Comprehensive treatment method for high-mud content high-combination rate mixed copper ore

A technology of mixed copper ore and comprehensive treatment, which is applied in the comprehensive treatment of copper ore, and the comprehensive treatment of mixed copper ore with high binding rate. For the field with high mud content, it can solve the problems of high cost, large mud content, and large process investment. Achieve the effects of low cost, efficient recycling, and small process investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

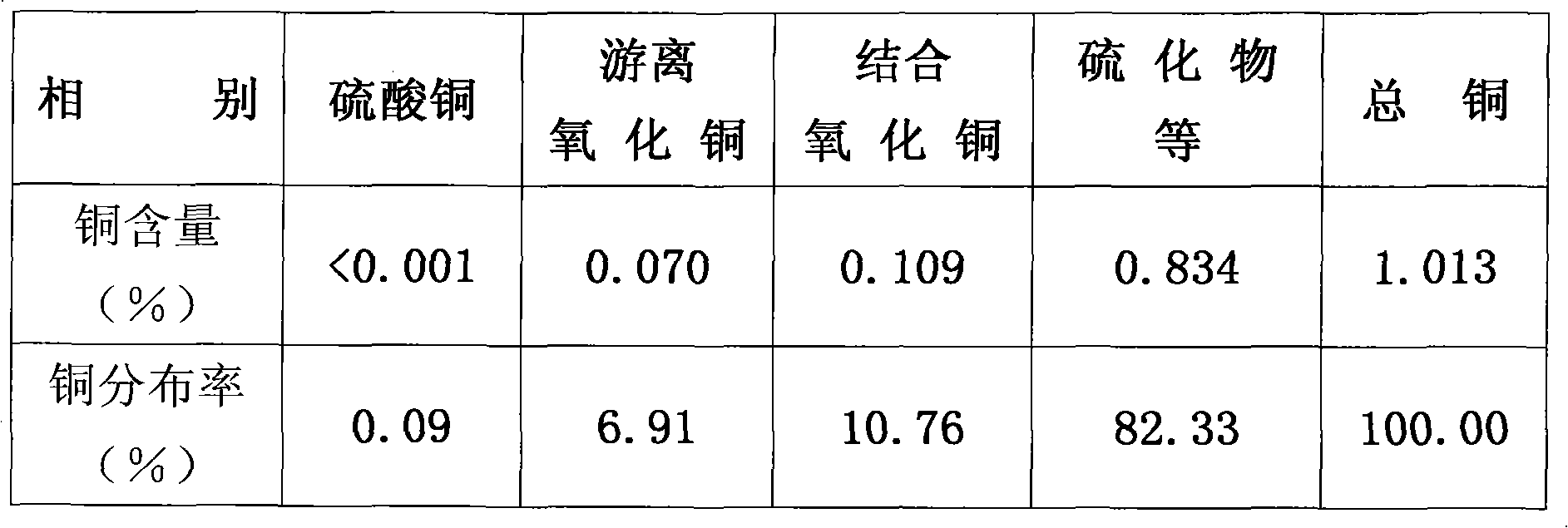

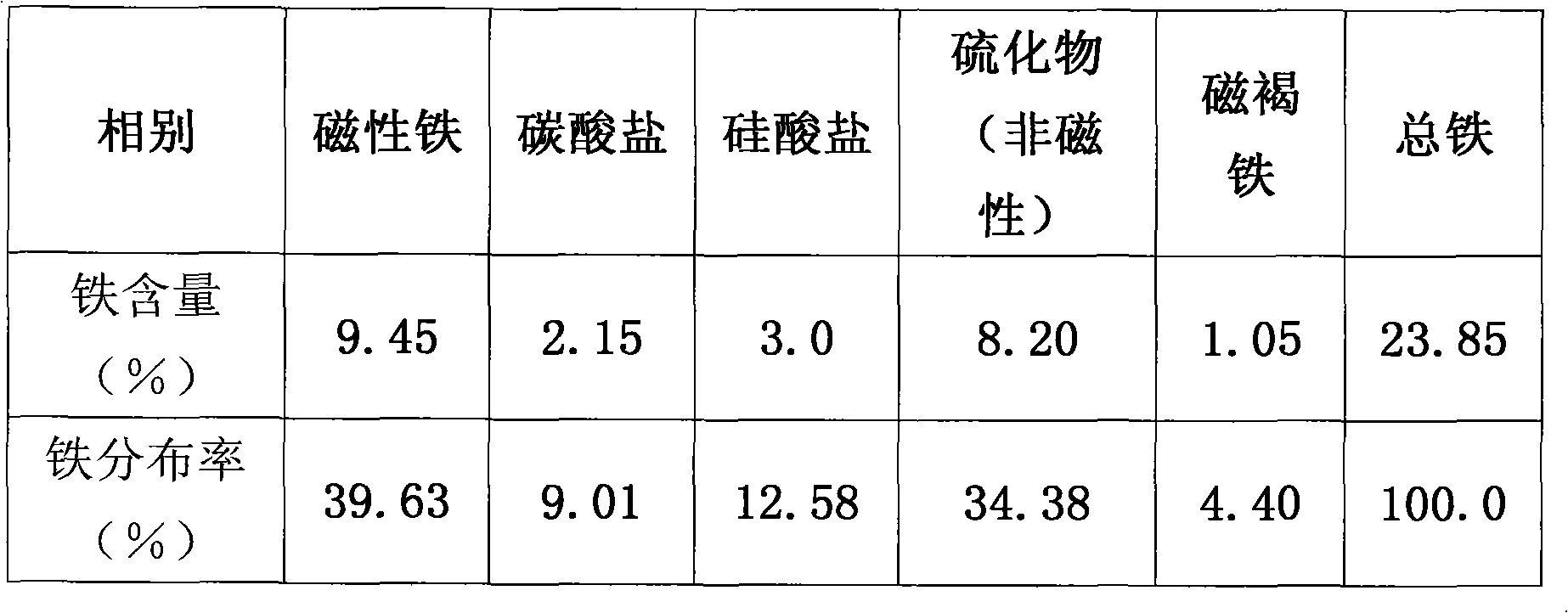

[0019] The chemical composition of the raw ore of mixed copper ore processed in this embodiment is shown in Table 1, the results of phase analysis of copper in the raw ore are shown in Table 2, and the results of phase analysis of iron in the raw ore are shown in Table 3.

