Process for purifying lithium tetraborate

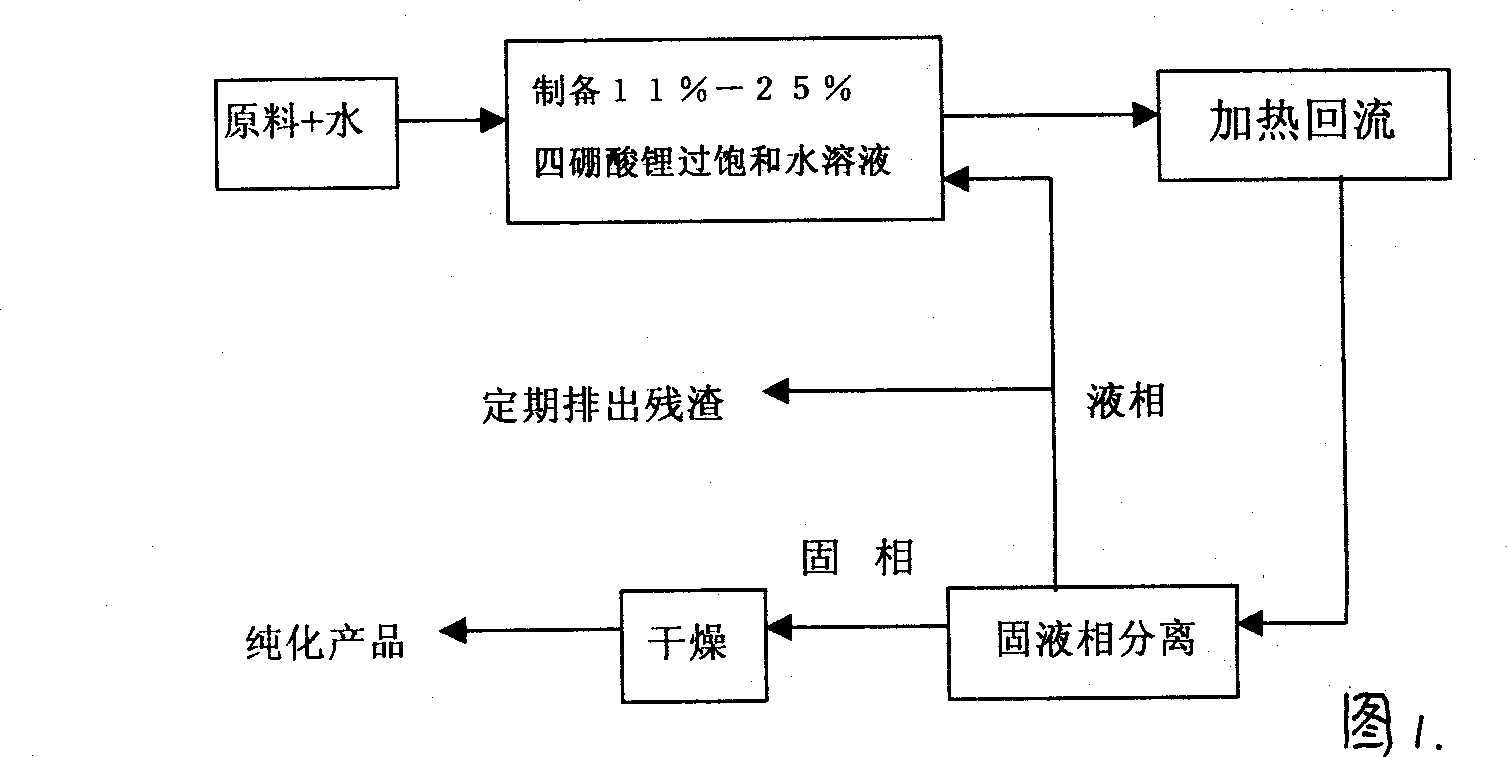

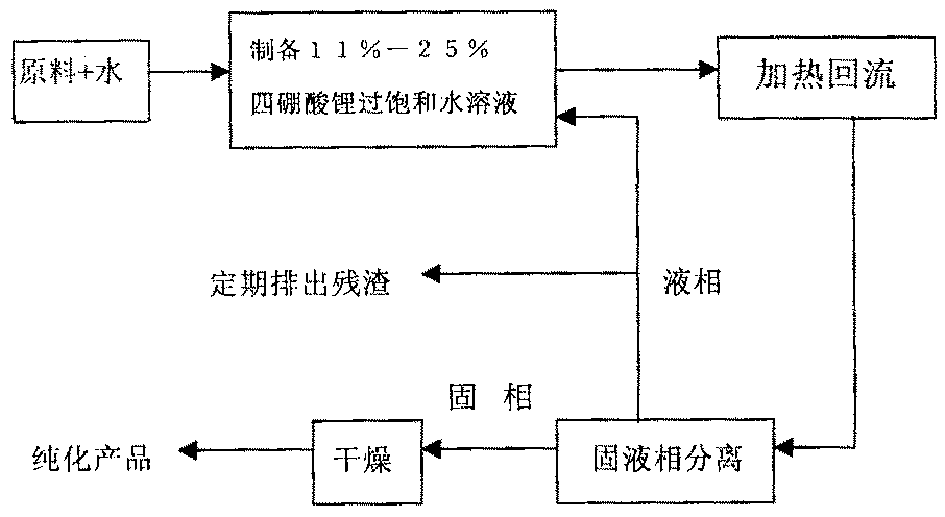

A purification method, lithium tetraborate technology, which is applied in the direction of borates, boron oxide compounds, etc., can solve the problem that lithium tetraborate aqueous solution is supersaturated and difficult to purify, and achieves the effects of easy operation, simple purification process and low process investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Embodiment 1, use commercially available lithium tetraborate (purity is 98.5%) with deionized water (conductivity is less than 1 * 10 -4 s.m. -1 ) is heated and dissolved, and prepared into a supersaturated aqueous solution with a mass concentration of 11% as a purified raw material liquid; the raw material liquid is placed in a heating reflux device, and heated to reflux under stirring conditions;

[0020]1.1 After heating and refluxing for 3 hours, separate the solid and liquid by filtration, and dry the solid phase naturally to obtain purified lithium tetraborate trihydrate. The detection and analysis results are: the recovery rate of lithium tetraborate is 45%, and the purity is 99.16%.

[0021] 1.2 After heating and refluxing for 5 hours, separate the solid and liquid by filtration, and dry the solid phase at 80°C to obtain purified lithium tetraborate trihydrate. The detection and analysis results are: the recovery rate of lithium tetraborate is 50%, and the purit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com