A comprehensive treatment method for mixed copper ore

A mixed copper ore and comprehensive treatment technology, which is applied to the comprehensive treatment of mixed copper ore with high oxidation rate, comprehensive treatment of copper ore resources, and can solve the problems of high cost, high mud content and high oxidation rate in areas with high mud content. Achieve the effect of small investment, low cost and efficient recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

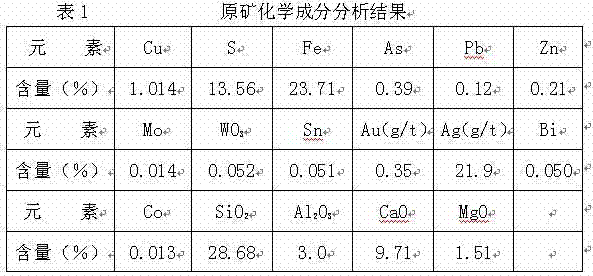

[0019] The raw ore chemical composition analysis results of this embodiment 1 are shown in Table 1, the copper phase analysis results in the raw ore are shown in Table 2, the iron phase analysis results in the raw ore are shown in Table 3, and the technical indicators after beneficiation are shown in Table 4.

[0020] In Example 1, the total dosage of chemicals is: xanthate 35g / t, YL-1 45g / t, sodium sulfide 20g / t, lime 8kg / t, butyl ammonium black medicine 5g / t, soda ash 0.35kg / t.

[0021] Above-mentioned raw ore is passed through following steps:

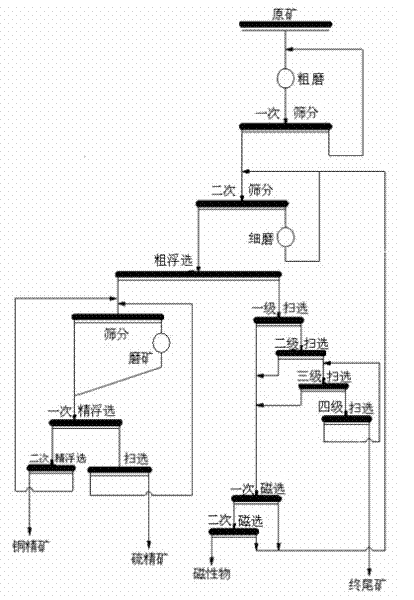

[0022] A. Coarsely grind the mixed copper ore with high mud content and high binding rate. After the primary screening, the mixed copper ore on the sieve is returned to the coarse grinding, and the mixed copper ore under the sieve is subjected to secondary screening, and the secondary sieved After the mixed copper ore on the sieve is finely ground, return to the secondary screening, and the mixed copper ore on the secondary sieve co...

Embodiment 2

[0029] The chemical composition analysis results of the raw ore in this embodiment 2 are shown in Table 5, the copper phase analysis results in the raw ore are shown in Table 6, the iron phase analysis results in the raw ore are shown in Table 7, and the technical indicators after beneficiation are shown in Table 8.

[0030] In Example 2, the total amount of chemicals used is: xanthate 34g / t, YL-1 46g / t, sodium sulfide 21g / t, lime 8kg / t, butyl ammonium black medicine 5g / t, soda ash 0.36kg / t.

[0031] Above-mentioned raw ore is passed through following steps:

[0032] A. Coarsely grind the mixed copper ore with high mud content and high binding rate. After the primary screening, the mixed copper ore on the sieve is returned to the coarse grinding, and the mixed copper ore under the sieve is subjected to secondary screening, and the secondary sieved After the mixed copper ore on the sieve is finely ground, return to the secondary screening, and the mixed copper ore on the second...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com