Silicon-based negative electrode material, preparation method thereof and application of silicon-based negative electrode material in lithium-ion battery

A technology of silicon-based negative electrode material and negative electrode material, applied in lithium battery, nanotechnology for material and surface science, negative electrode, etc. Connection and other problems, to achieve excellent cyclic expansion performance, stable electrical conductivity, and the effect of inhibiting expansion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0061] This embodiment provides a silicon-based negative electrode material for lithium-ion batteries, which is prepared by the following method:

[0062] Dissolve 4g of polyacrylic acid in 100g of distilled water, fully dissolve at a temperature of 40°C, add 1g of carbon nanofibers and 5g of flake graphite CSG-3 under stirring conditions, add 200g of ethanol after stirring for 2 hours, and continue stirring for 0.5 hours , then 90g SiO x (x = 1.0) was added therein under stirring, stirred at 60°C for 2 hours and then lowered to room temperature, the material was separated by suction filtration, then placed in a drying oven at 180°C for heat treatment for 4 hours, and taken out after cooling to obtain the corresponding SiO coated with polyacrylic acid, CSG-3 and carbon nanofibers x Negative electrode materials, that is, silicon-based negative electrode materials for lithium-ion batteries.

Embodiment 2

[0064] This embodiment provides a silicon-based negative electrode material for lithium-ion batteries, which is prepared by the following method:

[0065] Dissolve 2.5g of polyacrylic acid in 100g of distilled water, fully dissolve at 40°C, add 0.5g of carbon nanotubes and 3g of flake graphite CSG-3 under stirring, add 200g of ethanol after stirring for 4 hours, and continue stirring 0.5 hours, then 95g SiO x / C(x=1.0) was added under stirring, stirred at 60°C for 2 hours and then cooled to room temperature, the material was separated by suction filtration, then heat-treated in a drying oven at 180°C for 4 hours, and taken out after cooling to obtain Corresponding polyacrylic acid, CSG-3 and carbon nanotube coated SiO x / C negative electrode material, that is, silicon-based negative electrode material for lithium-ion batteries.

Embodiment 3

[0067] This embodiment provides a silicon-based negative electrode material for lithium-ion batteries, which is prepared by the following method:

[0068] Dissolve 2g of polyacrylic acid and 1g of sodium carboxymethylcellulose in 100g of distilled water, fully dissolve at 50°C, add 1g of graphene and 3g of flake graphite CSG-3, stir for 4 hours, add 200g of methanol, and continue stirring for 1 hours, and then 90gSiO x / C(x=1.0), stirred at 50°C for 4 hours and then cooled to room temperature, centrifuged to separate the material, then placed it in a drying oven at 250°C for heat treatment for 4 hours, and took it out after cooling to obtain the corresponding polyacrylic acid-carboxylate SiOx / C negative electrode material coated with sodium methylcellulose, CSG-3 and graphene, that is, a silicon-based negative electrode material for lithium-ion batteries.

