Method for absorbing vacuum tailed gas in production of polystyrene

A polystyrene and vacuum technology, applied in separation methods, chemical instruments and methods, dispersed particle separation, etc., can solve problems such as failure to meet discharge requirements, few mixtures, and inability to separate mixtures, improve absorption rate, and reduce investment. , the effect of high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

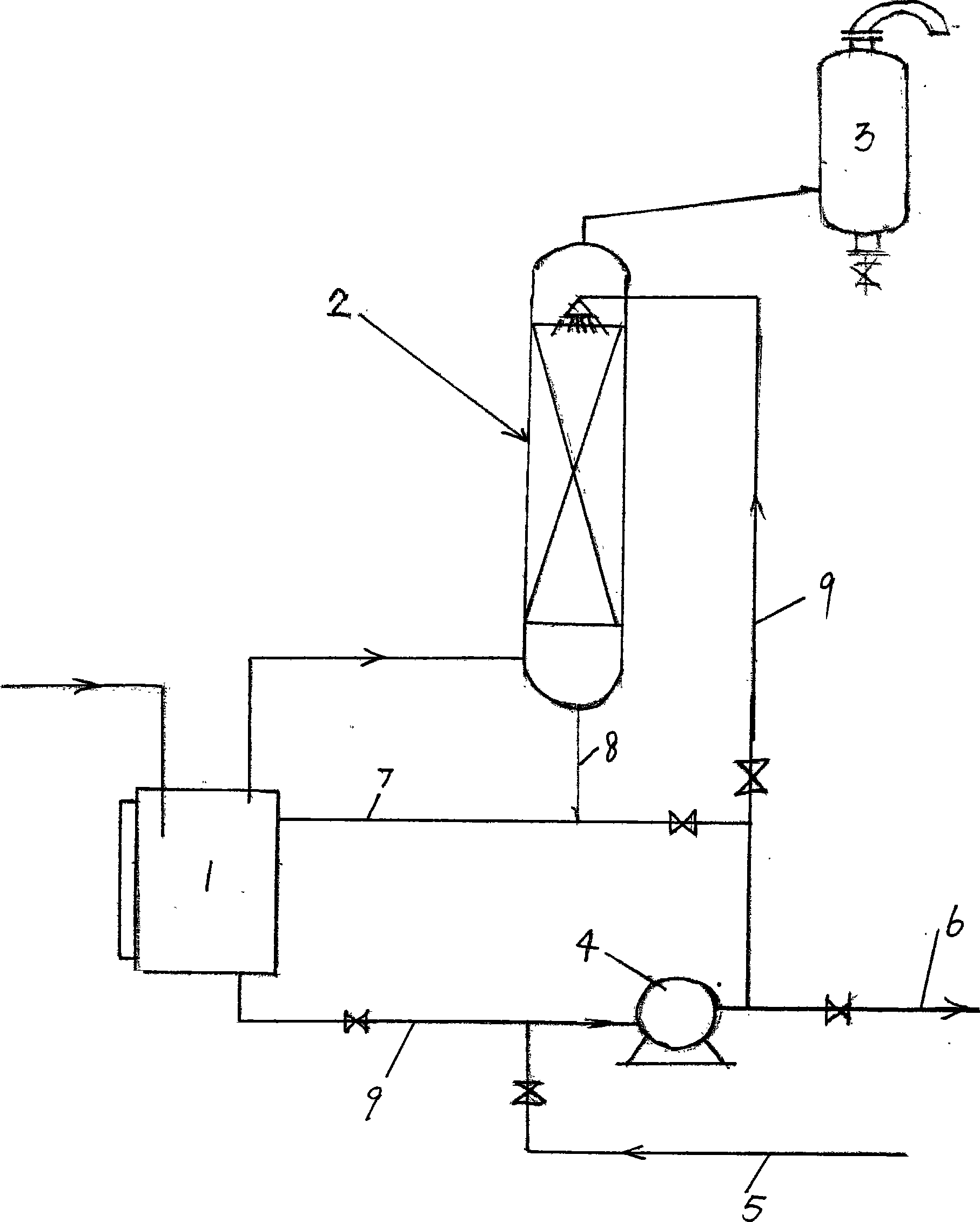

[0010] The absorption method of vacuum tail gas in the production of polystyrene, the vacuum tail gas is passed into the white oil tank 1, the overflow gas of the white oil tank 1 enters the lower part of the absorption tower 2 and contacts the white oil sprayed down in the countercurrent, and the absorption tower 2 is equipped with a ceramic ring packing, The gas from the top of the absorption tower 2 is adsorbed by activated carbon 3 and then emptied; a connecting pipe 9 is arranged between the white oil tank 1 and the upper sprinkler head of the absorption tower 2, a circulating pump 4 is installed on the connecting pipe 9, and a white oil feeding pipe 5 Connected to the pipeline between the white oil tank 1 and the circulating pump 4; the outlet of the circulating pump 4 is provided with another discharge pipe 6 to be connected with the polystyrene production process; the upper part of the white oil tank 1 is provided with an overflow pipeline 7, which is connected with the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com