Preparation method of coating slurry based on lithium manganese iron phosphate flexible slurry wrapped ternary material

A technology of lithium iron manganese phosphate and ternary materials, applied in electrical components, electrochemical generators, battery electrodes, etc., can solve the problems of unfavorable material circulation, large differences, damage to the integrity of ternary lattices, etc., to improve the cycle The performance, the method is simple and easy to implement, and the effect of convenient industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings. Such as Figure 1-4 Shown: a method for preparing coating slurry based on lithium manganese iron phosphate flexible coating ternary material, comprising the following steps:

[0025] (1) Weigh the flexible film-forming material, add N-methylpyrrolidone, dissolve and configure a viscous emulsion with a mass percentage of 2%-10%, stir to disperse or ball mill, the stirring speed is 300-12000 rpm, and the time is Between 5-240 minutes;

[0026] (2) Weigh the conductive agent of SUPER-P, conductive graphite or conductive carbon powder with a total solid content of 0-10% in the designed system;

[0027] (3) Weigh 5%-50% of the solid content of the designed system, lithium manganese iron phosphate material;

[0028] (4) Add the weighed lithium manganese iron phosphate into the prepared viscous emulsion, disperse and stir, or ultrason...

example 1

[0037] (1) Calculation in proportion: weigh 95g of N-methylpyrrolidone, 3g of PVDF and 2g of polyacrylic acid resin, disperse, stir and dissolve for 60 minutes. Configured as a 5% viscous emulsion;

[0038](2) Weigh SP with a total solid content of 5g, add it to the viscous emulsion prepared in the previous step, stir and disperse for 30 minutes, and make a uniform emulsion with good conductivity;

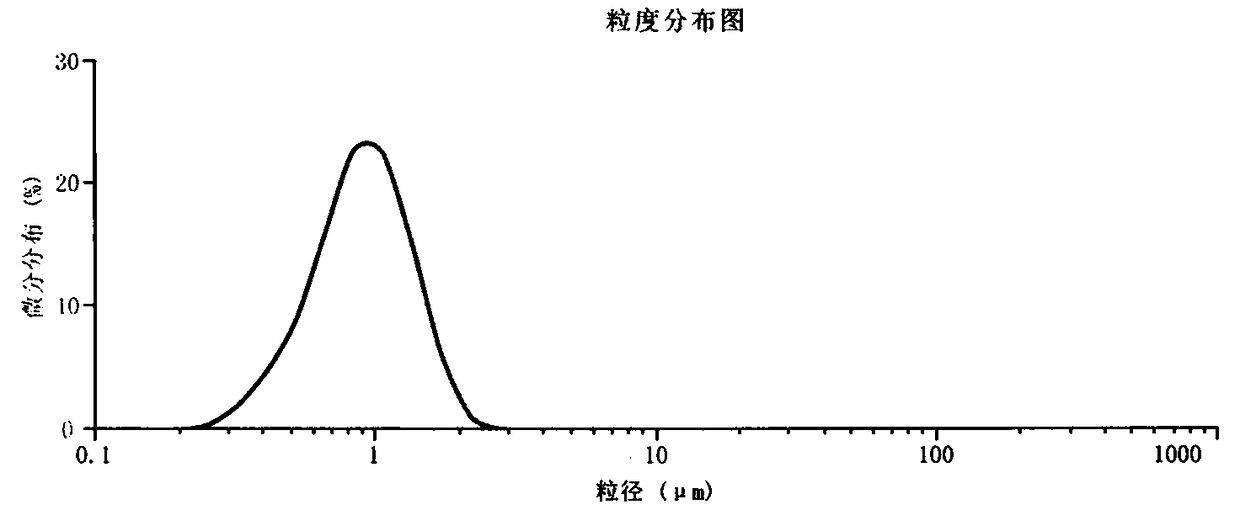

[0039] (3) Weigh the preferred nano-scale Mn:Fe=7:3 lithium manganese iron phosphate, material 10g, add to the viscous emulsion prepared in the previous step and ball mill for homogenization for 60 minutes. Configured into a uniform viscous and easy-to-film-forming slurry emulsion of lithium manganese iron phosphate;

