Medium-heavy automobile flange die forging process and punching and calibrating composite die thereof

A heavy-duty vehicle and flange technology, applied in forming tools, perforating tools, manufacturing tools, etc., can solve the problems of poor quality of forgings, low material utilization, and many production processes, and achieve short manufacturing cycles, good product quality, and machine tools. The effect of small processing volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

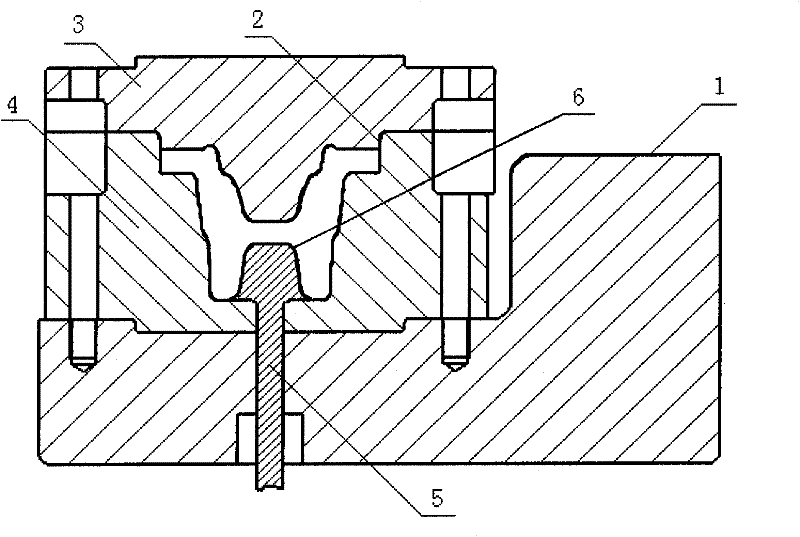

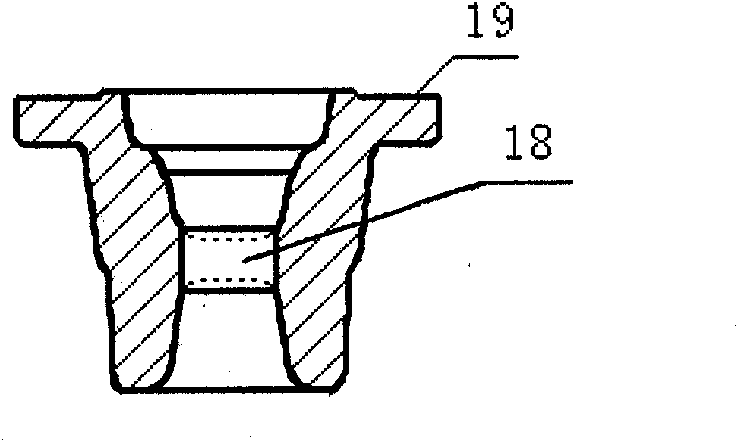

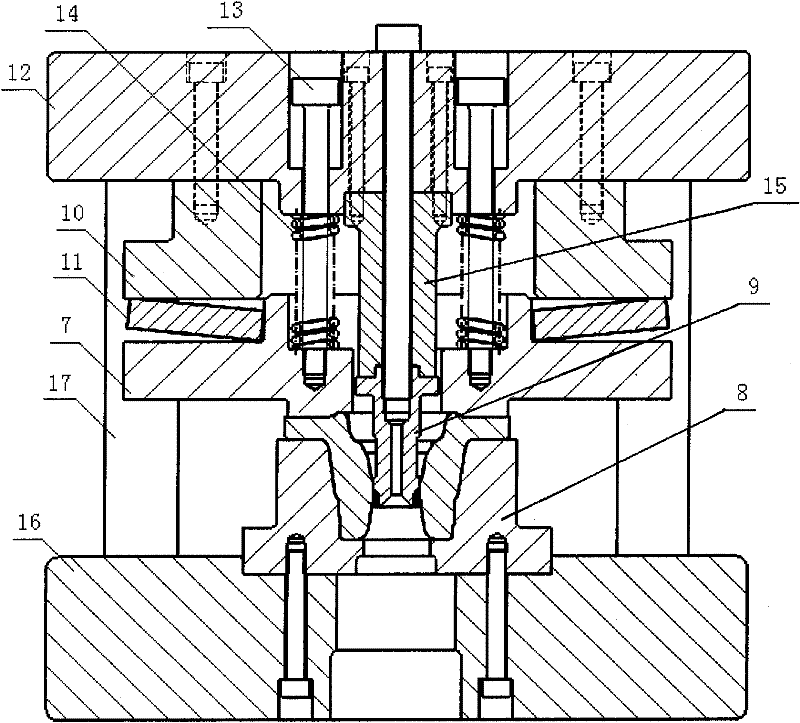

[0031] Below in conjunction with accompanying drawing, take the 106F type automobile flange of Dongfeng Motor Corporation as an example to illustrate the present invention, as figure 1 , figure 2 , image 3 , the flange die forging forging process is as follows:

[0032] 1. Cutting: Adopt GB4025C band saw machine to cut φ85 round steel with a length of 163±1mm;

[0033] Since we adopt a closed-type non-flash forging process, the process has strict requirements on the blanking quality. The blanking length of the round bar blank must be strictly controlled, and the flatness of the end surface must also be strictly controlled. In order to avoid the phenomenon that the round bar blank is placed crookedly in the forging cavity and the forging is not full and the local flash occurs.

[0034] 2. Heating: Use KGPS300-1 medium frequency induction heating furnace to heat the round bar blank to the temperature required by the forging process;

[0035]3. Closed flash-free forging wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com