High-efficiency biological strengthened treatment process for waste water generated in paper making

A bioaugmentation and papermaking wastewater technology, which is applied in processing wastewater treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve the problems of complex composition, large amount of wastewater, poor biodegradability, etc. To achieve the effect of reducing the sludge bulking rate, reducing the operating cost, and improving the quality of the effluent water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

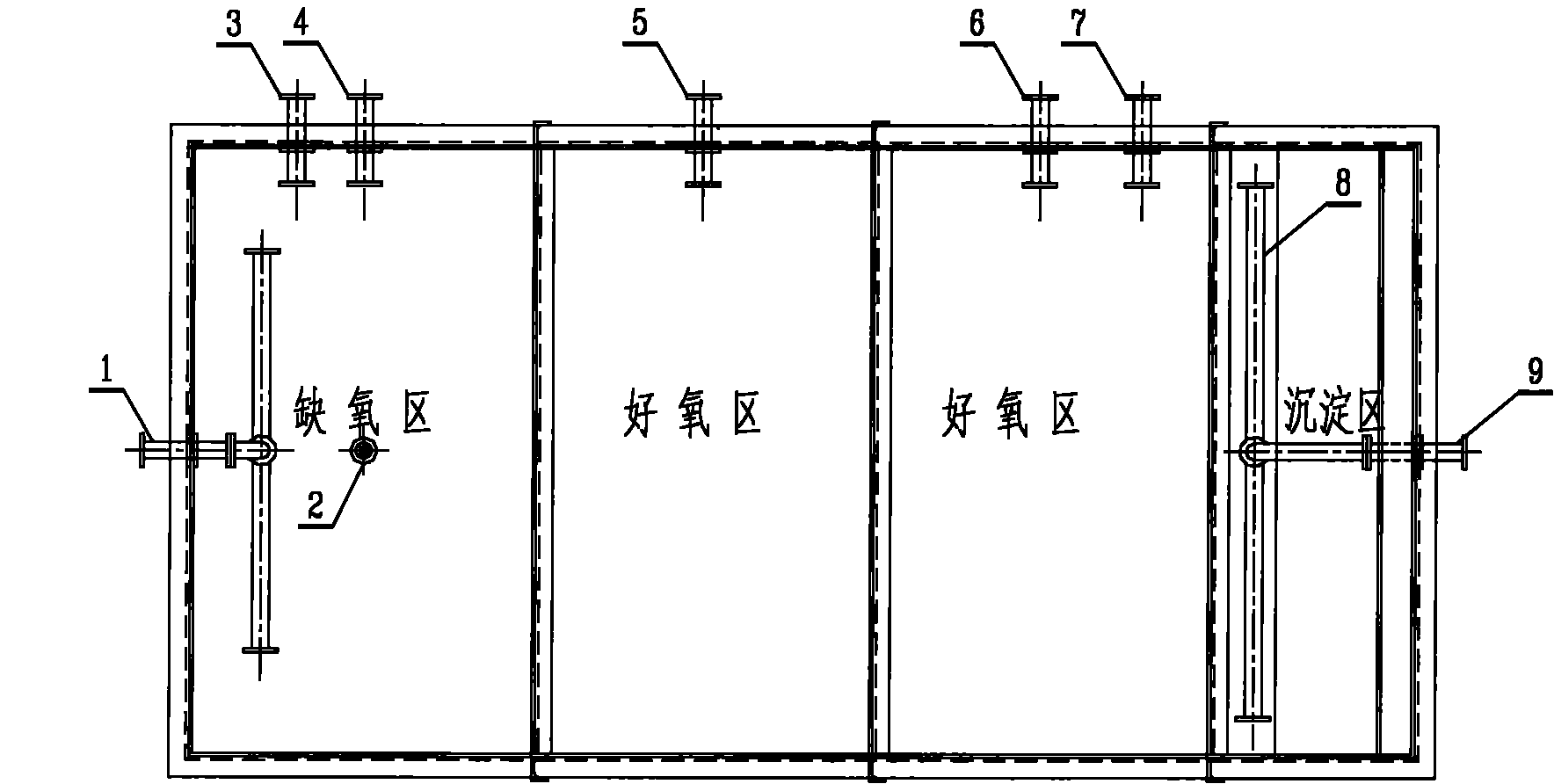

Method used

Image

Examples

Embodiment 1

[0027] The sewage of a papermaking enterprise enters the high-efficiency bioaugmentation tank after anaerobic treatment. COD is 464.4mg / L, NH3-N is 15.34 mg / L, TN is 22.33mg / L, TP is 2.1mg / L, and the chromaticity is 260 times. The high-efficiency bio-augmentation pool adopts 100% external return and 30% internal return. The dosage of powdered activated carbon is 50mg / L. The residence time is 20h. The aeration air supply is provided according to the air-to-water ratio of 20:1. The effluent quality COD is 104.3mg / L, NH3-N is 1.34mg / L, TN is 9.6mg / L, TP is 0.8mg / L, and the chromaticity is 80 times.

Embodiment 2

[0029] Other operations are as in Example 1. But do not add powdered activated carbon. The effluent quality COD is 148.3mg / L, NH3-N is 3.34mg / L, TN is 12.6mg / L, TP is 1.2mg / L, and the chromaticity is 120 times.

Embodiment 3

[0031] Other operations are as in Example 1. The effluent quality COD is 154.4mg / L, NH3-N is 3.34mg / L, TN is 32.4mg / L, TP is 0.9mg / L, and the chromaticity is 80 times.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com