Chlorosilane-containing slurry treatment method and chlorosilane-containing slurry treatment system

A treatment method and technology of a treatment system are applied in the field of chlorosilane-containing slag slurry treatment method and treatment system, which can solve the problems of high price and later maintenance costs, blockage of conveying equipment and pipelines, and short continuous operation period of the system, and achieve The effect of short investment recovery period, low operation and maintenance cost, and long continuous operation period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0108] A method for treating chlorosilane-containing slag slurry, comprising the following steps:

[0109] Set up a vertical 20m next to the washing tower 3 The slag slurry collection tank, the chlorosilane-containing slag slurry discharged from the cold hydrogenation system enters the slag slurry collection tank, and the top of the tank is vented to the cold hydrogenation process vent system. The slag slurry of the two production lines (two sets of cold hydrogenation units) is discharged into the collection tank for static separation. Stop discharging after discharging to 80% of the collection tank volume, about 23 tons. After standing still for about 4 hours, the incompatibility and density difference of the components in the slag slurry are used to make the slag slurry form a supernatant liquid and a bottom turbid liquid in the collection tank.

[0110] The supernatant is discharged from multiple chlorosilane outlets of different heights set on the slag slurry collection ...

Embodiment 2

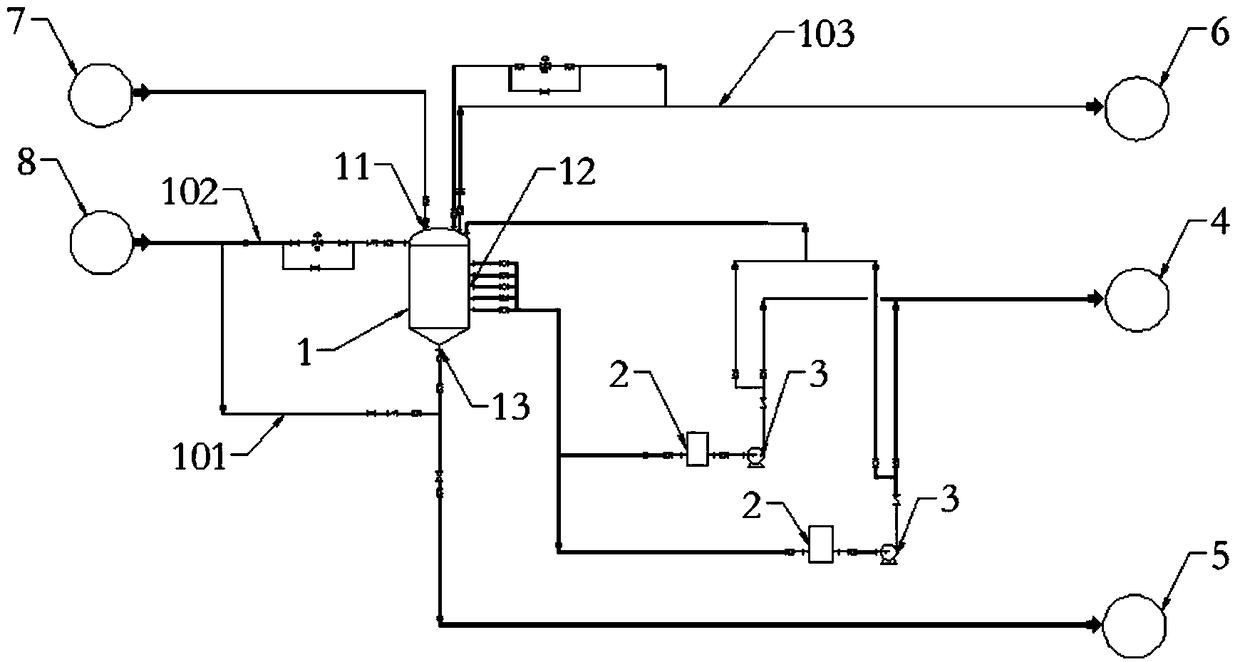

[0114] Such as figure 1 As shown, a chlorosilane-containing slag slurry treatment system includes a slag slurry collection tank 1, a filter 2, a delivery pump 3, a chlorosilane recovery device 4 and a washing device 5;

[0115] The slag slurry collection tank 1 is provided with a slag slurry inlet 11, a plurality of chlorosilane outlets 12 of different heights and a bottom outlet 13;

[0116] The chlorosilane discharge port 12 is connected to the chlorosilane recovery device 4 through the filter 2 and the delivery pump 3 in sequence;

[0117] The outlet 13 at the bottom of the slurry collection tank is connected to the washing device 5 .

[0118] Wherein, the slag slurry feed port 11 is connected with the slag slurry discharge port 7 of the cold hydrogenation system through a pipeline.

[0119] The arrangement of multiple chlorosilane outlets 12 of different heights includes:

[0120] The first outlet is set at the first position, and the height between the first position a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com