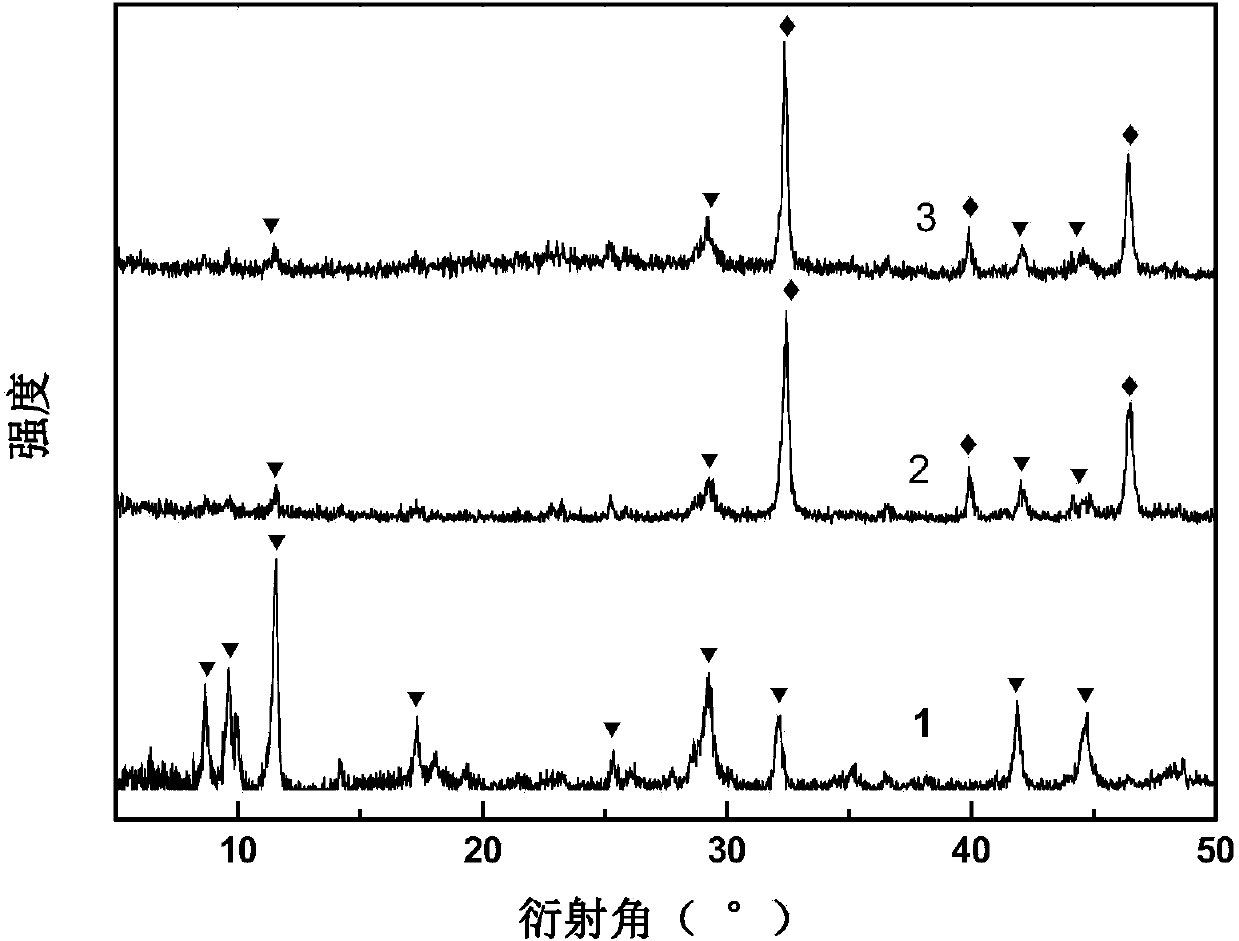

Preparation method of SrTiO3/TiO2 composite thermoelectric ceramic material

A ceramic material and thermoelectric technology, applied in the field of thermoelectric ceramics, can solve the problems of high sintering temperature and low thermoelectric performance of oxide-based thermoelectric materials, and achieve the effect of improving sintering performance and strong formability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0025] Specific embodiment one: this embodiment SrTiO 3 / TiO 2 The preparation method of composite thermoelectric ceramic material is implemented according to the following steps:

[0026] 1. Put K 2 CO 3 And TiO 2 After the powder is uniformly mixed, distilled water is added and stirred into a viscous mixture. The mixture is placed on a platinum sheet to form, and after drying, it is sent to a muffle furnace and kept at a temperature of 950-1100°C for 1-100h, and then taken out and cooled in the air. K 2 Ti 4 O 9 Fiber, then K 2 Ti 4 O 9 The fiber is put into distilled water while adding hydrochloric acid for pickling while stirring, the fiber is filtered out and washed with distilled water until the filtrate is neutral, and finally dried to obtain hydrated titanium dioxide fiber;

[0027] Second, the Sr(NO 3 ) 2 Dissolve in deionized water to obtain Sr(NO 3 ) 2 Solution, to Sr(NO 3 ) 2 Add the hydrated titanium dioxide fiber obtained in step one to the solution, disperse uniformly...

specific Embodiment approach 2

[0030] The second embodiment: The difference between this embodiment and the first embodiment is that the massage ratio of step one is 1:3. 2 CO 3 And TiO 2 mixing. Other steps and parameters are the same as in the first embodiment.

specific Embodiment approach 3

[0031] Specific embodiment three: This embodiment is different from specific embodiment one or two in that the step one is dried and then sent to the muffle furnace at a temperature of 950-1100°C for 1-100h, wherein the drying temperature is 70-90°C. Other steps and parameters are the same as those in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| sintering temperature | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com