Liquid-state high-lead slag side-blowing water-gas reduction process

A high-lead slag and water gas technology, applied in the field of metallurgy, can solve the problems of high viscosity of liquid high-lead slag, backward separation and extraction technology, low concentration of SO2 flue gas, etc., achieve good environmental conditions, reduce emission sources, and reduce plant occupation. land area effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below in conjunction with accompanying drawing and specific embodiment the present invention will be described in further detail:

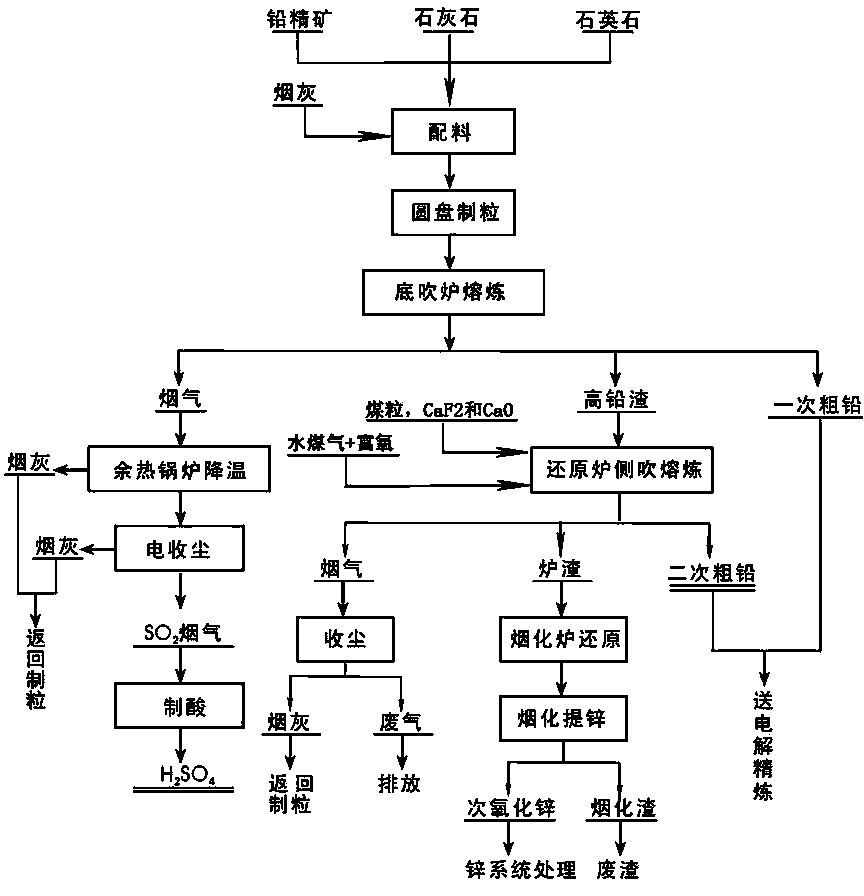

[0022] exist figure 1 Among them, a liquid high-lead slag side-blowing water gas + coal particle reduction process is to directly inject the liquid high-lead slag melt oxidized and smelted in the bottom-blown furnace into the reduction furnace, and use water gas + rich Oxygen air side blowing is directly reduced to secondary crude lead; the specific process is as follows:

[0023] ① Oxygen bottom blowing smelting

[0024] Lead concentrate, limestone and quartz stone, as well as bottom blowing furnace soot and reduction furnace soot are returned to the smelting workshop for mixing after weighing and batching to make pellets with a particle size of 5-10mm; the pellets are smelted with oxygen bottom blowing Oxidation smelting is carried out in the furnace to produce primary crude lead, molten high-lead slag and high-sulfur flue gas;

[0025...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com