Multilayer slag smelting reduction ironmaking method and apparatus thereof

A smelting furnace and slag layer technology, applied in the direction of fluidized bed furnace, etc., can solve the problems of unrealized industrialization, increased coal consumption, large investment, etc., and achieve the effects of simplifying the smelting reduction process, improving utilization efficiency, and high energy efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] Mineral powder: Iron ore powder, containing 54% iron, with a particle size of less than 100 mesh.

[0056] Flux: quicklime powder, CaO content 81%, particle size less than 100 mesh; dolomite powder, CaO content 29%, MgO content 19%, particle size less than 100 mesh.

[0057] Fuel: coal powder, fixed carbon content 79%, particle size less than 100 mesh.

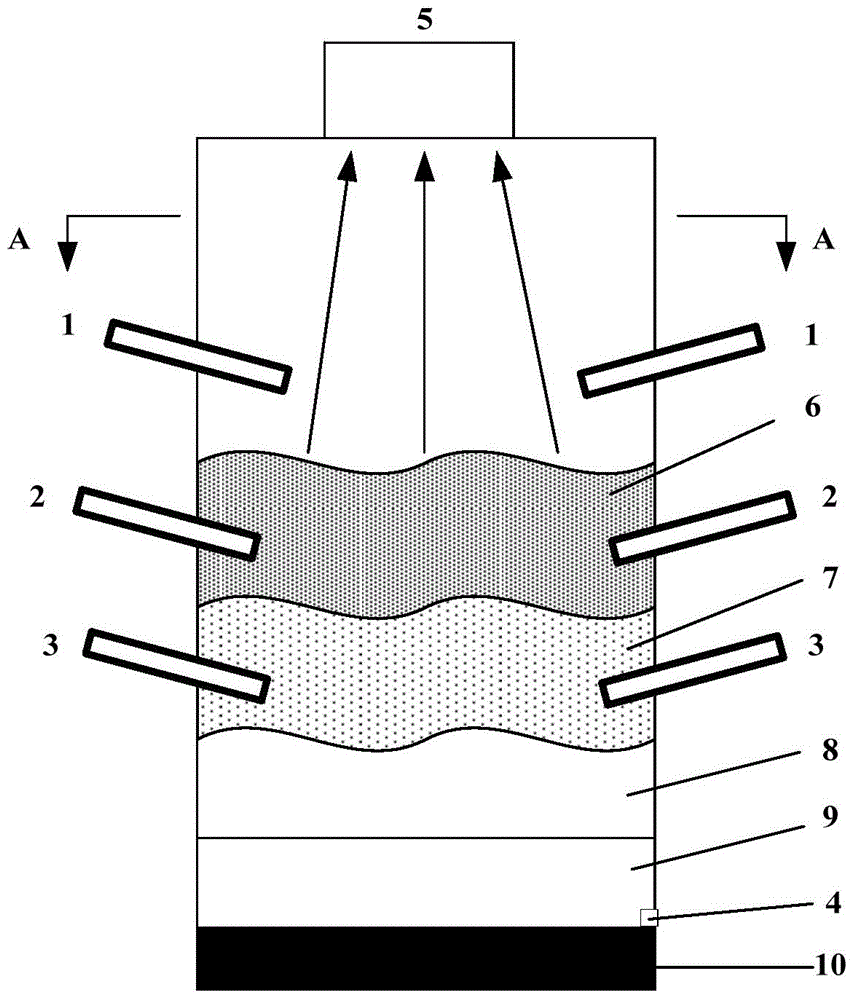

[0058] After mixing iron ore powder and flux (quicklime powder and dolomite powder) in a certain proportion, spray the mixture and oxygen-enriched air (oxygen-enriched rate 10%) at a temperature of 900°C into the molten slag layer 6 from the middle spray gun 2 In the process, the pressure of the oxygen-enriched air is 0.1Mpa, the oxygen-enriched air sprayed into the molten slag layer reacts with the CO gas entering the molten slag layer from the reducing slag layer to release heat, and melts the iron ore powder and part of the flux to form a certain smelting slag .

[0059] Spray pulverized coal and oxygen-enriched ai...

Embodiment 2

[0064] Mineral powder: copper tailings powder, containing 40% iron, particle size less than 100 mesh.

[0065] Flux: quicklime powder, CaO content 82%, particle size less than 100 mesh.

[0066] Fuel: coal powder, fixed carbon content 81%, particle size less than 100 mesh.

[0067] After mixing copper tailings powder and flux (quicklime powder) in a certain proportion, spray the mixture and pure oxygen at 25°C into the molten slag layer 6 from the middle layer spray gun 2, the pressure of pure oxygen is 0.15Mpa, spray into The pure oxygen in the molten slag layer reacts with the CO gas entering the molten slag layer from the reducing slag layer to release heat, melting the iron ore powder and part of the quicklime powder to form a certain smelting slag.

[0068] Coal powder and pure oxygen at 25°C are sprayed from the lower spray gun 3 into the reduced slag layer 7, the pure oxygen injected into the reduced slag layer reacts with the injected coal powder to produce CO, and at...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com