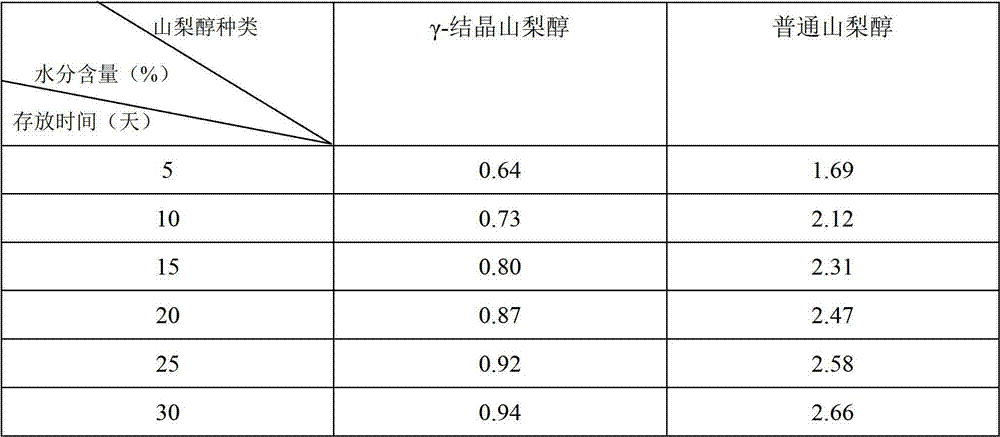

Preparation method of gamma-crystalline sorbitol

ActiveCN103172496AHigh content of γ-typeHigh melting pointHydroxy compound separation/purificationMolten stateSocial benefits

The invention discloses a preparation method of gamma-crystalline sorbitol. The preparation method comprises the following steps of: evaporating and concentrating VC (Vitamin C)-level liquid sorbitol to a molten state with solid mass concentration of more than 98%; cooling the molten sorbitol to 105 DEG C to 120 DEG C and spraying the cooled sorbitol to boiled sorbitol seed crystal while stirring and mixing, so that the molten sorbitol is crystallized to form the gamma-crystalline sorbitol; preserving the heat and curing the product obtained by the spraying, cooling the product, and crushing the product after the product is cooled to 20 DEG C to 40 DEG C; and jetting the clean steam to the crushed product and drying the crushed product to obtain the finished product gamma-crystalline sorbitol, wherein the fluidity of the obtained gamma-crystalline sorbitol product is improved to 80g / s or higher. The gamma-crystalline sorbitol obtained by the preparation method disclosed by the invention is high in gamma-form content of 90% or higher, high in melting point, unlikely to absorb moisture, good in fluidity, low in cost, capable of satisfying the application requirements in different fields including foods, daily chemicals, medicines and the like, and good in economic benefits and social benefits.