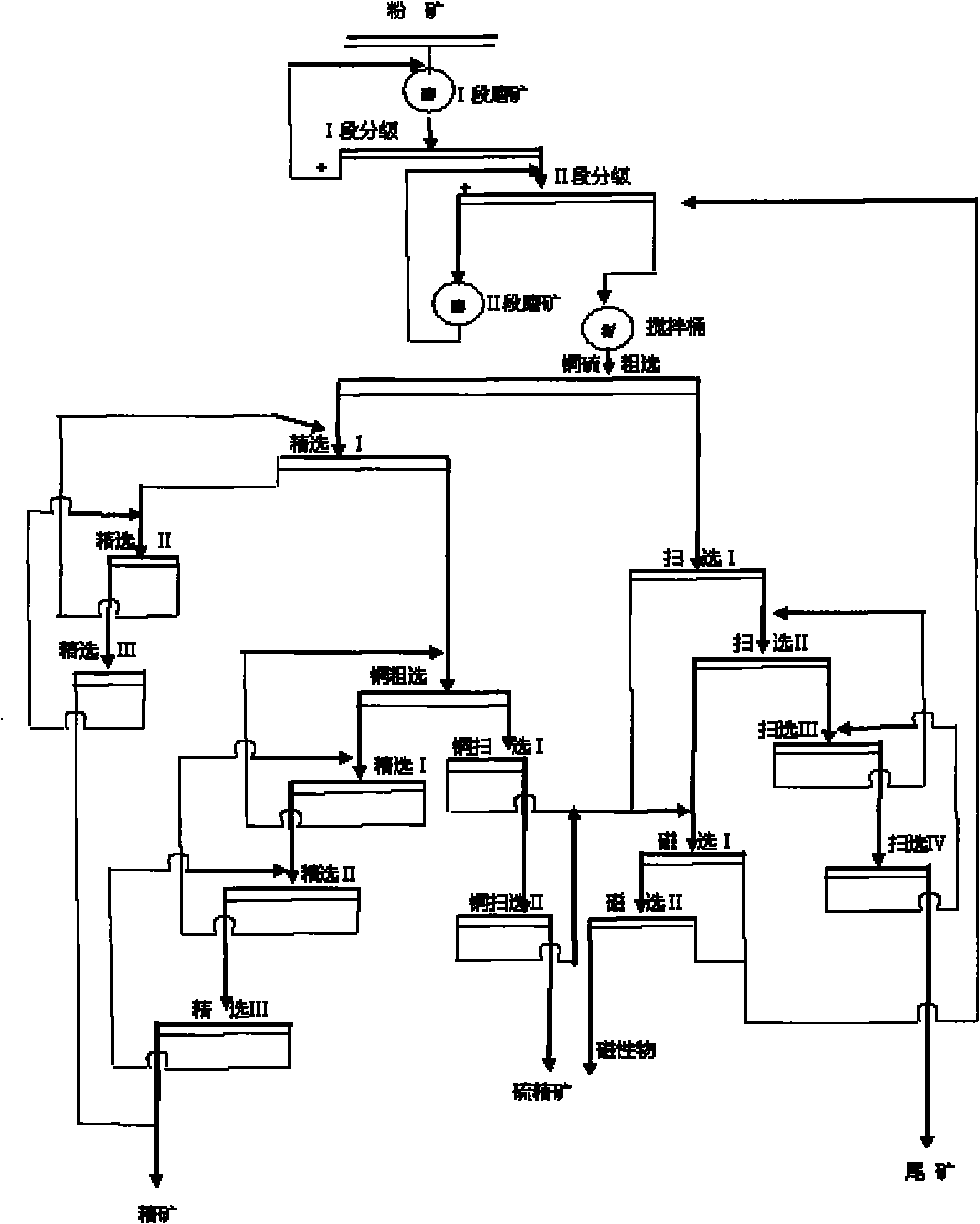

[0020] Process steps (in addition to conventional grinding and conventional magnetic separation, the rest of the roughing, beneficiation and sweeping are conventional flotation):

[0021] A. Coarsely grind the mixed copper ore with high mud content and high binding rate. After the primary screening, the mixed copper ore on the sieve is returned to the coarse grinding, and the mixed copper ore under the sieve is screened for the second time. Finely grind the mixed copper ore, and then return to the secondary screening. The mixed copper ore on the secondary sieve continues to be finely ground, and the mixed copper ore with a particle size of -0.074mm under the secondary sieve accounts for 87% of the mass ratio...

Embodiment 2

[0031] The chemical composition of the mixed copper ore raw ore processed in this embodiment is shown in Table 5, the copper phase analysis results in the raw ore are shown in Table 6, and the iron phase analysis results in the raw ore are shown in Table 7. The process steps are the same as in Example 1.

[0032] Process steps (in addition to conventional grinding and conventional magnetic separation, the rest of the roughing, beneficiation and sweeping are conventional flotation):

[0033] A. Coarsely grind the mixed copper ore with high mud content and high binding rate. After the primary screening, the mixed copper ore on the sieve is returned to the coarse grinding, and the mixed copper ore under the sieve is screened for the second time. Finely grind the mixed copper ore, and then return to the secondary screening. The mixed copper ore on the secondary sieve continues to be finely ground, and the -0.074mm particle size under the secondary sieve accounts for 85% of the mixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com