Novel technique for producing large-sized seamless steel pipe

A technology of seamless steel pipe and new technology, which is applied in the field of new technology for the production of large seamless steel pipes, to achieve the effect of improving the service life of the plug

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] A new process for the production of large-scale seamless steel pipes. The equipment used includes a heating furnace, a three-high cross-rolling piercing machine and a three-high cross-rolling finishing mill.

[0042] A guide and guard device is installed on the machine table of the three-roll skew piercing machine, which includes expansion and locking devices, lifting devices, bases and other components.

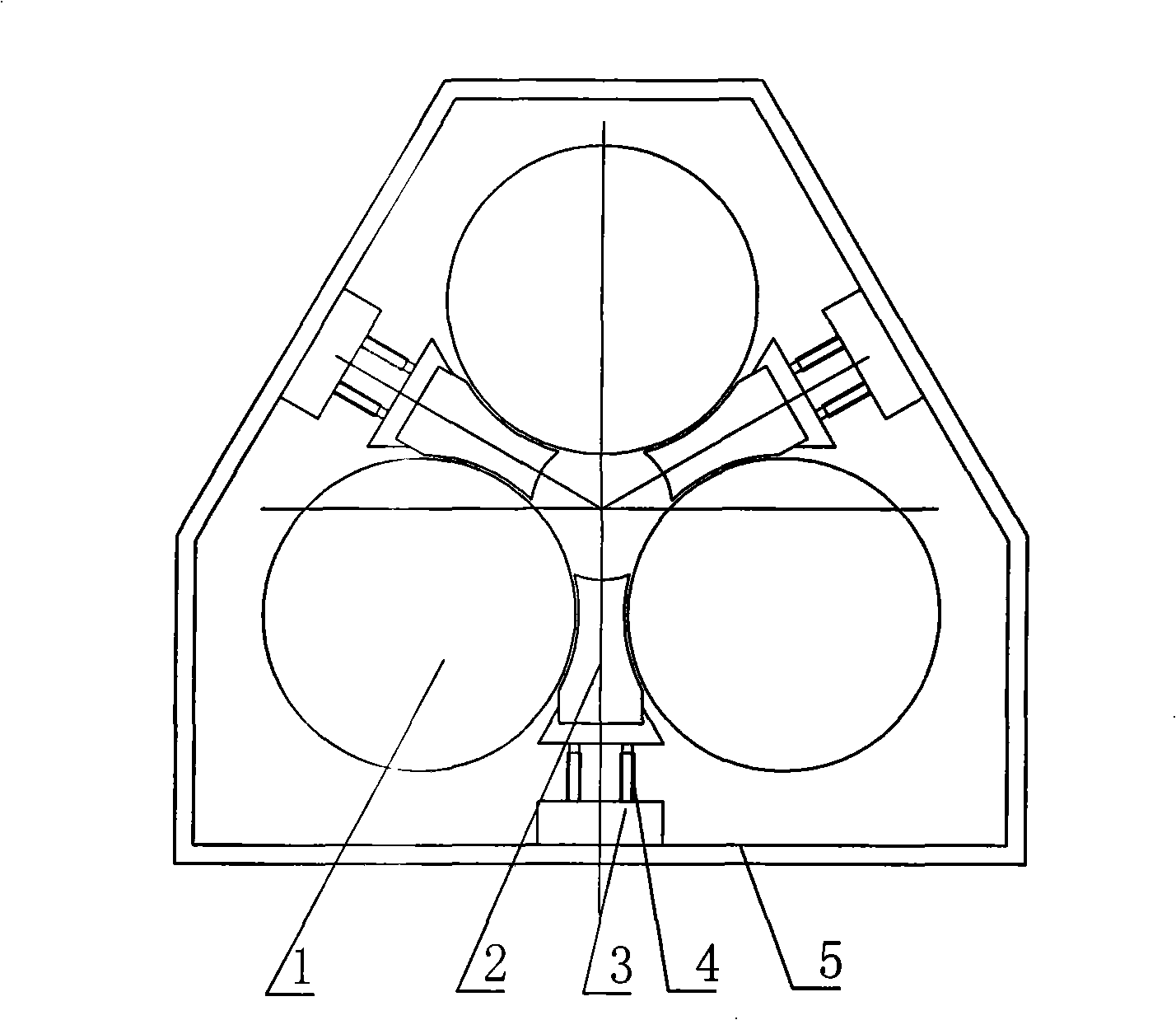

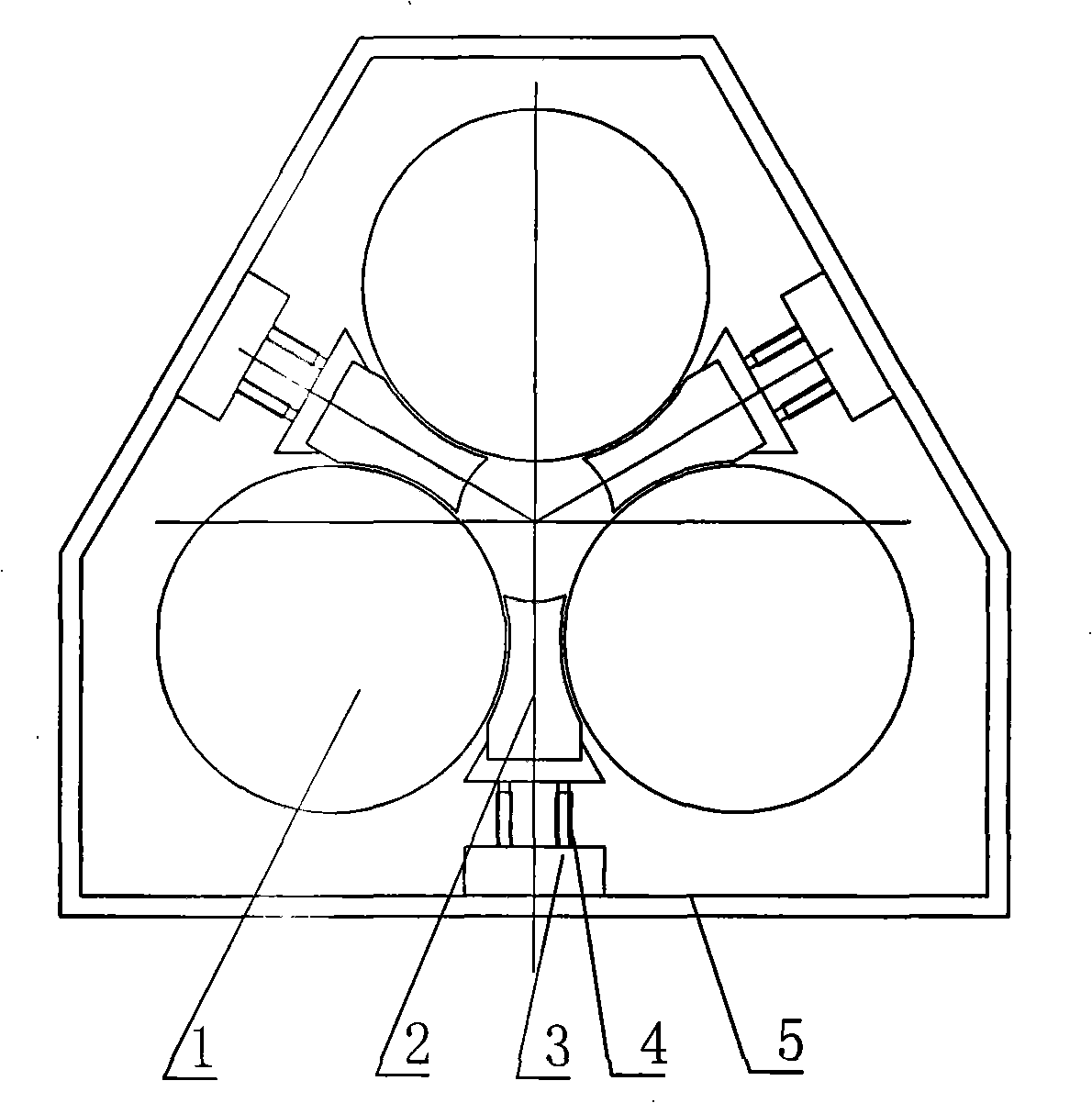

[0043] The guide and guard device is composed of a guide plate 2, a guide plate bracket 3, and a height-adjustable guide plate adjustment mechanism 4. The guide plate bracket 3 is fixed on the frame 5, and the guide plate 2 is arranged between the two corresponding rollers 1. The guide plates 2 of the three guides and guards are respectively set between the three rolls (see figure 1), together with the roll, form a closed round pass.