Owner:山东绿健生物技术有限公司

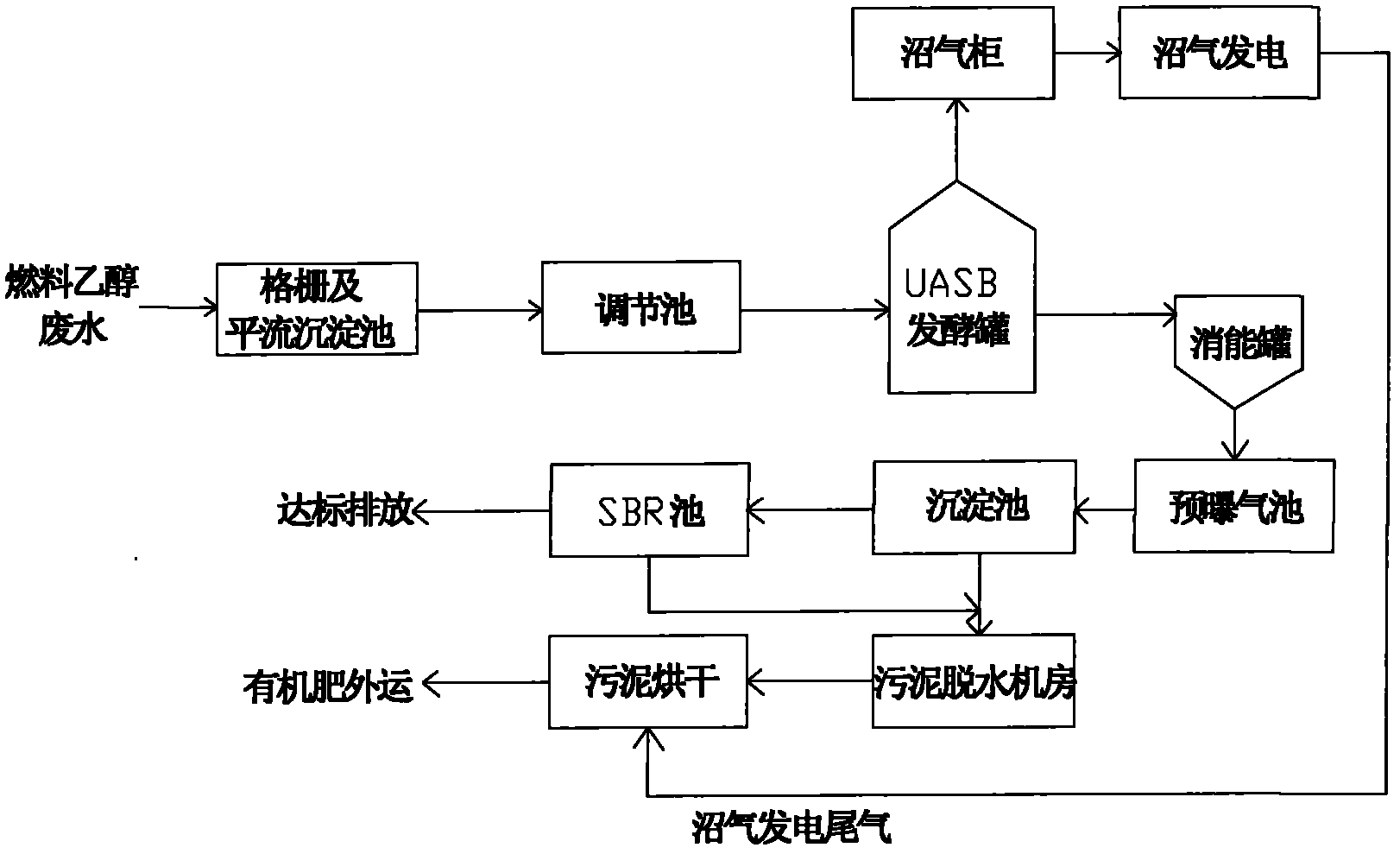

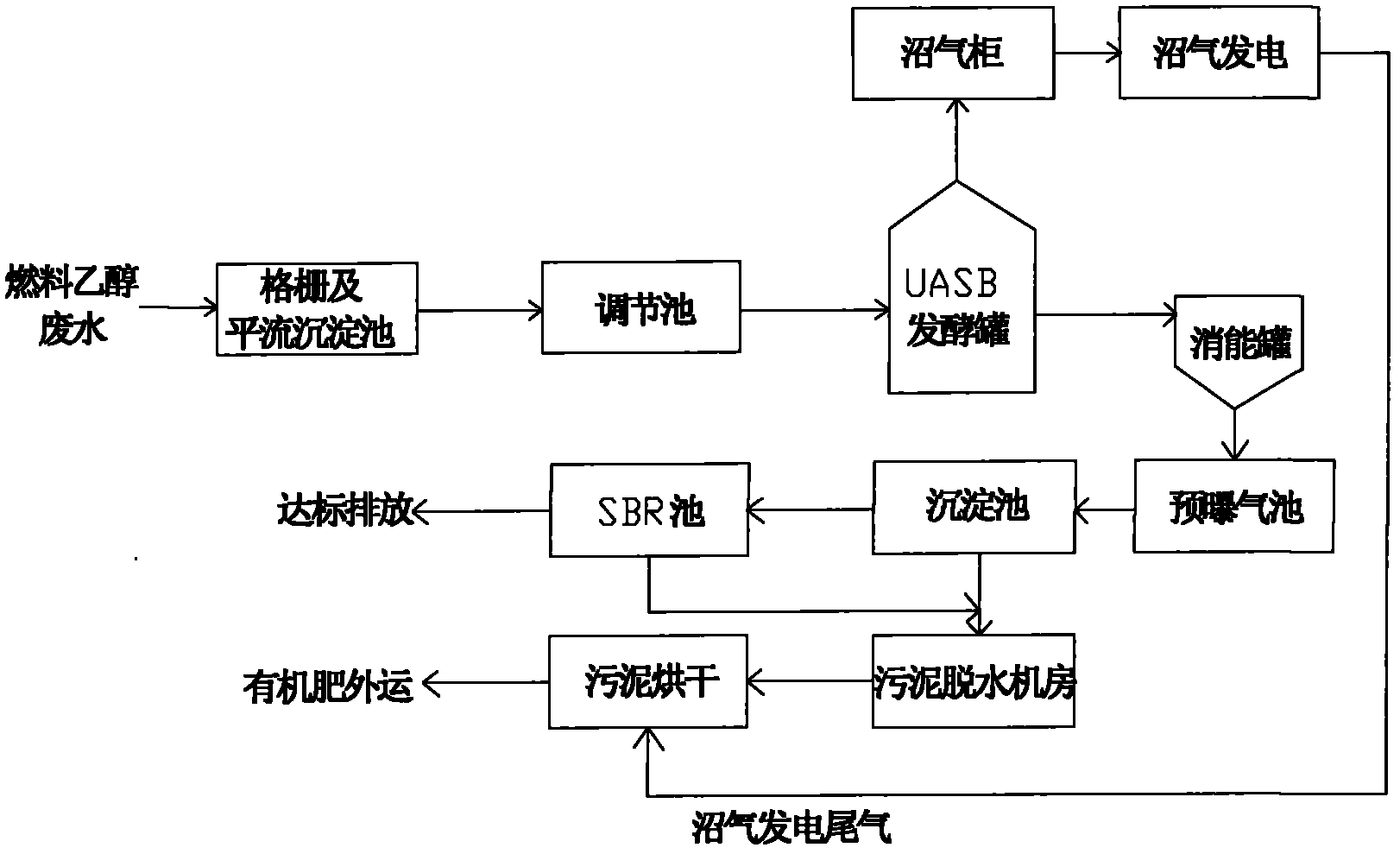

Method for treating wastewater containing high-concentration fuel ethanol by utilizing wheat and other gains as main raw materials

InactiveCN102115294AImprove sedimentation efficiencySuppress generationSludge treatment by de-watering/drying/thickeningBio-organic fraction processingSequencing batch reactorEmission standard

The invention discloses a method for treating wastewater containing high-concentration fuel ethanol by utilizing wheat and other gains as main raw materials. The method comprises the following steps: carrying out anaerobic treatment in an intermediate temperature fermentation upflow anaerobic sludge blanket (UASB) retort by using primary anaerobic treatment and secondary aerobic treatment; after the effluent potential energy of anaerobic effluent is reduced by an energy dissipation jar and partial anaerobic sludge is precipitated, feeding the anaerobic effluent into a pre-aeration pool; and after passing through a sedimentation pool, causing pre-aeration pool effluent to a sequencing batch reactor (SBR) pool for aeration and precipitation so that the effluent reaches the emission standard. Marsh gas generated in an anaerobic fermentation jar can be used as a renewable energy source to be fed into a marsh gas cabinet for marsh gas generation, generated electricity energy can meet sewage treatment electro-requirement and then the residual electricity energy can be supplied for fuel ethanol production. The remained sludge generated in a marsh gas production and sewage treatment process is subjected to concentrated separation and then is dried by using high-temperature tail gas generated in marsh gas generation so as to obtain an organic fertilizer. The method has the advantages of low operation cost and high treatment efficiency, the whole sewage treatment system achieves zero energy supply, the generated electricity energy is slightly remained, and the anaerobic effluent in the operation process has less possibility of incrustation and blockage, thereby achieving the win-win purpose of environment and energy source.

