Device and process for making gas and reducing iron through coal derived fusion melting bed

A technology for reducing iron and coal-based, which is used in the field of gas-making reduction and coal-based fused bed gas-making and reduced iron devices, can solve the problems of not easy to increase carbon conversion rate, pollute metals, and be difficult to use, and reach the applicable scope of coal types. Wide, high carbon conversion rate, reasonable structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

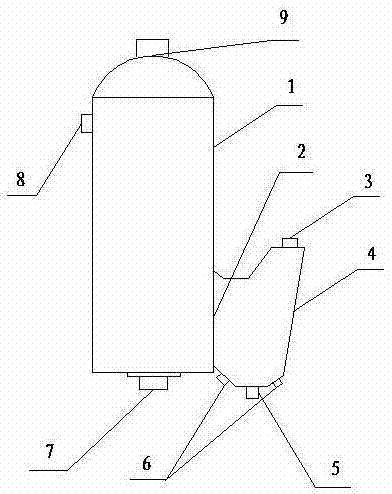

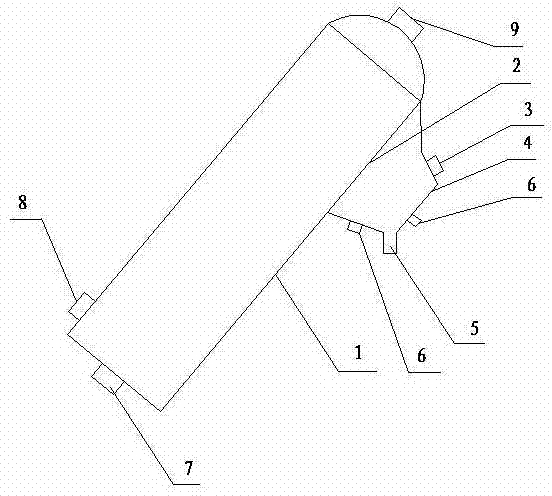

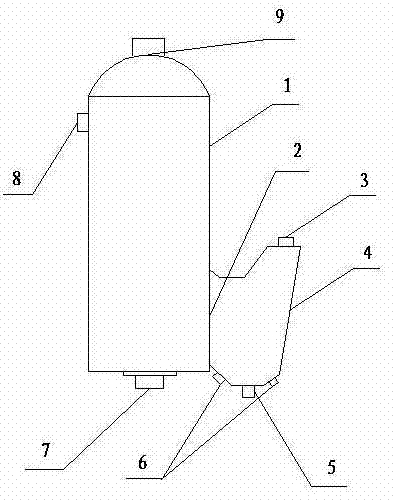

[0024] Embodiment 1, with reference to figure 1 , 2, a coal-based molten bed gas reduction iron device, it includes a fixed connection reduction furnace 1 and a gasification furnace 4, the reduction furnace 1 is provided with a reduction chamber, the reduction furnace 1 top and bottom are respectively provided with feed inlets 9. The material outlet 7 and the gas outlet 8; the gasifier 4 is a molten bed gasifier, the gasifier 4 is provided with a gasification chamber, and the gasifier 4 is provided with a coal injection nozzle 3 and an air nozzle 6 and the slagging outlet 5, a grate plate 2 is provided at the junction of the reduction furnace 1 and the gasification furnace 4, and the grate plate 2 is provided with a ventilation hole connecting the reduction chamber and the gasification chamber.

Embodiment 2

[0025] Embodiment 2, in the device for reducing iron by coal-based molten bed gas production described in Embodiment 1: the reduction furnace 1 is a shaft furnace, an open hearth furnace or a slope furnace.

Embodiment 3

[0026] Example 3, in the coal-based molten bed gas reduction device described in Example 1: the reduction furnace 1 is a shaft furnace, and the gasification furnace 4 is fixed at the lower part of the shaft furnace.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com