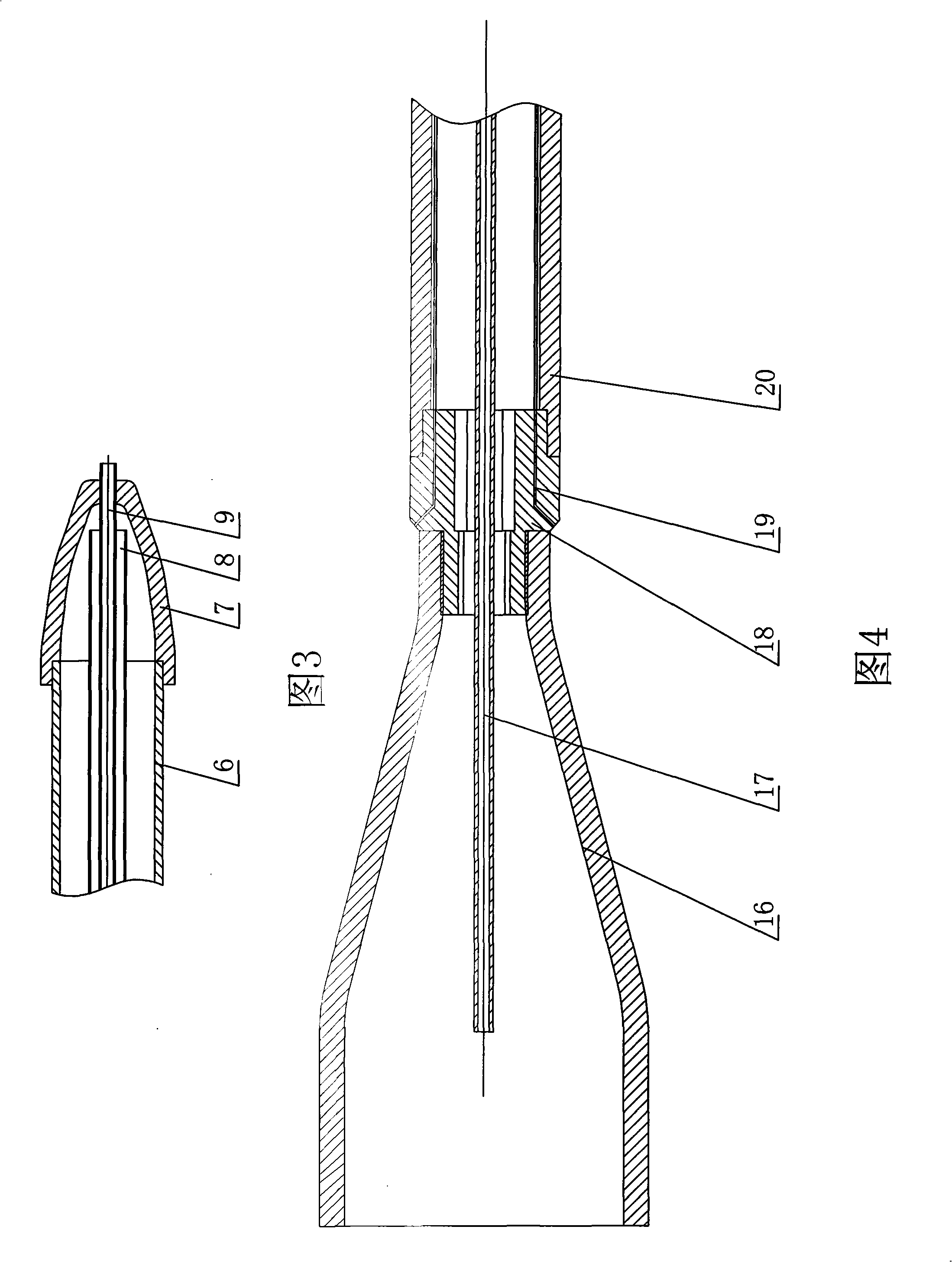

[0044] The plug 7 and the plug 6 of the three-roll cross-rolling piercing machine are threadedly connected, and the plug 7 and the plug 6 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com