Owner:ZHONGJU TIANGUAN BIOLOGICAL ENERGY

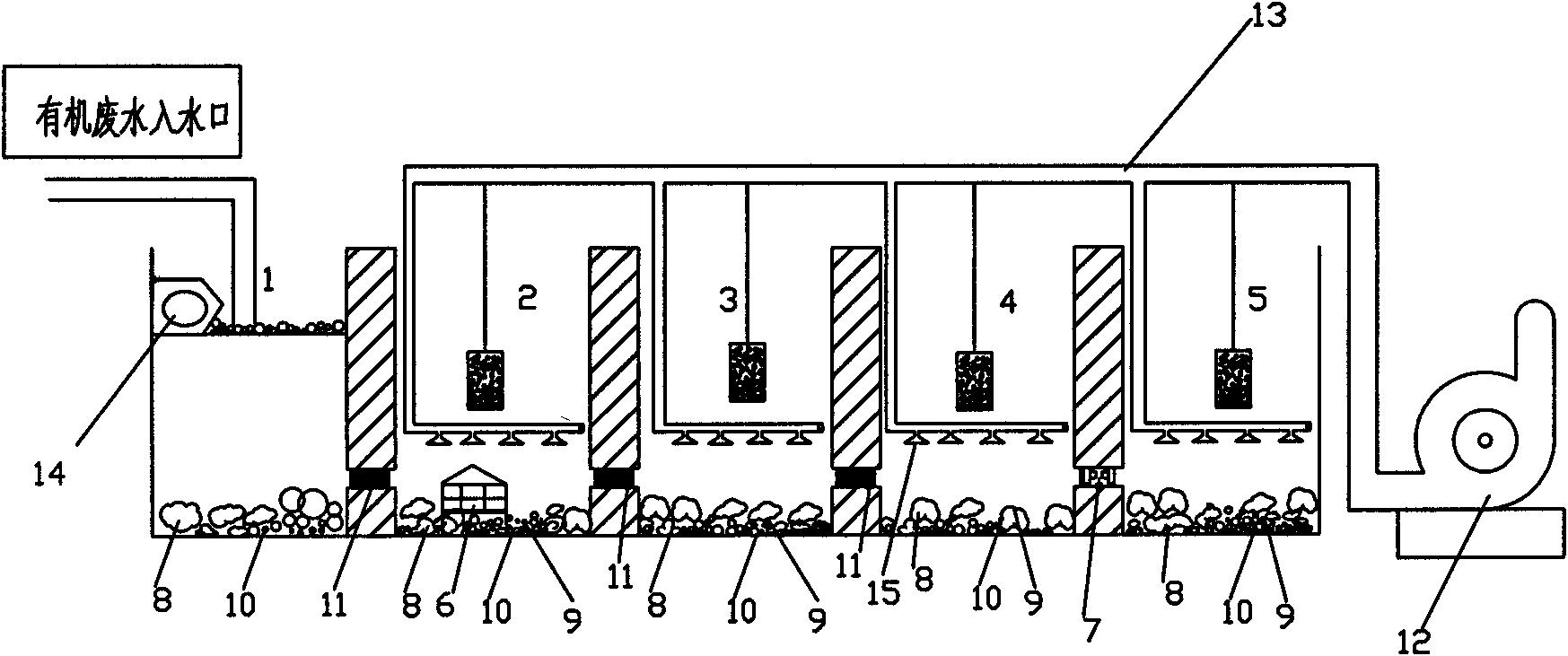

Method for treating sewage by adopting biological-physical combined method

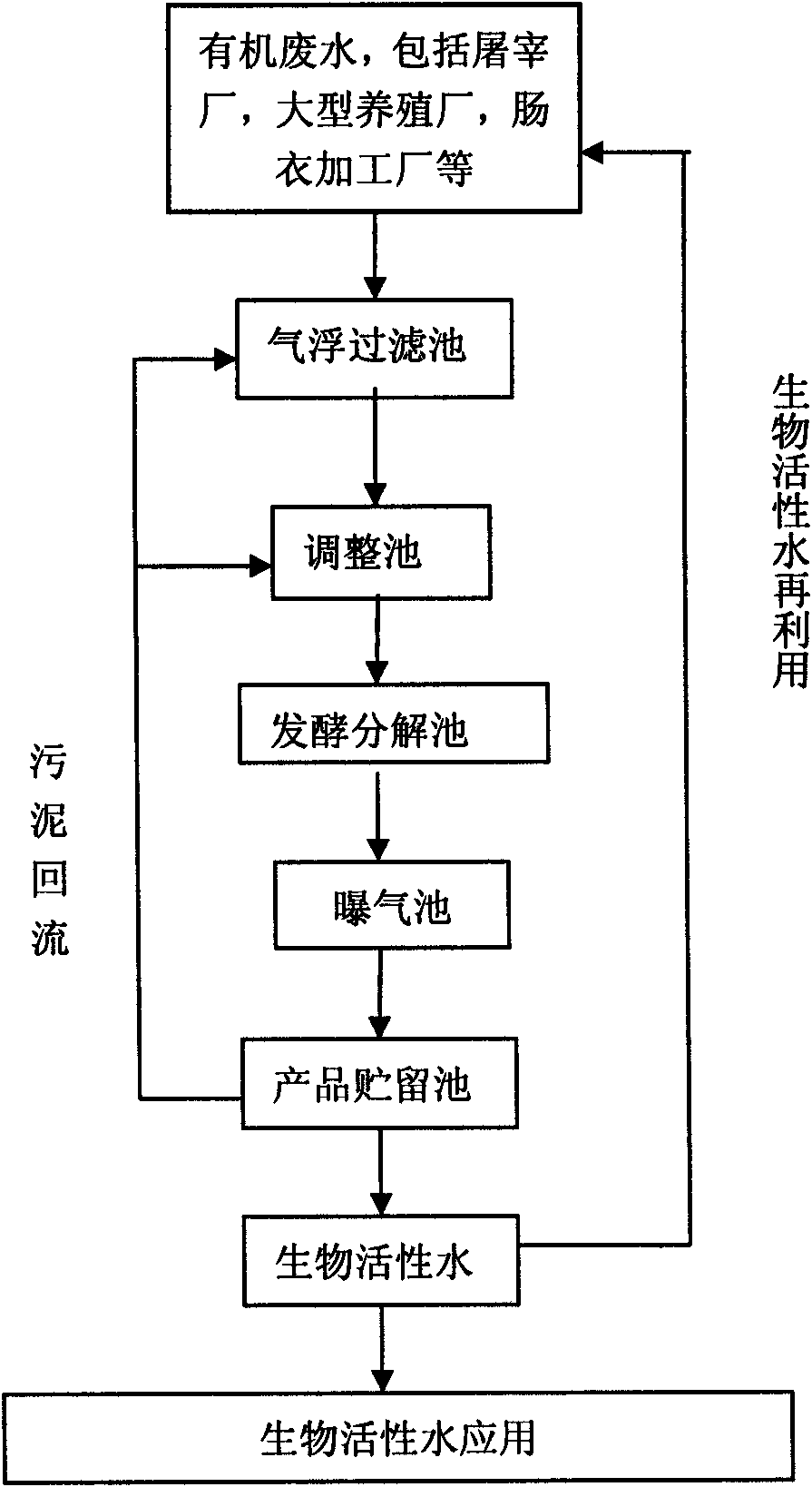

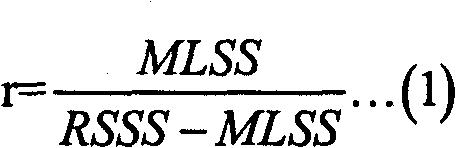

InactiveCN102126816ALow costImprove efficiencyMultistage water/sewage treatmentWater/sewage treatment by flotationAutomatic controlRetention basin

The invention relates to a method for treating sewage by adopting a biological-physical combined method. The method comprises the following steps of: making organic sewage water pass through an air floatation filter tank, a regulating pond, a zymolysis pond, an aeration biological pond and a product retention basin; and fermenting the organic sewage under the actions of microflorae, sludge, volcanic rock and the air, decomposing, purifying and the like to produce biologically active water which can be recycled in the growing process of animals and plants. The system has the advantages of capability of realizing full-automatic control, easiness in operating, small technical investment, low sewage treatment cost, high sewage treatment efficiency and stable performance.

Owner:YULIN UNIV

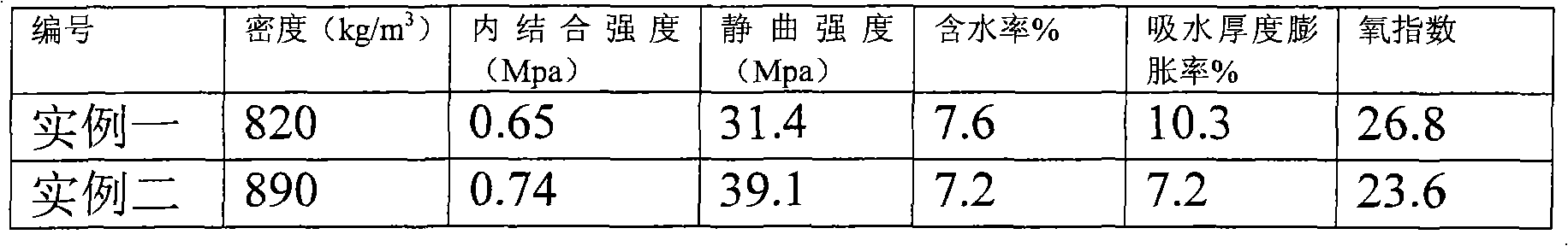

Method for preparing environmentally-friendly flame retardant fiberboard by utilizing xylose waste residue

ActiveCN101949112AReduce the number of links in the production processLess process investmentFibreboardXyloseWater content

