Method for treating wastewater containing high-concentration fuel ethanol by utilizing wheat and other gains as main raw materials

A technology of high-concentration wastewater and main raw materials, applied in waste fuel, adsorbed water/sewage treatment, biological organic part treatment, etc. Removal effect, improve precipitation efficiency, reduce COD load effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

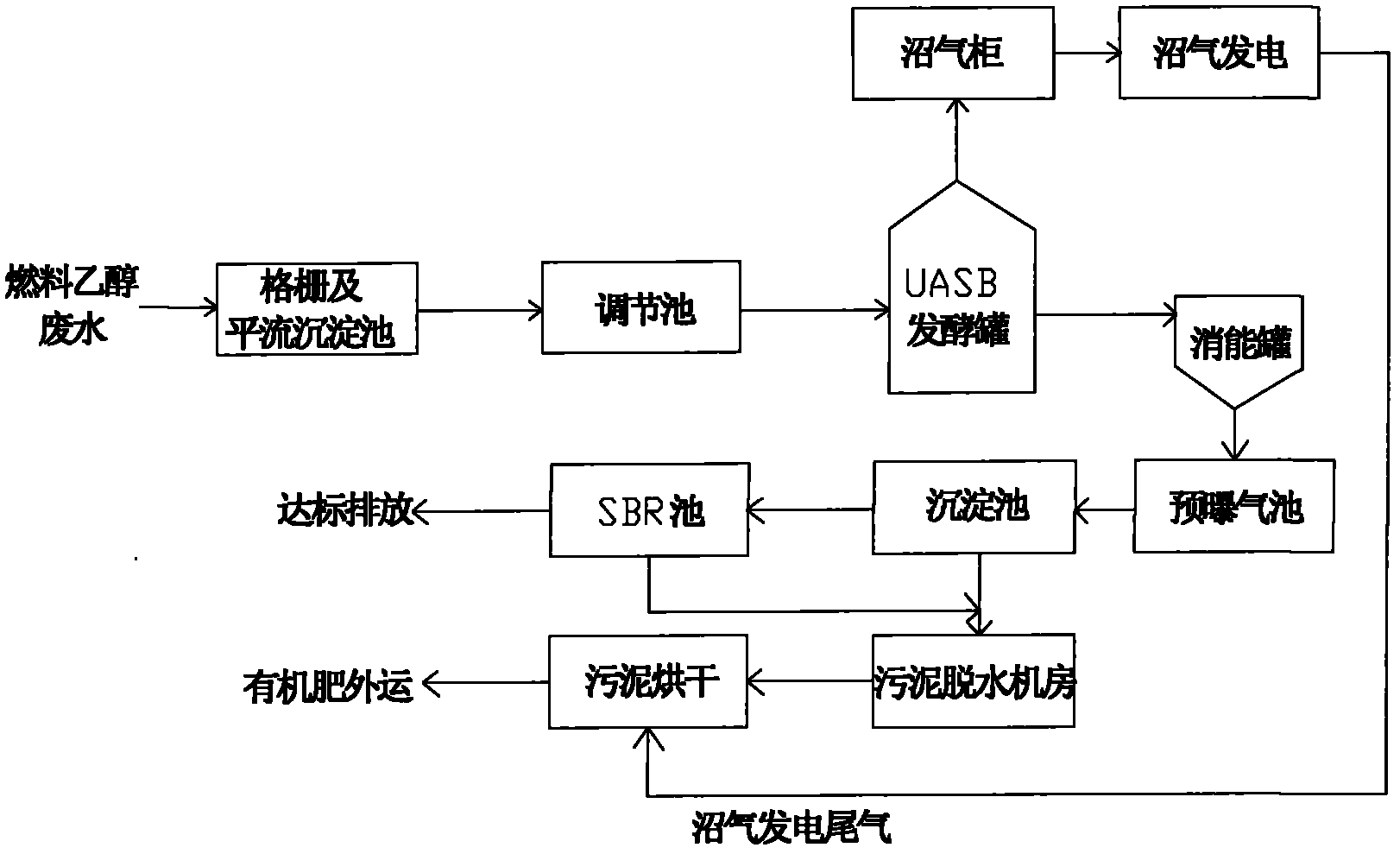

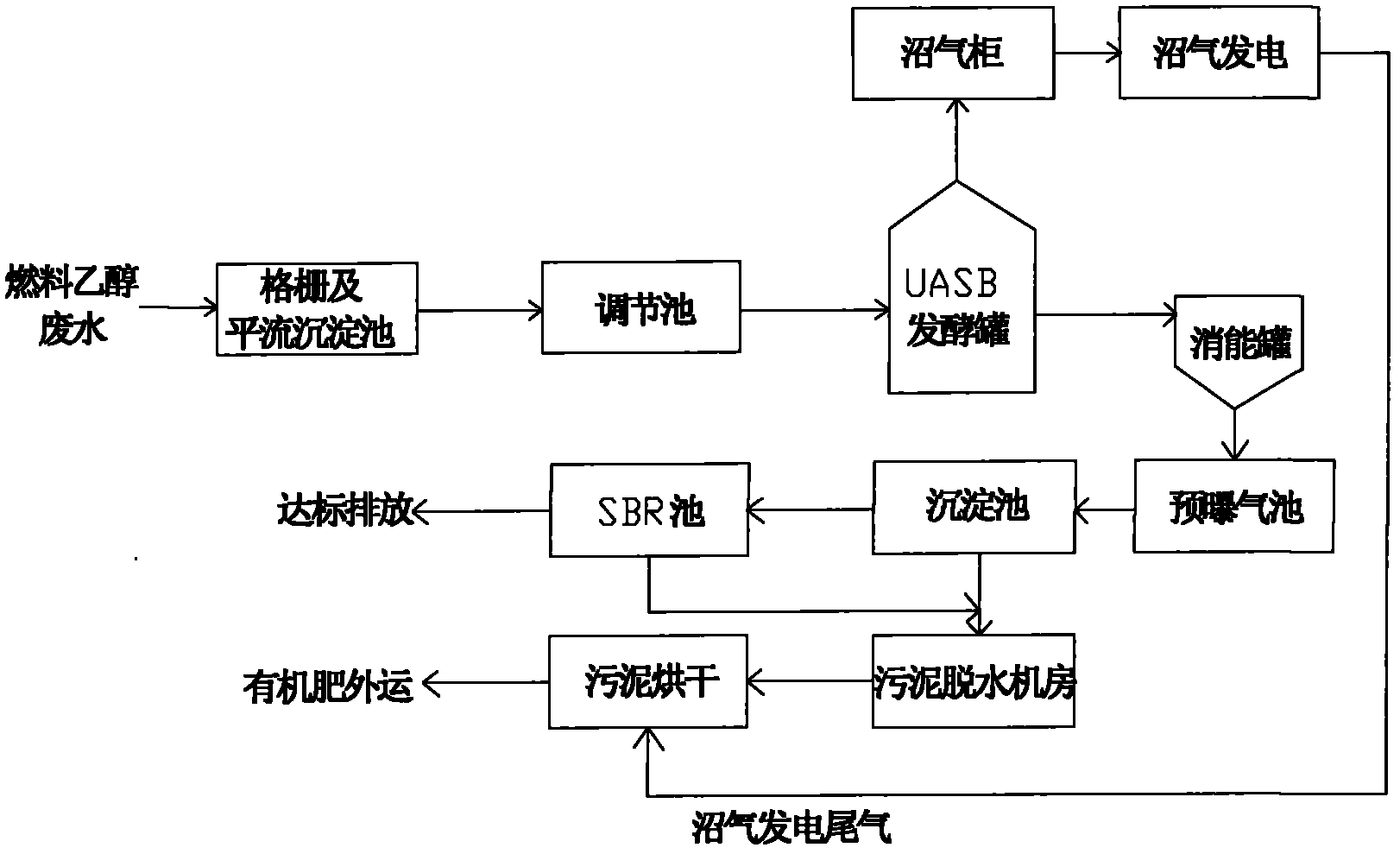

[0015] Such as figure 1 Shown is the fuel ethanol high-concentration waste water treatment method that is main raw material with grains such as wheat, is characterized in that is to realize by following process steps:

[0016] 1. The high-concentration fuel ethanol wastewater with wheat and other grains as the main raw material is pretreated by the grid and the flow sedimentation tank, and then enters the adjustment tank to adjust the pH of the influent to meet the water inflow and ecological environment requirements of the USAB reaction tank;

[0017] 2. Then use the medium-temperature fermentation UASB reaction tank for anaerobic fermentation to generate biogas, the pH is 6-8.5, the anaerobic influent COD is controlled at 4500-5500mg / L, the fermentation temperature is 37°C-42°C, and the volume load is controlled at 5-7KgCOD / m 3 , The biogas enters the biogas cabinet for biogas power generation, and the high-temperature tail gas generated by biogas power generation is used ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com