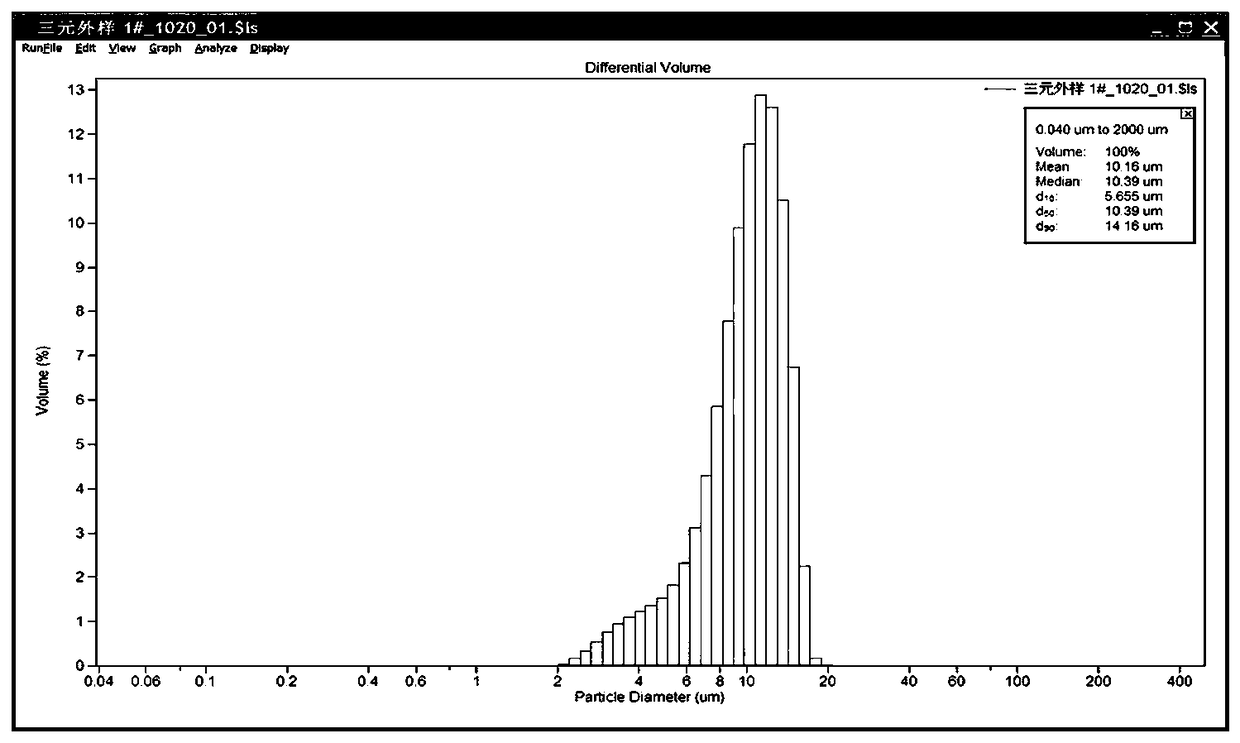

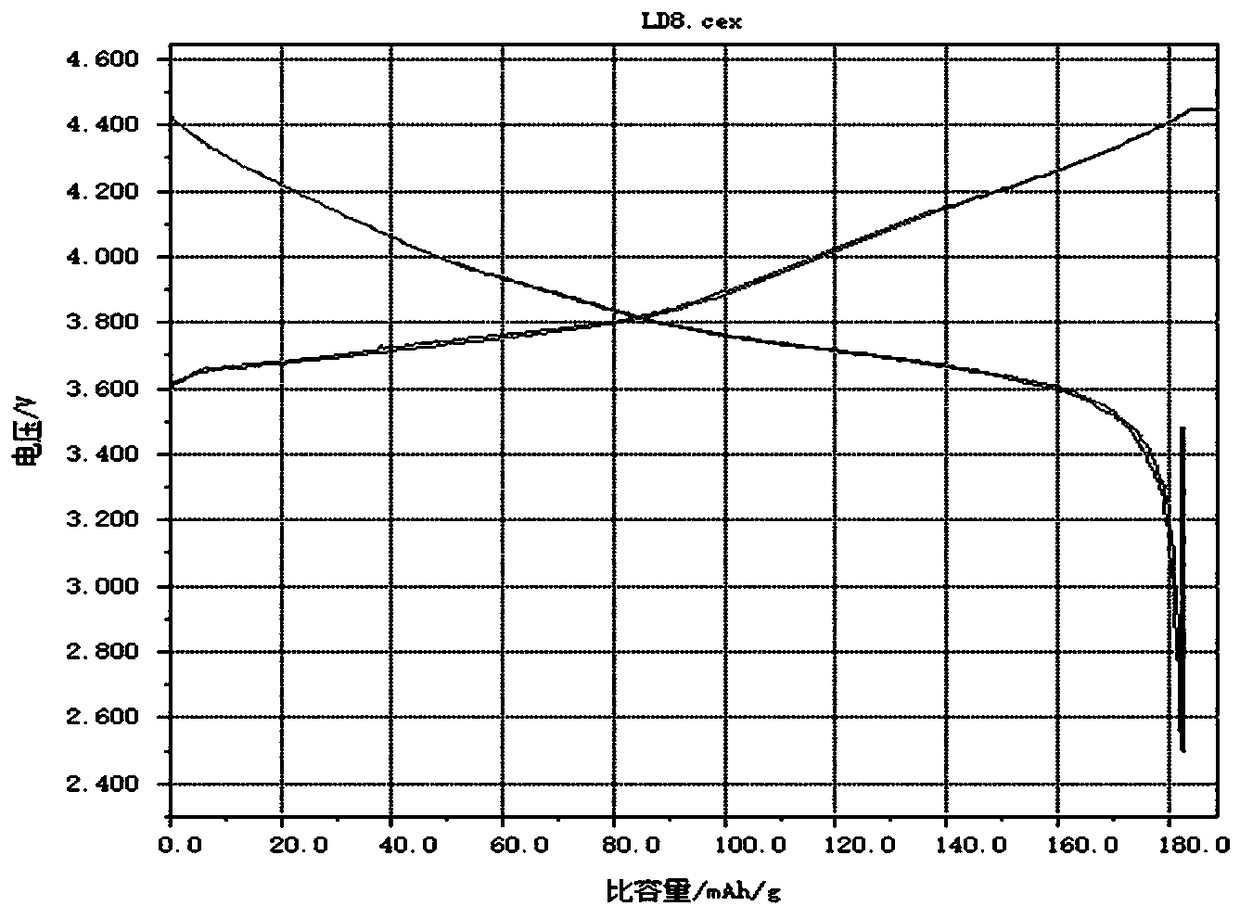

[0040] (4) Weigh 80g of the pre-selected NCM622 ternary material. Add it into the prepared viscous easy film-forming emulsion, stir and disperse evenly, and the time is 180 minutes. In this step, it is enough to stir and disperse evenly, so that the ternary materi...

example 2

[0043] (1) Calculation in proportion: weigh 90g of N-methylpyrrolidone, 2g of PVDF and 8g of polyacrylic acid resin, disperse, stir and dissolve for 100 minutes. Configured as a 10% viscous emulsion;

[0044] (2) Weigh conductive graphite with a total solid content of 5gde, add it to the viscous emulsion prepared in the previous step, stir and disperse for 60 minutes, and make a uniform emulsion with good conductivity;

[0045] (3) Weigh the preferred nano-scale Mn:Fe=8:2 lithium manganese iron phosphate, material 15g, add to the viscous emulsion prepared in the previous step and ball mill for 30 minutes. Configured into a uniform viscous and easy-to-film-forming slurry emulsion of lithium manganese iron phosphate;

[0046] (4) Weigh 75g of the pre-selected NCM523 ternary material. Add it into the prepared viscous easy film-forming emulsion, stir and disperse evenly, and the time is 200 minutes. Dispersing stirring speed 2000 rpm. Stir and disperse evenly, so that the tern...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com