The invention discloses a method for preparing an environmentally-friendly flame retardant fiberboard by utilizing xylose waste residue, comprising the following steps: centrifuging the xylose waste residue, separating the liquid in the xylose waste residue; controlling the water content of the waste residue to be 50-60% and the fiber mesh number to be 30-100 meshes; filtering water in fiber for 18-22s; applying phosphorus flame retardant to carry out flame retardant treatment, wherein, the additive amount is 10-15% of the weight of the dried fiber configured in step a; applying urea formaldehyde resin, waterproofing agent and curing agent, and evenly stirring, wherein, the applying amount of the urea formaldehyde resin is 10-14% of the weight of the dried fiber, the applying amount of the waterproofing agent is 1-3% of the weight of the dried fiber, and the applying amount of the curing agent is 0.5-3% of the weight of the dried fiber; drying, controlling the water content of the fiber to be 8-14%, and then storing into a storage bin; prepressing the dried fiber into a plate blank; prepressing, and feeding the prepressed plate blank into a hot press for hot-pressing; and trimming, polishing and grading the plate blank after the plate blank is aired to the room temperature to obtain the finished product. The method of the invention reduces a fiberboard production process link,does not need the steps of softening and hot grinding by utilizing the xylose waste residue to produce the flame retardant fiberboard, thus reducing the process investment, lowering the production cost, and having obvious economic benefits.

