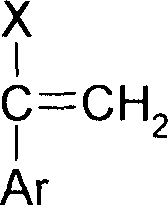

Continuous bulk polymerization process for preparing extruded acrylonitrile-butadiene-styrene graft copolymer

An extrusion-grade, styrene technology, applied in the field of polymer preparation, can solve the problems of long process, difficult to meet food-grade requirements, complex and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

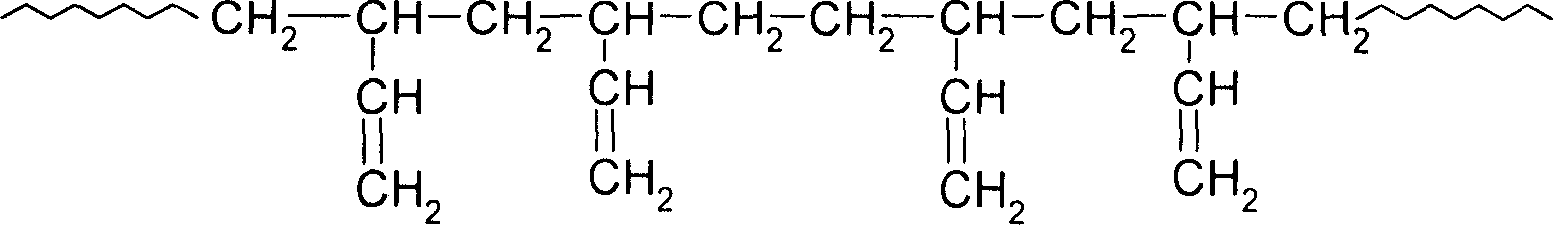

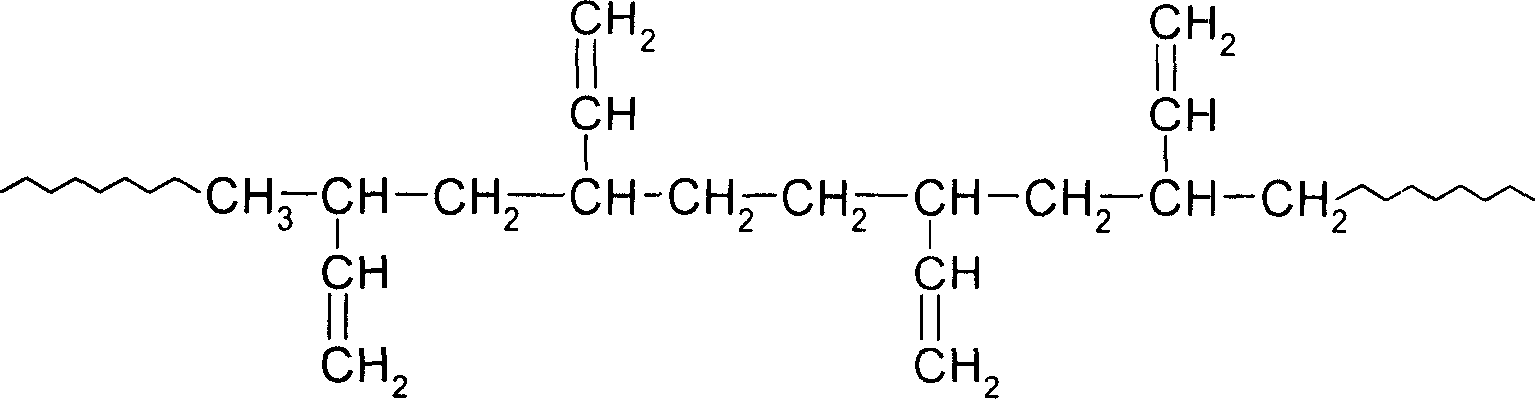

Method used

Image

Examples

Embodiment 1

[0106] The reaction system of this embodiment uses four reactors in series. In this embodiment, all materials are added to the first reactor. First add 20kg ethylbenzene and 48.95kg styrene into the rubber dissolving tank, start stirring, and then cut 10kg into 10×10mm Asahi Asaprene TM 730AX rubber is added to the rubber dissolving tank through the glue port, and stirred and dissolved at room temperature for 10 hours to obtain a rubber solution mixture. Then add 19.04kg acrylonitrile, then add 1.37kg white oil, 0.0294kg antioxidant 3,5-tert-butyl-4-hydroxy-phenyl-octadecyl ester, 0.029kg chain transfer agent dimer a-methyl Styrene, 0.0147kg initiator tert-butyl perbenzoate, and then continue to stir and disperse for 30 minutes.

[0107] The feed rate of the reactor is 1540mL / h; the pressure of the entire system is controlled at 0.9±0.2MPa; the reaction temperature of the 4 reactors is controlled to 100℃; 106℃; 125℃; 145℃; the stirring speed of the reactor is successively 100, 100...

Embodiment 2

[0113] The reaction system of this embodiment still uses four reactors in series. In this embodiment, all materials are added to the first reactor. Add 20kg of ethylbenzene and 48.95kg of styrene into the rubber dissolving tank, and start stirring to cut into 10*10mm Asahi Asaprene TM 10kg of 730AX rubber is added to the rubber dissolving tank through the glue port, and stirred and dissolved at room temperature for 9 hours. Then add 19.04kg of acrylonitrile, 1.37kg of white oil, 0.0294kg of antioxidant 3,5-tert-butyl-4-hydroxy-phenyl-octadecyl ester, and 0.0392kg of chain transfer agent dimer a-methylbenzene Ethylene, 0.0147kg initiator tert-butyl perbenzoate, continue to stir and disperse for 30 minutes.

[0114] The feed volume of the reactor is 1540mL / h; the system pressure is controlled at 0.9±0.2MPa; the reaction temperature of the four reactors is 101℃; 110℃; 130℃; 150℃; the stirring speed of the reactor is 100, 180, 30, 15rpm; the reactor volume used is 3.9L.

[0115] At th...

Embodiment 3

[0119] The reaction system of this embodiment uses five reactors in series. In this embodiment, part of the material is added to the first reactor, and part of the material is grafted to a certain degree through the fifth reactor (also called "grafting reactor") and reversed, and then added to the subsequent third reactor. The way. Add 19.8kg ethylbenzene and 48.5kg styrene into the rubber dissolving tank, start stirring and cut into 10 * 9kg of 10mm Asahi AsapreneTM 730AX rubber and 1kg of CB565 rubber are added to the rubber dissolving tank through the glue port, and stirred and dissolved at room temperature for 11 hours. Then add 18.5kg of acrylonitrile, 1.37kg of white oil, 0.0294kg of antioxidant 3,5-tert-butyl-4-hydroxy-phenyl-octadecyl ester, and 0.0368kg of chain transfer agent dimer a-methylstyrene , 0.0147kg initiator tert-butyl perbenzoate, continue to stir and disperse for 30 minutes.

[0120] The main feed rate of the reactor is 1540mL / h; the system pressure is contro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com