Preparation method of gamma-crystalline sorbitol

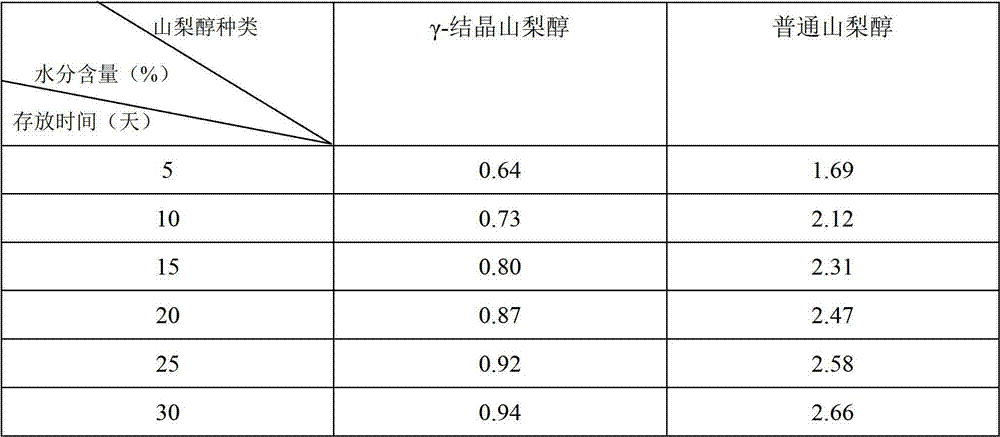

A technology for crystallizing sorbitol and sorbitol, which is applied in the field of preparation of γ-crystal sorbitol, can solve the problems that moisture absorption is not well improved, the viscosity of molten sorbitol is high, equipment wear is very serious, and the like. Economic and social benefits, good mobility, and not easy to absorb moisture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

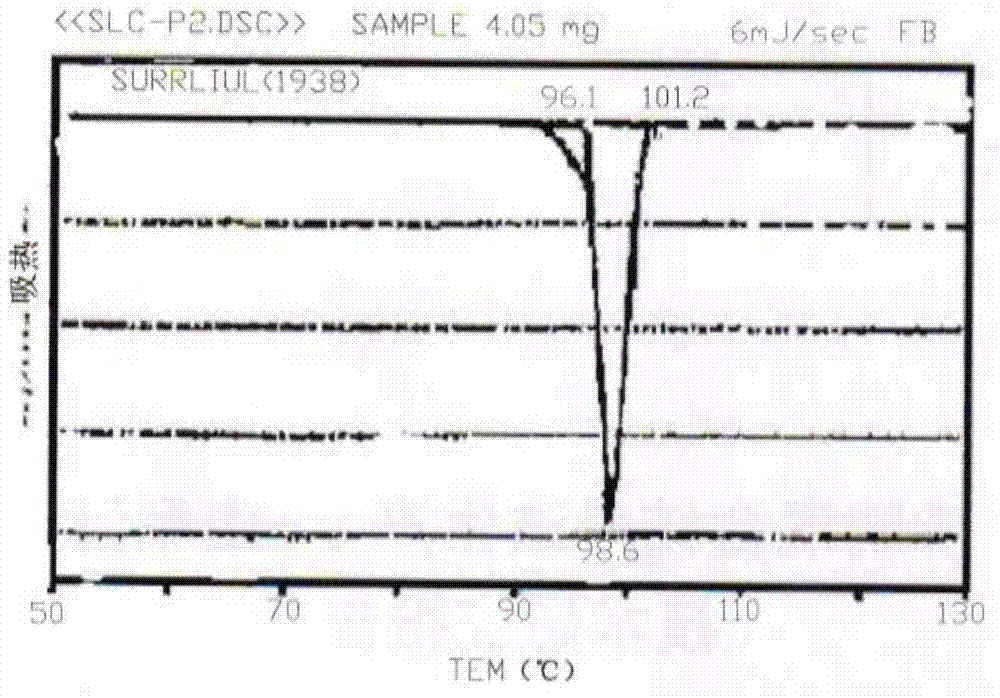

[0020] Example 1 Preparation of γ-crystalline sorbitol

[0021] Take 100kg of liquid sorbitol with a mass concentration of 70%, and use a scraper evaporator to evaporate to a molten state with a mass concentration of 99.5%, wherein the evaporation pressure is -0.08MPa, and the temperature is 110°C. After the temperature drops to 105°C, the Spray under 0.5MPa pressure on the boiling sorbitol crystal seed, the quality of sorbitol crystal seed is 35kg, the dosage ratio of molten sorbitol and sorbitol crystal seed is 2:1, stir and mix while spraying, the stirring speed is revolution speed 10r / min, rotation speed 60r / min; after spraying, the temperature is 80°C, heat preservation and aging for 4h, and then cool down to 20°C at a speed of 10°C / h, the content of γ-crystalline sorbitol in the obtained product reaches 92.25%, the melting point It is 96.5°C; after cooling down, it is pulverized, and then the pulverized material is sprayed with 95°C clean steam for 5 minutes, and the fl...

Embodiment 2

[0022] Example 2 Preparation of γ-crystalline sorbitol

[0023] Take 100kg of liquid sorbitol with a mass concentration of 70%, and use a scraper evaporator to evaporate to a molten state with a mass concentration of 98%, wherein the evaporation pressure is -0.098MPa, and the temperature is 130°C. After the temperature drops to 120°C, the Spray under the pressure of 0.2MPa on the boiling sorbitol crystal seed, the quality of sorbitol crystal seed is 140kg, the dosage ratio of molten sorbitol and sorbitol crystal seed is 1:2, stir and mix while spraying, the stirring speed is revolution speed 2r / min, rotation speed 40r / min; after spraying, the temperature is 50°C, heat preservation and aging for 1h, and then cool down to 40°C at a speed of 6°C / h, the content of γ-crystalline sorbitol in the obtained product is 90.11%, the melting point It is 95.2°C; after cooling down, it is pulverized, and then the pulverized material is sprayed with 80°C clean steam for 10 minutes, and the f...

Embodiment 3

[0024] Example 3 Preparation of γ-crystalline sorbitol

[0025] Take 100kg of liquid sorbitol with a mass concentration of 70%, and use a scraper evaporator to evaporate to a molten state with a mass concentration of 99.2%, wherein the evaporation pressure is -0.093MPa, and the temperature is 120°C. After the temperature drops to 110°C, the Spray under the pressure of 0.3MPa on the boiling sorbitol crystal seed, the mass of sorbitol crystal seed is 70kg, the dosage ratio of molten sorbitol and sorbitol crystal seed is 1:1, stir and mix while spraying, the stirring speed is revolution speed 6r / min, rotation speed 50r / min; after spraying, the temperature is 60°C, heat preservation and aging for 3h, and then cool down to 30°C at a speed of 8°C / h, the content of γ-crystalline sorbitol in the obtained product reaches 95.32%, the melting point It is 97.3°C; after cooling down, it is pulverized, and then the pulverized material is sprayed with 90°C clean steam for 8 minutes, and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| fluidity | aaaaa | aaaaa |

| fluidity | aaaaa | aaaaa |

| fluidity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com