Owner:GANSU HEYUAN BIOLOGICAL PRODS

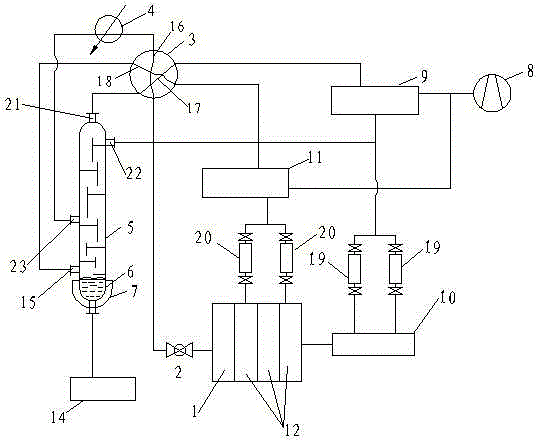

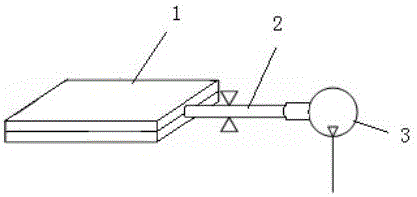

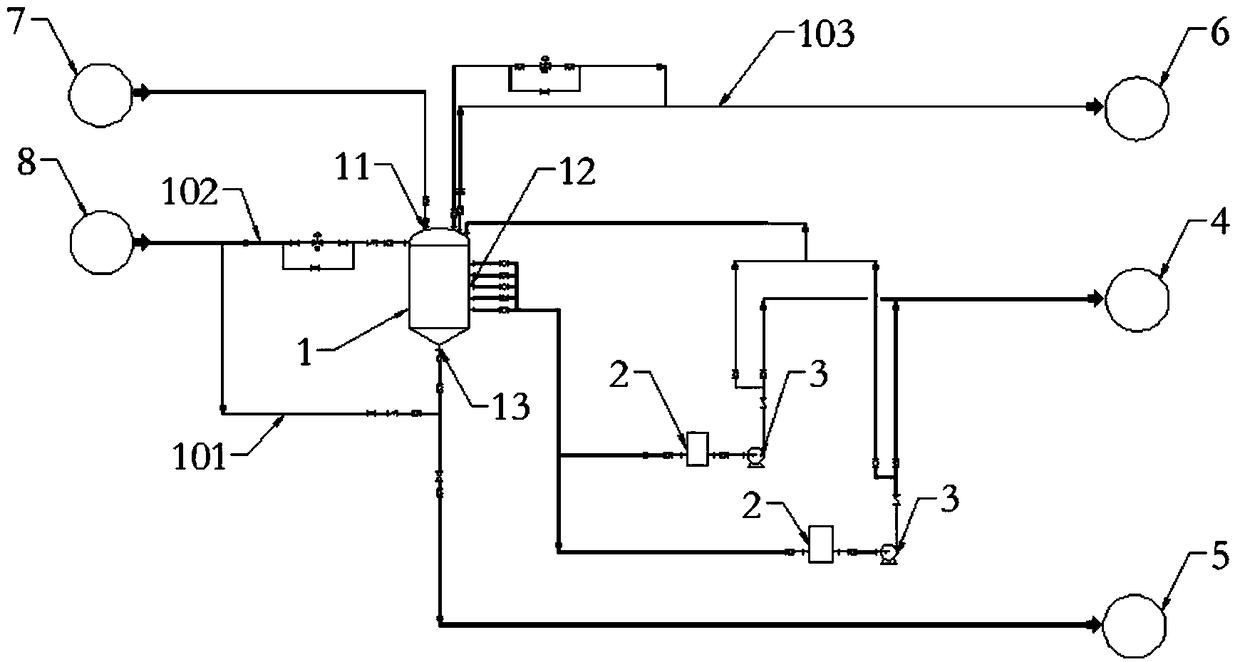

Chlorosilane-containing slurry treatment method and chlorosilane-containing slurry treatment system

PendingCN108751202AQuality improvementAlleviate problems such as blockingSiliconHalogenated silanesRecovery periodSlurry

The invention belongs to the technical field of polycrystalline silicon production, and relates to a chlorosilane-containing slurry treatment method and a chlorosilane-containing slurry treatment system. The chlorosilane-containing slurry treatment method disclosed by the invention comprises the following steps: chlorosilane-containing slurry gets into a slurry collection tank, and is kept still,and by utilizing the incompatibility and density difference between components in the slurry, the slurry is formed into supernate and bottom turbid liquid in the slurry collection tank; the supernateis discharged out from a plurality of chlorosilane outlets which are arranged at different heights on the slurry collection tank, sequentially passes through a filter and a delivery pump, and gets into a chlorosilane recovery device; and the bottom turbid liquid gets into a washing device from the bottom outlet of the slurry collection tank under the effect of pressure difference and is washed. According to the invention, the chlorosilane recovery rate is high, the quality of recovered chlorosilane is better, and the requirement of electronic-grade polycrystalline silicon production on qualitycan be met. Moreover, the investment of the process is low, safety is good, the continuous operation period is long, later operation and maintenance costs are low, the investment recovery period is short, and risk is low.

Owner:青海黄河上游水电开发有限责任公司新能源分公司 +2

High-efficiency biological strengthened treatment process for waste water generated in paper making

InactiveCN101955306AReduce the chance of sludge bulkingRun smoothlyTreatment with aerobic and anaerobic processesMultistage water/sewage treatmentActivated carbonPre treatment

The invention provides a method of feeding powdered activated carbon in the specific position for solving the problems occurring in the biochemical treatment process of waste water generated in paper making; and simultaneously, an anoxic pool is arranged for removing nitrates in the water, controlling TN in the discharged water and reducing the sludge bulking probability. The pretreated waste water generated in paper making automatically flows into or is lifted by a water pump to enter an anoxic zone of a high-efficiency biological strengthened treatment pool; the waste water treated in the anoxic zone automatically flows into an aerobic zone; the waste water treated in the aerobic zone automatically flows into a settling zone; and the water treated in the settling zone automatically flows into or is lifted by the water pump to enter subsequent treatment units or is discharged. The reactor enables the biochemical treatment unit of the waste water generated in paper making to have the advantages of stable operation, better quality of the discharged water, reduced operation cost and the like.

