A kind of flame-retardant composite material floor and preparation method thereof

A flame-retardant composite material and flooring technology, which is applied in aircraft floors, aircraft accessories, etc., to ensure durable use, excellent environmental corrosion resistance, and reliable bonding effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

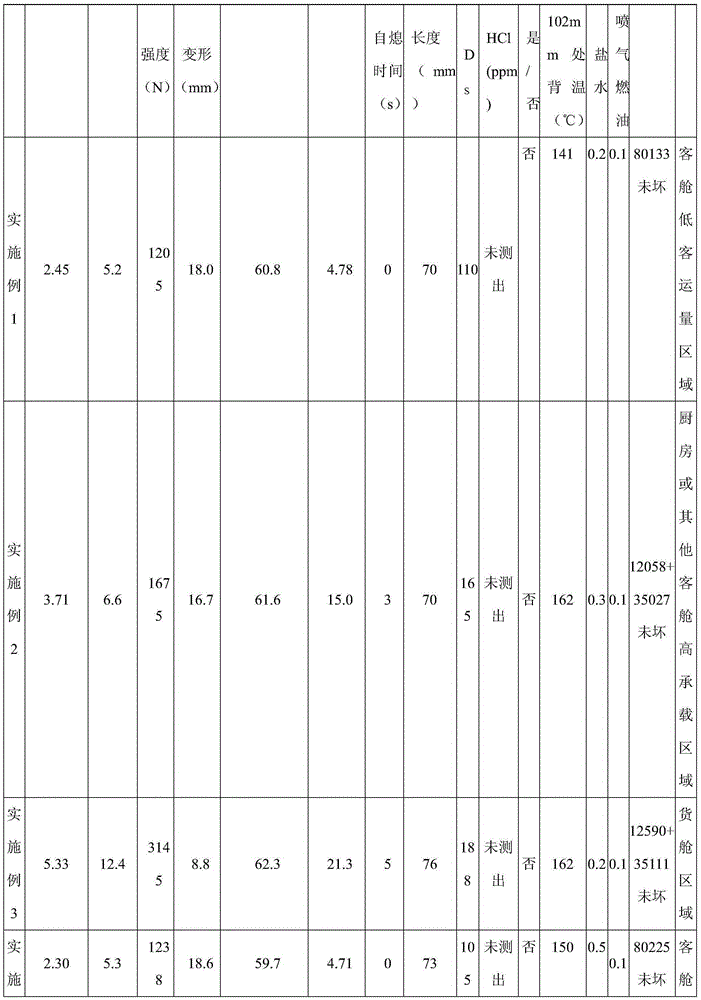

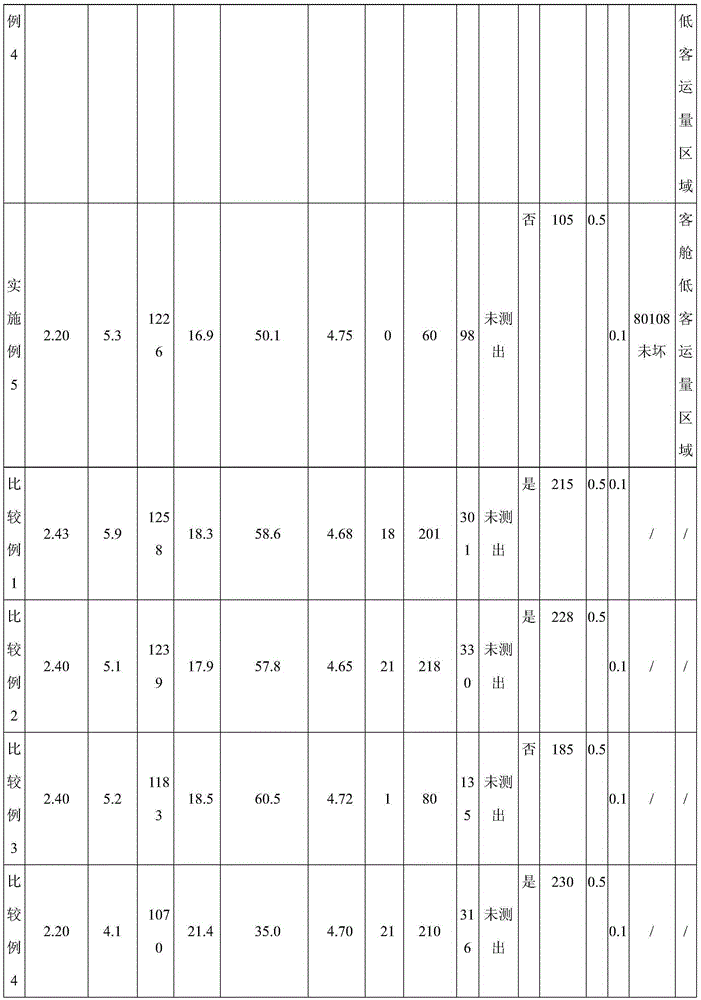

Embodiment 1

[0045] It is required to prepare 9.9mm ~ 10.4mm thickness, surface density ≤ 2.5kg / m 2 The standard floor is used in the low-passenger area of the cabin; according to the design load and thickness requirements, type I aramid paper honeycomb (Nomex honeycomb) is selected, with a cell size of 1.83mm and a density of 80kg / m 3 , the thickness is 9.5mm.

[0046] Prepared by method one, the steps are:

[0047] 1) Add 40kgE44 epoxy resin, 20kgAFG-90 epoxy resin and 20kg acetone in a 100L reactor, and stir at a speed of 100 rpm to obtain an epoxy resin solution;

[0048] 2) in the epoxy resin solution that step 1) obtains, add successively 8.5kg carboxyl-terminated nitrile rubber toughening agent, 3kg aluminum hydroxide and 6kg polyphosphate flame retardant, 6kg dicyandiamide curing agent and 3kg1,1 -Dimethyl 3-phenylurea accelerator, then stirred at a speed of 500 rpm for 100 minutes, and finally the stirred mixed solution was ground by three rollers to obtain a modified epoxy re...

Embodiment 2

[0054] It is required to prepare 9.9mm ~ 10.4mm thickness, surface density ≤ 3.8kg / m 2 The standard floor is used in the kitchen or other high-load areas of the passenger cabin; according to the design load and thickness requirements, type I aramid paper honeycomb (Nomex honeycomb) is selected, with a cell size of 1.83mm and a density of 144kg / m 3 , the thickness is 9.2mm.

