Method for concentrating titanium white waste acids through gas-liquid contact technology

A technology of gas-liquid contact and titanium dioxide waste acid, applied in chemical instruments and methods, sulfur trioxide/sulfuric acid, inorganic chemistry, etc., can solve the problems of easy blockage of evaporation pipelines, high requirements for equipment materials, and simple treatment methods, and achieve The effect of low equipment material requirements, significant environmental benefits, and reliable process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

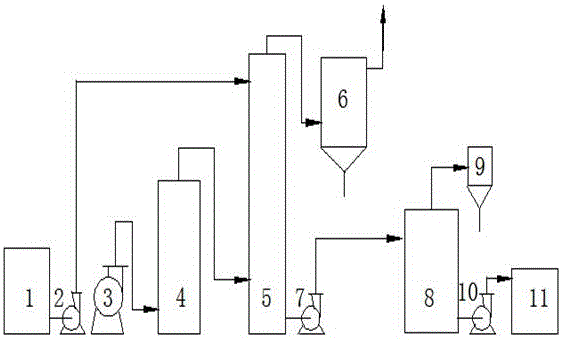

Embodiment 1

[0020] Use the corrosion-resistant dilute acid pump 2 to press the 100°C titanium dioxide waste acid in the titanium dioxide waste acid tank 1 into the gas-liquid contact evaporator 5, spray the titanium dioxide waste acid into a mist through the nozzle, and at the same time, the blower 3 blows the high-temperature hot blast furnace The high-temperature hot air generated in 4 is sent to the gas-liquid contact evaporator 5, and directly contacts with the titanium dioxide waste acid droplets sprayed by multiple nozzles from bottom to top. Due to the large contact area, long contact time and sufficient heat exchange, the gas can be quickly Cooling, while the water in the titanium white waste acid is evaporated in large quantities, and the dilute waste acid with an acid concentration of 20% is concentrated to more than 45%; the gas-liquid mixture in the upper part of the gas-liquid contact evaporator 5 enters the gas-liquid separator 6, The gas-liquid mixture rotates at a high spee...

Embodiment 2

[0022] Use the corrosion-resistant dilute acid pump 2 to press the 100°C titanium dioxide waste acid in the titanium dioxide waste acid tank 1 into the gas-liquid contact evaporator 5, spray the titanium dioxide waste acid into a mist through the nozzle, and at the same time, the blower 3 blows the high-temperature hot blast furnace The high-temperature hot air generated in 4 is sent to the gas-liquid contact evaporator 5, and directly contacts with the titanium dioxide waste acid droplets sprayed by multiple nozzles from bottom to top. Due to the large contact area, long contact time and sufficient heat exchange, the gas can be quickly Cooling, while the water in the titanium white waste acid is evaporated in large quantities, and the dilute waste acid with an acid concentration of 30% is concentrated to more than 60%; the gas-liquid mixture in the upper part of the gas-liquid contact evaporator 5 enters the gas-liquid separator 6, The gas-liquid mixture rotates at a high spee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com