Method and device for recycling and treating waste gas with VOCs (volatile organic compounds)

A technology for waste gas recovery and treatment methods, applied in gas treatment, separation methods, chemical instruments and methods, etc., can solve the problems of secondary pollution, waste of VOCs, waste of raw materials, etc., to reduce production energy consumption, save production costs, improve The effect of absorption efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

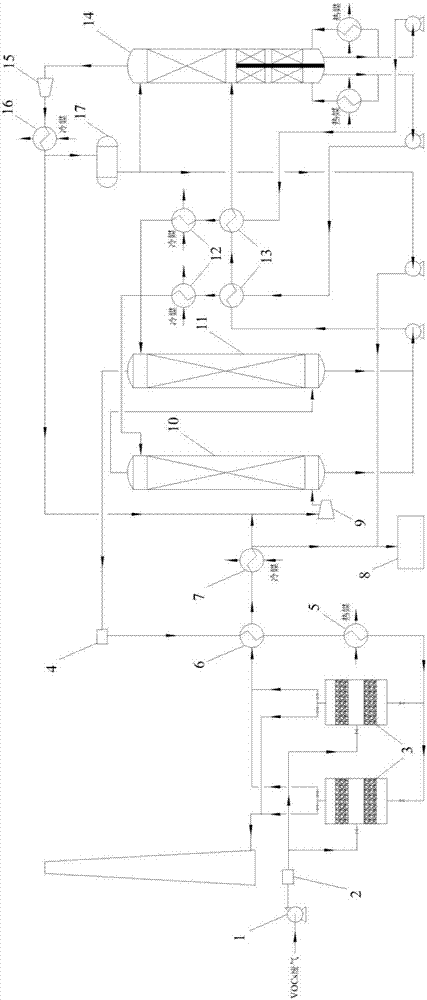

[0033] Such as figure 1 As shown, the process using the VOCs waste gas recovery treatment method and device includes the following steps:

[0034] A. Adsorption: VOCs exhaust gas is transported to the filter in the pre-treatment device 2 through the induced draft fan 1 to remove solid and liquid particles contained in the VOCs exhaust gas, and then the VOCs exhaust gas is cooled by finned tubes in the pre-treatment device 2 The VOCs waste gas is cooled down to 30-40°C and then enters the adsorber 3 through the air inlet of the adsorber 3. The adsorption material in the adsorber 3 is two layers up and down, and the adsorption material is activated carbon or molecular sieve. The thickness of one layer of adsorption material is 600-800mm; the exhaust gas is purified by the upper and lower layers of adsorption material and then discharged from the gas outlet of the adsorber 3, and the discharged clean gas is discharged into the atmosphere through the chimney.

[0035] B. Desorpti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com