Efficient sewage sedimentation tank

A sedimentation tank and sewage technology, which is applied in sedimentation separation, sedimentation tanks, chemical instruments and methods, etc., can solve the problems of prolonged sedimentation time and low efficiency, and achieve the effect of improving sedimentation efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

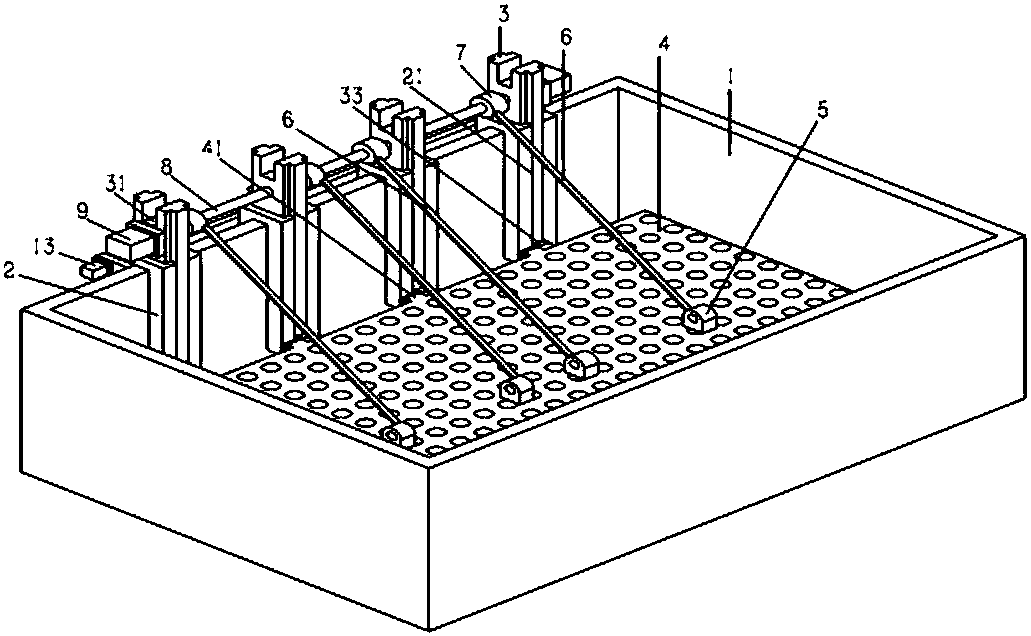

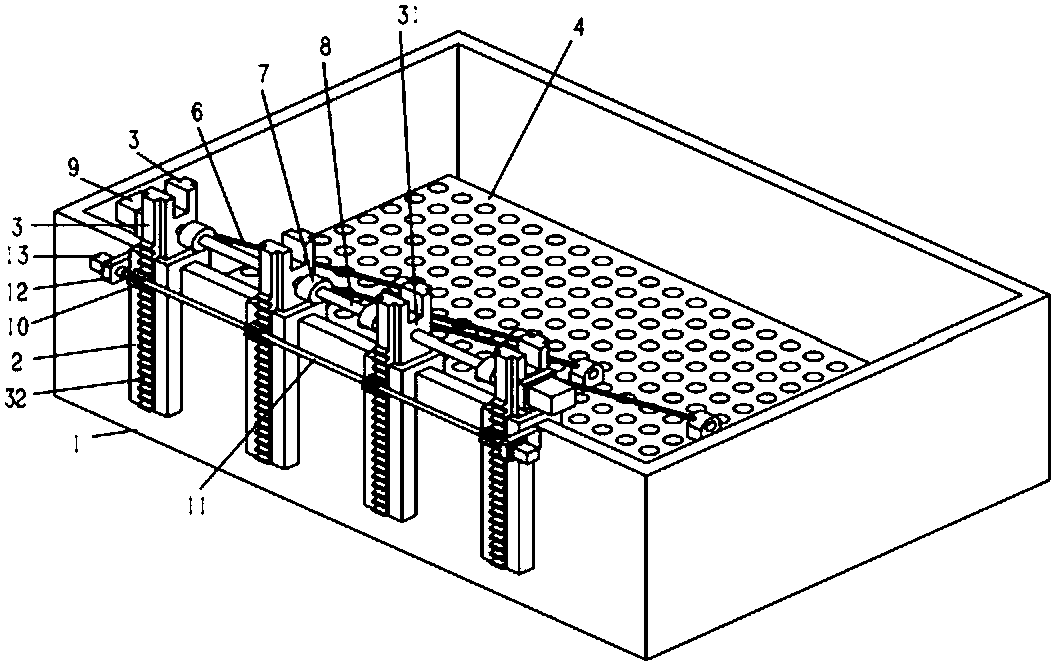

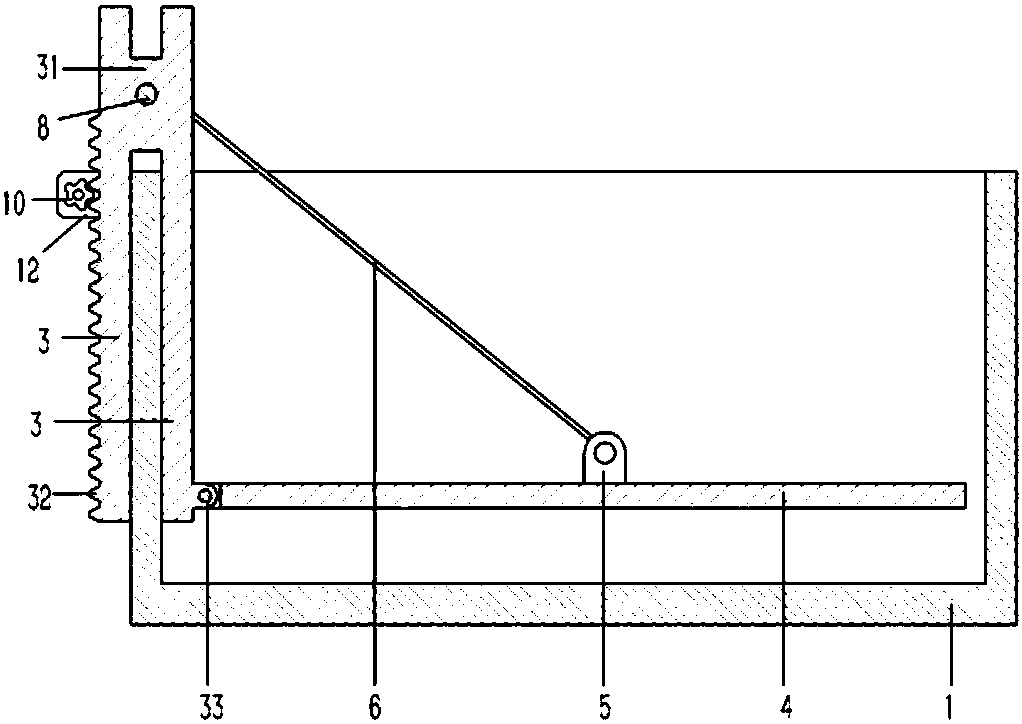

[0018] Example: see Figures 1 to 3 As shown, a high-efficiency sewage sedimentation tank includes a sedimentation tank 1, a "冂"-shaped fixing seat 2 is fixed on the side wall of the sedimentation tank 1, and T-shaped Guide rail groove 21, a vertical T-shaped guide rail 3 is inserted into the guide rail groove 21 of the fixed seat 2, and a connecting block 31 is formed between the two T-shaped guide rails 3 on the same fixed seat 2, and the connecting blocks 31 are distributed On the upper side of the fixed seat 2; the bottom end of the T-shaped guide rail 3 inside the sedimentation tank 1 is formed with lugs 33, and a horizontal orifice plate 4 is inserted in the sedimentation tank 1, and a number of hinged seats 41 are formed on one side of the orifice plate 4 , the hinge seat 41 on the orifice plate 4 is hinged with the lug 33 of the T-shaped guide rail 3 through the hinge shaft, and several bearings 5 are fixed on the orifice plate 4, and the connecting block 31 of the T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com