Temperature field controllable aluminum nitride crystal growth device and process

A growth device and crystal growth technology, applied in crystal growth, single crystal growth, single crystal growth, etc., can solve the problems that it is difficult to meet the temperature field conditions of aluminum nitride crystals and fail to meet the requirements for precise control of the temperature field, and achieve Accurate temperature field control, feasible process, and strong operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

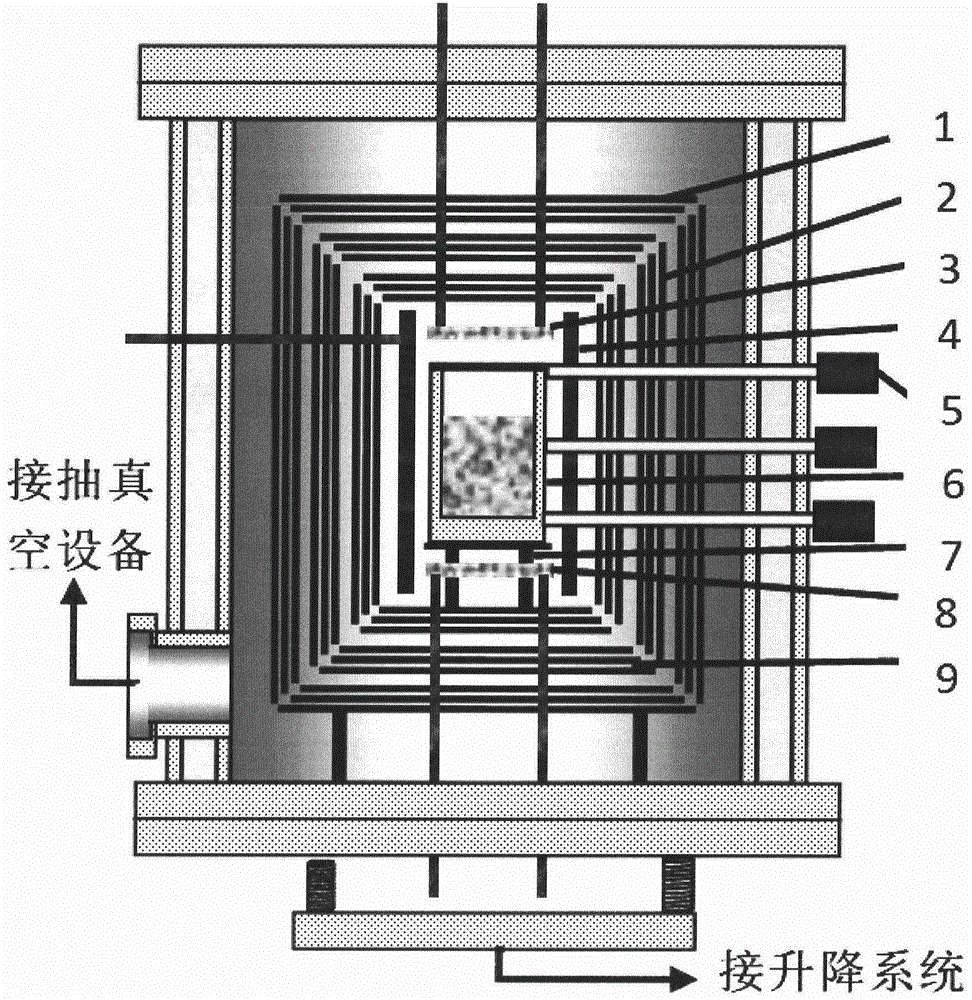

[0020] The invention provides an aluminum nitride crystal growth device and process with controllable temperature field. Next give an embodiment of the present invention for further description. In this example, the figure 1 The growth device shown comprises a top heater (3), a middle heater (4), a bottom heater (8), a top insulation layer (1), a side insulation layer (2), a bottom insulation layer (9), It consists of an infrared thermometer (5), a crucible (6) and a crucible support (7). The material of each heater is metal tungsten, the top heater (3) and the bottom heater (8) adopt a mosquito-repellent coil-shaped disc structure, and the middle heater (4) adopts a mesh-shaped cylindrical structure, and the three are coaxial , and the positions of the first two in the vertical direction can extend into the middle heater (4). The top insulation layer (1), the side insulation layer (2) and the bottom insulation layer (9) all adopt the method of metal total reflection heat s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com