Light truck painting process adopting water-based BIB2 matched with solvent type 1K varnish

A solvent-based, process-based technology, applied in the field of car paint spraying, can solve the problems of large equipment investment and energy consumption, production line cannot be produced, high consumption of materials and auxiliary materials, etc., and achieve the effect of small footprint, reduced paint consumption, and compact process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

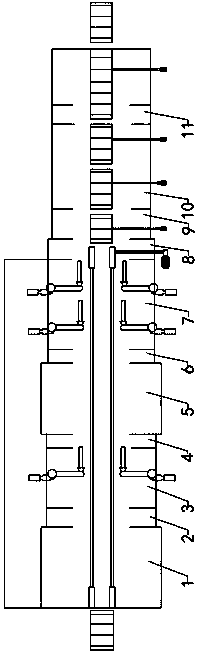

Image

Examples

Embodiment 1

[0035] The technological process of paint spraying for light trucks is wiping, deionized wind blowing, B1 outer surface spraying, B2 inner surface spraying, B2 outer surface spraying, hot flash drying, forced cooling, 1K varnish spraying, leveling, and baking Dry;

[0036] After the outer surface of B1 is sprayed, the inner surface of B2 is sprayed. The process of spraying the inner surface of B2 is also the normal temperature leveling process of the paint film on the outer surface of B1. The leveling time is 660s; after the inner surface of B2 is sprayed, then the outer surface of B2 is sprayed. ;The hot flash drying process is divided into two parts: dehydration and high temperature flash drying. The dehydration temperature is 42.5°C, the dehydration time is 225s, the high temperature flash drying temperature is 85°C, and the high temperature flash drying time is 225s; after the hot flash drying is completed, 1K varnish is applied Spraying, leveling at room temperature for 4...

Embodiment 2

[0038] The technological process of paint spraying for light trucks is wiping, deionized wind blowing, B1 outer surface spraying, B2 inner surface spraying, B2 outer surface spraying, hot flash drying, forced cooling, 1K varnish spraying, leveling, and baking Dry;

[0039] After the outer surface of B1 is sprayed, the inner surface of B2 is sprayed. The process of spraying the inner surface of B2 is also the normal temperature leveling process of the paint film on the outer surface of B1. The leveling time is 680s; after the inner surface of B2 is sprayed, then the outer surface of B2 is sprayed. ;The hot flash drying process is divided into two parts: dehydration and high temperature flash drying. The dehydration temperature is 42°C, the dehydration time is 230s, the high temperature flash drying temperature is 84°C, and the high temperature flash drying time is 230s; after the hot flash drying is completed, 1K varnish is applied Spraying, leveling at room temperature for 440...

Embodiment 3

[0041] The technological process of paint spraying for light trucks is wiping, deionized wind blowing, B1 outer surface spraying, B2 inner surface spraying, B2 outer surface spraying, hot flash drying, forced cooling, 1K varnish spraying, leveling, and baking Dry;

[0042] After the outer surface of B1 is sprayed, the inner surface of B2 is sprayed. The process of spraying the inner surface of B2 is also the normal temperature leveling process of the paint film on the outer surface of B1. The leveling time is 640s; after the inner surface of B2 is sprayed, then the outer surface of B2 is sprayed. ;The hot flash drying process is divided into two parts: dehydration and high temperature flash drying. The dehydration temperature is 43°C, the dehydration time is 220s, the high temperature flash drying temperature is 86°C, and the high temperature flash drying time is 240s; after the hot flash drying is completed, 1K varnish is applied Spraying, leveling at room temperature for 460...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com