[0055] Prepared by method one, the steps are:

[0056] 1) Add 40kgE44 epoxy resin, 20kgAFG-90 epoxy resin and 20kg acetone in a 100L reactor, and stir at a speed of 100 rpm to obtain an epoxy resin solution;

[0057] 2) in the epoxy resin solution that step 1) obtains, add successively 8.5kg carboxyl-terminated nitrile rubber toughening agent, 3kg aluminum hydroxide and 6kg polyphosphate flame retardant, 6kg dicyandiamide curing agent and 3kg1,1 -Dimethyl 3-phenylurea accelerator, then stirred at a speed of 500 rpm for 100 minutes, and finally the stirred mixed solution was ground by three rollers to obt...

Embodiment 3

[0062] It is required to prepare 9.9mm ~ 10.4mm thickness, surface density ≤ 5.4kg / m 2 The standard floor is used in the cargo compartment area; according to the design load and thickness requirements, type I aramid paper honeycomb (Nomex honeycomb) is selected, with a cell size of 1.83mm and a density of 192kg / m 3 , the thickness is 8.8mm.

[0063] Prepared by method one, the steps are:

[0064] 1) Add 40kgE44 epoxy resin, 20kgAFG-90 epoxy resin and 20kg acetone in a 100L reactor, and stir at a speed of 100 rpm to obtain an epoxy resin solution;

[0065] 2) in the epoxy resin solution that step 1) obtains, add successively 8.5kg carboxyl-terminated nitrile rubber toughening agent, 3kg aluminum hydroxide and 6kg polyphosphate flame retardant, 6kg dicyandiamide curing agent and 3kg1,1 -Dimethyl 3-phenylurea accelerator, then stirred at a speed of 500 rpm for 100 minutes, and finally the stirred mixed solution was ground by three rollers to obtain a modified epoxy resin matrix...

PUM

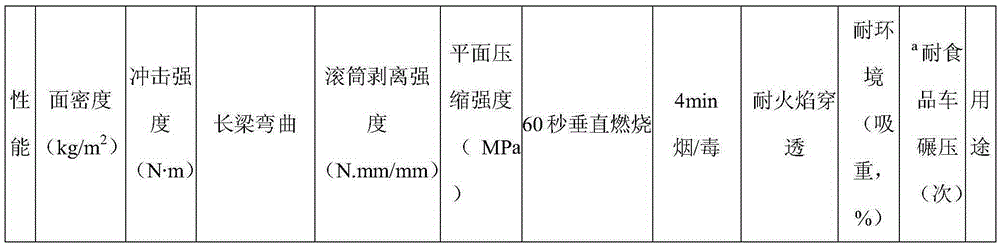

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com