Owner:JIANGSU PROVINCIAL ACAD OF ENVIRONMENTAL SCI

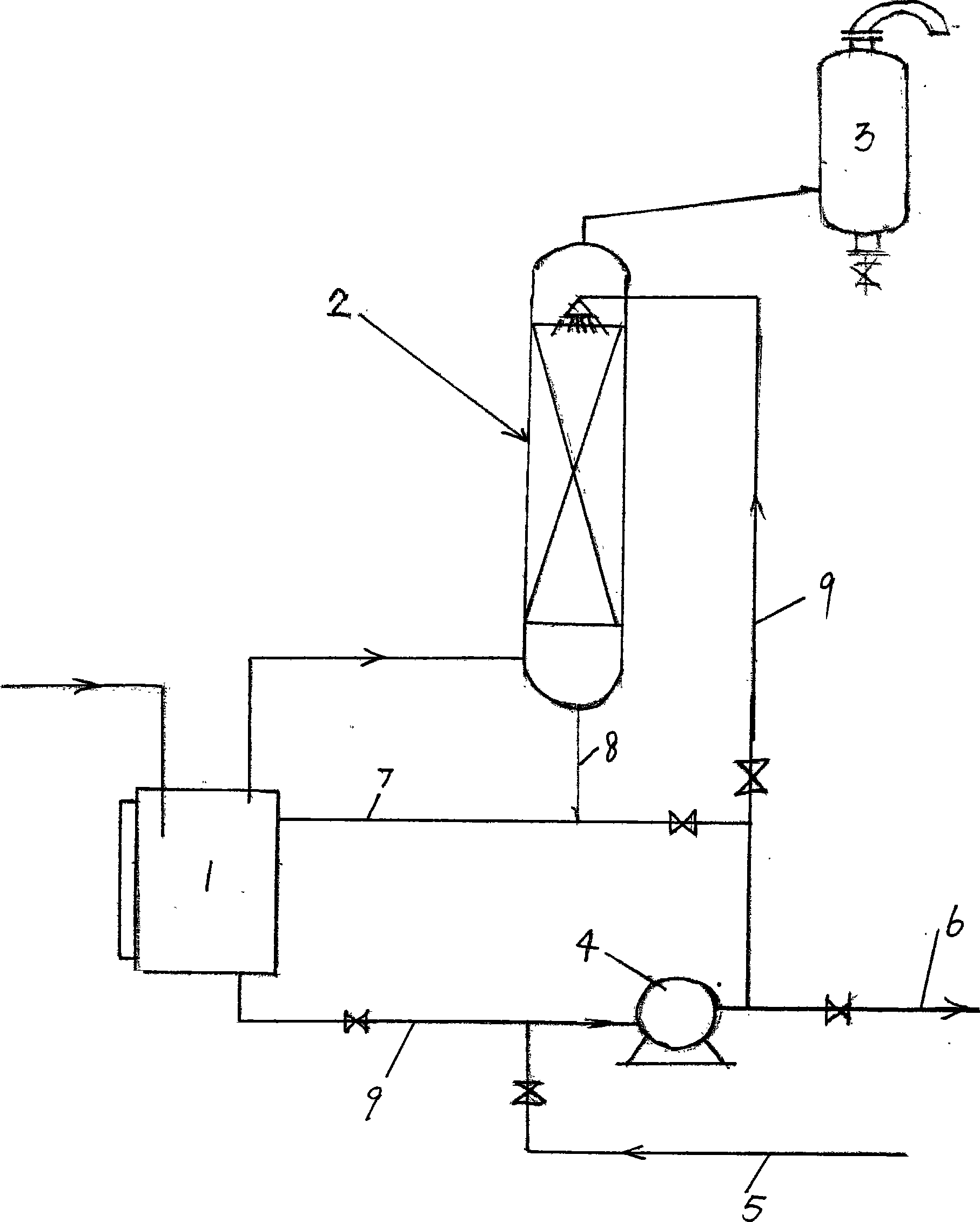

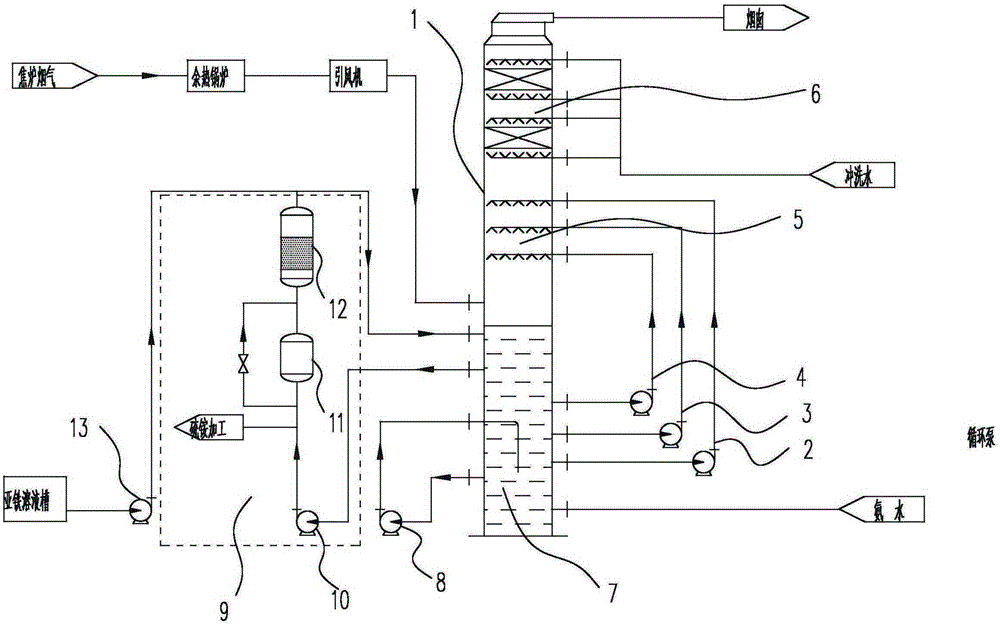

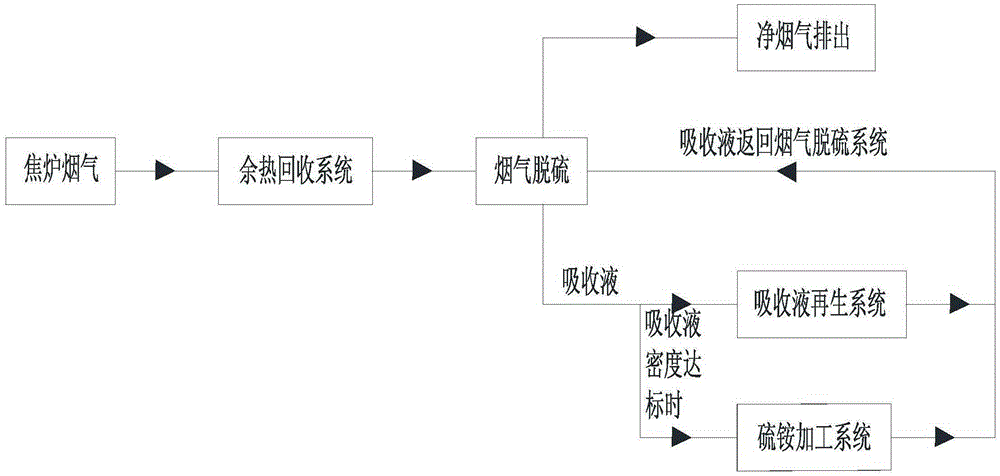

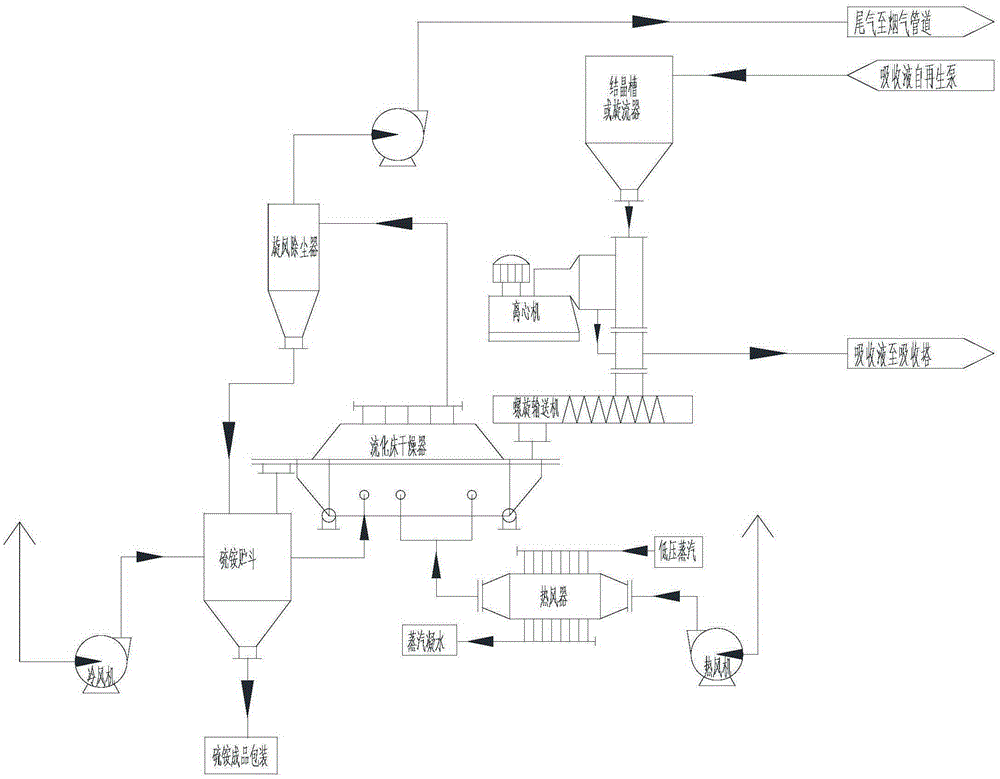

Coke oven flue-gas treatment system and treatment method thereof

ActiveCN105233660ARealize resource operationLess investmentDispersed particle separationProcess systemsFlue gas

Provided are a coke oven flue-gas treatment system and a treatment method thereof. The coke oven flue-gas treatment system and the treatment method thereof, which can reduce effect and improve effects to the largest extent, are provided. The system comprises a coke oven flue-gas inlet, an absorption tower and a clean flue-gas discharging port. The coke oven flue-gas inlet is arranged in the middle of the absorption tower, and the clean flue-gas discharging port is arranged at the top of the absorption tower. An absorption spraying section positioned on the upper portion of the coke oven flue-gas inlet, a washing demisting section positioned on the upper portion of the absorption spraying section and located on the lower portion of the clean flue-gas discharging port and a grout tank positioned on the lower portion of the coke oven flue-gas inlet to accommodate absorption liquid are further arranged in the absorption tower. An absorption spraying loop, a ferrous solution supplementing loop and an ammonia water supplementing loop are arranged in the grout tank. The coke oven flue-gas treatment system is small in investment and low in energy consumption and running cost, a process system is mature and reliable, the desulfurization efficiency is as high as over 95%, and the environmental protection requirements are met.

