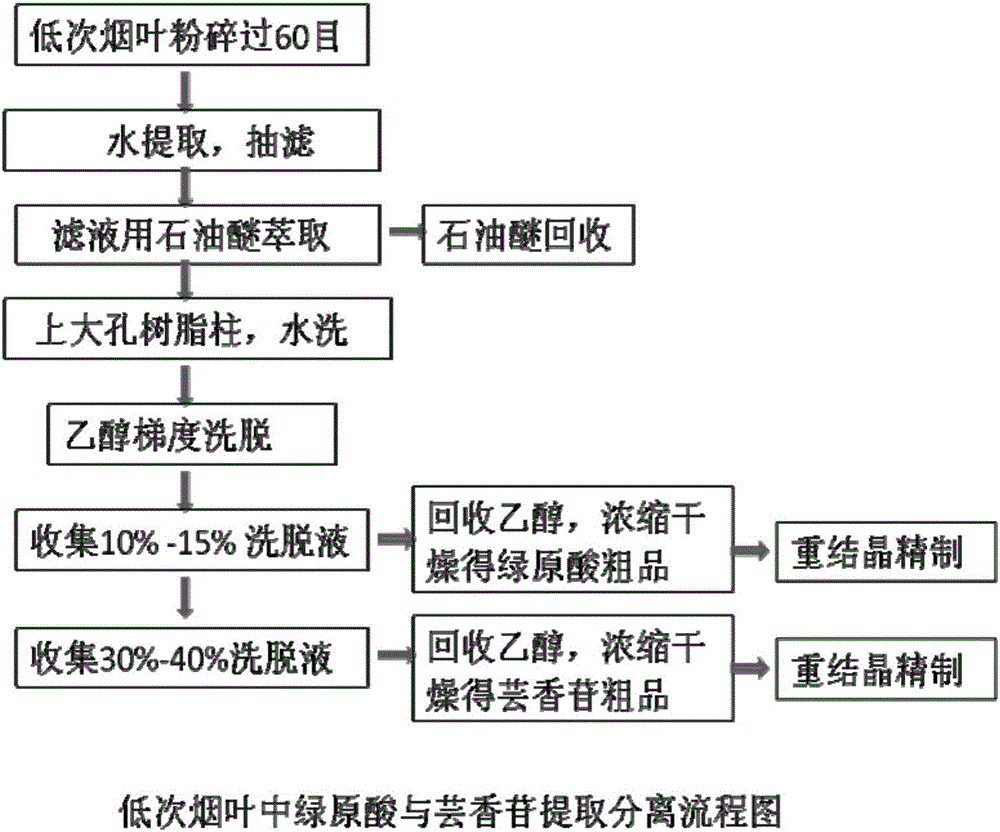

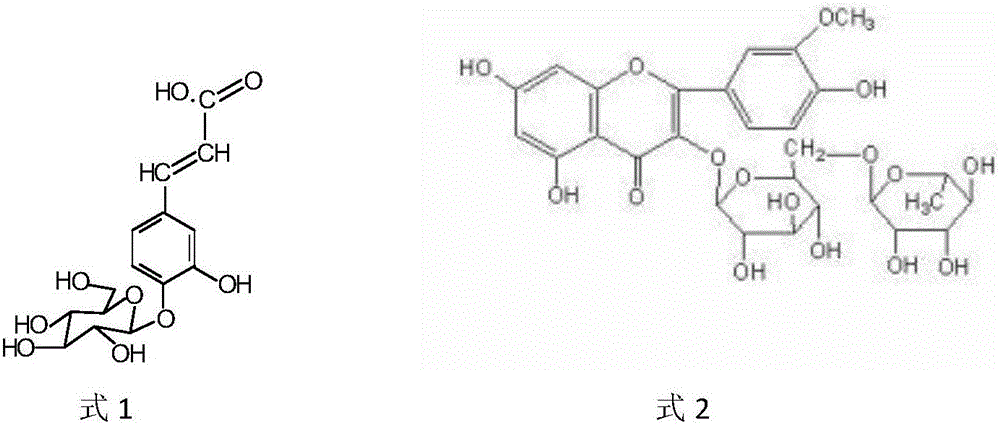

Method for simultaneously separating chlorogenic acid and rutin from tobacco leaves

A technology of chlorogenic acid and rutin, applied in chemical instruments and methods, separation/purification of carboxylate, preparation of carboxylate, etc., to achieve the effect of simple operation, lower extraction cost and simple separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] 1. Simultaneous extraction of tobacco chlorogenic acid and rutin

[0031] Weigh 200g of tobacco leaf powder sample passed through a 60-mesh sieve, dissolve it in 4000ml of water at a material-to-liquid ratio of 1:20, pour it into a stirring extractor and set the extraction temperature at 50°C, and extract with stirring and extraction for 120 minutes. The obtained extract was subjected to suction filtration, the residue was filtered off, and the filtrate was collected. The extraction rates of tobacco chlorogenic acid and rutin in the filtrate reach 84% and 99% respectively (according to the experimental data of recovery rate). The contents of chlorogenic acid and rutin in the filtrate reached 21.7 mg / g and 16.5 mg / g, respectively. The filtrate is extracted with petroleum ether to remove impurities according to the volume ratio of 1:1, the upper organic phase is recovered, and the lower aqueous phase is combined to obtain the chlorogenic acid and rutin extract. At this ...

Embodiment 2

[0039] 1. Simultaneous extraction of tobacco chlorogenic acid and rutin

[0040] Weigh 200g of tobacco leaf powder sample passed through a 60-mesh sieve, dissolve it in 5000ml of water at a material-to-liquid ratio of 1:25, pour it into a stirring extractor and set the extraction temperature at 50°C, and extract with stirring and extraction for 120 minutes. The obtained extract was subjected to suction filtration, the residue was filtered off, and the filtrate was collected. The filtrate is extracted with petroleum ether to remove impurities according to the volume ratio of 1:1, the upper organic phase is recovered, and the lower aqueous phase is combined to obtain the chlorogenic acid and rutin extract.

[0041] 2. Separation of tobacco chlorogenic acid and rutin

[0042] 1. Isolation of chlorogenic acid

[0043] Put the pretreated HPD‐100 type macroporous resin into the chromatography column, so that the column surface is flat, without inclination, without air bubbles in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com