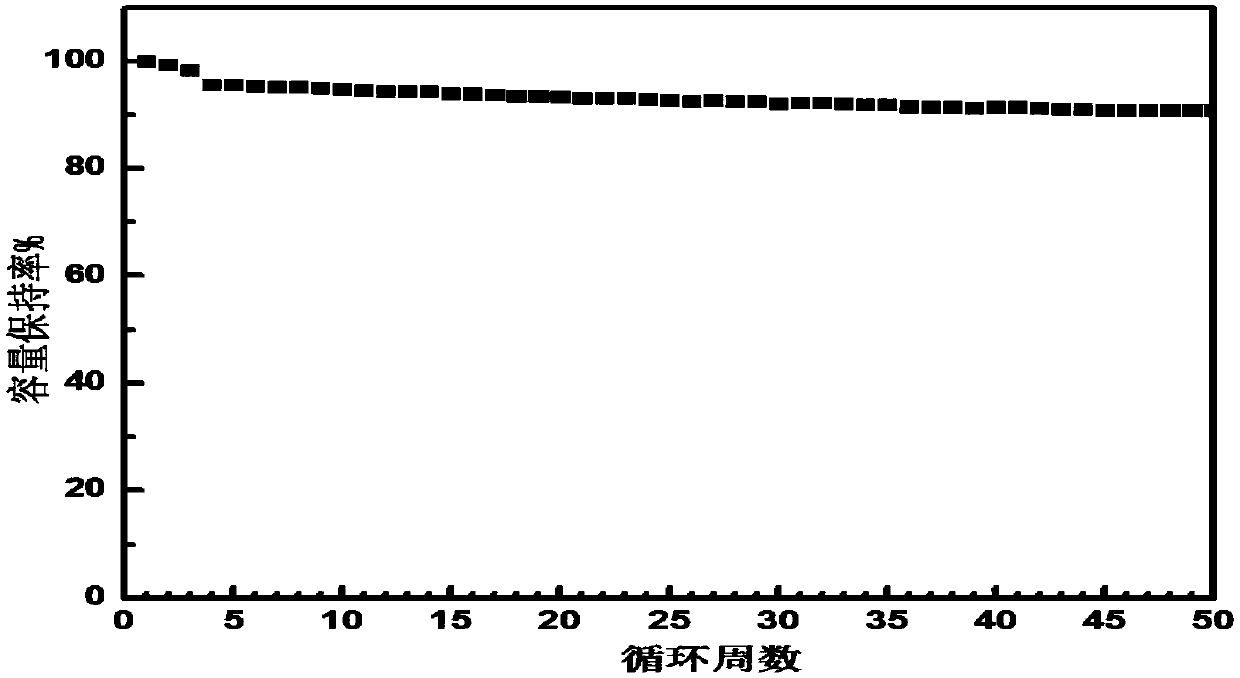

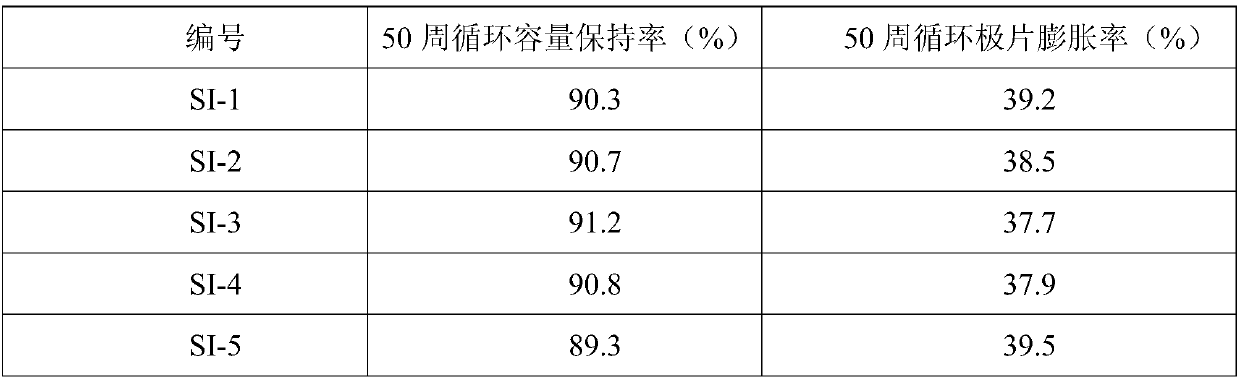

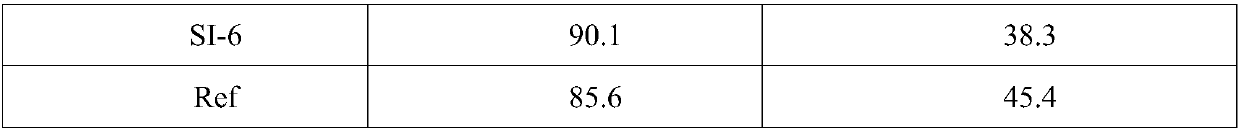

[0069] figure 1 It is the 50-cycle cycle capacity retention figure of the battery made of the silicon-based negative el...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com