Owner:JIANYE QINGSONG GROUP

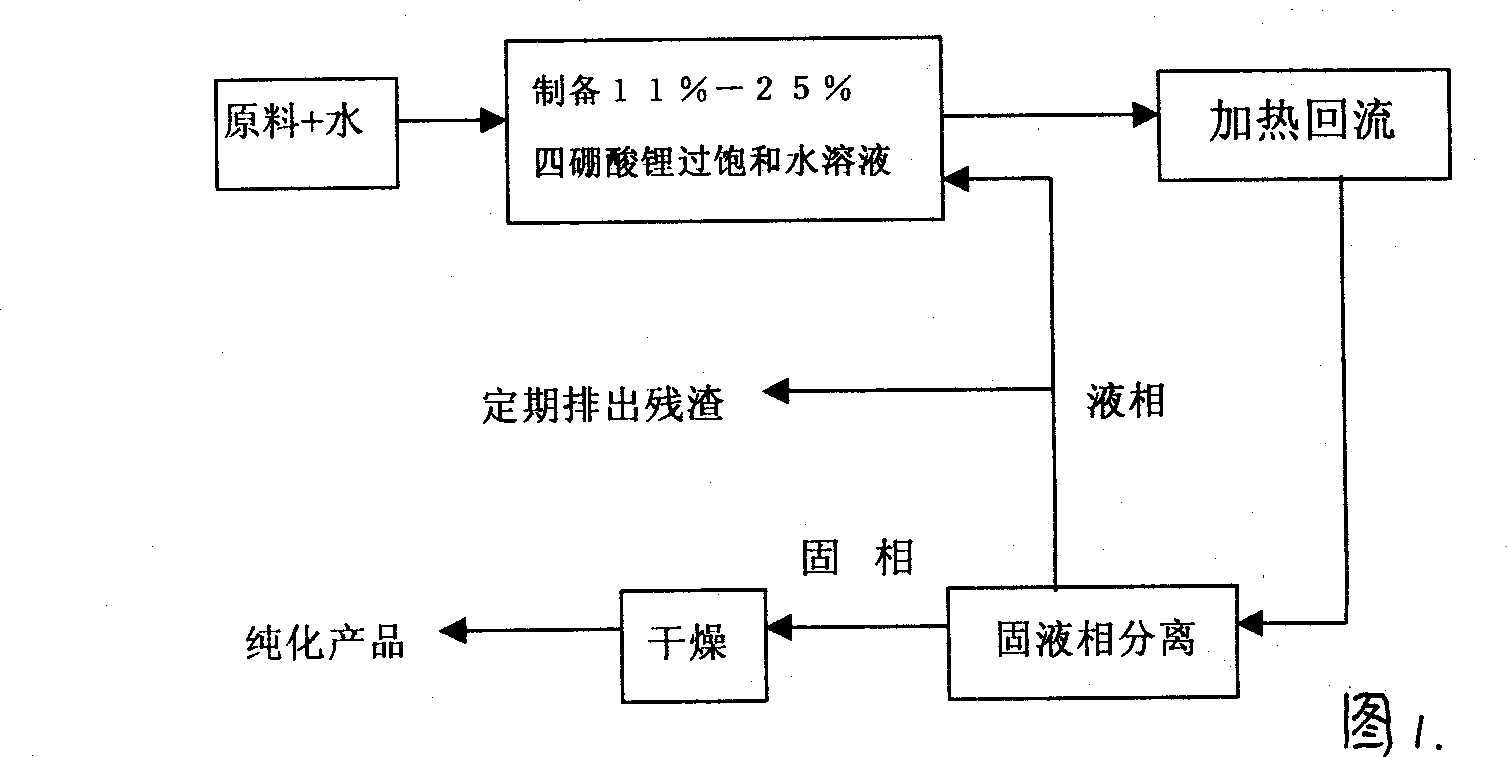

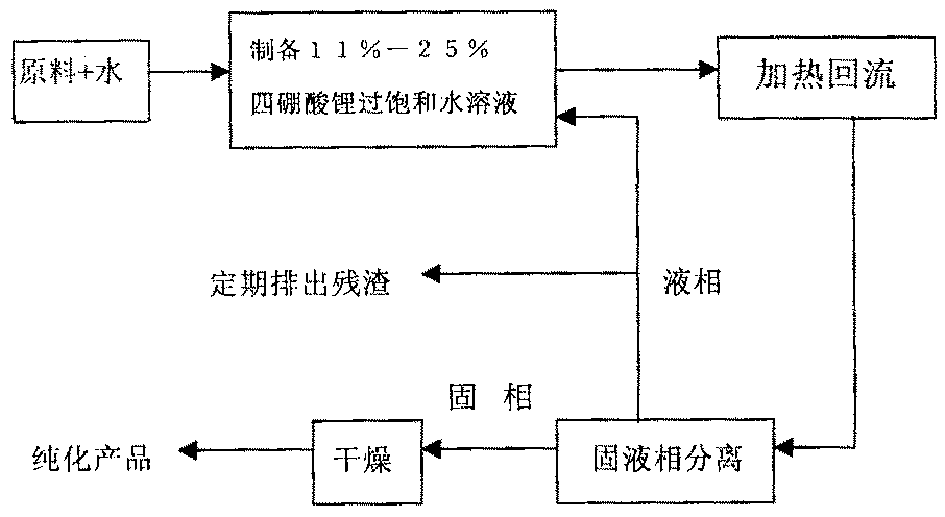

Process for purifying lithium tetraborate

InactiveCN1363516AAchieve purificationSolve the difficult problem of crystallizationBoratesSaturated aqueous solutionSolid phases

A process for purifying lithium tetraborate including preparing 11-25 mass% over-saturated aqueous solution of lithium tetraborate, thermal reflux for 2-5 hr while stirring, solid-liquid separation and drying solid-phase substance. Its advantages include simple process and no environmental pollution.

Owner:QINGHAI INST OF SALT LAKES OF CHINESE ACAD OF SCI

Light truck painting process adopting water-based BIB2 matched with solvent type 1K varnish

InactiveCN108246590AMeet the requirements of collinear production of spraying processMeet the requirements of collinear productionLiquid surface applicatorsCoatingsWork periodWater based

The invention provides a light truck painting process adopting water-based BIB2 matched with solvent type 1K varnish and belongs to the technical field of vehicle paint spraying. The process is characterized by including the steps of wiping clean, blowing with deionized wind, painting B1 outer surface, painting B2 inner surface, painting B2 outer surface, performing hot flash off, conducting forced cooling, painting IK varnish, levelling and drying; the B2 inner plate painting process also serves as the normal-temperature levelling process of B1 outer plate paint film, the levelling time is 600-720s; the hot flash off process is divided into the dewatering part and the high-temperature flash off part, the dewatering temperature is 40-45 DEG C, the dewatering time is 210-240 s, the high-temperature flash off temperature is 80-90 DEG C, and the high-temperature flash off time is 210-240 s; after the hot flash off process is finished, 1K varnish painting is conducted. The process requiresless investment, the work period is short, the place for automobile improvement covers a small area, the production rhythm is fast, and the energy consumption is small.

Owner:SHANDONG TANGJUN OULING AUTOMOBILE MFG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com